The main requirement for any home is that it must be warm. To achieve this, it is necessary to insulate not only the walls, but also the attic. Professional craftsmen will insulate the attic efficiently and quickly, but their work is expensive. So if you want to save money, get ready to do it right yourself.

materials

Most often, attic insulation is carried out using polyurethane foam, mineral wool or expanded clay.

Each of these materials has certain advantages and disadvantages.

Polyurethane foam (PPU)

This material is a type of plastic. With its help, the attic floor, roof, gables are insulated. PPU has many advantages:

- strengthening the strength of the roof (after application, the PPU layer turns into a single structure without cracks and cracks);

- low thermal conductivity;

- durability (service life of at least 30 years);

- excellent adhesion with any building materials (no need to use additional fasteners when applying);

- lightness, small layer thickness (which saves attic space and reduces the load on supporting structures);

- moisture resistance (PPU, due to its properties, protects itself from moisture, so there is no need to create moisture and vapor barrier layers);

- resistance to mold, penetration of rodents and insects;

- possibility of operation at any temperature (not afraid of drops from -200° to +200° С).

Such a heater is made right on the spot from a minimum number of components. Polyurethane foam is an excellent protection for the attic of a private house from cold, moisture and heat loss.

PPU is afraid of exposure to ultraviolet radiation, so it must be protected with a layer of plaster or paint, covered with various panels. Polyurethane foam is a slow-burning material, but under the influence of high temperature it will begin to smolder. Do not use it in places where there is strong heating.

Mineral wool

With it, you can completely insulate the attic in a private house. Since the structure of the material is such that it perfectly passes steam, then with inside it must be protected with a vapor and waterproofing layer.

Mineral wool is a non-combustible material, at a temperature of +1000 ° C it does not even melt. It is resistant to biological effects (microorganisms do not multiply in it). It has low thermal conductivity.

Mineral wool is produced in the form of mats or rolls. It is laid between the rafters and lags.

The weight of the material is considerable, which increases the load on the supporting structures. Before proceeding with the insulation of the attic, you need to make sure that the roof and all supporting structures are reliable. Or, provide for the use of this type of insulation at the design stage of the house and strengthen the supporting structures.

The ingress of moisture adversely affects the thermal properties of mineral wool.

Expanded clay

Expanded clay can be used to insulate the attic of a private house. This, moreover, it is lightweight, fireproof, environmentally friendly. Expanded clay is strong and durable, moisture resistant, not afraid of temperature changes. Most often they insulate the floor of the attic. Applying the material indoors, you need to create a vapor barrier coating.

When insulating a cold attic with expanded clay, a frame is created (a special “box” on the floor, into which insulation granules are poured, a wooden floor is laid on top of it). This "eats" a certain amount of space.

When insulating the attic of a house, it is better to choose several types of heat insulator. used for horizontal surfaces, mineral wool or polyurethane foam - for vertical ones. Such an arrangement will be cheaper, and installation is more convenient.

Warming technology

Before insulating the attic, for example, with mineral wool, it is necessary to prepare the following tools and materials:

- mounting stapler (with staples 5-7 mm);

- special tape;

- mounting foam;

- construction knife;

- waterproofing film;

- vapor barrier material;

- glue for mineral wool (nails and screws);

- eye and hand protection.

Before starting work, it is necessary to measure the area to be insulated: for this, the width of the surfaces is multiplied by their length. Then you need to decide how many layers of insulation will be used. For central Russia, a layer of mineral wool for warming the attic of a private house should be at least 20 cm.

Room preparation

It is necessary to completely free the room from foreign objects. Remove all seals from the slots, construction debris, cobwebs. All surfaces must be properly cleaned. It is necessary to provide good lighting in the attic. Then put in essential tool and material.

For convenience, you can put several sheets of plywood on the logs of the attic floor. Seal all cracks in the roof ventilation ducts mounting foam.

In the event that an attic is not planned in the attic, it is made ventilated. To do this, special ventilation troughs are attached with brackets under the roof.

If cold attic insulated to create additional premises, then you do not need to install such gutters.

