The change house is an independent room for household needs, which needs thermal insulation. Sometimes it is used as a dwelling in the winter, which requires minimal heat loss. You can insulate a change house both with the help of professional workers, and on your own. If you decide to do it yourself, then you must remember that the change house from various materials requires an individual approach.

According to the material from which change houses are made, they are divided into:

- metal;

- wooden;

- combined.

The warming of a wooden change house deserves special attention. It is very vulnerable to the influence of cold, which requires careful implementation of all stages of thermal insulation. If we talk about a metal change house, then it shows better resistance to negative effects, as it is well protected from moisture penetration. In any case, an insulated change house will be much more economical when.

How to insulate a house

Market building materials provides a wide range of heaters for various purposes. The most popular of them are polystyrene and mineral wool. These materials have several significant differences.

Styrofoam- not subject to decay, resistant to moisture, has a very low coefficient of thermal conductivity - 0.033-0.037 W / (mK). Of the shortcomings, it is worth noting that it is highly flammable, but the auto-ignition temperature is 460 degrees, which is twice as high as, for example, paper. This material is designed for outdoor insulation precisely because of its moisture resistance.

Mineral wool - There are 3 main types: basalt, stone and glass wool. The thermal conductivity of these materials, on average, is 0.041-0.044 W/(mK). Mineral wool is fire resistant, but prone to moisture accumulation, so this material is more suitable for insulation from the inside.

Warming of a change house outside

Insulation of the utility room from the outside has its positive and negative sides. External insulation will act as additional protection for the walls of the change house, which will extend the life of the product. Insulation of a change house from the outside can be done using:

- polystyrene;

- glass wool;

- basalt slabs;

- slag wool.

When performing insulation from the outside, the internal volume of the room is preserved. If you use cheap materials for insulation, which will include various chemicals, then remaining outside, they will not affect the atmosphere inside the change house. The disadvantage of this method of thermal insulation is the additional costs that are necessary for sheathing the change house with siding or clapboard, arranging vapor barrier when using mineral wool.

Insulation of the change house from the inside

For the internal arrangement of the change house, it is best to use non-toxic and non-flammable heaters. The best option is mineral wool. The process of thermal insulation itself is carried out in several stages:

- a frame is arranged on the wall and upholstered with boards;

- the space between the boards and the wall is densely filled with insulation;

- waterproofing is being installed;

- cladding is done.

If the change house is insulated not for living, but for workers, then you can perform this process with polystyrene foam, foam foam or polystyrene foam, which will allow you to leave the insulation open. These materials also do not need waterproofing.

Insulation of the floor of the change house

To insulate the floor of the change house, depending on the design, the following materials are used:

- mineral wool,

- Styrofoam,

- extruded polystyrene foam.

The bars on the floor are mounted in increments of 50-60 centimeters. The distance between them is filled with insulation, on top of which a vapor barrier film is attached. The final step is fixing the floorboard.

Roof insulation

This process is preferably carried out outside. To do this, you need to dismantle roofing material, if possible, lay the thermal insulation and reattach the material that was used for the roof.

If, for some reason, insulation cannot be carried out, then roof insulation is carried out inside. To do this, bars are mounted on the surface of the ceiling, the space between which will be filled with insulation. As finishing can be used wooden lining, sheets of plywood or chipboard.

Videos insulation

Since the purchase of the change house, it had only a draft floor in the form edged board inches of poor quality, but carefully lined by the manufacturer of a thin polyethylene film. The stage of warming and laying the finishing floor has come.

After removing the p / e film, the draft floor appeared in such an unsightly form:

Raw boards dried out, centimetric gaps formed. During the construction of the change house, the manufacturer "qualitatively" sealed up all the gaps available at that time with mounting foam so that it would not see through:

I removed all this sludge from the cracks, covered it with two layers of antiseptic:

After the antiseptic had dried, I laid the membrane, secured it with staples. I was too lazy to cut, I laid two full canvases with an offset, the overlap turned out to be notable, it almost came out in two layers:

Missed the bottom of the wall protective composition, since then there will be no access to this space. Started installing insulation. To make it easier and faster, I combined the laying of the insulation with the fastening of the support bar for the finished floor. Well, it’s like lags, but nifiga is not lag, because lags with a section of 50x50 are not lags. I laid a row of insulation, fixed the bar:

Since a lot of different junk has already accumulated in the change house (tools, materials, overalls, elements field kitchen and furniture, children's toys, etc.), then it was decided to do the floor in two stages - half a change house, alternately dragging things to the opposite half. That is, first the first three meters of insulation and coating, then the second three meters. It turned out to be quite convenient - it is easier to turn a three-meter sheet pile than a six-meter one. However, the first half ended with a cut row of insulation. Not scary.

