Those who work with wood know how important circular saws are. This tool should always work properly and be in perfect order. It is known that any piercing and cutting tools have the ability to become dull. Circular saws for wood are no exception. Their sharpening requires special attention. When the first signs appear that the saw begins to function poorly, you should start sharpening, as in the future the tool will begin to dull even more.

Sharpening of the circular saw is carried out different ways: file, on the machine, in a vice and on weight.

Circular saws for wood, which need to be sharpened periodically, are especially important when arranging country house from wood. Circular saws are also called circular saws. This tool is important because it is able to cut wooden parts with high accuracy.

So is it possible to do the sharpening yourself? Yes, self-sharpening possible. Timely sharpening circular saws on wood will allow not only to have a sharp working tool at hand, but also to increase its service life. In particular, it is necessary to monitor the condition of circular saws, whose power is relatively low, since a poorly sharpened saw begins to overheat. And overheating can completely disable the working tool.

Signs of deteriorating saw sharpness

If the following symptoms appear, sharpen the saw blade immediately:

- A noticeable increase in the temperature of the safety cover on the saw motor.

- Cutting requires increased physical effort.

- Possible temporary smoke from the engine.

- The appearance of a burning smell.

- The appearance of dark spots on the edges of the saw (soot).

- The wooden beam does not move smoothly, but jumps along the machine.

- During operation, a suspicious noise is heard.

- There is a distortion of the teeth circular saw.

Work Requirements

There are also a number of work requirements, compliance with which is necessary for safety and high-quality tool sharpening. When sharpening, the disc must be set in such a way that all the teeth are clearly visible. Only in this case can quality sharpening be guaranteed. The disc must remain in the same position during sharpening. It should fit very tightly against the retaining bars or vise.

In general, the sharpening of the disc should be done on the machine. However, sometimes it is recommended to remove the disc and secure it in a vise. During the bending of the teeth, you need to tightly fix the disk in a vice and use pliers. The angle of inclination of each tooth must be controlled at all times. If you do not observe the angle of inclination, then the efficiency of the subsequent operation of the tool will be close to zero. Before you begin to bend the teeth, you need to make appropriate notes on their original position.

Sharpening rules:

- First of all, you need to ensure that the removal of metal occurs evenly along the profile of the saw teeth.

- In no case should the disc be pressed against the grinding wheel, as this can lead to heating and heating of the material, which leads to deformations.

- The profile and height of the teeth after sharpening must be maintained.

- When sharpening, it is also very important to use coolant.

- It is impossible for burrs to form during sharpening.

- As for the sharpening edges, in theory there is a rule: you need to sharpen either the front side of the teeth, or the front and back. However, very often experienced craftsmen sharpen from the back side, as they believe that this is much more convenient.

Teeth setting rules

Before you start sharpening a circular saw, you need to know that this will require setting the teeth. The teeth must alternately bent to the side and sharpened. However, it should be taken into account that the bending of each of the teeth must be carried out at the same distance. In order to do this, a special tool is used - wiring. With this tool, each tooth is retracted approximately at the middle of its height.

If the wiring is done correctly, then the width of the cut will be thicker than the saw blade. Proper sharpening assumes that the disk itself does not touch the material of the cut, but only the teeth layer by layer remove the surface of the tree. Therefore, the wider the set of teeth, the more voluminous the cut will be and the less likely it will be that jamming will occur. However, it is extremely difficult to achieve such an effect. Many begin to spread the teeth with a key, but this method is completely unsuitable for expensive quality saws. Therefore, you need to use only the tool that is intended for this.

When sharpening a saw, the type of wood that will be sawn also deserves special attention. For softer woods, a wider set is required so that the cut is smooth and does not have roughness and bumps. The most optimal deviation of the teeth is 5-10 mm to one side. The wiring must be done before sharpening, otherwise the teeth may be deformed and the saw will become unusable.

In total, there are 3 main types of wiring:

- Cleaning - with such a layout, every third tooth remains in its original position. This type is suitable for those cases when it is required to cut especially hard woods.

- Classical - alternately, the teeth are bent to the left and right.

- Wavy - with such a layout, each tooth has its own position, as a result of which a wave of teeth is formed. This method is one of the most effective, but also the most difficult. Experienced craftsmen leave a distance of 0.3-0.7 mm with this method.

Used for sharpening materials and tools

So, for work you may need:

- 2 bars;

- whetstone;

- vise;

- wiring;

- file.

Sharpening a circular saw: the classic method

There are several different methods for sharpening saw blades, but the following is a classic. Start sharpening from the back. The front part, which runs into the material during work, remains in the same position.

