All motorists know how important it is to maintain a certain temperature in the garage. A stable temperature has a beneficial effect on the safety of the car and its technical system. In an insulated room, there is no need for a long warm-up of the engine before the upcoming trip.

This reduces fuel costs and your time. In such a garage, it is more convenient not only to maintain, but also to repair the car. However, many motorists have no idea where to start arranging the premises, do not take into account some important aspects. For example, often users try to heat an uninsulated or poorly insulated garage.

In this case, a lot of energy resources are lost without obtaining the required amount of heat in return. Therefore, you must first solve the problem with the thermal insulation of the garage, and only then plan the heating system. How to insulate the garage door - this will be discussed below.

Warming garage doors

Causes and features of insulation of gates and doors in the garage

Sometimes car owners who have a garage do not always pay due attention to car storage. For many users, having a garage puts all worries aside, as they find it warmer in winter than outside. So does it need to be insulated?

The reason is that there are noticeable temperature differences in the garage, especially during the off-season. Such phenomena can be a source of condensation. The body of the car under these conditions quickly begins to rust, failures appear in electronic system, which is fraught with safe driving.

A constant increase in humidity affects not only the car, but also the condition of the garage itself (mold forms, fungus appears, etc.).

Especially the problem of insulating gates and doors arises in the case of car maintenance and repair, as well as when installing a workshop in the garage in winter time. At the same time, it should be noted that most of the heat from the room leaves through the swing gates.

There are several reasons why heat loss occurs:

- Basically, the gates are made of metal, which is significantly inferior in terms of heat saving to concrete, from which the ceiling and walls are erected.

- Due to the large area, the gap between the leaves has a significant length, and even with the smallest gap in the gate joint, the total heat loss will be large.

- Additional doors are often installed in one of the gate leaves, which also significantly affects heat loss. When installing them, you need to imagine in advance how to insulate the doors in the garage.

It is desirable to install insulation from the inside, as this will protect against vandals and reduce the requirements for its aesthetics.

Built-in garage door

Built-in garage door Material selection

For correct calculation necessary materials, you need to know the exact dimensions of garage doors, doors and the characteristics of the insulation used.

Attention! To exclude marriage and other unforeseen nuances that have arisen, it is recommended to purchase consumable with a margin.

There are no special restrictions on the choice of insulation for garage doors. With any possibility of fixing it on the inside of the sashes and at the same time without significant weighting, such a material can be considered suitable for use. In order to know how to insulate a garage door and what kind of insulating material to use, you need to take into account some of its features.

Consider the most common heat-insulating products suitable for insulating garage doors:

- Fiberglass, felt, mineral wool. These products have the same parameters of vapor permeability and thermal conductivity, as well as the same specific gravity. But it is very undesirable to use them as a heater for garage doors.

This is due to the fact that the dew point will be located inside the insulation due to its small thickness, which leads to constant moisture during the off-season. This phenomenon is inevitable when cold air seeps into a warm room.

- Reed and peat slabs. Such a heater is suitable for use in a garage, but it has poor mechanical strength and, moreover, the cost is quite high.

- Polymer insulation. It is cheap, effective in application, but quite sensitive to external influences.

- Different types synthetic material. With low thermal conductivity, foam plastic and expanded polystyrene are lightweight, easy to process and easily fixed on any surface.

Such heat insulators are the most convenient heaters for installation on garage doors. Apply foam or extruded polystyrene foam, there is no significant difference for this coating: they have the same characteristic properties.

Different types of insulation for garage doors

Different types of insulation for garage doors Tool and additional material

In addition to choosing a heater, before installing it, it is also necessary to prepare other materials and tools:

- Wooden bars with a face equal to the thickness of the insulation.

- Screwdriver and screws.

- Drill.

- Cladding boards.

- Metal brush.

- Primer.

- Antiseptic.

- Mounting foam.

Need decorative Decoration Materials, which can additionally be used as a heat insulator around the entire perimeter of the gate.

Panel mounting tool

Panel mounting tool Self-insulated garage doors

After the insulation has been selected (polystyrene in our case), additional materials have been purchased and tools have been prepared, work on thermal insulation can begin. At the same time, one should not forget about security measures and personal protection.

First of all, you need to do the preparatory work:

- First you need to cover everything with an antiseptic wooden elements. This will protect the bars from the appearance of mold and fungus on them. The inner surface of metal gates and built-in doors must also be prepared for better adhesion: remove rust and dirt from the surface of the gate with a brush.

- Then carefully primed the treated canvas. When applying an antiseptic and a priming solution, it is recommended to apply them in two layers: along and across.

- Saw the bars in such a way that they can be placed over the entire area of \u200b\u200bthe wings with a gap equal to the width of the foam.

- Install a crate, which, in addition to fixing foam sheets, will serve as additional protection against mechanical stress.

- Make markings and cut the insulation blanks so that they are slightly smaller than the crate cells on each side (for better fastening).

- Moisten the surface of the sashes with a spray bottle or sponge.

- Apply mounting foam as glue and waterproofing on the surfaces of individual cells of the crate.

- Install the prepared foam boards in the crate niche and hold for some time until the insulation is fixed to the sash surface.

On a note! For the installation of the crate and various accessories in the case of a large thickness of the metal, it is necessary to pre-drill holes for self-tapping screws.

After installing the insulation, you need to fill mounting foam all voids and cracks, and the excess that protrudes along the edges can be removed only in case of complete hardening.

Styrofoam garage door insulation

Styrofoam garage door insulation Final finishing work

When the main area of the gate is insulated, it remains to install insulation around the entire perimeter of the outer contour of the gate frame and doors.

Clarification! Swing gates, in fact, are two boxes welded from a corner and sheathed on top with sheet iron with an overlap to overlap the wings between them. The doors are similarly constructed, only they are smaller and built into one of the halves of the gate.

Procedure:

- It is effective to use heaters made of elastic or porous material with a large cross-sectional size. Strengthening it to the edge of the gate and built-in doors can be done either by gluing or by means of a metal plate.