Installation of a waterproofing layer

A waterproofing film is needed to protect the mineral wool and the entire room from moisture. This layer is especially important if the attic of a house with an old roof is insulated.

The film must be tightly stretched onto the truss structure of the entire roof with small overlaps. So the waterproofing layer will become airtight. Fix it with a mounting stapler.

On the one hand, mineral wool slabs are treated with glue (it is applied with a spatula) and pressed tightly into fragments between the rafters. You can fix the insulation on nails or screws. Laying is carried out along the slope from the bottom up in two layers. The joints of the plates should be staggered: this will reduce heat loss. Often, mineral wool slabs are simply inserted into sections of the truss structure.

If mineral wool is used in rolls, then its installation is carried out directly from the roll in order to avoid removal required dimensions and cutting material. If necessary, you can cut off the mineral wool with a clerical or construction knife, after placing a plank under it.

Be sure to insulate communications in the attic, ventilation shafts.

Installation of a vapor barrier layer

So that moisture does not affect the life of mineral wool, it is necessary to fix the vapor barrier layer. The film is fixed with a stapler on the plates. For tightness, the joints are glued with special adhesive tape.

Making a crate for decorative trim

You can sheathe the attic space with OSB boards or drywall. To do this, you need to properly make the frame. To save money, you can install the crate flush with the truss system.

The rafters are the basis of the frame, between them you need to lay the crossbars. If this option is not suitable, you can create a full-fledged frame from a metal profile.

Floor insulation

When insulating a cold attic with mineral wool, logs are laid on the floor that will hold all the material. Then they perform work similar to the one described above: first waterproofing, then insulation and vapor barrier. After that, they are laid strictly according to the level, for example, OSB board 10-12 mm and cover it with varnish.

It is possible to insulate the attic with your own hands correctly and quickly if you correctly approach the choice of heat-insulating material and carefully study the technology of its installation.

Foreword. The attic protects the house from cold, moisture and the scorching rays of the sun. In addition, the heat from the house leaves it through the attic to a greater extent. Therefore, the question is “what is the best way to insulate the attic in a private house?” - the owner decides in the first place. We will also consider the issue of attic insulation in a private house with our own hands in this article and show a video lesson from Isover.

How to insulate the attic floor of a private house

Often the attic, due to its disorder, remains unused. But it is from the attic that you can make an excellent rest room or bedroom, if you correctly approach the choice of insulation and equip the attic for living quarters yourself. These issues can be resolved on their own, or you can invite a team of builders who, to insulate the attic wooden house, as well as ventilation devices for the attic floor will be able to offer several options.

Gables and attic floor are insulated using various types heaters. But more often, three types of insulation are used for attic thermal insulation. Consider the advantages and disadvantages of each:

– Organic derivatives (polyurethane foam);

– Heaters based on mineral wool;

- Bulk heaters such as expanded clay.

We analyze the better to insulate the attic of a private house

Insulation with polyurethane foam (PPU) attic

Polyurethane foam is the most popular insulation for roofs, gables and attic floors. Among its advantages are called low thermal conductivity with a small thickness. Its use is especially relevant here, because. the load on the supporting structures is reduced and a significant part of your attic space is saved.

PPU is applied by spraying, which creates a monolithic structure that perfectly protects housing from cold and moisture, as well as preventing heat from escaping from the house. Polyurethane foam does not absorb moisture and is resistant to mold, prevents the penetration of insects and rodents.

Attic insulation with polyurethane foam enhances the strength of the entire roof due to the creation of a single sprayed structure, without cracks and cracks. Also, PPU has high strength and wear resistance - the service life exceeds 30-40 years. PPU does not require the creation of moisture and vapor barrier, since it itself perfectly performs the functions of its moisture protection.

Warming with mineral wool of the floor of the house

Mineral wool is suitable for insulating attic floors and attic floors, as well as for insulating walls and roofs. However, mineral wool insulation implies the creation of external wind and moisture protection with the help of waterproofing. Mineral wool has a structure that perfectly transmits steam, therefore, from the side of the room, the insulation must be protected with hydro-, vapor barrier.

