During construction or repair work you need a tool that can work with wood efficiently and quickly, ensuring an even cut. This tool is a circular circular saw for wood, it is convenient and fast to work with it. But you don’t need to think that all circulars are the same, just buy the saw you like and a few replaceable, cheapest-priced disks, and you can get to work. In reality, everything is much more complicated, when choosing a saw, replaceable saw blades play a very important role.

Replacement discs from trusted manufacturers

We must not forget that circular saws occupy a leading position in the number of accidents. But any such case can always be prevented if choose the right saw and removable disks, as well as always use in a safe way sawing. A reliable and high-quality disc will always last longer, cut more accurately, do not “destroy” your circular saw and, of course, much safer.

For example, today the popularity of using miter or circular hand saws in repairs and construction is growing significantly. A variety of saw blade configurations began to appear on the market. You can buy more expensive, or you can save on price. But there is a well-known rule: one of the main indicators of convenience when working with a saw is the balance of the blade of the circle, resistance to side loads, heat, resistance to blunting and the disc production technology itself.

If the disc is of poor quality, then it will heat up more and faster, it is poorly balanced, which can either lead to deformation of the blade during operation, or the teeth will quickly become dull. A blunt circle is very dangerous. A poor-quality saw blade becomes more contaminated with sticky glue and resins, which dull the teeth. The wheel may jam and throw the workpiece back at you, causing injury. The result of an "inappropriate" saw blade is - a large number of defects, poor-quality and inaccurate sawing, reduced saw performance, engine breakdown or overheating and your safety.

That is, do not forget that with regard to saw blades, there is a “verified manufacturer and price” rule, and careful disk selection. Naturally, it is up to you, but do not forget that when purchasing cheap option from an unknown manufacturer, you run the risk of purchasing a disc with all its shortcomings. And then, probably, you will need to spend extra money on cutting material, a new circle, or, even worse, a new circular.

Why is there no universal saw blade for all kinds of work?

Alas, there are no such saw wheels that would equally cope with different tasks and materials or could be installed on any kind of circular saw. There is no disc that could do the same high-quality cut in both softwood and hardwood, rip or cross cut in materials with different coatings. Disks need to be selected to solve specific problems. It is from the saw wheel that it will depend on what material the circular saw will work with.

Alas, there are no such saw wheels that would equally cope with different tasks and materials or could be installed on any kind of circular saw. There is no disc that could do the same high-quality cut in both softwood and hardwood, rip or cross cut in materials with different coatings. Disks need to be selected to solve specific problems. It is from the saw wheel that it will depend on what material the circular saw will work with.

Yes, you will need to spend more money by purchasing several different saw blades to various kinds works. But this approach will be 100% justified in terms of the speed and quality of the work you have done.

For example, it's no secret that miter saws are better suited for cross cuts with negatively inclined wheels for a clean cut. At the same time, for longitudinal cutting, circles with a negative slope are the effect of “repulsion” of the part, an increase in vibration and material resistance. Wheels with a negative impudence usually have a larger number of teeth and a small interdental space. These sinuses are clogged with sawdust, increasing the load on the motor. You also need to remember that there are two main types of saw blades - carbide and monolithic.

What is the difference between carbide tooth discs and solid discs?

A disc is called monolithic if it is made of solid material. Carbide wheels are made with brazed teeth.

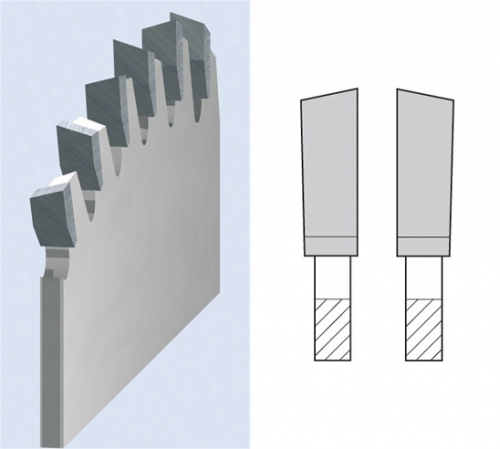

Monolithic circles can have two configurations:

- curved teeth with an elongated back, for sawing soft wood;

- sharp teeth for fine cross and rip cuts in soft and hard wood.

In terms of their performance, monolithic circles quickly become dull, require teeth setting and periodic sharpening. It is very easy to sharpen the teeth, they can withstand several sharpenings. Often discs have a large number of teeth.

Carbide wheels are much more reliable, teeth can be left unsharpened for a long time, often these wheels justify themselves, even if they are not resharpened at all. The benefits are enough:

- a large assortment;

- high-quality cut;

- reliable in work;

- do not require a divorce of teeth;

- have ample opportunities;

- Relatively low price.

The disadvantages include difficulty in regrinding teeth and an expensive price.

Saw blade selection

Start with careful study technical parameters

your circular saw for wood. You need to clearly know all its features and characteristics:

Start with careful study technical parameters

your circular saw for wood. You need to clearly know all its features and characteristics:

- What is the spindle speed of the circular saw?

- What is the power of the electric motor and possible loads?

- What is the outside diameter of the saw blade when using the saw?

- What is the section of the seat pin?

Also keep in mind that a high-priced, high-quality wheel will not make a regular circular saw a unique sawing machine. Everything must be proportionate.

Why is it important to know about permissible loads and engine power?

Wheels with a negative slope, with a large number of teeth, with a high torque give a significant engine load. Therefore, before buying any kind of saw blade, you need to learn as much as possible about the possibilities of a circular saw.

Why is it important to know the spindle speed?

The size of the circle must always be proportional to the power of the motor. The drive is designed to use a specific circle, so working with the wrong blade of a larger size can be very harmful to the tool. Theoretically, when the protective cover allows, the use of a disk with slightly increased dimensions (by millimeters) is allowed, but it is desirable to comply with all specifications to the end to avoid complications.