In order to start sharpening the disc, you can leave the disc directly in the machine or remove it from the machine and fix it in a vise. In the first method, be sure to turn off the power to the machine by removing the cord from the outlet. To fix the disc in one position, 2 bars are used that fix it like wedges. The bars must be pressed tightly against the teeth to avoid their movement. The tooth from which sharpening begins should be marked with a felt-tip pen on the side.

When sharpening the first tooth, you need to remember the number of movements made with a grinding wheel or other tool.

All subsequent teeth must be sharpened with the same intensity and number of movements.

When working in a vice, the principle of operation is the same. Some more experienced craftsmen perform sharpening by weight, but this requires a lot of experience. After full sharpening the disk is inserted back into the machine. Next, you need to saw some unnecessary wooden block, while watching the work of the saw. It is necessary to pay attention to whether there are extraneous noises and uneven movement of the beam. If there is extraneous noise or creaking, you need to take a felt-tip pen and fix it tightly near the saw. Then slowly turn the dial. As a result, it will be seen where the height of the teeth is greater or less than the rest.

Other sharpening methods

- Full profile - is the most accurate and high quality, as it is performed on a professional grinder. A special circle, which is selected in size, passes the entire interdental cavity at a time along with the surface of the adjacent tooth. With such sharpening, deformation of the teeth is excluded. The only disadvantage of this method is that different saws require different circles.

- Tooth edge sharpening - convenience this method is that sharpening can be done both professionally and at home. If the work is performed on the machine, then you need to purchase special circles for different disks. However, it is still better to do the work at home, since usually the amount of work is small and can be done using a regular needle file. For high-quality sharpening, it is enough to make 4-5 movements with a needle file - and the tooth will be sharp.

Protective goggles must be worn during work. When sharpening, it is necessary to remove only such an amount of metal that is necessary to completely remove cracks and deformations. When sharpening, the disk must always remain in the same position relative to the machine.

If there is no sharpening for a long time, more material must be removed. The shape of all the teeth must be exactly the same, as well as the height. All remaining burrs must be completely removed.

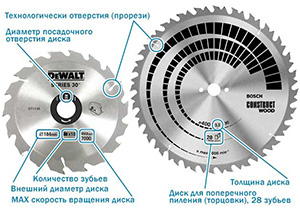

Circular saws with hard-alloy teeth consist of a blade (disk) made of steel 9HF, 65G, 50HFA, etc., and hard-alloy plates that act as cutters.In domestic saws, sintered tungsten-cobalt alloys of grades VK (VK6, VK15, etc., the figure means the percentage of cobalt) are used as the material for cutting plates. BK6 has a hardness of 88.5 HRA, BK15 has a hardness of 86 HRA. Foreign manufacturers use their alloys. Hard alloys VK consist mainly of tungsten carbide cemented with cobalt. The characteristics of the alloy depend not only on its chemical composition, but also on the grain size of the carbide phase. The smaller the grain, the higher the hardness and strength of the alloy.

Fasten hard-alloy plates to a disk by high-temperature soldering. As a material for soldering, at best, silver solders (PSr-40, PSr-45) are used, in the worst case, copper-zinc solders (L-63, MNMTs-68-4-2).

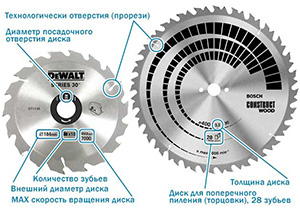

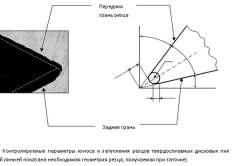

Carbide tooth geometry

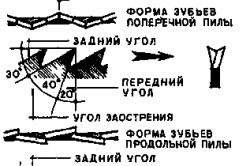

Carbide tooth has four working planes - front (A), back (B), and two auxiliary side (C). Intersecting with each other, these planes form cutting edges - the main one (1) and two auxiliary ones (2 and 3). The given definition of faces and edges of the tooth is given in accordance with GOST 9769-79.