Mineral wool is laid in the form of rolls or mats. Usually mineral wool is laid between the rafters, and on the floor - between the lags. Inevitably, seams form between fragments of material and structures. They must be carefully foamed and sealed with adhesive tape. For central Russia, a layer of insulation of at least 200 mm is required.

Mineral wool has a considerable weight - the load on the supporting pillars and floors is significantly increased. Therefore, before insulating the attic with this material, you should make sure that the supporting structures and the roof are reliable. You ask - and this is all that can be used to insulate the attic? And how was the attic floor insulated before the invention of polyurethane foam and mineral wool?

Expanded clay insulation of the attic floor of the house

Expanded clay is a bulk insulation, it is perfect for insulating an attic floor, because it creates a ventilated space, while retaining heat. Expanded clay is light, in terms of flammability, it is safe and environmentally friendly. Thanks to the manufacturing technology, expanded clay is strong and durable, resistant to moisture, high and low temperatures.

Expanded clay differs in the size of granules. Attic insulation with expanded clay is often carried out in the floor area. From the inside, expanded clay needs a vapor barrier coating. The material needs a frame, and this "eats" part of the attic space. A special “box” is usually created on the floor, where expanded clay is poured, and a wooden floor is laid on top.

More often, expanded clay insulation and attic insulation with sawdust complement mineral wool or polyurethane foam, especially for horizontal surfaces. You should not choose only one option than to insulate the attic in a private house - you should correctly combine materials. For horizontal surfaces, it is better to use bulk insulation, they are cheaper and more convenient in the device.

Insulation with sawdust and foam attic

Insulation with sawdust can be used as one of the ways to insulate the attic. But this method is no longer in demand today as it used to be. The main disadvantage is the flammability of the material, which is not suitable for the roof of the house. Attic foam insulation is easy to implement, but it also has a significant drawback - a fire hazard and the release of toxins during combustion.

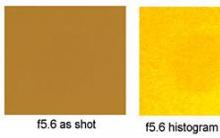

Comparison table of thermal conductivity of materials

Video: how to insulate the attic in a private house

Through the uninsulated attic leaves a large number of heat for which money is paid. As a result, the temperature in the room does not rise, and the cost of public Utilities are growing. The only way out is to insulate a cold attic with inexpensive building materials. If you have time and extra money, you can insulate the roof, but this is not necessary, because it is enough to insulate the ceiling from the side of the attic and all the heat will remain in the room.

Why is attic insulation needed?

If the attic is not insulated, the likelihood of mold growth in the room increases.

The floor area in a private house is equal to the ceiling area, through which most of the heat escapes. In a cold living room, more moisture is formed, so the likelihood of fungus formation increases, which leads to respiratory diseases in the future. Most discomfort arise in the bathroom, the floor and walls in which do not have time to dry out, discomfort is created, in addition, the cold in the bathroom contributes to colds when there is a sharp change in temperature. Children in such conditions are more likely to get sick.

Insulating materials, for the most part, drain water well, so when insulating, condensate will not accumulate on the walls. Warm air dries out excess moisture, while the walls and floor warm up.

If the roof slopes and the gable are insulated, moisture will not form in the attic and the smell of mold will not be heard. It's over hard work but doable as the materials are light in weight.

It is best to carry out work on the insulation of the attic with your own hands, so as not to spend extra money on wages. Choose a heater technical specifications, calculate its quantity and lay it according to available technologies. All work may take 1 day.

Thermal insulation materials

In the market of heaters you can find both natural and artificial materials. Their difference lies in cost, efficiency, service life, thermal conductivity.

Mineral wool

Basalt wool

Mineral wool or its varieties - glass wool, basalt insulation, slag wool - are characterized by an increased coefficient of thermal conductivity due to the structure of randomly arranged fibers. Cold air in winter it does not penetrate into the room from the outside, and in summer it is cool in it, since the cotton wool does not let air flows cooled by the air conditioner.

- The material does not crumble and does not cause an allergic reaction. You can work with stone wool without protective equipment.

- Service life is about 50 years.

- Mineral wool from volcanic rock comes in different densities - you can choose suitable option for any region, including the coldest.

- Basalt wool is a lightweight material, so one person can handle its installation.