Next, he laid the vapor barrier. The job is extremely inconvenient. I don’t know, maybe there is some special technology, but I didn’t come up with anything smarter than throwing temporary boards over the insulation to walk on them. Jumping on these boards, constantly moving and shifting the vapor barrier, is still entertainment. However, he did a good job:

The entire perimeter was glued with butyl rubber tape to ensure a closed volume:

It is possible to lay a finishing floor. He brought a tongue, cut into three meters:

Previously, the entire sheet pile was covered with a protective composition of the Yassa Panel from below, and along the side and end faces. Covered, like plywood on the walls, in one layer, wait for drying and cover in two layers for too long. Boards dry:

While covering the last board, the first one had already dried up, I started laying:

Linoleum will be used as a finishing coating, since the change house is a small room, dirt from the outside will actively drag inside, no tree will last long. For this reason, I fastened the tongue with screws vertically through. In addition, with a hidden fastening at the end, each board would be fixed by one screw in width, which would have a negative impact in the future with possible wet torsion of the boards. And so two screws in width - more reliable:

When laying the grooved board, I deliberately violated the technology of this work. It is supposed to press each new board with clamps to the previously fixed ones before attaching it to the logs. But, I didn’t have such long clamps, it was unreasonable to buy them for the sake of such a small area, and the object itself is not demanding. Therefore, I simply knocked it out with a hammer and pressed it with a crowbar so that no cracks were visible.

The entire sheet pile is laid, leaving a centimeter around the perimeter for foaming:

TOTAL: 209626 rubles.

Materials for warming change houses

Polyfoam is an environmentally friendly material that is not afraid of biological effects and does not cause allergic reaction. For those who are interested in how to properly insulate a change house with polystyrene foam, we will immediately say that it is quite easy to do this, because this material has a very light weight, which does not require reinforcement of load-bearing structures, and also, it is available for processing with any tools.

The advantages of polystyrene include the following nuances:

- fire resistance;

- durability;

- moisture resistance;

- not afraid of temperature changes.

The disadvantage of this insulation is the impossibility of filling some recesses or rounded configurations, since its sheets are quite rigid and do not bend. Because of this, condensation can accumulate in the voids, which leads to decay. wooden structures and to the formation of corrosion in metal.

Also keep in mind that some paints and varnishes and drying oil can damage or even dissolve polystyrene foam. Direct sunlight also contributes to the gradual destruction of this insulation. To prevent this from happening, it must be carefully plastered on top with cement.

Before you insulate the change house car from the outside with foam, you should study its parameters, because some sheets will be useless for winter residence and suitable only for packaging household appliances. In this case, the PSB-S brand should be the fortieth brand. Then pay attention to the density and what kind of edge is obtained if it is broken. If the break is uneven and small balls are visible, then it is a low-grade product. If there are regular polyhedra in this place, then you need to choose this particular polystyrene foam.

- Penoplex and Technonickel;

- Polimeri Europa;

- Basf;

- Styrochem, etc.

mineral wool has higher quality thermal insulation and is fire resistant. In addition, this material significantly improves sound insulation.

Mineral wool consists of randomly arranged fibers, which can be glass, slag or stone. Moreover, slag wool is not as environmentally friendly as others, but it can be taken with bare hands.

The advantages of this heater are:

- fire resistance;

- soft material is strong enough;

- does not let heat in in summer and retains heat for a long time in winter;

- high coefficient of vapor permeability;

- service life from 25 to 50 years.

When working with glass wool, it is necessary to observe safety precautions, because glass particles painfully dig into the skin. It is usually used in production.

Slag wool is practically not used now, but stone wool now the most in demand, because, the basalt present in its composition improves the quality of thermal insulation at times. In addition, mineral wool of this type does not pose a danger during installation, does not lend itself to combustion and deformation, but it also costs more than its counterparts.

Mineral wool does not need special fastening - they fit quite tightly between the frame rails. It is only necessary to ensure that the connecting lines are offset.

Unlike polystyrene, mineral wool perfectly fills all the voids. Most summer residents prefer this particular type of insulation for change houses.

Cotton insulation is one of the safest, environmentally friendly and high-quality insulation. It is difficult to cut, but otherwise it is flawless.

vivoz-gbo.ru

How to insulate a trailer for the winter with your own hands

Trailer - temporary mobile housing, in demand at the construction sites, geological and oil and gas works.

Structures can be converted into a temporary office, country house, utility room and workshop.

If you plan to use the trailer in the winter, it must be properly insulated. When choosing a heater, it is important to take into account both the properties of the material and the technical characteristics of the change house itself. Basalt slabs, fiberglass, mineral wool, polyurethane foam and foam plastic are often used.

What materials will be needed

You can insulate the trailer with the following materials:

- Polyfoam ― inexpensive, easy and moisture resistant material. Suitable for thermal insulation of walls in wooden change houses with a short service life.

- Fiberglass and mineral wool. Both materials are characterized by fireproof and heat-insulating properties. The disadvantage of fiberglass is the content of toxic components.

- Basalt slabs made from compressed fibers obtained from the processing of volcanic rock. They are easy to cut according to the required parameters and stack. They have a slight thickness, they can be insulated from the inside without compromising space.

- Polyurethane foam is a popular thermal insulation material that is produced in liquid and solid form. Rigid polyurethane foam boards and panels increase thermal capacity exterior finish trailer and strengthen the roof structure. Liquid insulation is sprayed inside the trailer - this allows you to carefully fill all possible paths for the penetration of cold air, providing effective thermal insulation.

Preparation for work

Before work on insulation, it is necessary to free the trailer from everything superfluous and prepare the following materials and tools:

- Vapor barrier for floors, walls, ceilings and roofs. Choice of polyethylene, burlap, membrane, foil or liquid insulation;

- insulation;

- Wooden beam;

- Mastic for wood processing;

- Hammer, screws and nails;

- Penofol;

- Mounting foam and gun for economical use;

- Silicone sealant.

door insulation

When insulating a change house, it is necessary to pay attention to the door, about 20-25% of heat can be lost through it. It is important to separate the door from the main room by building a vestibule that acts as a buffer between the street and the trailer.