Why do I need to know the diameter of the seat pin?

The most common problem: any saw model has its own pin diameter. Sometimes it can be quite difficult to choose a circle that would meet all the requirements and have exactly your seat. At present, it is possible to purchase discs with "non-native" landing diameters. This requires additional buy an adapter ring under your seat, if this ring is on sale.

Why is it important to know the allowable outer dimensions of a disc?

Any tool is designed only for equipment of a specific diameter. This means that the drive power, the protective cover, the engine - all these elements of a circular saw for wood are limited by the specified technical capabilities.

Choosing a circle for a specific job, pay attention to these factors, how:

What kind of work is planned to be done?

Is it a rip cut or a cross cut? Tool type: table saw, miter saw or hand saw? What materials need to be cut: hard wood, soft wood, wood coated on one or both sides, chipboard, formwork, laminate, non-ferrous metals, building tree, sheet metal or just profiles and pipes, etc. It is better to take a pen and a piece of paper and write it all down.

Why is it important to pay attention to the design of the saw blade?

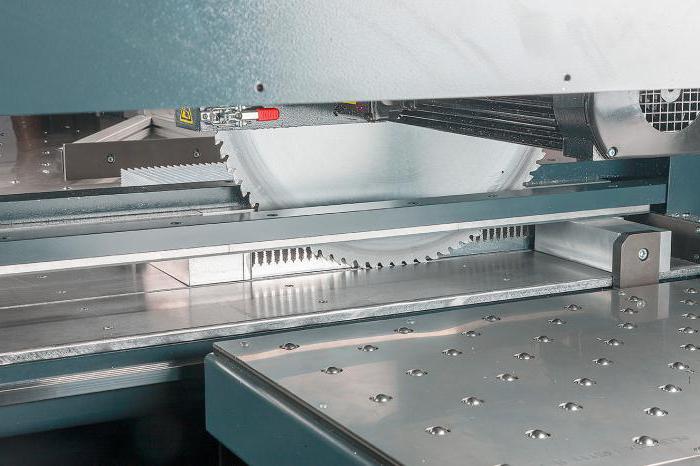

The disc body can give detailed information about its quality. quality disc undergoes computer balancing and made by laser cutting. Each circle is polished separately. You can see this if you check the disc in the light. In a high-quality saw wheel, the grinding marks diverge in circles from seat. This means that the wheel was balanced, calibrated and ground separately, and not the entire sheet of metal was ground before cutting the blades.

The disc body can give detailed information about its quality. quality disc undergoes computer balancing and made by laser cutting. Each circle is polished separately. You can see this if you check the disc in the light. In a high-quality saw wheel, the grinding marks diverge in circles from seat. This means that the wheel was balanced, calibrated and ground separately, and not the entire sheet of metal was ground before cutting the blades.

You also need to pay attention to how the surface is polished. If there are signs rough processing and roughness, then this circle will not give the proper result in work, the teeth will become dull faster, the temperature of the circle will rise more strongly.

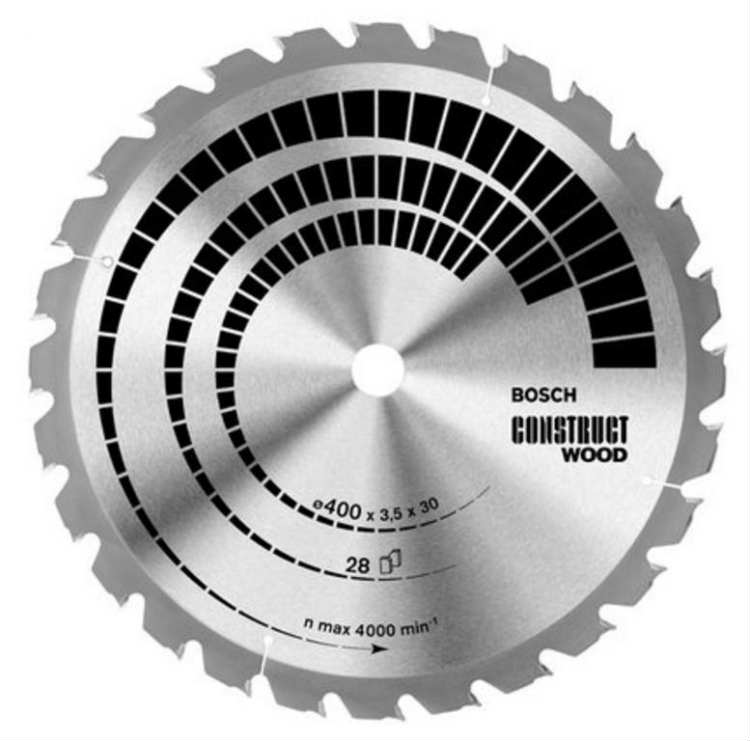

On the body of the web, it is mandatory to have temperature compensation slots with a hole. These slots are required to reduce the temperature of the blade, as well as to protect against saw noise and vibrations.

Why is it important to pay attention to the outer size of a circle?

Each tool is specifically designed for tooling of a given diameter. Using other sizes may have negative consequences. Outside diameter does not affect the cutting speed, but only the depth of cut. But, the deeper the canvas is immersed in the tree, the more the load on the motor increases. Experts advise keeping the minimum depth of cut. This reduces heat, improves cut quality, and reduces engine stress and cutting resistance.

Why is it important to pay attention to the diameter of the seat?

The circle must be tightly on the landing pin. Some disks, for rigidity of fixation, are made with additional holes along the edges for narrow pins.

Why is it important to pay attention to the number of teeth on a wheel?