- Mineral wool from basalt does not burn. It can be melted at very high temperatures, so the attic will be safe.

Additional pluses basalt insulation is to reduce the noise level in the room, since sound waves cannot pass through the layer of air that is among the fibers. At the same time, the denser the material, the smaller the air gap and the more sounds it transmits, so the insulation can be chosen with average thermal conductivity and sound insulation.

Basalt insulation can be used to insulate the chimney, then even more heat will remain in the room where there is a stove or fireplace.

When using glass wool and slag wool, you will have to wear a protective suit, goggles and gloves, as thin fibers break and can get into the respiratory system, eyes and skin. These materials are also non-combustible, but melt at much lower temperatures. In this case, the material loses its structure and useful properties.

Styrofoam

Styrofoam does not weigh down the ceiling structure, but has a low strength factor

Insulation of the attic in the house cold roof can be done with foam. This material also has advantages:

- Low weight and cost.

- Does not highlight harmful substances when heated, so it is chemically neutral and safe.

- Contains a flame retardant that does not support combustion.

- Microorganisms and mold do not start in the foam.

- Does not weigh down the structure of the ceiling.

Of the shortcomings:

- Low coefficient of strength, therefore, additional protection of the material is required in the form of boards laid on top supported by logs. This will require additional costs and time.

- The material does not allow air to pass through, so dampness and condensation may form in the room.

- Rodents that are found in private homes damage the foam, build burrows out of it, so additional coverage is needed.

Styrofoam is used most often for outdoor work under plaster. As a heater for an attic in a private house, it is not profitable - it requires large investments to protect the material itself.

Styrofoam ceiling insulation in a house with a cold roof is more profitable from the inside, but it can lower the ceilings.

Penoplex (expanded polystyrene)

Thanks to the spongy structure, foam is easy to cut

Penoplex insulation is made from granules of synthetic material polystyrene or expanded polystyrene. This is a heater, which is a porous structure with separately located cells. Honeycombs do not touch each other, which on the one hand is positive quality, on the other hand, a negative point. The fact is that polystyrene foam does not pass moisture well, it will accumulate inside the room, causing dampness.

The advantage of polystyrene is its cost and small thickness. The air inside makes up 98% of the total volume of the material, which is why it is so cheap. Compared to stone wool, the thermal conductivity is lower. To achieve good thermal insulation, it is necessary to buy polystyrene foam of greater thickness, which will cost more.

Penoplex is combustible, therefore, in terms of fire safety, it is absolutely useless. The melting point is 75 degrees, so it can not be laid next to heating appliances. In the attic it can be a chimney from the stove.

polyurethane foam

Insulation with polyurethane foam

In terms of service life, as well as heat-retaining characteristics, it is worth paying attention to polyurethane foam, which is applied by spraying. In this case, there is no need to build logs for laying mineral wool or expanded clay, save money by purchasing cheap fragile materials.

Behind a short time you can create a monolithic floor in the attic, in which rodents will not settle, mold will not start, cracks will not appear. When using polyurethane foam, you do not have to buy additional vapor and waterproofing.

Expanded clay bulk

Expanded clay is resistant to ignition and exposure to a humid environment

You can insulate the attic with expanded clay. This is a durable material that is used in bulk with prepared cells. If you need to move around the attic, you will have to build a floor on top wooden joists. Advantages of expanded clay:

- strength;

- durability;

- does not absorb moisture;

- retains heat well;

- passes air;

- can be used in combination with other materials, which is preferable.

Most often, expanded clay is combined with mineral wool or polyurethane foam is sprayed onto it so as not to waste time building a frame.

Thermal insulation layer thickness

To insulate the attic in a house with a cold roof, you can use heat-insulating materials of any density, since the room is not residential. If you plan to lay mineral wool on the roof slopes, you can prepare a material of lower density and thickness, since as a result the ceiling insulation will be double, but laid in two places.

For ease of movement on soft insulation, it is necessary to build paths made of wood or other material so as not to violate the properties when compressing the heat-insulating layer.