- If the garage door has built-in entrance doors, then a locking mechanism must be inserted into them. And in order to find out how to properly insulate the internal lock in the garage, you need to take into account the extension of the striker plate (bolt). For thermal insulation of the lock, a fabric or rubber strip is used, which is pressed with a decorative metal plate around the entire perimeter of the locking mechanism.

- As a protection and aesthetic appearance, the entire inner part of the gates and doors is sheathed with facing material. For this purpose, sheets of plywood, chipboard, plastic are suitable, and planed boards can also be used. Here it is necessary to cut the blanks so that the joints of the plates are located on the beams of the crate and, when installing them, maintain minimal gaps.

Attach sheets of facing material it is most convenient with the help of self-tapping screws. After finishing the work, it is desirable to process the skin for the most attractive appearance: cover with stain or paint.

Garage doors sheathed with clapboard

Garage doors sheathed with clapboard On this, the insulation can be considered complete. In the case of high-quality and accurate work, garage doors will serve you for a long period without additional insulation. Now your car is not particularly afraid of sub-zero winter conditions and temperature changes during the off-season. Cold air will not penetrate from the outside through the metal gate. As a result of the insulation made in the garage, a comfortable temperature regime will remain, which means that you no longer have to worry about the condition of your car.

A garage for a car owner is not only a place to store a car, but also a workshop, a place to store tools, a pantry for summer cottages. In the article, we will explain what material is best for thermal insulation, and we will tell you how to insulate garage doors.

Why insulate garage doors?

Having installed the gate, car owners eventually understand that in order to maintain comfortable temperature in autumn-winter period they need to be insulated. In addition, the car itself and material assets will retain their presentation and working condition longer if the temperature does not fall below 12 °, and the humidity does not exceed 70%. In such a room it is quite possible to arrange a workshop for year-round use, and country supplies will not freeze.

Temperature fluctuations in the garage lead to condensation, which adversely affects the anti-corrosion properties of the car

Door insulation will solve many problems and increase the life of the car.

What types of garage doors need to be insulated

According to the material of manufacture, the gate can be completely metal or wooden with iron sheathing. According to the method of opening the canvas in garages, they install Various types gate:

- Swing double doors with or without a gate;

- Sliding, single-floor or double-floor;

- Sectional, lifting and turning;

- Roller blinds.

You can insulate on your own all types of gates except roller shutters. When insulating sectional doors, difficulties can also arise, since the automation is designed for the weight of the leaf without insulation. Difficulties will not arise when insulating gates with manual opening, swing or sliding.

The lifting mechanism may not withstand the heavy weight of the heat-insulating material, therefore sectional doors are not designed for insulation

Choosing the right insulation

For the insulation of the gate, an effective heat-insulating material with a low weight is suitable. Of the heat insulators offered by the construction market, slabs made of mineral wool (stone, basalt), foamed or extruded polystyrene foam and polyurethane foam have the best performance. The coefficient of thermal conductivity of heaters at high humidity(conditions B), W/(m °C):

- Polyurethane foam - 0.04;

- Foamed polystyrene, graphite-containing or extruded - 0.031;

- Mineral wool basalt 0.044.

The volumetric weight of these materials ranges from 25 to 40 kg/m3, and 50 mm of any of them is enough to bring the door leaf in line with the current standards for heat transfer resistance of external enclosing structures. These thermal insulation materials are durable, environmentally friendly, and do not harm nature and human health upon contact.

Polyurethane foam (PPU) is produced in the form of plates or a two-component composition for spraying, extruded polystyrene foam is a plate material of various thicknesses, basalt fiber insulation is produced in the form of rigid and semi-rigid plates, as well as soft mats.

Polyurethane foam is a honeycomb-type artificial filling that is tested and safe, which confirms its widespread use in everyday life.

For work, it is preferable to choose soft basalt mats, since the height of the structure is small, the insulation is not loaded and rigidity is not needed, and the mass of mats is less than that of the plates.

How to insulate garage doors from the inside

Do-it-yourself insulation of the gate from the inside requires preliminary preparation: after choosing the insulation material, it is necessary to prepare the surface, and only then proceed to work.

Surface preparation

Work is easier to carry out when the door leaves are in the supine position. Cloths of old gates require cleaning from rust, priming and protection from further corrosion. For cleaning, you can use one of 3 methods:

- Chemical - we treat the surface with a rust converter;

- Mechanical - using a special nozzle on a drill or manually, with a brush with metal bristles;

- Painting - paints, for example "Hammerite", which are at the same time rust converters, a primer and a paint composition.

A grinder with a polymer-abrasive brush will become perfect choice for cleaning metal surfaces

If you have chosen mechanical or chemical method, then after processing and cleaning the rust, the surface is dedusted, degreased, primed, then painted with a composition for metal. Primer and paint based on alkyd, acrylic or pentaphthalic resins must be designed for operation in conditions of high humidity and a wide range of temperatures.

Creation of a crate

The crate is needed to give the structure rigidity and fix the insulating material. The crate is performed depending on the size and design of the gate, it can be made of wooden beam section 50x50 mm or from metal corner 50x5 mm.

A wooden beam is attached along the perimeter to the frame of the door leaf, along the perimeter of the gate, bolt and lock, then horizontally, in increments of 600 minus 5 mm. The location of the elements of the crate is marked on the canvases with a marker, it is desirable to use the bars in one piece, without joining.

The crate helps to fix the insulation, and the front layer of the cladding will also be held on it.

Lathing for slab heat insulator or mats should be carried out in a horizontal direction to prevent possible slipping of the insulation from its own weight. Wooden bars before installation of the crate are treated with an antiseptic to prevent decay, damage by insects and fungal diseases.

It is important! For antiseptic treatment of timber, choose a composition with a validity period of 10-25 years, so that after a couple of seasons you do not have to do the work again.

In the case of sprayed insulation, the direction of the frame does not play a role, but the surface of the gate should be treated with an adhesive primer to improve the adhesion of PPU to the metal sheet. The wooden crate is fastened to the frame of the canvas with galvanized self-tapping screws for 1/2 of the thickness of the beam in increments of no more than 25 cm, metal - with bolts or welding.