The most reliable in terms of thermal insulation are:

- Solid wood doors;

- Frame doors filled with mineral wool or polystyrene.

Installing door frame, all joints are filled with foam. In order not to miss even the slightest sections, it must be applied in zigzag movements. Too deep cavities doorway pre-foamed. The excess is easily cut off.

Watch the video:

If the trailer has standard doors, you need to glue the door frame around the perimeter with a special sealing rubber with a self-adhesive layer. A snug fit will significantly reduce heat loss.

Floor insulation

Work is performed in the following sequence:

- If there is still no rough flooring in the trailer, it must be nailed. Then it is necessary to clean its surface of debris and dry and bend the protruding nails.

- The next step is laying the waterproofing. It protects the structure from moisture penetration from below and maintains its reliability. Waterproofing is being installed construction stapler with joints of at least 20 cm. To be more reliable, they are additionally glued with adhesive tape.

- The gaps between the lags are filled with foam or mineral wool. The minimum allowable layer is 10 cm, and the recommended one is from 15 to 20 cm.

- All existing gaps between the heat-insulating plates are filled with foam. It expands as it dries, if excess funds come out, they are carefully cut off with a knife.

- Penofol is laid on the base of the floor in the trailer - a material that retains and effectively reflects heat in the room. The joints are connected with a special construction adhesive tape with a metallized surface.

- The final stage is the fixing of the finishing floor covering. For these purposes, oriented strand boards, moisture-resistant plywood are usually used. Such materials can be additionally painted or covered with linoleum.

Walls

When insulating a wooden change house, you need to pay due attention to the walls.

- Attach a vapor-tight waterproofing film so that all moisture can easily escape.

- Lay the foam plastic, having previously built a frame from a bar, taking into account the thickness of the insulation sheets. In order for the thermal insulation material to fit as tightly as possible into the frame, the distance between the bars should be 5 mm less than the width of the foam panel.

- Fill the gaps with foam, leaving no voids.

- Attach penofol on top.

- Nail the lath crate to attach the finish coat.

- Perform finishing work.

Ceiling insulation

A significant part of the warm air rising up is lost through the ceiling, so its insulation is a necessary step.

- From the outside, a waterproofing material is laid that protects the roofing crate.

- Heat insulator plates are laid in the gaps between the beams and fastened with heat-insulating glue or mounting foam.

- Penofol is laid.

- A lining or sheet decorative material is attached.

Window

Two options to choose from will help to avoid heat loss through the windows of a trailer insulated for the winter:

- In the frame of the usual wooden window with two glasses, mount a third glass;

- Replace standard windows with effective metal-plastic double-glazed windows.

Heating of change houses

Heating of a change house in a cold season is done by devices without open flame.

These are mainly oil radiators, closed-fired ovens and heat guns.

- Heat guns are compact and powerful devices. There are electric, gas, water, infrared, diesel, and versatile multi-fuel options.

- The lockable oven is safe and economical. Equip it with a protective cover, which improves the conversion of warm air and eliminates heat radiation inside the trailer.

- The oil cooler is energy efficient and has a horizontal position sensor that shuts off the device if it falls.

Proper insulation of all elements of the trailer will create in it comfortable conditions for winter stay.

kak-uteplit.ru

Metal insulated change houses: with your own hands, how to insulate

A change house is a small trailer or mobile room that can be used for a wide variety of tasks. Change houses were often used during the Soviet era, when seasonal workers or builders of large projects needed to quickly deploy their equipment.

In a pinch, they could even live in such structures for a while. All that was needed was to modify them a little with their own hands and equip the thermal insulation.

Standard metal insulated change house

In this article, we will take a closer look at change houses, their purpose and modification possibilities and the ability to install mineral wool Knauf.

1 Features and design of change houses

The scheme itself is very simple. It is a small structure made of panels and frames. The building is of medium size. As a rule, the change house has a width of about 2-3 meters and about 5-7 meters in length.

Its shape is the most trivial - that is, rectangular. If you look at it from afar, you can confuse it with a refrigerator trailer. However, change houses have doors, windows, openings for communications.

They are made from several layers of material. Plastic is used on the inside, metal is used on the outside.

As you can see, change houses are a mobile convenient solution for those who need to quickly place something like a transshipment base with insulation on a cut off area plastic windows. Builders use them to place their tools, provide basic needs, including recreation.

Summer residents buy change houses in situations where it is necessary to organize something like a barn. Sometimes they even live in them. If they are insulated and put on a normal foundation, then the change house turns into a rather useful residential block.

Outside, it is protected by a metal corrugated board. Interestingly, you can insulate the change house with your own hands. Moreover, the heater is selected the cheapest. The most commonly used foam.

As for the design, standard change houses are assembled from an internal frame. That is, the frame itself is first mounted (most often made of wood), and then the interior and exterior trim is laid on it.

As we have already said, outside the standard technology they use metal sheets. From the inside, the number of options is increasing.

The surface of the floor is covered with boards or something similar with basement insulation from the inside. It all depends on the specific purpose of the change house.

to the menu

1.1 Insulated cabins

Initially, change houses were not insulated. They were produced as temporary structures that can be quickly assembled and mounted anywhere. Wintering specimens were, of course, present, but rarely used.