Preparing the attic for insulation

Attic ready for insulation

Before starting work, it is necessary to calculate the area of \u200b\u200bthe room and the amount of building materials. The main thing is the thickness of the insulation, which is needed in middle lane where the temperature can drop to minus 30 degrees. The thickness of the mineral wool must be at least 20 cm.

After calculations:

- Remove all debris and dust so that the seal does not absorb it.

- Seal the cracks in the roof with construction foam.

- Remove sharp objects. They can damage the protective layer of cotton wool.

After cleaning, you can bring Construction Materials, tools, as well as an additional lamp for illumination.

vapor barrier

Vapor barrier is a must when working with mineral wool

According to the laws of physics, warm air saturated with steam will always rise up, passing through walls and ceilings. This process is called diffusion.

Different materials have different degrees of vapor permeability. High resistance to the diffusion process can be provided by the formation of condensate or the accumulation of moisture between floors. In such places, floors are usually made of wood, and wood, saturated with moisture, loses its strength.

When the lower room is warming up, and the upper one is cold, a vapor barrier is a must. In case of application stone wool you can buy material with a hydrophobic coating that will not allow steam to pass into the cold room above, where water droplets form from it.

In technical documentation, there are two concepts: steam resistance and vapor permeability coefficient. These are different concepts.

To organize the vapor barrier, two materials are used - a film to cover the entire area and adhesive tapes to connect the layers of hydrophobic insulation so that steam does not penetrate into the cracks.

The characteristics by which the vapor barrier is chosen should take into account strength (polyethylene film is not suitable), UV resistance, since the sun's rays sometimes enter the windows, which can damage materials.

Waterproofing

Installation of a waterproofing layer

To protect the attic from flooding, and ceilings and repairs from water drips, it is recommended to lay a layer of waterproofing material on the roof slopes.

- Built-up - overlapped and connected with a burner. Most cheap option- synthetic materials.

- Sprayable. A solid film-membrane is created.

- Powder. Water is added to it immediately before installation.

- liquid - suitable for concrete floors, soaking into their surface.

- Coating on a bituminous basis.

Before you buy waterproofing, you need to re-read the properties: the material must pass air, but retain water. Some cheap films create the greenhouse effect in a cold, unheated attic, causing mold to form on the walls.

Announcement: If you properly insulate the attic of the house, you can significantly save on heating. To do it yourself, you need to know the technology of insulation and what kind of heaters are - let's talk about it.

Gone are the days when attic insulation was straw or old blankets. And the attic itself has ceased to be a cold kennel in which rubbish is stored. Almost in every country house from it they make a living room - an attic. Equipped with furniture and appliances. Such an attic should be well insulated and protected from moisture. In addition, high-quality attic insulation will help to avoid heat loss throughout the house.

The market offers many different heaters, but let's talk about those that have proven to be the most convenient and reliable - these are polystyrene foam, mineral wool, polyurethane foam and expanded clay. A good owner of this material can easily insulate the attic of the house without the help of a specialist. We will understand the pros and cons of each of them, as well as the installation features.

Important: use lime mortar to treat all the cracks and joints on the roof before the attic insulation begins!

Attic insulation technology with mineral wool

Mineral wool is a simple and inexpensive insulation. It is produced in the form of plates or rolls. There is foil mineral wool - it does not absorb moisture and will last longer. If you want to save money, you can buy a simple mineral wool, but then be sure to cover it plastic wrap or foil - this is a good alternative to foil mineral wool.

Installation of mineral wool

We lay mineral wool on the crate between the rafters or lags. Remember that the mineral wool layer must be at least 200 mm, which is more than the thickness of the rafters, so pad to increase it.

We lay a vapor barrier film on top of the mineral wool. There should be no joints, the edges of the film overlap, and the joints are fixed with adhesive tape or glue. Next comes either lining, or boards, you can fiberboard - this is already at your discretion.

Properties

Mineral wool has good thermal insulation properties.

Elasticity - it is convenient to insulate gables, floors and walls of the attic.

Good soundproofing.

Mice won't start.

But there are disadvantages - this is a heavy material, overloading the roof structure, so make sure that all beams and ceilings are in good condition.