Foam insulation

Work algorithm:

- Expanded polystyrene plates are cut to the desired size.

- For better adhesion to metal smooth surface plates are pricked with a needle roller.

- The adhesive composition (mounting foam, adhesive foam) is applied around the perimeter of the plate, retreating from the edge of 1.5-2 cm, and in the center with 1-2 marks.

- The slab is pressed against the metal and fixed with a load, leveling the level of the crate with a rail-rule.

The main rule for using polystyrene foam is that the fewer joints, the better.

The adhesive should not get on the end of the heat insulator in order to avoid the appearance of cold bridges. The gaps between the plates are filled with scraps of polystyrene foam.

The use of mineral wool

Operating procedure:

- Soft mineral wool mats are cut to the size of the crate cells plus 5 mm for spreading.

- Mats are coated with adhesive around the perimeter and in the center in 1-2 places.

- The mat is placed in place and pressed to fix it.

- The slots are filled with scraps of material on the mounting foam.

Since the water absorption of mineral wool is greater than that of expanded polystyrene and polyurethane foam, a vapor barrier film (not household polyethylene!) Is fixed on the surface of the mats with a stapler to prevent absorption of water vapor by the material.

Mineral wool is a gyroscopic material, therefore, before laying insulation, it is necessary to take care of waterproofing

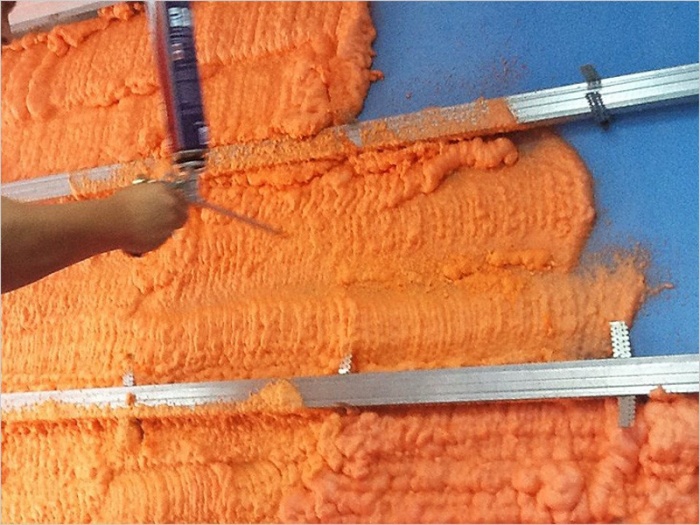

Use of polyurethane foam

When using slab polyurethane foam, the insulation process is similar to thermal insulation with foam. If you decide to spray foam, you will need professional equipment that you can rent or invite a team of professionals. It will cost more, but guarantees a quality result.

Polyurethane foam insulation is suitable for sectional doors, as the material itself has a low volumetric weight.

It is important! When spraying, it is necessary to use a protective suit, goggles, a respirator, work in the air or in a room with good ventilation.

Performance of work: spraying is carried out in layers, monitoring the thickness of the material so that it matches the thickness of the crate. After the foam has hardened, the excess foam is cut off.

Before covering the gate with polyurethane foam, it is necessary to close the openings and parts of the gate into which foam is not desirable.

Finish lining

Finishing will not only make the garage space more attractive, habitable, but it will also protect polyurethane foam and polystyrene foam from the damaging effects of sunlight.

The interior of the gate can be made from a variety of materials:

- Moisture resistant plywood - a classic finish with excellent performance;

- OSV board - oriented strand board quality material for external and internal facing;

- Lining wooden;

- Lining plastic;

- Sheet plastic is opaque.

To prevent the appearance of cold bridges with a metal crate, before fastening finishing it is advisable to glue the shelves of the frame and corners with foil tape.

Materials are cut to size. To fasten the plastic lining - siding, a connecting U-shaped profile is mounted around the perimeter of the canvases. The cladding is attached to the crate with self-tapping screws in special grooves; when fastening, the self-tapping screws are not screwed up to the stop, leaving a gap of 1.5 mm for thermal expansion. Siding orientation can be either horizontal or vertical.

Plywood, OSV boards, lining after installation must be primed with an antiseptic and painted with a composition for wood materials for outdoor use, paying special attention to protecting the ends, since rotting and fungal infection begin from them.

General view of the insulated gate after facing with moisture-resistant plywood

For finishing sectional doors, you can use foil insulation made of foamed polyethylene foam, fixing it with a similar adhesive tape, or sheet plastic, which is attached to the insulation with a stapler.

The advantage of artificial materials for sheathing is their resistance to decay, durability and ease of maintenance, the disadvantage is the release of harmful substances during combustion.

Mounting seals

Particular attention should be paid to sealing the porches, since heat loss through cracks is up to 30% of all heat loss. The seal can be single-circuit, when the seal is attached along the contour of the opening, double-circuit, with the fastening of profiles to the opening and the door leaf.

Rubber seal due to the elongated tail is perfectly attached to the gap

The sealing of the porches is carried out with special seals:

- Rubber have different forms(flat, round, tubular), the choice depends on the size of the slots;

- Silicone is most often produced in the form of a tape: they are soft and elastic, designed to fill small gaps;

- Brushes are equipped with piles of different heights, impregnated with a protective compound, have a service life of at least 8 years;

- Polyurethane foam - take the form of a gap, resistant to temperature changes, but afraid of light.

The sealant is fixed on three sides of the opening with self-tapping screws or glue, on the gate leaves in the center and on the bottom leaves. In the lower part of the canvases with a large gap, it is better to use brush seals, along the perimeter of the opening - tubular, at the junction of the wings - silicone. If the gate has a wicket door, then the sealing profiles should be fixed along the perimeter of the opening in the door leaf.

Video: do-it-yourself garage door insulation

Performing insulation will not be difficult for a person who owns tools. It takes only a small financial investment and time to implement the plan. Carrying out work in accordance with the technology will help create comfortable conditions in your garage even during winter frosts.