The number of teeth is responsible for the cleanliness and speed of cutting. The greater the number of teeth, the better the finish cut, but the load on the motor increases and the removal of chips is complicated, which slows down the feed of the saw in the material and its speed. And a small number of teeth means a wide interdental distance, which favorably affects the removal of chips, speeding up the sawing process. But the quality is rough and rough.

A large number of teeth is often found on circles big size with negative teeth. A large number of range from 60-80 teeth. To small - a range of 15-50 teeth.

A range of 30-70 is considered average. It is more suitable for different types of work. Often, wheels with an average number of teeth can cut in various materials, make both transverse and longitudinal cuts, cuts in both soft and hard wood.

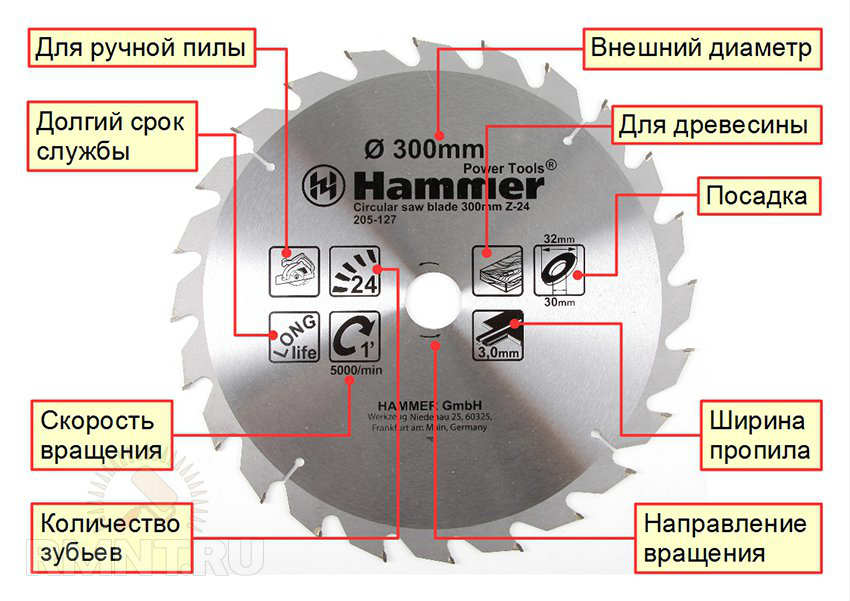

Why is it important to pay attention to disc labeling?

A high-quality saw blade is marked not with paint, but with a laser. The inscriptions can help you choose the right disc, as well as help in future maintenance. On the canvas of the circle can be indicated: the thickness of the canvas, external diameter, number of teeth, bore diameter, tooth configuration pictogram, series saw blade and the number of revolutions of the disk.

Why is it important to pay attention to the number of revolutions of the circle?

For safe operation it is necessary that the possible speed of rotation of the circle exceeds the maximum allowable spindle speed tool.

For safe operation it is necessary that the possible speed of rotation of the circle exceeds the maximum allowable spindle speed tool.

The maximum possible wheel speed varies according to the size of the disk. It is unacceptable to exceed the speed indicated on the circle canvas. The consequences of over-rotation are the risk of serious injury, reduced blade life and loss of cut quality.

Almost any manufacturer has discs for all major types of materials. The differences are in the amount of know-how, product quality and, of course, in price. Also, a feature of a serious manufacturer is a convenient simple classification and the breadth of the range. As is often the case in the market, all the advantages and disadvantages are balanced. Cheap blades cut worse and dull faster. A reliable and high-quality disc lasts longer, cuts more accurately, but also costs more. Therefore, the choice of a particular brand is to some extent a matter of taste.

It is difficult to imagine construction work without sawing any materials. At home, in the country or on personal plot not to do without an automatic saw. With proper equipment and use of equipment, labor productivity increases significantly.

An important element of any saw is a disk. The speed and quality of product processing, the amount of marriage and waste, as well as the safety of the performer and others depend on the correct choice of this consumable.

Is it possible to pick up a universal saw blade?

Choosing a saw blade is almost a science. At the same time, many parameters should be taken into account and characteristics should be compared different models. If there is no experience, then it would be more correct to seek the advice of a specialist. At the same time, it is not always possible to get really necessary information from the sellers of saw blades. It is better to entrust the choice to a professional who has the skills to cut different materials on a circular saw.

Why is it so important not to make a mistake with the choice of disk? First of all, a competent approach to the purchase is required for security purposes. Circular saws are leading in the number of accidents at work. Such statistics can be changed if each contractor and organizer of construction works takes a more responsible approach to the question: “How to choose the right saw blade?”

Some try to save money consumables and look for "universal" saw blades. But, there really aren't any. It is impossible to find a saw blade that would cut hard / soft wood, metal or various composites with the same quality. The disk is selected for the solution of a specific task. Of course, this approach involves an increase in the cost of work, but this is justified by an increase in speed, quality and safety.

For example, discs with a negative tooth angle fit under miter saws and provide a clean cross cut. But it is impossible to use them for sawing tables (longitudinal cutting) - such discs create the effect of "repulsion" of the workpiece, increase vibration and material resistance. Saw blades in which the teeth are set at a negative angle usually have small interdental sinuses and a large number of teeth. These recesses fill up quickly. sawdust which increases the load on the engine.

Basic criteria for choosing discs

The cutting tool has certain characteristics, dimensions, purpose, parameters and properties of the material from which the disc is made.

So, what criteria should you pay attention to.

Disk type. All saw blades are divided into two categories: solid and carbide.

Monolithic saw blades are made of solid metal - high carbon or high speed steel. Cutting tools of this type can have two configurations:

- hacksaw-sharp teeth - suitable for cross/longitudinal fine cuts in soft and hard wood;

- curved teeth with a wide back - suitable for working with soft wood.