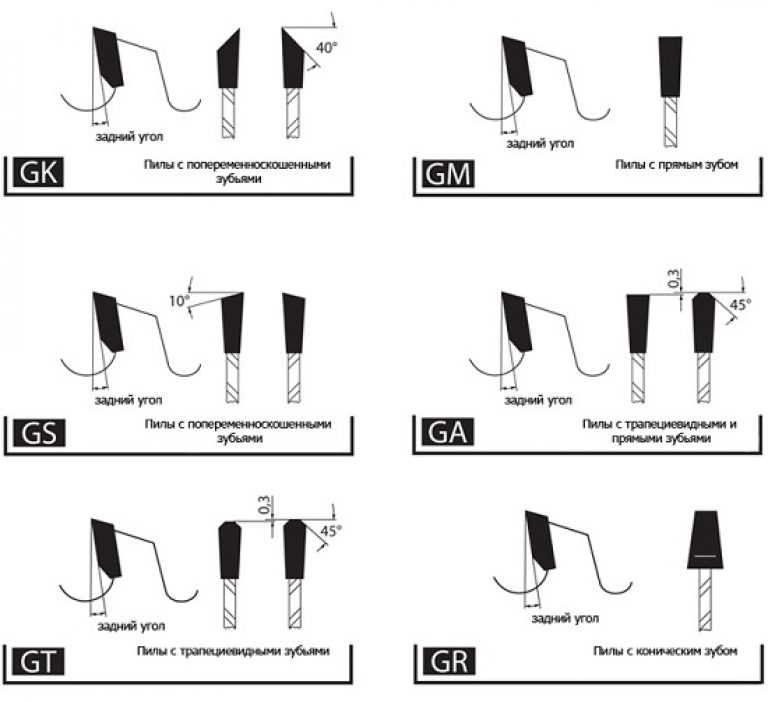

The following types of teeth are distinguished by shape.

Typically used in fast rip saws where quality is not a concern.

Oblique (beveled) tooth with the left and right angle of inclination of the rear plane. Teeth with different angles of inclination alternate with each other, which is why they are called alternately beveled. This is the most common form of the tooth. Depending on the size of the sharpening angles, saws with alternately beveled teeth are used for sawing a wide variety of materials (wood, chipboard, plastics) - both in the longitudinal and transverse directions. Saws with a large angle of inclination of the rear plane are used as scoring saws when cutting boards with double-sided lamination. Their use avoids chipping of the coating at the edges of the cut. Increasing the bevel angle reduces the cutting force and reduces the risk of chipping, but at the same time reduces the tool life and strength of the tooth.

The teeth can have an inclination not only of the rear, but also of the front plane.

A feature of these teeth is the relatively slow rate of blunting of the cutting edges compared to alternately beveled teeth. They are usually used in combination with a straight tooth.

![]()

Alternating with the latter and slightly rising above it, the trapezoidal tooth performs rough sawing, and the straight one following it - finishing. Saws with alternating straight and trapezoidal teeth are used for cutting boards with double-sided lamination (chipboard, MDF, etc.), as well as for sawing plastics.

Cone tooth saws are auxiliary and are used to cut the bottom layer of the laminate, preventing it from chipping when the main saw passes.

In the vast majority of cases, the front face of the teeth is flat, but there are saws with a concave front face. They are used for fine cross cutting.

Tooth sharpening angles

There are four main sharpening angles of a circular saw, which, along with the shape of the tooth, determine its characteristics. These are the front angle (γ), rear (α) and bevel angles of the front and rear planes (ε 1 and ε 2). The taper angle (β) has an auxiliary value, since it is set by the front and back angles (β=90°-γ-α).

The values of the sharpening angles are determined by the purpose of the saw - i.e. for cutting what material and in what direction it is intended. Rip saws have a relatively large rake angle (15°-25°). For crosscut saws, the angle γ usually ranges from 5-10°. General purpose saws designed for crosscutting and rip sawing have an average rake angle - typically 15°.

The sharpening angles are determined not only by the direction of the cut, but also by the hardness of the material being cut. The higher the hardness, the smaller the front and back angles should be (less sharpening of the tooth).

The front angle can be not only positive, but also negative. Saws with this angle are used for cutting non-ferrous metals and plastics.

Basic sharpening principles

The main wear of a carbide tooth occurs along its main (upper) cutting edge. In the process of work, the latter is rounded to 0.1-0.3 mm. Of the faces, the front wears out the fastest.When sawing massive workpieces, the side edges are also subject to rapid wear.

The saw must not be overblown. The cutting edge rounding radius should not exceed 0.1-0.2 mm. In addition to the fact that when working with a very blunt saw, productivity drops sharply, it takes several times more time to sharpen it than to sharpen a saw with normal bluntness. The degree of dullness can be determined both by the teeth themselves and by the type of cut they leave.

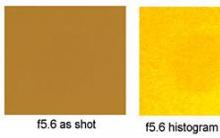

Proper sharpening of circular saws is to simultaneously ensure the proper sharpness of the cutting edge, to ensure the maximum number of sharpenings, which in the optimal case can reach 25-30 times. For this purpose, it is recommended to sharpen the carbide tooth along the front and back planes. In fact, the teeth can be sharpened along one front plane, but the number of possible sharpenings is almost two times less than when sharpening along two planes. The figure below clearly demonstrates why this happens.

Last pass when sharpening saw blades it is recommended to do on the back plane of the tooth. The standard amount of metal removal is 0.05-0.15 mm.

Before sharpening, it is necessary to clean the saw of impurities, such as resin, and check the sharpening angles. On some saws they are written on the disk.