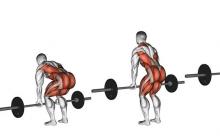

Filling the frame of the change house with mineral wool insulation

In addition, the cost of the structure also has a certain influence. Think for yourself, because the frame, plus a metal sheet and other materials (for example, for finishing the floor) is already an impressive expense.

And if you add a layer of insulation to them, then the design will become simply prohibitively expensive. Yes, and the fact is that we do not always need a warmed change house.

However, recently the market has expanded significantly, so all kinds of working variations of household modules have appeared on it, and in mass access.

In fact, all that manufacturers do is warming the change house in the conditions of manufacture. The frame of the module is additionally strengthened, and then a heater is mounted into it.

The result is a more expensive, but also more functional option with polystyrene foam. In such a change house, you can spend the winter and spend the night. And in summer it will be much cooler.

to the menu

2 Do-it-yourself insulation technology

A big plus of such structures is that you can remake them for the winter version with your own hands. In fact, the change house is already ready for decoration. After all, it does not need to build an additional frame.

If the metal sheathing sheets are in good condition, then it is enough to remove them and engage in insulation. They are also removed with their own hands and very simply.

The surface of the floor also has its own frame, like the roof. Although the roof is desirable to remake under pitched. So you will have something like an attic, and it will become much warmer inside.

That is, the building with PSB C 35 is thought out in such a way that you only need to purchase materials, find a basic tool and get down to business.

to the menu

2.1 Selection of insulation

Insulation in this case is chosen so that it is convenient to mount it under the frame. It is ideal to use slabs or aggregate, which easily fits under any shape.

Most often used:

The use of polystyrene foam is fully justified. Cheap, non-corrosive, it is very cheap, and in terms of its properties it is practically in no way inferior to mineral wool.

At the same time, it can be installed easily and simply. The foam is cut with your own hands, the plates are quickly adjusted to the working frame and mounted using additional fasteners.

The use of penoizol for warming change houses

The use of penoizol has even more attractive sides, but it is also more ambiguous. On the one hand, penoizol has the same properties as polystyrene. In some respects, he even overtakes him.

Yes, and it is even easier to mount penoizol in the frame of the walls or floor of the module. After all, you do not need to worry about the definition of measurements or something like that. Penoizol in its working form resembles foam, and it is foam.

They only need to fill the entire internal cavity of the walls, the material itself will expand to a certain size and fill all the openings.

Minvata is used less frequently. It fits perfectly for warming buildings, but a change house is a different matter. The insulation is just fine, but it is too heavy and expensive.

What is the point in the vapor permeability of mineral wool or its excellent thermal insulation qualities, if the foam has the same properties, but is sold cheaper?

So it turns out that filling the frame of the change house with mineral wool is simply unprofitable. Which, however, does not mean that it is not suitable for such tasks. It will do, but is it even worth trying - the question is for you.

to the menu

2.2 Wall insulation

Insulation of walls during thermal insulation of change houses is used in the first place. It is through the walls that the maximum thermal energy escapes. Which, however, is quite obvious. After all, it is the surface of the walls that is the largest and has full contact with the outside air.

The walls in most cases are protected by metal sheets, but inside the structure there is only one bare frame. But this is a big plus, because metal sheets are removed with their own hands and in a few minutes.

Then our task is to install insulation and insulation.

Stages of work:

- We remove the sheets, prepare the frame.

- If the frame is wooden, then we process it with antiseptics.

- We put a heater inside.

- On both sides we lay a waterproofing membrane.

- We sew the walls back.

- If necessary, the well is insulated from concrete rings.

Modified insulated change house with a pitched roof

Interestingly, many owners eventually change metal sheets for siding panels or other similar polymer solutions. Polymers last longer, do not transfer temperatures so easily, which means they will play a big role in insulation.

to the menu

2.3 Floor insulation

Second important point- floor finishing. It's even easier here. As a rule, the floor in the change house is already supported by the frame and is double. First comes the plywood floor, then the frame, and below it is a base plate or something similar.

That is, we just need to fill the void with insulation and lay a protective membrane over it. It is desirable to use high-quality waterproofing.

Fastening of all elements is carried out with a stapler or small nails.

to the menu

2.4 Roof insulation

The difficulty in insulating the roof lies only in the fact that you initially have to create it, and only then engage in the installation of thermal insulation, if it becomes necessary at all.

Initially, the roof was flat. It is faster for manufacturers to install it, the assembly scheme is facilitated, and the transportation of the module is easier.

However, in a stationary position, when you set out to turn the change house into a normal residential building, the presence of a roof made of slopes is simply necessary.

This is the only way to create reliable protection against atmospheric precipitation and significantly extend the operational life of the structure.

The roof is assembled at a slight angle, not higher than 30 degrees. They use standard bars, on top of which they put corrugated board or even slate.

The insides of the slopes are insulated, and then sheathed with waterproofing. The peculiarity of the roof is that internal waterproofing is also needed here in order to block steam flows that will come from inside the change house.

And here, as a heater, you can use not only polystyrene foam, but also mineral wool. Since it is easier to mount it in roof structures. However, here everything again depends on you and on the characteristics of the environment.

to the menu

2.5 Insulation of a change house with the help of improvised materials (video)

uteplimvse.ru

Warming the change house on your own. Technology | SC "Stroyudacha"

There are 3 main types of change houses, which differ in building materials for manufacturing: wood, metal and combined options. The heat insulator is selected separately for a specific type, taking into account its specifications. The types of heaters and thermal insulation of the outbuildings will be discussed in the article.