Not all car owners have a garage, but most of them dream of one. Not all happy owners of the garage have it insulated, but most of them, who have ever felt the charm of insulation, dream about it. And behind the seeming complexity of the warming process is a sequence of simple actions that any normal man can reproduce. In this article, car owners are invited to find out how from the inside, since they are the main source of general heat loss.

Why insulate garage doors?

Motorists can ask a quite reasonable question: “Why, in general, insulate the gate, and the garage itself? After all, this is a room for the periodic appearance of a person in it, and the car is under a roof and is protected from natural influences". In words, everything seems to be so, but it is necessary to sort it out in order. What are the arguments for insulating garage doors?

- The gate is the largest part of the garage in terms of area, which connects with external, not always favorable, natural conditions. It is through the gate that the maximum heat transfer occurs: in winter, the necessary heat tends to break out, and in hot summer, unnecessary heat penetrates into the garage.

How heat "leaks" from the garage door can be clearly seen on the thermogram

How heat "leaks" from the garage door can be clearly seen on the thermogram - Very often, garage owners organize workshops in them so as not to do the necessary carpentry or locksmith work at home, a lot of car repair operations can be done in the garage, and this involves a long stay in it. Therefore, the insulation of the gate is simply necessary.

- Garage insulation makes the temperature regime softer, without sharp fluctuations, and this saves from moisture condensation both in the garage and on the car, and especially in its hidden cavities. In properly insulated garages, car bodies are less susceptible to corrosion.

Another fundamental question is to insulate the gate from the outside or from the inside? Building science recommends insulating capital walls from the outside, and covering the insulation layer with plaster. Gates are a completely different design. Firstly, they need to be movable to open and close, and secondly, they perform a protective and anti-vandal function, which is best done by a metal sheet. Therefore, it is advisable to insulate them from the inside.

What types of garage doors need to be insulated

Most garage doors have a hinged design, which, of course, is simply necessary to insulate. The basis of such gates is a frame made of profile pipes and steel sheet as exterior finish. The very high thermal conductivity of steel is known, so we can assume that such non-insulated gates do not represent any barrier to heat leakage. AT swing gates The main thing is the presence of a gate, which greatly reduces heat loss during frequent movement of people. Therefore, if the garage is still at the construction stage, then it is necessary to order with a gate.

Lift-and-swivel are very fashionable now and overwhelmingly factory-made. Their web or sections are sandwich panels made of sheet steel on the outside and polyurethane foam on the inside. This design already has the necessary thermal insulation properties and does not require additional measures for insulation. These types of gates, at the request of the customer, can also be equipped with a gate, which must be done.

There are artisanal up-and-over gates, but in this case their insulation will not fundamentally differ from swing gates, since the same frame and steel sheet are the basis.

Roller doors cannot be insulated due to the peculiarities of their design. Yes, and they can be called garage doors with a very large interference, since they are inferior to all the others in terms of thermal insulation and anti-vandal properties.

The choice of insulation

Insulation is a material that has a minimum thermal conductivity. AT building science thermal conductivity is evaluated by a special indicator - the coefficient of thermal conductivity. And the smaller it is, the more likely this material is to become a heater.

In the presented table, its upper part is heaters, and the lower (from No. 16 onwards) building materials that need to be insulated. The insulation layer greatly slows down the transfer of thermal energy and the thicker this layer is, the better, but at the same time the principle of reasonable sufficiency is observed. For garage doors, a layer of insulation of 5 cm will be enough.

In today's rich selection of various building materials There are a huge number of heaters under different names. It is very difficult to navigate them, especially for an inexperienced person, but in fact there are only a few main classes, some of which are suitable for garage door insulation, and some are not.

Mineral wool

Mineral wool is a wonderful heat-insulating material that has proven itself very well in construction. Under this name, there are actually three subspecies of insulation:

- Glass wool, consisting of the finest glass fibers (5-15 microns) with a length of 15 to 50 mm. It has the required low thermal conductivity of 0.03-0.05 W/m*°K, a wide range of allowable temperatures from -60 to +450°C, good elasticity and strength. When working with it, always wear protective equipment, since the smallest fibers break easily, dig into the skin and enter the respiratory tract. The hygroscopicity of glass wool is moderate.

- Slag wool obtained from metallurgical production waste - blast-furnace slag. The fibers are thin - 4-12 microns, and the length is less than that of glass wool - about 15-16 mm. The thermal conductivity of this material is somewhat higher than that of glass wool 0.040-0.050 W / m * ° K, but quite acceptable. It is better not to use it to insulate a garage, as it is very hygroscopic and at the same time has an acidity that adversely affects the metal.

- Stone wool obtained by melting rocks of volcanic origin. In structure, it is very similar to slag wool, but it has better heat resistance and does not have acid aggressiveness. Thermal conductivity stone wool 0.03–0.04 W/m*°K. Phenol-formaldehyde resins are used as a binder in some types of this insulation, therefore, when heated, it can release phenols into the surrounding air, which are extremely harmful to humans. The hygroscopicity of this material is high.

Basalt wool is the most demanded among all porous heaters.

Basalt wool is the most demanded among all porous heaters. All types of mineral wool are highly hygroscopic, so their use for insulating garage doors is limited, since moisture will condense in the insulation layer, reducing the thermal insulation properties of this material. Glass wool is dangerous to work with, slag wool has residual acidity, therefore only stone basalt wool is applicable, provided that vapor barrier films are used.

Styrofoam

Foam plastics are called a fairly wide class of synthetic materials, the common thing for which is their foamed gas-filled structure, and the basis is some kind of polymer. It is by the type of this polymer that foams can be classified.

- Polystyrene foam - it is he who is most famous and looks like sintered gas-filled balls. Such foam is an excellent insulation and is used most often. Designated as PSB or PSB-S. In this class, the most interesting extruded (extruded) expanded polystyrene (EPS), which has the best strength, negligible hygroscopicity and resistance to ignition. For garage door insulation, EPPS is one of the best choices. In retail chains it can be called: Stirex, TechnoNIKOL, Penoplex, URSA XPS, etc.

- Polyvinyl chloride (PVC) foams - used in construction for heat and sound insulation. Panels from it are rigid or elastic. This is an excellent material, similar to XPS, which has increased fire resistance. By international standards marked as PVC. It is less common in retail chains than PSB or EPPS.