Equipment and materials for sharpening saw blades

Depending on the material from which the teeth are made, circular saw blades can be sharpened with CBN, green silicon carbide, or diamond (PCD) wheels. So, CBN wheels are able to sharpen high-performance high-speed steel wheels, diamond wheels and green silicon carbide wheels - hard alloy cutters.When using abrasive wheels (especially diamond wheels), it is desirable to cool them with coolant.

One of the significant disadvantages of diamond is the relatively low temperature stability - at a temperature of about 900°C, the diamond burns out.

With increasing temperature, microhardness abrasive materials decreases. Increasing the temperature to 1000°C reduces the microhardness by almost 2-2.5 times compared to the microhardness at room temperature. An increase in temperature to 1300°C causes a decrease in the hardness of abrasive materials by almost 4-6 times.

The use of water for cooling can lead to rust on machine parts and assemblies. To eliminate corrosion, soap and certain electrolytes (sodium carbonate, soda ash, trisodium phosphate, sodium nitrite, sodium silicate, etc.) are added to water, which form protective films. In normal grinding, soap and soda solutions are most often used, and in fine grinding, low-concentration emulsions are used.

However, when sharpening saw blades at home with a low intensity of grinding work, they do not resort to cooling the circle so often - not wanting to spend time on this.

To increase the productivity of sharpening with abrasive wheels and reduce specific wear, you should choose the largest grit that provides the required surface cleanliness of the tooth being sharpened.

To select the grit size of the abrasive, in accordance with the stage of sharpening, you can use the table in the article about sharpening bars. For example, in the case of using diamond wheels, wheels with a grain size of 160/125 or 125/100 can be used for rough sharpening, and 63/50 or 50/40 for finishing. Wheels with a grit size of 40/28 to 14/10 are used for chipping.

It is necessary to strive to ensure that the surface of the tooth is very smooth. If there are notches on the surface of the tooth, then the protrusions will crumble when the saw is used, and it will become dull very quickly.

The circumferential speed of the circle when sharpening carbide teeth should be about 10-18 m / s. This means that when using a wheel with a diameter of 125 mm, the engine speed should be about 1500-2700 rpm. Sharpening of more brittle alloys is carried out at a lower speed from this range. When sharpening carbide tools, the use of hard modes leads to the formation of increased stresses and cracks, and sometimes to chipping of the cutting edges, while wheel wear increases.

When using machines for sharpening circular saws, changing the relative position of the saw and the grinding wheel can be implemented in different ways - by moving one saw (the motor with the wheel is stationary), by simultaneously moving the saw and the engine, by moving only the motor with the wheel ( saw blade motionless).

Issued a large number of grinding machines of various functionality. The most complex and expensive programmable complexes are capable of providing a fully automatic sharpening mode, in which all operations are performed without the participation of a worker.

In the simplest and cheapest models, after installing and fixing the saw in a position that provides the required sharpening angle, all further operations are turning the saw around its axis (turning on the tooth), filing for grinding (introducing into contact with the wheel) and controlling the thickness of the tooth removed from the tooth. metal - are made by the worker manually. Such simple models it is advisable to use at home, when sharpening circular saws is episodic.

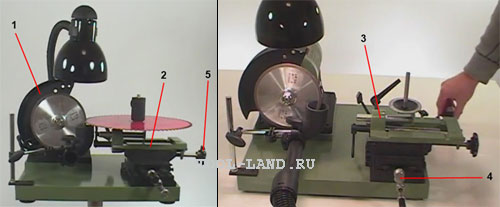

An example of the simplest machine for sharpening circular saws is the system, a photograph of which is shown in the photo below. It consists of two main units - an engine with a circle (1) and a caliper (2), on which a sharpened saw is installed. The turning mechanism (3) is used to change the angle of inclination of the blade (when sharpening teeth with a beveled front plane). With the help of the screw (4) the saw is displaced along the axis of the abrasive wheel. This ensures that the required value of the front angle of sharpening is set. The screw (5) is used to set the limiter in the desired position, preventing excessive entry of the wheel into the interdental cavity.

Saw blade sharpening process

Sharpening a straight tooth along the front plane. Sharpening of a straight tooth of carbide saw blades is carried out in the following sequence.The saw is mounted on a mandrel, clamped with a conical (centering) sleeve and a nut, then set in a strictly horizontal position by means of the mechanism (3). This provides a bevel angle of the front plane (ε 1) equal to 0°. On machines for sharpening disks that do not have a built-in angular scale in the tilt mechanism, this is done using a conventional pendulum goniometer. In this case, the levelness of the machine should be checked.

By turning the screw (4) of the mechanism that provides horizontal movement of the mandrel with a circle, the required front angle of sharpening is set. In other words, the saw moves to a position in which the front plane of the tooth fits snugly against the working surface of the circle.