General rules for thermal insulation

To properly insulate a wooden outbuilding, follow certain rules.

- First, we prevent heat loss through the roof - we cover the structure with a special film. Only after that it is possible to lay the roof in the form of corrugated board or ondulin.

- To increase heat resistance, MDF panels are used, installed on special profiles. We fill the free space with a heat insulator of your choice.

Change houses made of metal have high resistance to mechanical and other influences. Metal carcass completely protected from moisture by a special flooring. But the roof of the outbuilding is often subject to corrosive processes. To prevent corrosion, it should be treated with a polymer-based coating or paint and varnish products.

Wall structures are sheathed with clapboard, block house or plastic panels. Mineral wool or polyurethane foam act as heat insulators. To prevent heat loss, cracks and joints are sealed with a grooved board. Combined outbuildings are insulated in the same way.

Materials for insulation

A change house without insulation will not perform all the functions and tasks for which it is intended. Therefore, you should carefully consider and select the insulation technology, as well as select the appropriate insulator.

The modern market provides many thermal insulation materials. Let's consider the most common in detail.

Styrofoam

Such a heat insulator is mainly used to insulate the walls of outbuildings. Styrofoam insulation is beneficial when finishing wooden cabins. The material is resistant to moisture, simple and easy to install. Styrofoam insulation has disadvantages: a short service life and a large volume for good insulation, and with low-quality products - significant heat loss. Several layers of foam plastic will reduce the area of \u200b\u200bthe room, and improper operation of the structure will lead to a fire.

Mineral wool and fiberglass

The advantages of materials are fire safety and excellent thermal insulation characteristics, subject to all requirements. technological process. If you mount several layers of heat insulator, then the acoustic properties of the rooms will increase. Disadvantages - the constituent components are harmful to health.

Basalt slabs

Such fibers are produced by careful processing of basalt rocks. In the construction market, a common form of material is slabs, which are easy to cut to size and lay. The heat insulator is completely resistant to fire and does not lend itself to deformation processes for a long time. Easy-to-use material will not take up much free space, so the area of the change house will remain almost the same. The disadvantage is the many seams that remain after the installation of thermal insulation.

polyurethane foam

This heat-insulating material is the most widespread and effective for warming of economic constructions. There are 2 types: liquid and hard. Experts recommend using the second option to increase the heat capacity of the exterior finish of the building. It is great for strengthening the roofing system and the outer part of the walls. Using the unique structure of polyurethane foam, it is possible to mask possible defects in the roofing system and increase the temperature in the building.

PPU is sometimes applied in a different way - by spraying on the lining inside the premises. It fills all places where cold air enters, thereby providing maximum thermal insulation.

Advantages :

- high level of heat resistance;

- the material quickly becomes solid, which instantly stops heat loss;

- fits evenly, without seams and fasteners;

- does not contain chemicals, safe for health;

- protects the coating from mechanical and other influences;

- service life - from 30 years with proper use.

To carry out proper insulation, you need to know detailed technology and act in strict accordance with all stages of the thermal insulation process.

Do-it-yourself warming of a change house

The owners sometimes carry out thermal insulation of the change house on their own. A simple insulation technology allows even an inexperienced person to properly fix the heat-insulating material, the main thing is to observe the main points and first consult with an expert.

Thermal insulation of the change house outside

In order for the wall insulation to be successful and without additional costs, the owners carefully monitor the sequence of work being carried out. Thermal insulation of the outer side of the outbuilding begins with the installation of a layer of vapor barrier material. For this, materials such as polyethylene film, foil and others are used.

The main task of the vapor barrier layer is to ensure maximum ventilation of the facade of the building. If the mounting surface is too smooth, fasten the rails vertically, with their help the vapor barrier material will hold.

Now proceed to the installation of thermal insulation. Experts recommend using mineral wool or fiberglass products. For optimal protection of the building, two layers with a thickness of 10 centimeters each are enough, although when insulating a change house for living in winter, an additional layer is fixed. Mineral wool does not need special attachment to the main surface: due to the rigidity of the slab, they fit tightly to the vertical slats. Slots and solid joints are not allowed between them.

A special film is mounted on the heat insulator to provide waterproofing, which will prevent moisture from entering inside. The waterproofing material is fixed with furniture stapler. The film is overlapped by 10 centimeters to ensure maximum protection, the joints are sealed with special adhesive tape.

Internal thermal insulation

The next stage is the insulation of the interior of the change house. Each owner of the outbuilding chooses the methods of insulation independently. Among insulators for internal thermal insulation of household structures, their cotton insulation is common. It is environmentally friendly and safe. Such material is difficult to cut, so the work will take enough time. Some owners use thermal insulation materials similar to products for external insulation.

When installing insulation, it is important to remember about the arrangement of air ducts to quickly remove the resulting condensate. Air vents are located at the top and bottom of the wall. To enhance thermal insulation, the insulation is closed special material- penofol. Its surface creates a "thermos effect".

Thermal insulation with foam

For high-quality insulation, penofol is fixed in one piece, which significantly reduces the number of joints between pieces. All resulting seams are carefully sealed with special adhesive tape to ensure maximum tightness.

To ensure maximum heat savings, experts advise insulating the floor and ceiling. The whole process is similar to thermal insulation, which was described earlier. After finishing work on internal insulation, they think over the aesthetic design. Drywall sheets are attached to the insulation, which level the surface and increase the quality of sound insulation. Fasteners are self-tapping screws and dowels. Instead of GKL, fiberboards are sometimes used. The last stage is the finishing of the change house according to the preferences of the owner.