Important: direct contact with mineral wool is not safe. It can not be inhaled - use a respirator. Wear goggles to keep material particles out of your eyes. Contact of mineral wool with skin will cause irritation - wear gloves.

Properties and installation of polyurethane foam

Polyurethane foam material is a more reliable attic insulation, because it has advantages over mineral wool, but it is several times more expensive. Although, in the process of operation, it pays off completely.

Advantages of polyurethane foam

Polyurethane foam is a plastic material. It does not need additional waterproofing, it has its own moisture-proof properties.

This insulation is sprayed onto the floor, roof and gables of the attic with a thin layer, several times thinner than mineral wool. This allows them to fill the smallest gaps and hard-to-reach places, which will protect against drafts and the penetration of insects.

When spraying polyurethane foam, there are no joints, so no additional materials are needed for their processing.

There is no load on the attic structure, the roof becomes stronger - no hurricane will destroy it.

Important: polyurethane foam is a non-flammable material, has self-extinguishing properties - this is its plus. But this insulation is prone to smoldering, then toxic substances are released, so you should not use it near the chimney and stove.

Insulation with expanded polystyrene

Expanded polystyrene is similar to polystyrene, but polystyrene ignites easily and is toxic, so they are not recommended to insulate the attic for safety reasons. There are types of polystyrene foam that are similar to polyurethane foam - they do not burn.

Expanded polystyrene is produced in the form of plates, and is attached with a special glue. It is cheaper than polyurethane foam, but requires joint processing, like mineral wool. Common advantage polyurethane foam and expanded polystyrene is that they can be processed with anything - they will not lose their shape and properties.

How to insulate an attic with expanded clay

Expanded clay is often used to insulate the attic floor and save heat in the house. It is non-toxic and non-flammable. This insulation is produced in the form of granules. different sizes. Due to the fact that it is a bulk material, it not only retains heat, but also serves as ventilation.

Expanded clay is used mainly for warming only the floor. A frame is created in the form of a box, where expanded clay is then poured. First you need to lay a vapor barrier film.

You can combine heaters. For example, you can lay mineral wool on top of expanded clay or mix it with sawdust. Next, you can put wooden planks or lay linoleum. If you have a cold and non-residential attic, then you can pour expanded clay with concrete, but it must be thick so that it does not flow into the space between the granules.

We talked about how to insulate the attic, and now some tips on how to choose insulation, given the type of roof.

Main types of roofs

In order for the thermal insulation to be of high quality and not create unnecessary problems, it is important to consider the type of roof of the house.

In the case of a gable or shed roof, you need to try to make sure that the insulation fits very tightly to the truss structure. To do this, use additional fasteners. If you do not pay enough attention to this, then over time the mineral wool or tile material will sag and cold voids will appear.

Sloping roof - it is most often used for attics. Consists of several slopes. Windows are made on inclined ones, and the insulation is attached to horizontal ones more easily and does not sag over time, so this type of roof is easier to install heat-insulating material.

Important: before starting insulation work, cover wooden structures flame retardant and antiseptic!

Now that you know about the properties and features of the installation of insulation materials, it will not be difficult for you to insulate the attic with your own hands.

Video

2. We lay a vapor barrier film on top of the mineral wool. There should be no joints, the edges of the film overlap, and the joints are fixed with adhesive tape or glue. Next comes either lining, or boards, you can fiberboard - this is already at your discretion.

Have you built a house recently, but did not have enough space? They built it a long time ago, but the children are growing, has it become crowded in the house? A warm attic would help, but there are not enough funds? Insulate the attic in a private house with your own hands. Get more living space and reduce heating costs. To do this is not difficult at all. Ask: “How to insulate your attic in a private house?” About everything in order.

If you decide to do everything with your own hands, then initially you will have to abandon the insulation of the attic by spraying polyurethane foam. This technology requires additional equipment, certain skills or the hiring of specialists with them, and is justified if it is impossible to dismantle the roof. Thermal insulation with bulk materials is most likely a special case of thermal insulation of flat roofs, therefore it is not considered in the article.