- Urea-formaldehyde Styrofoam (CFP) - widely used for thermal insulation. Its advantage is that it does not increase in volume when it dries, so it is used in liquid form on construction sites to fill cavities. Known in retail chains under the names: Mattemplast, Poroplast cf, Unipor, Omiflex, Penoizol, Pentil. It can be used for thermal insulation of garage doors.

- Polyurethane foam (PPU) foam is known to us in two forms. Elastic polyurethane foam is nothing more than foam rubber, and hard polyurethane foam. Rigid polyurethane foam is suitable for thermal insulation purposes, as it has excellent adhesion to all surfaces, has excellent thermal insulation properties and is waterproofing. Can be applied directly on the construction site by spraying. Perhaps this is the best choice for thermal insulation of garage doors. The only drawback is that coating requires special equipment, which slightly increases the cost of thermal insulation.

Prices for thermal insulation materials

Thermal insulation materials

Judging by the types of garage doors described earlier, insulation is required, first of all, for swing doors, as well as lifting and turning ones made independently. Before starting the insulation, you should make an audit of the ventilation system in the garage. What is it for?

- Any garage must be provided with a ventilation system: supply and exhaust. Very often, the inlet is made in the gate, so this must be taken into account when insulating. The insulation should not block the ventilation hole.

- It happens that forced ventilation“organized” due to the loose fit of the garage door leaves. It is unacceptable! If there is no air inlet in the garage, then it should be arranged at the bottom of the gate.

Door surface preparation

Before starting work on thermal insulation of the gate, it is necessary to prepare the inner surface of the gate, on which there may be pockets of corrosion, old peeling paint, various contaminants, etc. To do this, you must:

- Large foci of corrosion, where there are exfoliating layers of rust, are cleaned with a brush with metal bristles.

- Further, it is better to resort to mechanized processing of the gate surface using brush heads on the drill.

- The best results are obtained by removing rust with polymer-abrasive brushes "Piranha", which works together with the grinder. Working with it is absolutely safe, but you should not forget about protective equipment. When working, you can pour water on the surface, the polymer pile penetrates into the most inaccessible places. Given that angle grinders machines (grinders) operate at high speeds, the cleaning process is very fast.

- After complete cleaning and degreasing, an anti-corrosion primer is applied in two layers. Any suitable one can be used. If the primer will be applied with a brush, then the second layer is applied perpendicular to the first. Best to use aerosol cans- the quality of the coating will be better.

Manufacture of crates for the insulation of the gate

With any method of thermal insulation, with any materials, in the design of the door leaf you will need a crate, which, firstly, will help to fix the insulation, and, secondly, the gate lining will be attached to it in the future. For the manufacture of the crate, you will need wooden bars with a section of 4 * 4 cm or 5 * 5 cm, depending on the design of the gate. The crate must be attached to the load-bearing frame of the door leaf: profiled steel pipe or corner. To make a wooden crate, you need:

- Prepare the required number of wooden blocks. When buying, you need to choose only dry wood.

- The bars are treated twice with an antiseptic composition to prevent their decay in difficult conditions of temperature extremes and high humidity.

- Bars are attached to the load-bearing elements of the gate with screws. To do this, after marking, it is necessary to mark the places of future holes, and then with a drill with a diameter corresponding to the screw, through holes. When fastening the bars, do not forget to pre-make holes in them with a thin drill so that the screw being screwed does not split them.

- If there is a ventilation hole on the door leaf, it must be bypassed with a crate around the perimeter. This also applies to locks and bolts.

- If there are no steel load-bearing elements on the central part of the door leaf, then the bars can be attached to each other in any convenient way: at the end, using corners, etc.

Insulation of garage doors with mineral wool

If a decision has already been made to insulate the gate with mineral wool, then it is better to choose basalt wool from well-known manufacturers. But before laying the insulation, you need to take care of waterproofing, since mineral wool is a very hygroscopic material. For these purposes, the following can be used:

- The inner side of the gate can be covered with waterproofing mastic, for example, bitumen-polymer.

- Self-adhesive materials Isolon or any other give very good results.

After waterproofing the surface of the gate, you can cut the insulation into pieces of such a size that they fit very tightly between the bars of the crate. Mineral wool can caking over time, so the denser the better. After laying all the insulation on top, a vapor barrier film is stretched and attached to the bars of the crate construction stapler. After this operation, we can say that the gate is ready for the final cladding.

Styrofoam door insulation

If ordinary PSB foam is used to insulate the gate, then the use of waterproofing is also desirable. This material is capable, although not in the same way as mineral wool, to absorb moisture, which reduces its thermal insulation properties. It is desirable to use XPS, which does not have hygroscopicity. Extruded polystyrene foam, although more expensive, does not require waterproofing. For the surface of the gate you need:

- After measuring the space between the bars of the crate, a plan is drawn up for cutting foam sheets. The main rule is a minimum of joints. At the same time, it should be taken into account that the size of the cut sheets should be 2-3 mm larger than the size of the cell - the foam should fit into place very tightly. You can cut the foam with a construction knife using a ruler.

Video: How to cut foam with a knife

- Styrofoam sheets can be glued to the door surface with mounting foam. It is better to use professional foam supplied by a gun, since its volumetric expansion is small. For gluing on the back side of the sheet, foam is continuously applied along all edges of the sheet and one line in the center parallel to the long side. Further, the sheet is installed in its place and firmly pressed with a bar or rule. By tapping, you can correct the position of the sheet. After a few minutes, the position is checked and corrected if necessary.

Video: How to glue polystyrene foam with mounting foam

- After installation of all sheets, all joints and cavities are processed with mounting foam. After the foam has dried, the excess is cut off and the surface can be lightly troweled. The gate is ready for cladding.

Door insulation with polyurethane foam

When insulating the gate in this way, it is no longer possible to do without the involvement of skilled labor and special equipment. Polyurethane foam is applied by a special installation by spraying in several layers. A wooden crate is still needed, since it is convenient to attach the finish lining of the gate to it.