The marker makes a mark of the tooth from which sharpening begins.

![]()

The engine is turned on and the front plane is sharpened - by putting the tooth in contact with the circle and several movements of the saw back and forth while simultaneously pressing the tooth against the circle. The thickness of the removed metal is regulated by the number of sharpening movements and the force of pressing the tooth against the abrasive wheel. After sharpening one tooth, the saw is removed from contact with the wheel, rotated by one tooth, and the sharpening operation is repeated. And so on until the marker mark makes a full circle, indicating that all the teeth are sharpened.

Sharpening a tooth beveled along the front plane. The difference between sharpening a beveled tooth and sharpening a straight one is that the saw must be installed not horizontally, but with an inclination - with an angle corresponding to the angle of the bevel of the front plane.

The angle of inclination of the saw is set using the same pendulum goniometer. First, a positive angle is set (in this case +8°).

After that, every second tooth is sharpened.

After sharpening half of the teeth, the saw blade angle changes from +8° to -8°.

And again, every second tooth is sharpened.

Sharpening on the back plane. To sharpen a tooth along the back plane, it is necessary that the saw blade sharpening machine allows you to install the saw in such a way that the back plane of the tooth will be in the same plane as the working surface of the abrasive wheel.

If there is no machine for sharpening saw blades

Sharpening circular saws on functional and convenient specialized machines does not require special professional skills. A little practice - and sharpening will go without any problems. But most people use carbide saw blades occasionally, as needed. Spending a significant amount on a special grinding machine, which is used for several hours a month, does not seem reasonable to everyone.Accurately maintaining the required sharpening angles, holding the saw in your hands on weight, is an impossible task even for a person with a unique eye and an enviable hardness of hands. The most reasonable thing in this case is to make the simplest sharpening device, which makes it possible to fix the saw in a certain position in relation to the circle.

The simplest of these devices for sharpening circular saws is a stand, the surface of which is flush with the axis of the grinding wheel. By placing a saw blade on it, it is possible to ensure the perpendicularity of the front and back planes of the tooth with respect to the saw blade. And if the upper surface of the stand is made movable - fixing one side hingedly, and the other - resting on a pair of bolts that can be screwed in and out - then it can be installed at any angle, making it possible to sharpen an oblique tooth along the front and rear planes.

True, in this case, one of the main problems remains unresolved - holding the same front and rear sharpening angles. This problem can be solved by fixing the center of the saw relative to the abrasive wheel in the desired position. One way to implement this is to make a groove on the surface of the stand for the mandrel on which the saw is mounted. By moving the mandrel with a circle along the groove, it will be possible to maintain the required front angle of sharpening the tooth. But for sharpening circular saws with different diameters or sharpening angles, it should be possible to either move the engine or the stand and the groove with it. Another way to ensure the required sharpening angle is simpler, and is to install stops on the table that fix the disk in the desired position. At the end of the article there is a video demonstrating such a device.

Sharpening quality control

The sharpened teeth must be free of cracks, chips, visible risks from the grinding wheel. The radius of rounding of the cutting edge should be no more than 0.015 mm. Visually, this can be defined as the absence of glare on the cutting edge.GOST 9769-79 establishes certain tolerance values for sharpening parameters. The end runout of the tops of the teeth should not exceed 0.2 mm (for saws with a diameter of up to 400 mm), the radial runout should not exceed 0.15 mm. The runout is checked using a conventional dial gauge.

Deviations of sharpening angles should not exceed:

- for front angle - ±1°30";

- for the rear corner and bevel angles of the front and rear planes - ± 2 °;

Video:

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Any cutting tool tends to become dull during operation. This also applies to saw blades, which must be sharpened regularly in order to cut wood quickly and efficiently.

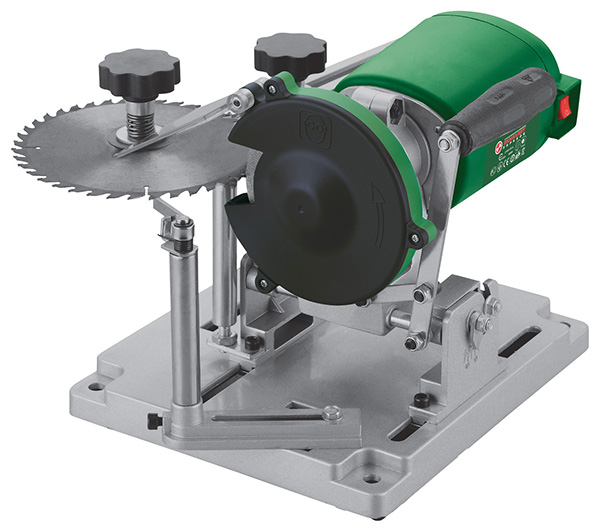

The easiest way to sharpen teeth on a circular saw is to use a regular file. But when working with your own hands, on bringing the cutting tool into working condition, there are many difficulties that only good specialist with sufficient experience. Much easier, faster and more efficient to use for this operation homemade machine for sharpening circular saws or sharpening machine for circular knives.