You can buy a wooden change house for a summer residence on the official website of Stroyudacha Insurance Company. The quality of the product is guaranteed!

strojudacha.ru

How to insulate a metal trailer, change house, container?

Metal trailers are quite often used not only as premises for household needs, but also for workers to live during the construction process. Based on this, this room needs reliable and proper thermal insulation, which will ensure minimal heat loss in the cold season. The design of the trailer allows you to perform insulation both with your own hands and with the help of professionals at minimal cost.

The choice of material for warming the trailer

Most of the materials used as insulation have a budgetary cost, which is determined by the purpose of this room.

bytovka.in.ua

insulation materials, insulation inside and out

Despite the fact that change houses are temporary buildings, they are used all year round. Therefore, they need to be insulated. Thermal insulation is especially necessary if the change house is used as housing in the cold season. The procedure should be performed for both metal and wooden buildings. Knowing how to insulate a change house quickly and efficiently with your own hands, you can save a significant amount of money.

Thermal insulation materials

The range of materials for thermal insulation is quite wide. To make a choice, it is important to know their features.

Polyurethane is the best material for insulation of buildings, since when using it there are no gaps and joints, which ensures maximum tightness.

Styrofoam is one of the most affordable heaters. It is usually used to insulate the walls of wooden buildings, including cabins. Polyfoam is easy to install and resistant to moisture. But it is worth noting that if the technology of laying the material is not followed, its service life is reduced. If foam plastic is chosen as a heater, special attention should be paid to its quality: low-grade products usually crumble.

Mineral wool has unsurpassed thermal insulation properties. It is fire resistant. Mineral wool allows not only to insulate the building, but also to improve its sound insulation. To achieve an excellent result, it is important to correctly calculate the required thickness of thermal insulation.

Basalt fibers are commercially available in the form of slabs. For their manufacture, the remains of mountain basalt rocks are processed. Such a heater during operation does not lend itself to deformation and does not support combustion. To carry out thermal insulation in a change house using basalt fiber, it is enough to use a thin layer of material. The disadvantages include seams that are formed as a result of installation, but they can be repaired.

Building facade insulation technology

Scheme of warming change house. Click on the photo to enlarge.

In order for thermal insulation to be performed efficiently, it is necessary to follow the sequence of work. Insulation of a change house begins with the installation of a vapor barrier layer. For this you can use:

- special film;

- polyethylene;

- aluminum foil.

The task of the vapor barrier is the ventilation of the facade. Therefore, if the surface is smooth, vertical slats should be attached to hold the material.

Next, you can lay the insulation material. It is recommended to use mineral wool or fiberglass, as for reliable protection 2 layers of material 10 cm thick will suffice. Mineral wool slabs do not require additional fastening to the surface: due to their rigidity, they fit tightly between the frame rails. There should be no gaps between the plates, and the connecting lines should be displaced, avoiding a continuous joint.

A waterproofing film is installed on top of the insulation, which will protect the mineral wool from moisture. Do-it-yourself protective material is attached to the frame using construction stapler. The waterproofing film is laid with an overlap of about 10 cm for better protection, and all joints are glued with construction tape.

Internal thermal insulation

The next step will be the internal insulation of the walls and floor of the change house with your own hands. High-quality materials for the internal insulation of a building include cotton insulation. It is environmentally friendly and the safest material for the health of others. The material is difficult to cut, so it will take much longer to work. You can use a similar external insulation.

When installing heat-insulating material, it is necessary to take care of the air vents to eliminate condensate, which should be located at the top and bottom of the wall. To enhance the thermal effect, the heat insulator can be covered with penofol. Its foil surface reflects heat creating a "thermos effect".

Insulation with nefol

To ensure high-quality thermal insulation, it is better to glue penofol in whole pieces, this will reduce the number of joints. All seams must be carefully taped with foil tape so that the coating is airtight.

For greater efficiency, the ceiling and floor in the change house should be insulated. The technology of carrying out is similar to the thermal insulation of walls. After interior work are completed, it is necessary to think about the aesthetic side. On top of the insulation cake, plasterboard sheets are attached to all surfaces - they will level the surface and increase the heat and sound insulation of the change house. For work, you should use self-tapping screws and dowels, as they will perfectly cope with this task. On request, the walls can be finished with fiberboard sheets. The next step will be finishing work.

ultra-term.ru

How to insulate a construction trailer?

When choosing a change house for a specific climate of the region of operation, the owner does not have any problems. For example, insulated change houses of the Sever type are purchased for Siberia. With an insufficient budget, the developer buys a change house of the minimum configuration and begins to look for information on how to insulate construction trailer.

According to the laws of heat engineering, the only correct option for wooden buildings is external insulation. Only in this case, the dew point, along with the thermal circuit, shifts outward, moisture does not penetrate and does not accumulate inside the wall and roof pie. For internal thermal insulation, an accurate calculation of the dew point will be required. This option is inconvenient by reducing the working space of the interior.

Depending on the thickness of the beam used in the racks of the power frame of the change house, the insulation can be placed inside the walls. AT budget models in change houses, the manufacturer lays a 5 cm layer of mineral wool, there is enough space inside the frame to increase the thickness of the layer without making changes to the design.

