During prolonged use, carbide-tipped circular saw blades may lose their original qualities. But this does not mean that you should purchase a new cutting tool. In most cases, sharpening can be done at home using any suitable machine.

The need to sharpen the saw

First you need to decide whether you need to sharpen or not. There are several obvious signs indicating the relevance of this procedure. If you ignore them, then in the future the disk may become unrepairable and will cause the failure of an expensive machine.

The advantage of using a brazed saw blade is to increase the service life. It is also designed for processing hardwoods. Surfacings are made of steel 9HF, 50 HVA, 65G and similar compositions. They are highly durable, but with significant use, the likelihood of their breakage will increase.

Timely sharpening of circular saws with a do-it-yourself machine is performed with the following obvious signs:

- increased load on the engine. The reason for this is the deterioration of sharpening and, as a result, the power unit needs more power to cut wood. If the motor design does not provide for protective relays, it may fail;

- degradation of cut quality. The first sign is an increase in the width of the cut, as well as the formation of chips and irregularities along its edges;

- increase in processing time of the workpiece. It takes longer than usual to form a cut.

The best way is to periodically check the condition of the soldered wood disc. To do this, you will need to temporarily leave the machine and dismantle the cutting tool. If it geometric parameters do not match the original ones - sharpening is required.

How to determine the sharpening angle of a circular saw

The best option would be to have an initial template, according to which you can correct the geometry of the cutting edge. Often it is made of thin-walled stainless metal, less often - of thick cardboard.

Carbide teeth are manufactured in accordance with GOST 9769-79. But their geometry and geometric dimensions are determined by the manufacturer based on the purpose of the saw. If there is no template, you must independently determine the required sharpening angles. To do this, it is recommended to use a pendulum goniometer.

Do-it-yourself template manufacturing technology.

- Take a new soldered disk, which is completely identical to the blunt one.

- On a solid sheet of cardboard, draw precise contours.

- Using a pendulum goniometer, determine the initial geometry of the carbide tipped.

- Enter the data on the template.

In the future, it can be used for self-sharpening on the machine or provided as a sample for companies providing similar services.

Additionally, it is recommended to compare the obtained data with the reference ones. In rip saws, the rake angle is typically 15°-25°. For transverse models, this figure ranges from 5° to 10°. In universal models, the rake angle is 15°.

It is important to remember that the rake angle can be negative. Similar models are used for cutting plastic sheets and non-ferrous metals.

Methods for sharpening circular saws

Any sharpening machine can be used to form a new cutting edge. It is important to initially choose the right emery wheel and use it to sharpen the edge. To do this, you must use corundum or diamond models.

The best option is to use special equipment designed to perform this work. But due to its high cost, in many cases its acquisition is impractical. Alternative way is the use grinder with the possibility of changing the angle of the corundum disk.

In no case should you do the sharpening by hand yourself. First, it will take a very long time. Secondly, the result obtained will not meet the standards. If it is not possible to sharpen the saw blade on wood on your own, it is recommended to use the services of specialized companies.

Do-it-yourself professional sharpening of circular saws is carried out according to the following rules:

- the main deformation occurs at the upper edge of the tooth. The edges are rounded from 0.1 to 0.3 mm. It is from this place that you need to start processing;

- sharpening is carried out along the front and rear edges. This will provide the possibility of repeating the procedure up to 25 times;

- the amount of removal should not exceed the value of 0.05-0.15 mm;

- the level of processing of the front and back faces should be the same.

After the sharpening of the disks on the tree is completed, it is recommended to bring it to a fine-grained sandpaper. This can be done manually or with a special machine.

Experts advise the use of special corundum discs, the end surface of which has a groove of a special shape. It will make the process easier.

Ways to increase the life of saw blades

The process of forming a new cutting edge is laborious and long. Therefore, it is recommended to fulfill a number of conditions to increase the life of the disk.

Hard solderings have a long service life. However, they are more likely to chip and break off. Alternative soft is practically not subject to such defects. But its service time is less than that of a solid one.

The appearance of roughness on the cutting surface is not allowed. In the future, they can lead to the appearance of chips and cracks.

The video shows an example of a do-it-yourself disk sharpening machine:

Drawings and tooth geometry

Sharpening of circular saws must be carried out clearly in compliance with the norms and requirements for the geometry of the teeth of each individual blade. To properly sharpen a circular saw with your own hands, you need to know the shape of the tooth and its geometry.