The disadvantages of monolithic disks include:

- dull quickly enough;

- require periodic teeth setting and sharpening.

The disc blade is able to withstand several regrindings. Usually monolithic specimens have many teeth. An additional plus of disks is the affordable cost.

Carbide saw blades are considered more reliable. They are made from durable tool steel. Discs reinforced with soldering containing high amounts of cobalt and tungsten carbides. These discs are most in demand due to a number of advantages:

- allow cutting many building materials;

- tooth setting does not need to be performed;

- reliable and durable;

- the period of work from sharpening to sharpening is much higher than that of their monolithic counterparts;

- the output is a cleaner cut;

- high cutting speed;

- on the construction market there is a wide range of disks for performing various tasks.

There are also two downsides to be noted:

- the complexity of sharpening - requires special equipment;

- relative cost.

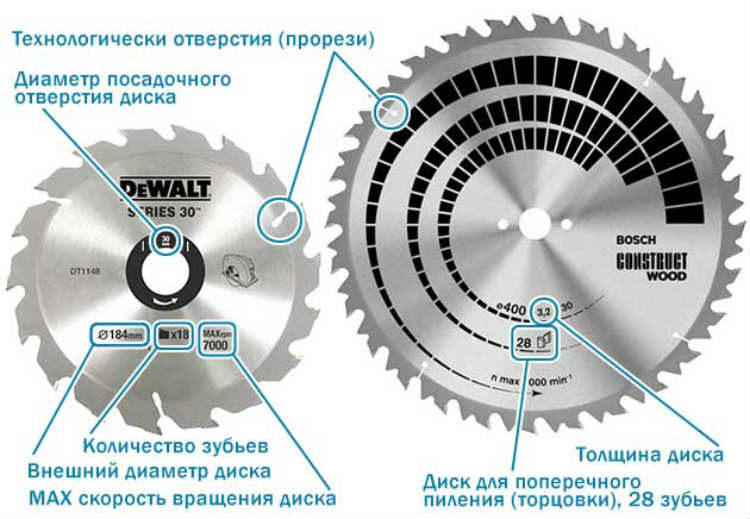

Outside diameter. This setting is determined internal dimension saw casing. A blade with large dimensions simply will not fit on a saw with a small diameter protective cover. Using too small a diameter can lead to undesirable consequences.

The outer diameter directly affects the cutting depth. The cutting speed does not depend on this parameter. For manual circular saws, the dimensions of the cutting tool are about 130-250 mm.

Important! The more the disc blade is immersed in the material, the more significant the load on the engine. The optimal protrusion of the teeth over the sawn material is no more than 10-20 mm.

Fit inner diameter. An important safety condition is a strong fastening of the "cutter". The saw blade must be firmly fixed on the seat pin.

Standard sizes of landing diameter: 16/20/22/30/32 mm. Some disc models are equipped with additional side recesses for narrow pins to enhance fixation.

Number of teeth. All types of saw blades can be conditionally classified into three groups according to the number of teeth:

- 80-90 pcs. - a large number of incisors;

- 40-80 pcs. - average number of incisors;

- 10-40 pcs. - a small number of incisors.

The choice of this parameter depends on the tasks. For a cross cut, it is better to use discs with a maximum number of teeth. Longitudinal sawing is best done with a “cutter” with a small number of teeth (up to 60).

Tooth shape. The configuration of the cutters has a significant impact on the quality of the cut. The form is selected according to the material that is breaded to be processed. The most popular saw blade for wood with variable teeth - they are suitable for sawing any kind of wood and are distinguished by an optimal price / quality ratio.

Tooth tilt. This criterion is determined by the deviation of the surface of the cutting edge from the radius of the saw blade. Negative angle of inclination - deviation towards the back side of the tooth blade. Positive - deviation in the opposite direction.

The angle of inclination of the tooth is divided into:

- 5-15° - standard slope;

- 15-20° - aggressive (positive) slope;

- from 0° to -5° - the usual (negative) deviation.

Positively pitched teeth are recommended for ripping- in the course of cutting there is a capture of material and collision of a disk on the processed detail. This speeds up the cutting of the workpiece as a whole. A negative slope slows down the workflow somewhat, but leaves a clean cut. Saw blades for metal have teeth with zero inclination.

Canvas thickness. The parameter depends on the operating mode and determines the width of the cut. Typical size - 3.2 mm.

A thin disc is more often used for cutting precious woods. The standard and thicker saw blade is suitable for rough materials. Blades with a thickness of 3.2 mm and more have saw blades for aluminum and laminate.

When arguing how to choose a saw blade, it should be remembered that thin specimens economically consume material, but are less strong and durable. Thick discs have a longer service life, but produce a less accurate cut.

Disc structure. The disc web itself can provide the necessary information about the quality of the product. A good disc is made by laser cutting, subjected to computer balancing and polished separately. Signs of such processing are noticeable if you look at the disk in the light. Traces from the grinding tool diverge in circles from the inner hole - which means that the “cutter” was ground, balanced and calibrated after cutting the metal.

Advice. If there are signs of rough processing and roughness on the discs, then it is better to refuse to buy it. Such an instance in operation will be very hot, and the teeth will quickly become dull.

The disc blade must necessarily contain compensation temperature slots. Grooves are located at the ends of the slots. These elements reduce saw noise, harmful vibrations and the heating temperature of the blade itself. Rounded holes at the moment of loading at the primary dynamic pressure of the teeth reduce the risk of blade breakage.

Canvas marking. Manufacturers of quality discs mark their product with a laser, not paint. The inscription should not be erased after prolonged use of the saw blade, since the information contained may be needed not only during purchase, but also during maintenance.

Disc marking displays:

- web thickness;

- outer / landing diameter of the disk;

- number of teeth;

- the number of revolutions of the disk;

- tooth configuration icon;

- disk series.