If there is a home-made electric sharpening machine for circular saws, regardless of whether it is a factory tool or home-made, you should know the basic principles for using such equipment. Especially when there is a need to sharpen the teeth of saw blades that have different geometry and sharpening angles.

1 Tooth shapes on saw blades

There are several of them, and they appeared as a result of optimization impact of the cutting edge on the material being cut, which can have different properties.

The main tooth shapes are:

- straight - used for longitudinal sawing, when high quality is not necessary;

- oblique (beveled tooth) - has a variable right and left angle of inclination of the posterior (sometimes also anterior) plane. It is used for sawing both in the longitudinal and transverse directions. The most common shape for circular saws. This configuration is convenient to use when cutting boards with double-sided lamination, as it does not give chips along the edges of the cut;

- trapezoidal - characterized by a long period of retention of the cutting edge in a sharp state. Usually on saw blades, teeth of this shape alternate with straight teeth, somewhat rising above them. Trapezoidal teeth, in this case, make rough sawing, and straight teeth - fine;

- conical - this form of teeth is used in auxiliary operations. For example, a layer of laminate is cut to prevent the appearance of splinters during the main sawing.

The front edge of all teeth is flat, but in some types of circular saws it is concave.

![]()

This allows you to perform high-quality finishing cross-cutting.

1.1 Sharpening angles

Sharpening of the teeth of a circular saw is carried out taking into account the four main angles that are formed at the intersection of the planes:

- front corner;

- back corner;

- bevel angles of the front and rear planes.

as a helper, the angle of sharpening is also taken into account, which is given by the front and back angles.

Sharpening angles depend on the purpose of the saw:

- for longitudinal sawing, a rake angle of 15 to 20 degrees is suitable;

- at cross cutting- from 5 to 10 degrees;

- with universal use, on average - 15 degrees.

It is important to consider the sharpening angles not only in the direction of the cut, but also in terms of the hardness of the wood - the harder it is, the smaller the front and rear angles should be.

2 Equipment for sharpening saw blades

These are grinding machines for circular saws, which constructively made in the following variations:

- when sharpening, only the saw moves (the engine with the grinding wheel is stationary);

- both a sharpened saw and an engine with a circle can move;

- only the motor with the grinding wheel attached to it moves (the saw blade remains stationary).

As standard example A grinding machine can be a device that consists of two components - an engine with a grinding wheel mounted on its shaft, and a caliper on which a sharpened circular saw is attached.

To ensure angular sharpening in this device, a system must be provided that allows you to change the angle of inclination of the blade (for teeth with a beveled front plane).

2.1 Machine JMY8-70

The JMY8-70 electric grinding machine, which is made in China, has a fairly large number of positive feedback. Some craftsmen take his device as a basis when they assemble a home-made machine for their own needs with their own hands.

The JMY8-70 machine is designed for sharpening circular saw blades that made of hard high-speed alloys. On the machine, it is possible to process the front and rear plane of the teeth, as well as to perform angular sharpening.

Main advantages:

- has a diamond grinding wheel, the diameter of which is 125 mm;

- equipped with an inclined saw holder, which allows for angular sharpening;

- the body is made of cast steel used in the aviation industry;

- installed on rubber gaskets, which significantly reduce the impact of vibration on the material being processed;

- It has a simple adjustment that even a non-specialist can handle.

The manufacturer upon shipment completes the machine detailed instruction, which describes in detail all the possible functions of the device and how to perform them.

Specifications:

- the grinding wheel has dimensions - 125 × 10x8 mm;

- the grinding wheel can be rotated up to 20 degrees;

- diameter of the sharpened saw — from 70 to 800 mm;

- grinding wheel rotation speed - 2850 rpm;

- weight - 35 kg.

2.2 Homemade grinder

A lot of people, when working with their own hands, use carbide circular saws not regularly, but from time to time. Therefore, buying factory equipment does not make economic sense. A homemade grinding machine is a great solution that will allow you not to contact third-party organizations.

The main argument is that when sharpening a circular saw on a regular grinding wheel with your own hands, it is very difficult to maintain the required sharpening angles. Therefore, a device is needed allows you to fix the saw blade in a specific position in relation to the grinding wheel.