Regardless of the scheme / method of thermal insulation of the trailer, it should be taken into account that the main heat losses are present in the floors, junctions of enclosing structures and in the adjoining walls to door / window blocks.

External thermal insulation

This option for insulating a construction trailer is always preferable for the following reasons:

- cost-effectiveness - interior linings are usually more expensive decorative materials on facades, they should not be touched, external siding (painted galvanized, block house or lining) can be carefully removed to be used in a ventilated facade

- variability - the owner can use any insulation

- design - exterior walls can be decorated with imitation masonry (basement siding), textured plaster(wet facade), other facings

Currently, ecowool is considered the best heat insulator, since this is the only material inside which rodents and insects are guaranteed not to live. Laying requires fairly high skills, so it’s cheaper to turn to specialists who have special equipment for the wet-adhesive method of applying ecowool.

Modular change houses remain practically the only option for mobile construction, for which a ventilated facade is cheaper than a wet one for a number of reasons:

- in order to reuse facade claddings, they must first be dismantled

- for wet facade you need to sheathe the walls outside sheet material(plywood, OSB, chipboard) to glue polystyrene foam or mineral wool to it

- there is no such problem for a ventilated facade - the crate is stuffed onto the existing frame, the heat-insulating material is placed in its cells, the surface is sewn up with the same lining that was used before

AT last version the dimensions of the trailer will increase, but the developer will have to buy more a large number of lining or siding.

Warming from the inside

To save work space internal insulation the lining of the trailer should be dismantled. In this case, it remains only to build up the frame elements to the required depth so that polystyrene foam or stone wool fits in its cells.

When using wadded and loose heat-insulating materials, a layer of vapor barrier must be laid under the cladding. The most demanded heaters:

- mineral wool - completely fireproof, but does not have sufficient rigidity, moves down inside the walls over time, forming cold bridges

- expanded polystyrene - has a stable geometry, but melts on contact with fire

- ecowool is a non-combustible bulk material, the laying of which is better only when using special equipment for the wet-glue application method

Employees of the Change House of the Russian Federation use rational technologies and budget materials to reduce the price of products. For a specific region and operating conditions, the developer can buy a construction trailer from a sandwich, and will be relieved of the need self-insulation on the object.

Please enable JavaScript to view the comments powered by Disqus.

www.bytovki-rf.ru

When installing floors in a change house, the most common method is used - laying the floor covering on a frame made of wooden lag. An obligatory element that is part of the "pie" of the floor is a layer of insulation that protects the premises of the change house from the cold in winter and from the heat in summer.

Material selection

The height of the wooden logs is selected according to the size of the strapping beam laid along the perimeter of the structure. Usually, when building a change house with your own hands, a beam of 10 x 10 cm is used for strapping, then a board of 10 x 5 cm is suitable for the logs. The number of beams depends on the installation step, taken along the width of the insulation plates, equal to 600 mm. For the device of the subfloor, you will need bars 2 x 2 cm and the same thickness of the board of the second grade or OSB plywood 18 mm.

The material for the flooring is selected based on the living conditions. If the country change house is operated all year round and heated, then it is easier to lay a finishing floor from chipboard sheets, on top of which any coating is laid - from linoleum to laminate. For summer living, you will have to put planed boards and simple linoleum on the logs, which is not afraid of moisture.

The ceiling is insulated with the following materials to choose from:

expanded clay;

mineral wool in slabs or rolls with a density of up to 80 kg/m3;

foam plastic with a density of 25-35 kg / m3;

expanded polystyrene extruded 30-40 kg / m3 density.

Each of the heaters has its pros and cons. Mineral wool needs protection from moisture and good ventilation to remove it, but it does not burn. Foamed polymers are not afraid of moisture, but they are flammable, and mice eat foam. Expanded clay is cheap, but has low thermal insulation properties, it must be covered with a thick layer (from 30 cm).

For the device of hydro - and vapor barrier, special films are needed. Waterproofing is carried out by a diffusion membrane that allows steam to pass through, but repels water. Its task is to protect the floors from wind and moisture from below, allowing the steam that forms in the "pie" of insulation to escape. Vapor barrier is a film that prevents steam from getting inside the “pie” from the premises.

Work procedure

The lag is installed in 2 ways. At the first, the logs are inserted into the grooves of a beam of smaller width, laid on the strapping with the second tier. Then a shelf is formed around the entire perimeter of the change house, where the boards of the subfloor will subsequently lie. A more popular way is to fasten to the strapping beam end-to-end, flush with the upper plane. The distance between the lags is adjusted to the width of the plates of the selected insulation.

The rough floor does not carry any load and serves for laying insulation. In the first method of installing the lag, the boards rest on the shelves and are nailed. In the second case, the floor device is made in the following order:

The cranial bars are nailed to the beams flush with the bottom plane.

Subfloor boards are laid on the formed shelves.

The areas between the lags are covered with a diffusion membrane, which is aimed at them with a stapler. The membrane indicates which side should face the insulation, do not confuse.

The cavities are filled with insulation and covered with vapor barrier. Film sheets are laid out over the entire area with an overlap of at least 10 cm and subsequent gluing with adhesive tape.

To ensure a ventilation gap of 2 cm between the film and flooring, on top of the lags, the slats of the counter-lattice are nailed.

The main flooring from boards or chipboard.

The finish coating is laid and skirting boards are mounted.