Important! The permissible number of revolutions of the blade must exceed the maximum permissible rotational speed of the saw spindle.

How Tooth Configuration Affects Cut Quality

There are many variations of tooth shapes. All of them are designed to perform a specific task:

Saw blades for wood: features of choice

When choosing a saw blade for wood, additional parameters must be taken into account:

- type of working tool used: angle grinder or circular saw;

- cut: longitudinal or transverse;

- the thickness of the treated wood;

- tree species.

Depending on the material, the optimal sawing speed is selected:

- 50-90 m/s - soft wood;

- 50-80 m/s - hardwoods;

- 80-85 m/s - exotic tree species;

- 60-80 m / s - joinery wood, chipboard;

- 40-60 m / s - laminate panels with one-two-sided coating;

- 30-60 m/s - MDF.

Additional Tips:

- Carbide discs with scoring knives are used for machines with automatic feeding wood.

- Disks with variable teeth of a straight shape, with an inclination of 10 ° are used for two-shaft and single-shaft machines, if the moisture content of the wood is not more than 15 °.

- Negative variable tooth blades are suitable for hand tools. This option provides a high-quality cut (cross) of massive wet or dried wood.

Overview of popular saw blade manufacturers

A wide range of saw blades is offered by domestic and foreign manufacturers. The products of the following companies are in special demand: Makita, Bosch, Zubr, Freud, Intertul, Werk, etc.

Corporation Makita(Japan) since 1915 specializes in the manufacture of power tools and components. The company has subsidiaries for production, sales and service in more than 100 countries around the world. All products are durable, accurate and easy to use.

Makita saw blades come in 13 different categories. The main types of disks:

- MFors - double beveled tooth, equipped with a clear M-shaped cutting edge;

- MacFors - discs designed for different models of hand saws;

- MacBladePlus blade is specially coated for smooth cutting, low friction and effective protection from resin and corrosion;

- specialized discs for cordless saws;

- disks for wood with nails and knots;

- cutters for metal - in particular for stainless steel, aluminum;

- special discs for circular saws;

- saw blades for composite materials, multilayer panels;

- laminate discs.

Saw blades showcase high performance and proven quality Bosch. Tools are divided into four groups:

Russian manufacturer " bison» supplies the domestic and world market with a wide range of quality tools and accessories, including saw blades. The company has developed 8 series of discs. Of these, 4 groups - category "Master" and 4 - category "Expert".

Saw blades "Master":

- "Quick cut" - for rough draft and very fast cuts of wood;

- "Optimal cut" - clean and fast cuts of chipboard, MDF, glued boards, plywood, hard / soft wood; tooth shape - ATV cutters with a variable angle;

- "Clean cut" - provides smooth cuts in wood, glued boards, chipboard and MDF lined with plastic, veneer, paper or film;

- "Precise multi-cut" - the saw blade is designed to work on laminate, aluminum, plastic and non-ferrous metal; form - TCG teeth with a negative inclination.

Freud saw blades have the following features:

- canvas with a hardness of 45 units. (according to the Rockwell scale);

- compensation slots are laser cut;

- discs are made of a special hard alloy;

- the production used the technology of tri-metal solder;

- the presence of a tension ring;

- saws have been dynamically balanced, as well as runout control in axial and radial directions.

When buying a saw blade, you must definitely take into account the characteristics of a circular saw:

- maximum number of revolutions;

- engine power;

- internal size of the protective cover;

- seat size on the motor shaft.

The choice of tooth configuration depends on the engine power. Negative slope and a large number of teeth will create a significant load on the engine - the equipment will have to operate in a "peak" mode, which is highly undesirable.

Spindle speed and RPM are related to the size of the saw blade. When buying, you should make sure that these parameters meet the requirements specified by the disc manufacturer.

It is not advisable to use discs for miter pendulum saws for circulating and manual machines. If the level of axial or radial runout of the machine is high enough, then you should not install an expensive disk on it.

With the need for cutting (sawing) lumber and wood, characterized by a dense structure, we are constantly faced. This is the main reason why this electric / tool (aka trimming, circular saw, circular saw) is now being purchased for domestic use along with a traditional electric drill, hammer drill or screwdriver.

A good owner always has such a “set” in the house. the main problem, which causes a certain difficulty for people without sufficient experience in cutting wood - how to choose a blade for a circular saw. The range of such canvases is impressive, and this is due to the versatility of trimming. With it, you can cut almost everything - wood, ceramics, plastics, some metals and even concrete. Let's figure out how to choose the right disk by tree.

Circular saws for wood are available in several modifications - hand tool and machine tools. The article is aimed at those who use . Therefore, further emphasis on manual models, since explaining to a specialist the nuances of acquiring cutting blades is a meaningless exercise.

All specified dimensions and tolerances are in mm.

Diameters

Everything is clear here - it means external and internal (it is also called a seat). The passport of the circular saw indicates the dimensions of the discs that can be installed on this model. Therefore, the author does not consider it necessary to delve into this issue and consider the entire range of canvases, since each reader has his own circular saw.

But situations are different. Someone has lost a document for a circular, someone inherited it, a third bought it from hand. How to proceed? There are two simple solutions.

Measure the specified disk parameters. An inaccuracy of 0.5 is not critical, since products are produced with a certain gradation of diameter values, and the store will immediately understand what exactly is required for a circular saw. But if the error is 2, then there is a risk of choosing the wrong size of the footprint (or 30, or 32). Therefore, it is advisable to use not a ruler for measurements, but a caliper.

Take the rejected disk with you and buy an identical one. Cutting blades are lightweight and small, so placing a sample in the same plastic bag is not a problem.