A home-made machine, on which you can sharpen circular saws with your own hands, may consist of the following components and parts:

- a fixed electric motor with the possibility of mounting a grinding disk on its shaft;

- table-stand, the surface of which is located at the same level in height with the axis of rotation of the grinding wheel;

- tilting the stand with hinges on one side and rotating (height-changing) screws on the other. This will allow you to perform angular sharpening along the front and rear planes;

- clamps to secure the saw blade. To do this, a groove is made on the surface of the stand for the mandrel on which the saw is installed. The movement of the mandrel, along with the disk, along the groove will allow you to maintain the required angle of sharpening the teeth;

- a device for moving an electric motor or a stand for angular sharpening of circular saws with different diameters;

- the presence of stops for reliable fixation of the tool during work.

2.3 Sharpening circular saws

The sequence of operations when sharpening the front plane of the tooth of a carbide saw blade:

- the saw is placed on the mandrel and fixed with a conical sleeve with a nut;

- it is set clearly horizontally using a pendulum goniometer, while the bevel angle of the front plane is equal to zero;

- moving the mandrel horizontally with the disk installed, the specified front angle of sharpening is set. In other words, the disk moves in such a way that the front plane of her tooth fits snugly against the surface of the grinding wheel;

- using a marker, a mark is made - from which tooth sharpening began;

- when the electric motor is turned on, several movements of the saw are made back and forth with pressing the surface to be sharpened against the working surface of the grinding wheel;

- the thickness of the metal removal is regulated by the clamping force and the number of translational movements;

- after the first tooth is sharpened, the saw is removed from contact with the grinding wheel and rotates around its axis by one tooth, which will be the next when sharpening;

- the operation is repeated according to the number of teeth on the saw blade.

A circular saw is an indispensable tool for frequent work with wood and similar materials. Especially such a tool is important in the arrangement of country houses.

But, like any piercing and cutting tool, the saw tends to become dull. Therefore, saw blades require periodic sharpening. We will talk about how to sharpen a circular saw blade in the framework of this article.

A dull blade affects the saw motor the most, as the load increases significantly. The most noticeable signs are noticeable heating of the motor casing and the appearance of dark spots on the sawn wood. These are the consequences of significant heating of the saw teeth. Accordingly, the smell of burning appears.

It also increases the amount of effort that must be applied when working with the tool. The bars do not move so smoothly, but with jumps. If the tool is not sharpened for a long time, smoke may appear from the motor.

Disk types

The discs differ in the shape of the teeth:

- straight tooth. It is often used in circular saws for ripping, and the quality is not so important.

- An oblique tooth with a left and right angle of inclination of the posterior plane. Incisors with different angles alternate, therefore they are called alternately beveled. This option is the most common. The slope value depends on the material to be cut. As the angle increases, the cutting force decreases, which helps to eliminate chipping. However, this reduces the strength of the tooth. The front plane can also be tilted..

- conical tooth. Such discs are used when making cuts in the lower layer of the laminate, thereby preventing the appearance of chips during fine sawing. Often the front face is flat, but in some cases the teeth have a concave face.

- Trapezoidal teeth. They have good resistance to blunt edges. As a rule, they are used in discs in conjunction with conventional teeth without bevels. In this combination, trapezoidal saws perform rough sawing, and straight saws for finishing.

Sharpening angles

The teeth have 4 characteristic sharpening angles:

- front;

- rear;

- bevel angle of the front planes;

- bevel angle of the rear planes.

There is also a taper angle, but it depends on the value of the front and rear angles.

The purpose of the saw directly affects the angle values. Depending on the material being cut and the direction in which the saw will be cut, the angles change.

For a cross cut, a rake angle is set in the range from 5 to 10 degrees. For longitudinal - from 15 to 25 degrees. For universal saws, the front angles are set to an average value of 15 degrees.

Also, the hardness of the material to be cut plays an important role. As the hardness of the material increases, the values of the angles decrease.

The front angle can also have a negative value. Saws of this type are used for cutting metals and plastics.

Tooth sharpening

Sharpening disks for a circular saw can be done in two main ways: using a specialized machine, or using improvised tools.

How to sharpen a circular saw blade with a machine?

The top edge of the tooth is most exposed to wear. During operation, its rounding is observed. The highest wear rate is at the leading edge.

Disks made of hard alloys are best sharpened in two planes. It is allowed to sharpen along one plane (more often along the front), however, then the number of sharpenings is reduced by about 2 times.

Before starting the process, it is necessary to clean the disc from contamination, as well as measure the angles.

It is important for abrasive wheels not to get too hot, especially diamond wheels.

With increasing temperature, the hardness of the materials from which the circles are made decreases. At a temperature of 1250-1350 degrees, the hardness of abrasives decreases by almost 5 times.

But the use of water as cooling can provoke corrosive processes. To avoid this, soap or electrolytes are added to promote the formation of a protective film.