During the laying of polymer insulation, all joints and cracks are filled with mounting foam, in the case of mineral wool, this is not necessary. Installation of flooring from boards or chipboard is carried out so that there is a small gap between the elements (up to 2 mm), otherwise the floors will subsequently creak annoyingly. The same applies to the ends of the boards adjacent to the walls.

Floors insulated with expanded clay

The method described above is not suitable for warming the floors of a change house with expanded clay, since the thickness of the heat-insulating layer is limited by the height of the beams (10 cm). Expanded clay needs to be poured three times more to get a good effect. To achieve this, it is necessary to use the space between the change house and the ground, formed after the installation of the building on a columnar foundation.

When the distance from the ground to the floor of the change house is 30 cm or more, then this cavity can be completely covered with expanded clay. Side gaps under the structure are sewn up with any suitable material, holding the scattering of insulation. Before backfilling, it is necessary to lay a waterproofing layer of roofing material on the ground, and cover the impromptu plinth from the inside with a waterproofing film.

After backfilling with expanded clay, it is not necessary to arrange a subfloor, it is enough to lay and hermetically glue the vapor barrier film, and then lay a finishing coating. As a vapor barrier, you can also use thin foil insulation made of foamed polyethylene, laid end-to-end with gluing with aluminum tape.

*information posted for informational purposes, to thank us, share the link to the page with your friends. You can send interesting material to our readers. We will be happy to answer all your questions and suggestions, as well as hear criticism and wishes at [email protected]Modern industry produces a large number of change houses different types, size, purpose. They are equipped with advanced technical devices, are as comfortable as possible, are used for both temporary and permanent residence, however, they have a rather high cost.

Possessing simple skills in working with a tool, it is enough just to make a change house with your own hands. To do this, you can use wood, plastic, metal sheets, painted or galvanized corrugated board. In order to feel comfortable in such a change house, you should consider effective system insulation. This is important not only for those who plan to use it in the winter.

AT summer heat in it it will be possible to hide from the exhausting heat, in spring slush, autumn bad weather - to warm up, cook food, relax in a warm and cozy room. An additional advantage of insulation is significant savings in heating costs and maintaining the desired temperature in the change house.

How to insulate a house

The trading network offers a large selection of heaters different systems insulation. Considering that there is no need to use expensive materials for a change house, varieties of mineral wool, fiberglass insulation, polyurethane, polystyrene.

These materials are easy to install, inexpensive, have light weight. With their help, the issue of improving the noise and sound insulation of the room is additionally solved.

Styrofoam. Often used for inexpensive insulation different rooms, with its help you can make a thermal protection of a change house for a summer residence. It has a very low thermal conductivity, does not rot, and is resistant to moisture. It should be noted that inexpensive types of foam have low strength, can be painted and destroyed over time. In the case of choosing this material, it is better to stop at more expensive varieties of increased density or extruded polystyrene foam, which have a much longer service life and quality parameters.

Polyurethane foam. This insulating material is inexpensive, is good insulation. Applying it with a construction gun, you can achieve a high degree of sealing cracks, holes, joints, hard-to-reach areas.

Mineral, basalt or glass wool. These insulation materials are widely represented by numerous offers from different manufacturers. They are issued different sizes, density, can be in mats or rolls. Given that the volume of the change house will decrease by the thickness of the insulation, you can use a heater of 50.75 mm, but the recommended size is 100 mm. Such types of insulation are easy to use, retain heat well, and are used as sound insulation.

An important condition for their use is protection against moisture and condensation. This is due to the fact that damp cotton wool has a sharp decrease in heat-shielding properties. Therefore, it should be protected from the inside of the room with a vapor barrier, and from the outside - covered with a wind barrier. The vapor barrier will not allow moisture from inside the change house to penetrate into the insulation, and the wind barrier will protect it from atmospheric precipitation and will help to remove condensate moisture.

Basic requirements for insulation

In order for the funds and efforts spent to lead to the expected result, some rules for warming the change house should be observed:

- existing joints, cracks in the walls, at the installation sites of windows and doors should be carefully sealed;

- in addition to walls, it is necessary to insulate the ceiling and floor of the room;

- provide for the installation of ventilation hatches or openings in the walls so that excess moisture does not accumulate inside, mold and fungus do not form;

- in the case of installing a change house on piles or posts, it is necessary to close up the free space between the ground and the floor with bricks, blocks, roofing material or other materials to eliminate drafts under the change house and create an air space that can become additional protection against heat loss;

- fix aluminum foil or other sheet reflective materials at the installation sites of heating devices that increase the flow of heat into the room.

Insulation installation

For the correct fastening of the insulation, wooden bars or slats are used, which are installed vertically, to which the materials of the insulation system are attached in a strictly defined sequence, starting from the wall of the change house:

- vapor permeable wind and hydroprotective membrane or wind barrier;

- mineral wool (basalt, glass wool);

- vapor barrier;

- decorative interior decoration- upholstery.

With accuracy and patience, it is easy to insulate the change house on your own. Modern materials allow you to inexpensively, quickly and easily turn a cold damp room into cozy room for temporary or permanent residence. And beautiful decorative coating from wooden or plastic lining, fiberboard sheets, plastic, drywall, OSB or plywood, will help create a stylish interior inside the change house.

Mars space program

The history of the origin of zero What is the name of zero

Gloria planet (anti-earth) - exposing all revelations Is it true that there is a planet behind the sun

20 cases of alleged reincarnation

The secret of the "sun stones": how the Vikings got from Norway to Greenland almost blindly