- Owners of imported circular saws, if there is no passport for the product, should do just that (purchase "one to one"). The fact is that on foreign-made models, disks with sizes that are not considered standard, generally accepted, are often installed. For example, if for most crosscuts the "landing" diameters are 20 (the next ones are already 30, 32), then for imported circular saws this parameter can be = 25.4. Here, when choosing a disk, it is easy to make a mistake.

- It is not difficult to determine the diameters by marking. If it has not been erased, then the alternation of numbers is necessarily visible on the circular saw disk. For example, 250 x 24 x 36. What does this mean? The first position is D external, the second position is D internal.

Disk teeth features

Size - the larger it is, the goes faster cutting wood. But there is no need to talk about the cleanliness of the cut, especially the transverse one. The edge is uneven, with a fringe along the edges. Such discs are suitable for rough work, when cutting accuracy does not matter. For example, when cutting boards or logs.

- In everyday life, you have to work with various samples of wood blanks. It is better if the owner has several disks at hand that differ in the size of the teeth. But if the circular saw is used irregularly, then the best choice is the average value given parameter. The number of incisors for such discs is from 45 to 75 (third position in the marking). Perhaps, in some cases, the effectiveness will be insufficient, but they are universal. They can cut boards, slabs, plywood. With some experience - and GKL.

- A clean and precise cut, strictly along the line, provides a circular saw blade, which has small teeth. Cutting speed will have to be reduced, but the quality will be on top.

Execution

Discs are produced in 2 versions - monolithic and more expensive, with welded teeth. They are characterized by high wear resistance and strength. They can be used to cut wood of any density (hardness) with a circular saw without the risk of damage. The downside is that such discs cannot be sharpened, so they are immediately rejected.

Monolithic products are cheaper and are not characterized by such strength as analogues with surfacing. But they have advantages - the price is lower, and self-sharpening is possible. With some diligence, mastering this "science" is not difficult. Therefore, with irregular work with a circular saw, especially on wood, it is advisable to choose just such discs.

Configuration

Depending on this feature, the products are indicated by the corresponding symbols. The difference is in the design of the cutters on the disk.

- FT is flat. Suitable for sawing wood of any species, but only in the longitudinal direction.

- ATB - replaceable. The discs of this group are equally well suited for cutting wood and slab, sheet samples. And in both directions (transverse, longitudinal).

- Combi - combined option. Alternation of FT and ATB incisors (1 through 4). The best choice when it is not known in advance which wood samples will have to be worked with. Disks of this group are universal in application, for all cases.

- TCG - trapezoidal modification of the FT disc. Perfectly cuts not only wood, but also soft metals, plastic.

Disc thickness

You should pay attention to this, since the choice has a number of nuances. The standard value is 3.2.

- It is more difficult to work with a circular saw with a thick disc, especially when cutting hardwoods. The wrong choice of mode is fraught with a quick breakdown. In addition, the amount of waste in the form of sawdust increases.

- A thin disc gives a more accurate cut. But here, too, there is a minus - the rapid heating of the metal. You don’t have to think about high performance, since the circular saw will often have to be stopped to cool the tool.

brand

The main recommendation is that it is advisable to purchase discs from the same manufacturer as the circular saw, that is, “native”. But this is not always possible, especially for those living in rural areas. What to choose if you focus not on cost, but on durability?

- With intensive use of a circular saw, you should purchase, albeit more expensive, but the most reliable discs from Bosch, Makita, DeWalt.

- In the middle price category (with decent indicators of resource and cut quality), products under the brand name "Attack" can be distinguished. Judging by the reviews on the Web, these discs have shown themselves well.

- If a circular saw is not used so often in everyday life, for example, when cutting rails for a picket fence, thin boards, bars, branches, and so on, then for such small household tasks you can also buy inexpensive discs "made in China". With careful handling of the circular saw, right choice cutting mode, they will serve the owner for more than one year.

note

On sale, unfortunately, fakes are not uncommon. What to check?

- You need to look at the label first. Well-known manufacturers apply it with a laser. If this is stamping with paint, then it is better to pass by, and not be tempted by the low cost. With such a cutting tool, a circular saw will not work for long, even if you have to cut wood with a small density.

- A high-quality disc, if viewed in the light, "plays with highlights." This means that the sample was both ground and polished. Therefore, there will be no problems with such a product. But the matte (dull) reflection of the edges at any position of the disk - clear sign inferior or counterfeit products.

- The presence of slots. These are special grooves that are needed to compensate for the temperature deformation of the metal. Their absence is the second "pointer" to a fake.

Choosing a disk is not such a simple matter. It is necessary to take into account many different factors - the specifics of working with wood, the intensity of tool use, the features of a circular saw, and so on. Well, and your experience, of course, on which depends, among other things, the correct definition of the optimal mode. The main recommendations are given, and the author hopes that they will help the reader make a worthy purchase.

Good luck in choosing the right drive!

With the need for cutting (sawing) lumber and wood, characterized by a dense structure, we are constantly faced. This is the main reason why this electric tool (aka saw, circular saw, circular saw) is now bought for domestic use along with a traditional electric drill, hammer drill or screwdriver. A good owner always has such a “set” in the house. The main problem that causes some difficulty for people without sufficient experience in cutting wood is how select disk for a circular saw. The range of such canvases is significant, and this is due to the versatility of the saw. With it, you can cut almost everything - wood, ceramics, plastic, some metals and even concrete. Let's figure out how to choose the right disk by tree.

A circular saw for wood is available in several modifications - hand tools and machine tools. The article is aimed at those who use the saw at home. Therefore, further emphasis on manual models, since explaining to a specialist the nuances of acquiring cutting blades is a pointless exercise.

How to choose a disk - criteria for choosing disks

diameters

Everything is clear here - we mean external and internal (it is also called a seat). The passport of the circular saw indicates the dimensions of the discs that can be installed on this model. Therefore, the author does not consider it necessary to delve into this issue and consider the entire range of paintings, since each reader has his own circular saw. But situations are different. Someone has lost a document for a circular, who inherited it, the third bought it from hand. How to proceed?