But the use of water as cooling can provoke corrosive processes. To avoid this, soap or electrolytes are added to promote the formation of a protective film.

For normal grinding, a soap or soda solution is used, for the final one, with low-concentration emulsions.

To increase the efficiency of sharpening, as well as reduce wear, it is necessary to use the largest grit that provides the desired surface finish.

For example, for diamond wheels, during rough turning, a sharpener with a grain size of 160/125 is used, for the main one - 50/40. Materials with a smaller grain size serve to get rid of notches.

It is important to achieve maximum smoothness of the teeth, since in the presence of notches, the irregularities crumble during operation, and this will dull the saw much faster.

Sharpening a saw with straight teeth. The disk is installed in a special frame on the machine, and is clamped in it with a conical sleeve and a nut. The position is then adjusted so that it is horizontal, thus providing a zero bevel angle.

If the installation does not have a mechanism for tilting the angular scale, then this is done with a pendulum goniometer. It is also important to check the horizontalness of the installation itself.

As a result, the saw is fixed so that the front plane of the tooth will be located right next to the sharpening surface of the circle. The first tooth to be sharpened is marked in any way. Next, the engine starts and sharpening is performed. Produce the required number of movements back and forth. The layer of metal that will be removed in the process depends on the number of movements performed and the force of pressing. This continues until the sharpening process has gone through the entire disc.

Bevel tooth sharpening. The difference from the turning process of the previous type of teeth is that the disc is fixed not in a horizontal position, but at an angle. Its value is measured with a pendulum goniometer. First, a positive angle is set and every second tooth is sharpened, according to the same principle as ordinary teeth. Then the positive angle changes to a negative one, and it is sharpened in the same way, through one tooth.

Sharpening on the back plane. Such sharpening is carried out on machines with the possibility of fixing the saw so that the rear plane is in the same plane with the surface of the grindstone.

How to sharpen a circular saw blade on your own?

Not for all people, buying a special machine is a rational decision. And if you hold the disc in your hands on weight, it is difficult to maintain the desired sharpening angles. To do this, make a device that allows you to position the disk in the desired position relative to the sharpener.

The best solution is a stand, in which the surface is flush with the axis of the grinding wheel. It is also possible to fix one of the sides on the hinge, thus achieving its mobility, and to rest the other on several bolts that can be adjusted. This will allow you to set the disc at any angle for sharpening teeth with a bevel.

Also important detail is the sharpening of all teeth with the same angles. To do this, you need to fix the center of the disc in the desired position in relation to the sharpener. One way is to make a groove on the surface of the stand for the mandrel on which the saw will be installed.

Useful video

The video shows how to sharpen a circular saw blade on your own.

Sharpening circular saws, both carbide and conventional, costs 350-450 rubles

Circular saws, indispensable in any carpentry, become dull with prolonged use and become less productive. This is especially noticeable with constant use for cutting. various materials without periodic and high-quality sharpening. When the teeth intercede, the saw does not break, but it only needs to sharpen the teeth with high quality. There are several ways to do this. You can try to sharpen it yourself with a file, which is very problematic and inaccurate. We recommend that you turn to professionals in a specialized center, that is, to our company. We sharpen circular saw blades exclusively for professional equipment. After the correct sharpening of the saw, its sharpness is not inferior to the factory quality.

Sharpening of saw blades is done on a special machine with observance of the sharpening angle

We responsibly approach the sharpening of cutting tools

All this is achieved thanks to many years of experience and professionalism of our specialists. Qualitatively sharpened cutting edge of circular saws will speed up and make more accurate the cutting process at your enterprise. If you prevent a strong stepping of the saw in time, you can save time and money on restoration or the purchase of a new tool.

Sharpening of carbide-tipped saw blades is done at your place within 20-30 minutes

Most people that, they can easily cope with sharpening circular saws on your own and it's very easy. But we want to warn you that for this you need to have special knowledge and many years of experience. It happens that when you try to sharpen the saw yourself, it cannot be restored in specialized centers. To prolong the service life, the instructions for the tool must be strictly followed, and thus the service life can be noticeably extended. No need to waste time and expose expensive equipment to possible damage.

Most people that, they can easily cope with sharpening circular saws on your own and it's very easy. But we want to warn you that for this you need to have special knowledge and many years of experience. It happens that when you try to sharpen the saw yourself, it cannot be restored in specialized centers. To prolong the service life, the instructions for the tool must be strictly followed, and thus the service life can be noticeably extended. No need to waste time and expose expensive equipment to possible damage.

The influence of the middle name on the name Yuri

Name Ilya - meaning and contraindications

Baby keeps crying

What does the name Aidar mean, the mystery of the name

Name Ilya - meaning and contraindications