First of all, you need to decide on the type of insulation and its thickness. If the question arose, what is the best way to insulate the attic of a private house, using only one's own strength, the answer will be as follows. Roll or plate heaters made from mineral fiber, as well as polystyrene. All of them are relatively light weight, allowing to reduce the load on the truss system, provide full thermal insulation, subject to simple rules installation.

Dust and fibers from insulators from cutting and laying can cause allergic reactions. Therefore, to carry out the work, it is necessary to prepare funds personal protection and security:

- work clothes made of dense fabric, providing maximum protection of the skin from contact with insulating materials;

- closed shoes with non-slip soles;

- headdress, preferably with fields;

- gloves, better rubberized;

- protective mask or respirator;

- mounting belt and safety cable.

To carry out the work you will need the following tool:

- tape measure and ruler;

- construction stapler;

- wood saw, electric jigsaw, circular saw;

- screwdriver or drill;

- hammer;

- construction knife with replaceable blades (18 or 25 mm);

- ladder ( scaffolding, tour-tower).

The following materials should be prepared:

- insulation in accordance with the estimated coverage area;

- steam and waterproofing membranes (with about 10% margin);

- a counter rail with a thickness of at least 25 mm, width across the thickness of the rafters;

- boards for the device of internal and external crates;

- nails, screws, staples for a construction stapler.

When installing the insulation of an existing roof, you may need:

- nail puller;

- boards for rafters (to replace those that have become unusable);

- new roofing material.

Preparing the work front

Since the insulation technology for the new and existing roof is the same, we will consider the insulation of the old roof, which requires more work.

Although they say that to break, not to build, the issue of dismantling must be approached wisely. The removed materials that have retained their properties can be used during installation, thereby saving.

Depending on the available roofing we are dismantling it. The place for storage is determined at a distance from the place of work, sufficient for the installation of ladders or other lifting mechanisms on the roof. If it is intended to be re-used, then carefully lay it on a flat area on logs to maintain the correct geometric shape. At large volume sheet materials we produce additional re-laying with lags to increase the stability of the foot and evenly distribute deforming loads.

We carry out the dismantling of the existing crate, establishing the possibility of reusing the removed materials. Warehousing is carried out in the same manner as the roofing material.

Existing rafters, supports and girders (horizontal roof boards) are inspected. If elements unsuitable for further operation are identified, they are replaced. This does not require special skills. Having removed the old element, a new one is made in its image and likeness and installed in place.

Existing rafters, supports and girders (horizontal roof boards) are inspected. If elements unsuitable for further operation are identified, they are replaced. This does not require special skills. Having removed the old element, a new one is made in its image and likeness and installed in place.

What shouldn't be

Do you know how a greenhouse works? If to explain primitively, then a film is stretched over the frame, which provides isolation of space from the external environment. It was noticed that with a sealed shell, water drops condense on the film. In the absence of ventilation high humidity detrimental effect on the growth of plants and the condition of the retaining structures. Therefore, the greenhouse must be equipped with ventilation to maintain the necessary microclimate. To eliminate the greenhouse effect when insulating the attic, it is necessary to use, together with thermal insulation, hydro- and vapor barrier.

Do you know how a greenhouse works? If to explain primitively, then a film is stretched over the frame, which provides isolation of space from the external environment. It was noticed that with a sealed shell, water drops condense on the film. In the absence of ventilation high humidity detrimental effect on the growth of plants and the condition of the retaining structures. Therefore, the greenhouse must be equipped with ventilation to maintain the necessary microclimate. To eliminate the greenhouse effect when insulating the attic, it is necessary to use, together with thermal insulation, hydro- and vapor barrier.

Vapor barrier installation

First of all, we install a vapor barrier film from inside the future room, separating the attic volume from the volume of the roof. The use of ordinary polyethylene is not recommended. Read the manufacturer's instructions before installation. It is written there which side the film must be laid to perform the functions assigned to it. The laying of the film in the attic is carried out perpendicular to the rafters with an overlap of layers of at least 10 cm with insulation of the joints with construction tape. Some manufacturers of membranes apply a line on the material along which the border of the connection of the canvases passes. This greatly simplifies the installation process. The film is fixed using a stapler with a staple of 14 mm and a step of 0.3 m.