It has clear advantages:

- Polyurethane foam (PPU) has excellent adhesion to almost all surfaces, and over time, its properties do not change.

- The thermal insulation properties of polyurethane foam are very high - its thermal conductivity coefficient is 0.019-0.035 W / m * ° K.

- When applying PPU by spraying, no cavities remain and no "cold bridges" are formed.

- PPU is an excellent hydro and vapor barrier, so additional waterproofing is not required.

- The service life of PPU thermal insulation, according to manufacturers, is at least 70 years.

Video: Applying polyurethane foam coating to the garage door

Before applying the coating, close the gate hinges, locks, bolts and ventilation holes with a film, pasting it around the edges with masking tape. Coating is carried out only in protective clothing, goggles and a respirator. After applying the calculated layer of insulation and its complete drying, the excess on the crate can be cut with a construction knife. After that, the gate is ready for cladding.

Lining the inner surface of the gate

The main thing is already done! Garage doors are already equipped with thermal insulation, but no one has yet canceled aesthetics and practicality, so it is best to veneer with some material. What can serve as a lining?

- Cladding with corrugated board is a practical solution, but based on the experience of people who have done this, moisture can condense on the surface.

- Cladding with plastic clapboard - looks good, easy installation, but the surface is very easy to damage.

- Facing wooden clapboard- one of the most practical and beautiful solutions, but wood treatment with antiseptics and fire retardants is required.

- Cladding with sheets of OSB (oriented strand board). This option is perhaps the best, since OSB sheets are not subject to decay, have the necessary strength and have a beautiful appearance. If desired, you can paint the surface in any preferred color.

The cladding is fastened to the lathing bars with screws with a press washer.

Additional measures to insulate the garage door

Gate leaf seals

One of the main ways to lose precious heat from the garage space is a loose fit of the gate leaves. Very rarely they fit so tightly together that they exclude any movement of air. Therefore, it is always necessary to use seals, which come in different profiles and sizes.

For a snug fit of the gate leaves and the gate, a rubber seal with a round section with a diameter of 20 mm has proven itself best. Due to the rubber tail, this seal is easily attached to any door. To do this, a perforated steel strip is taken and, in a predetermined place, the tail of the seal is pressed with it and screwed with self-tapping screws in increments of 15-20 cm to the gate leaf. It is desirable to smear the tail of the tape with glue No. 88 before installation.

Another area where heat can escape from the garage is at the bottom of the gate. Naturally, one cannot do without a gap in this place. Rubber seals are not suitable for this purpose, but there are special brush profiles specifically designed to seal the bottom of the gate. The installation of this profile is quite simple - it must be screwed to the bottom of the gate with self-tapping screws in increments of 15-20 cm. Wherein, when fully closed, the brushes should bend about a third of their length.

garage curtain

A significant plus in saving heat in the garage in winter is the garage curtain, which is hung directly behind the gate. The curtain material must meet certain requirements:

- The material must be dense, as light materials do little to prevent heat leakage.

- Resistant to high humidity and mold.

- Fire resistance.

- Strength and elasticity.

All these requirements are perfectly met by an ordinary tarpaulin, however, with a small caveat - it must have a water-repellent impregnation. They also make curtains from heavy PVC fabric, but tarpaulin sun is equally out of competition.

best material for garage curtains - tarpaulin. It is worth buying along with eyelets

best material for garage curtains - tarpaulin. It is worth buying along with eyelets Along with the tarpaulin, eyelets should also be purchased, which are inserted into the fabric at a distance of 20 cm. Opposite the gate in the fabric of the curtains, you need to make a cut for free movement without moving the entire panel.

Conclusion

- Warming the garage and garage doors is not overkill. These measures will allow you to better keep the car, it is comfortable in the garage as cold winter and hot summers.

- Garage doors are only insulated from the inside.

- The best way to warm - spraying.

Video: Garage door insulation option

Video: Another option for insulation

Cold and damp inside the garage have a negative impact on both the condition of the car and the garage itself.

According to the regulations, the temperature in a heated garage should never fall below +5 - under such conditions, the car will always be ready for work, it will not be damp and cold in the garage, mold will not appear, it will be comfortable to be in it. After all, the garage is not only the “home” of the car, but also a place for storage, a workshop.

For creating comfortable conditions the garage needs to be insulated. Separately, it is necessary to highlight the insulation of the gate, because it is through the gate, most often made of metal, that the most heat escapes, and it is more difficult to perform it than the thermal insulation of the roof or walls. How to insulate garage doors from the inside with your own hands?

What materials can be used

To insulate garage doors with their own hands, they most often use

- mineral wool,

- extruded polystyrene foam,

- Styrofoam,

- polyurethane foam.

Insulation with liquid polyurethane foam is a modern and effective, but expensive way. Spraying polyurethane foam requires special equipment. The advantages of this method are the formation of a uniform coating without seams and a long service life (up to 70 years).

You can insulate garage doors with mineral wool. For this material, it is necessary to lay waterproofing and vapor barrier, since cotton wool absorbs water, which worsens its heat-insulating properties. It is advisable to use basalt wool from well-known companies.

Best value for money for self-insulation garage doors fit XPS and Styrofoam. These insulating materials have the following advantages:

- have a low density, and therefore a small mass,

- have a low coefficient of thermal conductivity, that is, they do not transmit heat well,

- do not decompose under the influence of water and air,

- under observance of operating conditions do not emit harmful substances,

- does not absorb water well: in foam plastic, the water absorption rate is 1%, in XPS - 0.4%.

The video shows how to insulate a garage door with polystyrene foam with your own hands.

You will also need materials for finishing. It can be

- OSB boards-3 or OSB-4,

- plastic lining,

- wooden lining,

- profiled sheet

Finishing not only improves the appearance of warm garage doors, but also protects the insulation from external influences, for example, from mechanical damage and aggressive chemicals (gasoline, solvents).

The most practical is considered to be facing with OSB boards. They have several benefits:

- lungs,

- easy to process them

- have a low price

- looks aesthetically pleasing

- have low vapor permeability.

Usually, plates 1 cm thick, 125 * 250 cm wide and long are used. For facing the gate, 1-2 sheets are required.