Measure the specified disk parameters. An inaccuracy of 0.5 is not critical, since products are produced with a certain gradation of diameter values, and the store will immediately understand what is needed for a circular saw. But if the error is 2, then there is a risk of choosing the wrong size of the footprint (either 30 or 32). Therefore, it is advisable to use not a ruler for measurements, but a caliper.

When working with imported circular saws, if there is no passport for the product, you should do just that (buy "one to one"). The fact is that on foreign-made models, disks with sizes that are not considered standard, generally accepted, are often installed. For example, if for most crosscuts the "landing" diameters are 20 (so 30, 32), then for imported circular saws this parameter can be = 25.4. Here, when choosing a disk, it is easy to make a mistake.

It is not difficult to determine the diameters by marking. If it has not been erased, then the alternation of numbers is necessarily visible on the circular saw disk. For example, 250 x 24 x 36 What does this mean? The first position is D external, the second is D internal.

Features of disc teeth

Size - the larger it is, the faster the sawing of the tree. But there is no need to talk about the cleanliness of the cut, especially the transverse one. The edge is uneven, with a fringe along the edges. Such discs are suitable for rough work, when cutting accuracy does not matter. For example, when cutting boards or logs.

In everyday life, you have to work with various samples of wood blanks. It is better if the owner has several disks at hand that differ in the size of the teeth. But if the circular saw is used irregularly, then the best choice is the average value of this parameter. The number of incisors for such discs is from 45 to 75 (third position in the marking). Perhaps, in some cases, the effectiveness will be insufficient, but they are universal. They can cut boards, slabs, plywood. With some experience - and GKL.

A clean and precise cut, strictly in line, is provided by a circular saw blade with small teeth. Cutting speed will have to be reduced, but the quality will be on top.

performance

Discs are produced in 2 versions - monolithic and more expensive, with welded teeth. They are characterized by high wear resistance and strength. They can be used without the risk of damaging a tree of any density (hardness) with a circular saw. The downside is that such discs cannot be sharpened, so they are immediately rejected. Monolithic products are cheaper and are not characterized by such strength as analogues with surfacing. But they have advantages - the price is lower, and self-sharpening is possible. With some diligence, mastering this "science" is not difficult. Therefore, with irregular work with a circular saw, especially on wood, it is advisable to choose just such discs.

configuration

Depending on the features of the product, they are indicated by the corresponding symbols. The difference is in the design of the incisors on the disk.

FT is flat. Suitable for sawing wood of any species, but only in the longitudinal direction.

ATB is variable. The discs of this group are equally well suited for cutting wood and slab, sheet samples. And in both directions (transverse, longitudinal).

Combi - combined option. Alternating FT and ATB incisors (1 of 4). The best choice when it is not known in advance which wood samples will have to be worked with. Disks of this group are universal in application, for all cases.

TCG is a trapezoidal modification of the FT disc. Perfectly cuts not only wood, but also soft metals, plastic.

disc thickness

You should pay attention to this, since the choice has a number of nuances. The value is 3.2.

It is more difficult to work with a circular saw with a thick disc, especially when cutting hardwoods. The wrong choice of mode threatens with a quick breakdown. In addition, the amount of waste in the form of sawdust increases.

A thin disc gives a more accurate cut. But here, too, there is a minus - the rapid heating of the metal. You don’t have to think about high productivity, because the circular saw will often have to be stopped to cool the tool.

brand

The main recommendation is that it is advisable to buy discs from the same manufacturer as the circular saw, that is, “native”. But this is not always possible, especially for those living in rural areas. What to choose if you focus not on cost, but on durability?

With intensive use of a circular saw, you should buy, albeit expensive, but reliable discs from Bosch, Makita, DeWalt.

In the middle price category (with decent indicators of resource and cut quality), products under the brand name "Attack" can be distinguished. Judging by the reviews on the Web, these discs have shown themselves well.

If a circular saw is not used so often in everyday life, for example, when cutting rails for a fence, thin boards, bars, branches, etc., then inexpensive “made in China” discs can also be purchased for such small household tasks. With careful handling of a circular saw, the correct choice of cutting mode, they will serve the owner for more than one year.

How to choose a disk - pay attention

On sale, unfortunately, fakes are not uncommon. How to check?

You need to look at the label first. Well-known manufacturers apply it with a laser. If this is stamping with paint, then it is better to pass by, and not be tempted by low cost. With such a cutting tool, a circular saw will not work for long, even if you have to cut wood with a small density.

A high-quality disc, if viewed in the light, "plays with highlights." This means that the sample was both ground and polished. So, with such a product, there will be no problems. But the matte (dull) reflection of the edges at any position of the disk is a clear sign of low-grade products or counterfeit products.

The presence of openings. These are special grooves that are needed to compensate for the temperature deformation of the metal. Their absence is the second "pointer" to a fake.

Choosing a disk is not such a simple matter. It is necessary to take into account many different factors - the specifics of working with wood, the intensity of tool use, the features of a circular saw, and so on. Well, and your experience, of course, on which depends, among other things, the correct definition of the optimal mode.

It is a versatile tool that can work with a variety of materials - from wood to plastic and sandwich panels. But in order for the cut to be smooth and without nicks, a well-chosen circular saw blade is required. Note that there is no universal disc suitable for all materials, since each product solves its own problems. In addition, you should not save money by buying products of an unknown brand - it is not safe in the first place.

Types of saw blades

All saw blades are divided into two types:

- Monolithic are created from solid metal and are distinguished by sharply sharpened teeth. They are popular due to their affordable price, the possibility of recovery, that is, re-sharpening. On the other hand, monolithic products wear out faster.