First of all, we install a vapor barrier film from inside the future room, separating the attic volume from the volume of the roof. The use of ordinary polyethylene is not recommended. Read the manufacturer's instructions before installation. It is written there which side the film must be laid to perform the functions assigned to it. The laying of the film in the attic is carried out perpendicular to the rafters with an overlap of layers of at least 10 cm with insulation of the joints with construction tape. Some manufacturers of membranes apply a line on the material along which the border of the connection of the canvases passes. This greatly simplifies the installation process. The film is fixed using a stapler with a staple of 14 mm and a step of 0.3 m.

Then the inner crate is installed, to which the final finish of the attic is subsequently attached. A lattice of 25 mm edged (unedged) boards is equipped with a step of 25 cm. This will avoid deflection of the insulation inward under its own weight. The board is fastened with nails of at least 70 mm or screws of at least 50 mm, 2 or more nails (screws) in each rafter.

Then the inner crate is installed, to which the final finish of the attic is subsequently attached. A lattice of 25 mm edged (unedged) boards is equipped with a step of 25 cm. This will avoid deflection of the insulation inward under its own weight. The board is fastened with nails of at least 70 mm or screws of at least 50 mm, 2 or more nails (screws) in each rafter.

Working outside

Due to the fact that access to the interior is closed, the work on the insulation from the outside is carried out from the bottom up in parallel to provide access to higher sections of the roof.

To ensure your own safety, when insulating the attic of a private house with mineral wool, use a mounting belt, a safety cable and head, hand and foot protection.

To ensure your own safety, when insulating the attic of a private house with mineral wool, use a mounting belt, a safety cable and head, hand and foot protection.

We carry out the following work across the entire width of the roof at a distance of about 2 m for each pass:

- install a crate for laying insulation,

- we lay the heater;

- we spread and fix the waterproofing;

- we fix the counter rail;

- install the outer cladding.

There is no consensus on whether it is worth laying an additional crate under the insulation on top of the vapor barrier. In the event that it is decided to do this, a 25x10 mm rail is laid parallel to the rafters, then perpendicular.

If it was planned in advance truss system under laying the insulation, then proceed to its installation. If not, then cut the insulating material. At the same time, remember that the width of the thermal insulation should be 10-20 mm more than the width of the opening. Laying is recommended to be carried out in 2 layers with overlapping with the 2nd layer of the joints of the first.

The waterproofing membrane is laid from the bottom up. We fasten with a stapler with a 14 mm staple. The first strip should go beyond the rafters by 2 cm. The strips are connected using double-sided reinforced construction tape glued to the bottom layer of the membrane along the overlay border. Remove the tape before applying the top layer. protective film. The width of the overlap is adjustable according to the line printed on the membrane, but not less than 10 cm. The strips are glued together by pressing. It is necessary to create a slight sagging of the material to ensure normal operation when the temperature changes in the under-roof space.

We fix the counter rail 25 mm and a width equal to the rafter board with nails or screws with a length of at least 50 mm on the rafters.

We make the lathing device from 25 mm edged (unedged) boards with a step of 25 cm. At the same time, the first (lower) two boards are laid with a gap of 10 cm. reliable fastening roofing material and installation of a drainage system.

Acting in this way, we insulate the pitched roof at all heights to the very top. In this case, the waterproofing should not reach the ridge of the roof by 4-5 cm. Now you can proceed with the installation of the roofing material, either new or dismantled.

Thermal insulation of the attic with foam will give a good effect of saving money and time. When using it, there is no need to install a vapor barrier film due to the zero vapor permeability of the material. But this increases the fire hazard of the roof, so you should think twice before using it as an internal thermal insulation.

Now, knowing how to insulate the attic in a private house and how to do it, you can rely only on yourself to make the house more comfortable and warmer. Subject to the installation technology, you can be sure that the next repair will be done by grandchildren, and even great-grandchildren.

Build for fun!

At the end, we invite you to see interesting video about attic insulation

The influence of the middle name on the name Yuri

Name Ilya - meaning and contraindications

Baby keeps crying

What does the name Aidar mean, the mystery of the name

Name Ilya - meaning and contraindications