Wooden lining is beautiful, condensation does not accumulate on it, but it must be treated with antiseptic and flame retardants. Plastic lining looks good, but is soft and easily damaged. The profiled sheet is durable, but condensation accumulates on it.

Various gate designs and their insulation

Sectional

Such gates are an "accordion" that folds and rises to the ceiling. Industrially manufactured models already have their own polyurethane foam insulation, and all joints between sections are additionally insulated. Usually this is enough, but you can additionally glue foam sheets on each section.

lifting and turning

Such garage doors, when opened, rise up and turn at a right angle. You can buy them ready-made or make your own. These garage doors are already insulated. The insulation is a panel of polyurethane foam with a thickness of 4.5 cm, which is enough even for the northern regions.

Roller shutters

They are made of lamellas, like blinds, and are wound on a roller when they are lifted. A small layer of insulation can be made between the lamellas and on them, a thick layer cannot be made due to the design features, therefore in Russia it is not advisable to use such gates for heated garages.

Swing

The simplest and most popular design, made of sheet steel or profiled sheet, is quite durable. To minimize heat loss, even when installing the gate, a wicket should be provided in them. Do-it-yourself insulation of garage doors is easiest on this design.

Rollback

They represent a whole metal structure that moves along the rails. Such gates are rarely found in garages, however, if you have just such a system, they are insulated in the same way as swing gates.

What you need to insulate the gate

To insulate the garage door with your own hands, you will need the following tools:

- drill with drills for wood and metal,

- screwdriver or screwdrivers

- sandpaper,

- clamps,

- hacksaw or jigsaw,

- mounting knife,

- a hammer,

- square,

- a metal brush or brush from a drill,

- roulette,

- roller,6

- iron ruler 1 m long.

Of the materials needed

- insulation,

- finishing material,

- wooden bars for framing,

- mounting foam for sealing joints,

- composition for anticorrosive treatment of metal surfaces,

- wood preservative,

- for styrofoam and mineral wool, a waterproofing material such as bituminous mastic, isolon, vapor barrier film.

Training

To properly insulate garage doors, they need to be prepared. All wooden surfaces must be treated with an antiseptic and antifungal agent with a brush. You may need one or two coats, each of which should dry.

Attention! It is necessary to apply an antiseptic with gloves - these compounds are harmful to the skin.

The gates themselves are cleaned of rust and peeling paint with a metal brush or a special nozzle for a drill. After that they are cleaned sandpaper and degreased with solvent. When it dries, apply an anti-corrosion primer. The composition must be designed for use over a wide temperature range. Apply it in two layers: one along the gate, the other across.

crate

The next step is the crate. It is made from 4 * 4 cm bars and attached to the gate frame and to other elements on their surface, for example, to stiffeners. Before sawing the bars, you need to measure the garage door and make a drawing. The step of the crate must be at least 40 cm.

To fasten the crate in the frame, holes are drilled in increments of about 20 cm. If the frame is made from a corner, 3.5 * 30 mm screws are usually used for fastening to the frame and 4.5 * 70 mm for fastening the bars to the end. If the frame is made of profile pipe, then, accordingly, take longer screws. Fasteners should go into the bar no less than half of its thickness, and at the end of the bar - no less than 3 cm. Clamps are used to firmly press the bars to the frame. Then, using a screwdriver, screw them with self-tapping screws.

Warming

When cutting insulation, remember that the fewer joints, the better. Insulation is placed between the bars of the crate. 9

Styrofoam or expanded polystyrene sheets are lubricated with mounting foam or a suitable adhesive - special for foam plastic or "liquid nails". It is better to take a professional polyurethane foam, which increases in volume less and is conveniently applied with a gun. Glue must be applied around the perimeter and at the corners of the foam sheets and evenly distributed over the entire surface.

If mounting foam is used to insulate the garage door, the surface needs to be slightly moistened. The foam is applied to the sheet and left for a few minutes to increase in volume. Then the foam is glued to the gate. After 15 minutes, you need to press the sheets tightly again. After all the sheets are mounted, all remaining gaps and cracks are also filled with foam.

Mineral wool is fixed to the crate with dowels. A vapor barrier film is laid on top, fixing it to the crate with a furniture stapler.

Important! If ventilation holes have been made in the gate, they must not be closed, this is dangerous! It is necessary to leave holes in the insulation layer.

After laying the insulation, OSB boards or other selected material are screwed to the crate. The sheets are cut so that the number of joints is minimal, and those that are available fall on the bars of the crate. Sawing OSB with a hacksaw or electric jigsaw.

Foam insulation

Warm garage doors can be obtained using mounting foam, which allows you to create a single surface without joints. For 7 sq.m. The gate will require approximately 5 cylinders of foam. The technology is extremely simple: foam is applied to the prepared surface, then it hardens, after which the excess is cut off. From above it can be plastered, painted, covered with OSB or chipboard.

Additional measures

In order to properly insulate garage doors, you need to make sure that they close tightly and without gaps. Usually they use a round seal with a thickness of 20 mm with a rubber "tail", for which they are attached to the gate with a perforated tape and self-tapping screws.

A seal is also installed at the bottom of the gate, but rubber ones are not suitable for this. For the lower part of the gate, brush profiles are used, which are also fastened with self-tapping screws.

The garage, in our reality, often serves its owner as a car service station and a workshop. And sometimes - a cellar, a pantry, a warehouse, and God knows what else. Therefore, the creation of a certain microclimate in it, and hence the need for insulation, is not a whim of the car owner, but a vital necessity.

The main heat exchanger, of course, is the garage door, made of metal. In summer, they serve as a huge battery that actively heats the air inside the garage, and in winter as a refrigerator. Their warming will radically improve the situation. And if with protection from the summer heat everything is more or less clear - almost any insulation system is suitable here, then protection from the cold will require more deliberate approaches. It's about the choice of heater.

The physics of heat transfer in a garage

Even if your garage is not heated in winter, a car with a warm engine put into it after a trip serves as a kind of heating device for some time. So, first of all, at the gate, there are 2 air flows: warm from the inside, cold from the outside, which is why condensation forms on the inner wall of the garage door leaf. If the frost is large enough, then it turns into frost - the water freezes.