- Carbide discs are more reliable and durable, as they are equipped with sharp cobalt tips on the teeth or. Due to the use of carbide materials, the products are more durable and reliable, however, if the discs become dull, it will not be easy to restore them.

The shape of the teeth matters!

When choosing a saw blade, you should pay attention to design features products, the location of the teeth, their shape:

- straight identical teeth are suitable for cutting chipboard, wood, plywood or aluminum;

- variable alternating teeth cope with sawing soft and hard textured wood or plywood, as well as with a transverse cut;

- a circular saw blade with trapezoidal teeth can be used when working with chipboard, soft non-ferrous metals, plastic. Due to the special shape of the teeth, the material does not split, and the cut itself is carried out in two stages - first, a rough cut is made, then the edges are trimmed;

- teeth can have a positive or negative slope: the first is needed when sawing blanks with thick walls, the second - with thin walls;

- rare teeth with deep cavities between them provide a good longitudinal cut of wood, while sawdust is easily removed;

- small, closely spaced teeth allow cross cutting of materials. The most convenient among these types is a circular saw blade, each tooth of which has a special ledge behind. Due to this design, the cut is performed quickly and evenly.

Before choosing one or another disk, you need to decide for yourself a few questions.

Are the technical data correct?

Each saw blade is matched to a specific type of circular saw. Therefore, when choosing, it is worth considering the power of its engine, and the speed of rotation of the spindle, and the diameter of the landing pin. A circular saw blade with a high number of revolutions and teeth at a negative angle of inclination will put a greater load on the engine. Therefore, you should definitely find out what the capabilities of your saw are. It is worth remembering that each saw has a bore diameter, so the blade must match its size. Selecting a saw blade requires attention to details such as blade series, blade design and outer dimension, bore diameter.

How will you drink?

The saw blade for a circular saw should be chosen taking into account the type of cut - it can be transverse or longitudinal. In addition, the materials you plan to cut also play an important role - wood, plastic, chipboard, non-ferrous metals, pipes ... We note one thing - each series of discs is designed specifically for certain types of work.

The quality of the blade blade directly affects the sawing efficiency. Good canvas created through laser cutting, and balancing is performed on the computer. Grinding of each disk is carried out separately. A high-quality canvas in the light will reflect the marks from the grinding tool. If the blade is rough and looks rough, the circular saw blade will not work efficiently and will dull faster.

We take into account the diameter

Each saw has its own dimensions, and therefore the equipment for it must be chosen taking into account this parameter. The diameter of the disks is important, because if the diameters are different, this will lead to losses. So, the depth of sawing depends on the outer diameter. Experts say that the depth of sawing over the workpiece should be minimal: in this case, the cut will be better, the heat will decrease, and the load on the engine will be minimal. It is important that the disc is firmly fixed on the seat pin.

We count the teeth

Among the most popular tools in the arsenal home master- a circular saw. A metal disc for it should be selected taking into account the number of teeth, on which the speed and cleanliness of cutting depend. If there are a lot of teeth, then the cut will be clean, however, the load on the engine will increase, and the chips will be more difficult to remove. With a small number of teeth, the cut is rough and rough, but the chips are easily removed, and the cut is faster. A large number of teeth is considered 80-90, a small number - 10-40.

How to sharpen?

Like any other tool, the saw needs timely care. The most crucial moment is the sharpening of disks for a circular saw. Experts note that the carbide tooth wears out along the main upper except, and if massive workpieces are sawn, then the side edges also wear out quickly. Excessive blunting of the saw should not be allowed, as it will be less productive, and it’s not a fact that it will be possible to sharpen the discs.

Proper sharpening involves simultaneously ensuring the proper sharpness of the cutting edge. If you sharpen them along one front plane, then the number of sharpenings will be less. Many owners of such tools are interested in how to sharpen a circular saw blade. And it depends on the material of the teeth. Sharpening is most often performed on a CBN or green carbide wheel or based on diamond wheels. Elborovye circles should be used when sharpening saws from and diamond - for cutters made of hard alloys. To sharpen quickly, but have less effect on the degree of wear, you should choose with the highest grit.

For sharpening, you can use machines that have different functionality. The most difficult and expensive models ways to provide automated sharpening. When sharpening, the teeth should be set apart: if this is done incorrectly, then during the cut there will be a smell of burning, extraneous noise, and the material itself will move jerkily, which is not very convenient.

In general, the condition of the disks should be constantly monitored, since their wear will affect the increased load on the mechanisms and sooner or later lead to its complete failure. Regular sharpening can extend the life of the equipment, improve productivity and reduce the time for the sawing process itself. If after sharpening the cut remains sloppy, and the material moves unevenly, then more attention should be paid to the location of the teeth.

conclusions

How to choose saw blades? This is easy to do if you follow a few rules:

- Find out on the label the diameter of the mounting hole and the external diameter of the blade - they must correspond to the requirements of the characteristics of your saw.

- Pay attention to the thickness of the disc: thin ones provide a good and clean cut and are used when working with valuable wood species, while thick ones are advisable to use when rough cutting materials.

- The disk should indicate what the maximum allowable number of revolutions is. A low speed will allow you to develop a high cutting speed, but will lead to disk deformation and a poor-quality saw.

- Evaluate the quality of the saw blade blade: if it is good, then the cutting plane will be smooth, without roughness and flaws.

And most importantly - watch out for safety and choose those that are designed for a specific type of saw. Also think about where to sharpen the circular saw blade if you cannot do it on your own.

Chantilly Castle - the second in France after Versailles Chantilly Castle how to get from Paris

Amusement park "The Land of Legends Theme Park" in Turkey

Holy places in Greece. Greece Orthodox. Pilgrimage to the feast of St. Nicholas

Picodi: All discounts in one place!

How to get to Dolmabahce Palace