If insulation is laid from the inside of the garage door, then warm air will not flow to the canvas. That's right, but the insulation to the insulation is different. If you lay mineral or any other wool, then it will inevitably get wet in a garage, because the car itself is a source of excess moisture, especially in winter. At the same time, not only will it lose its thermal performance to a large extent, but it will also provoke accelerated corrosion of the gate metal.

If you heat your garage in the winter, this process will only get worse.

This method of garage door insulation can only be used when you do not operate the car in winter or this happens extremely rarely. And even then, before closing the gate, insulated with mineral wool, you need to let the car cool down enough. But the products in the cellar will not freeze and in the summer such insulation will save. But we will not consider this option of warming in this article because of its unsuitability, especially since there are more effective ways.

Simple ways to insulate garage doors from the inside

Since cotton wool is not quite suitable, it is necessary to find effective heaters that do not absorb moisture. The simplest, but, unfortunately, not the most economical, will be the method of pasting garage doors with thick foamed polyethylene, such as is used for soundproofing bodies, but thicker. It has an adhesive layer on one side. You just need to degrease the canvas, let it dry, and stick the material cut to size. Its thickness can reach 35 mm.

There is a thick polyethylene foam without an adhesive layer. It can be glued to permanent sticky glue (such is used on adhesive tape), which is purchased via the Internet.

Or use several layers of underlay under a laminate of the same material. It is better to fix such a substrate using a wooden crate and slats. And this whole pie is better protected from the inside by some sheet material, protecting from mechanical damage: plywood, OSB, plastic panels etc.

But this will not be enough if there are gaps around the gate, as in the photo. To eliminate them, various seals or even metal seals with a seal should be used if the gaps are very large.

The second option simple solution thermal insulation of the gate opening will be the installation of thick curtains.

This solution is as simple as it is effective. The only inconvenience is the need to constantly raise or extend such a curtain when entering and leaving the car.

The main requirement: a tight fit of the curtains to the walls and floor, especially from below, so as not to blow cold air, which is known to be at the bottom. The air gap between the door leaf and the curtain will serve as a door insulation, and air circulation will actively dry the resulting condensate.

Curtain material can be any, but dense: tarpaulin, awning fabric, dense polyethylene. The most commonly used type of garage door insulation will be their insulation with polystyrene foam.

How to insulate garage doors with styrofoam

The choice of polystyrene foam for insulating garage doors from the inside with your own hands is simply explained:

- relative cheapness of the material;

- ease of cutting;

- insulation efficiency (one and a half times more effective than mineral wool);

- the possibility of operation without additional protection.

Styrofoam, unlike cotton wool, is absolutely hydrophobic, a fungus does not start in it and it does not release small particles of fibers into the air.

Consider the process of insulating garage doors with polystyrene foam in more detail. There are 2 types of it:

- from foamed granules (otherwise called ball);

- extruded.

The second is denser, but quite expensive and, unlike PSB-S, quite flammable. It is only slightly “warmer” than ordinary white, so thickness plays a role in warming. For garage doors, a layer of 50 mm will suffice.

Step-by-step instructions for insulating garage doors:

1 . We clean the gate from dust, dirt and oil stains.

2. We strengthen wooden slats 50 mm thick. You can do this with self-tapping screws to the shelf of the corners, you can through the outside through the door leaf, or you can glue it with polyurethane glue - a balloon for polyurethane foam, applied with a foam mounting gun, is also suitable.

3. With its help, we glue polystyrene, filling the cavities between the slats.

Glue on sheets of expanded polystyrene should be applied quite thickly, ideally - continuous.

4. We also foam the joints of foam sheets and the places where it adjoins the rails with mounting foam (you can use the same foam glue). After polymerization, excess foam is removed with a sharp knife flush with the foam.

5. We close the entire surface of the gate with foil foam insulation (it is better to take it with aluminum foil, and not spraying) with a shiny layer inside the garage. We use self-tapping screws with a cone-shaped hat, deepening them into the rail.

6. We close the insulation with sheets of plywood or OSB, screwing them to the frame rails.

7. We glue the sealant in a quarter of the openings, we foam the cracks around the box.

It is desirable to paint over the inner lining or open it with varnish.

do-it-yourself insulation of garage doors from the inside with polyurethane foam

And yet, the best way to insulate garage doors from the inside is to spray polyurethane foam on them. First, it is by far the most effective insulation: it is one and a half times better than expanded polystyrene and three times better than mineral wool, and secondly, having excellent adhesion, it fills all the cavities of the garage door, leaving not the slightest void.

Ideally, a high-density polyurethane foam should be used and applied with a special machine. Only it is unlikely that you have one in the corner of the garage, and hire a team with necessary equipment quite expensive, but the raw materials themselves are not very cheap. But there are 2 options in which you can do the work yourself:

1. One of them is described in our self-manufacturing SIP panels:

Mounting foam in cylinders is the same polyurethane foam, though of low density, but it will do its job no worse than sprayed through high-pressure installations. An airbrush for this method of application can be used old, but with a large nozzle, and you will definitely find a compressor, if not with you, then in one of the neighboring garages. The foam must be applied continuously, so that the result is a layer of 30 mm. You can do this in several steps.

2. The second is somewhat more expensive, but less troublesome. For this, you will need to purchase a PU Foam Kit, consisting of two containers with components A and B (polyol and isocyanate), when mixed to form polyurethane foam, a hose and a spray gun.

These kits come in different capacities, with a fairly accurately calculated foam output by volume. It is not so difficult to calculate it.

There are kits from other companies, and the spraying process itself will become clear to you after watching the demo video. After polymerization, the foam can be painted or closed with an inner lining in a convenient way.

Dear readers, if you still have questions, ask them using the form below. We will be glad to communicate with you;)

Chocolate biscuit: the secrets of cooking in a slow cooker and oven

Chemical composition and nutritional value

Apple chips at home

Braised cabbage with white beans, recipe

How to reduce the ass, hips and stomach at home?