- Signs of need for sharpening and tools used

- Varieties of working elements of the saw blade of a circular electric saw

- Principles and angles of sharpening the working elements of a circular saw

- Do-it-yourself sharpening of a circular saw at home

Sharpening circular saws with your own hands is not difficult for a person who has the skills to work with metalwork equipment. The popularity of circular saws is due to the advantages provided by the operation of this equipment. The main advantages of this tool are cutting accuracy, high quality and cleanliness of its surface. Circular saws- a very popular tool that is very actively used, which leads to rapid wear of the working surfaces. Recovery is carried out by sharpening the working element of the tool.

Signs of need for sharpening and tools used

In order to sharpen the saw, you need to prepare the following tools:

- file;

- assembly vise;

- a block of wood;

- colored marker.

Sharpening of the circular saw is carried out as needed. The need for sharpening saws on wood is determined depending on the intensity of use of the tool.

There are several signs of this:

- Saw sharpening is required if, during the operation of the device, a strong heating is observed on the safety cover in the area of the electric drive. In some cases, an increase in temperature causes smoke to form from under the saw guard.

- It is necessary to sharpen the saw when, in order to obtain a high-quality result, a stronger impact must be exerted on the saw blade.

- During the operation of the unit, dark marks appear at the place where the cut was formed, which are traces of soot. The formation of such marks may be accompanied by the appearance of a characteristic smell of burnt wood. If these signs occur, stop using the tool and sharpen the working edges on the cutting elements of the saw blade of the electric saw.

Back to index

Varieties of working elements of the saw blade of a circular electric saw

In order to know how to correctly sharpen elements on disks circular saws, it is required to study the structural features of that part of the disk tool with which wood is sawn. The main element of this part of the disc are the teeth. The production of teeth is carried out using carbide metals. In each of the teeth, four working planes are distinguished:

- front;

- back;

- right and left side.

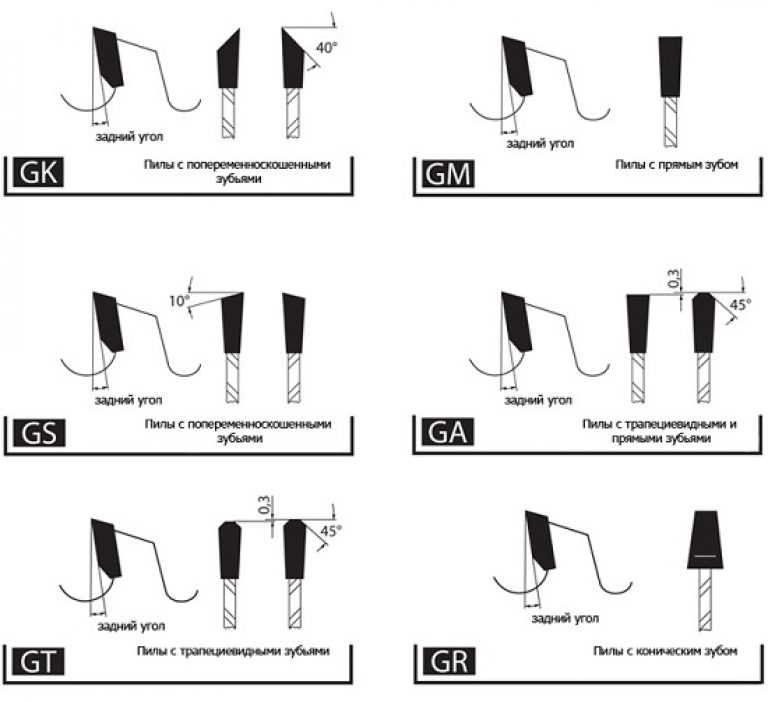

The planes provide a supporting role. In the geometry of the tooth, one main and two additional cutting edges are distinguished. The edges for cutting the material are formed on the line of intersection of the work planes. Depending on the configuration, all the cutting parts of the working element of the unit can be divided into several varieties:

- straight;

- bevelled;

- trapezoidal;

- conical.

Straight teeth are used for fast ripping. This type of cutting elements is not used when obtaining an ideal cut quality.

Beveled working elements are characterized by the presence of a flat surface on the back of the tooth on the left or right side. Some models of circular saws have working elements with different sides of the bevel, which alternate with each other. Such discs are called alternately bevelled. This type of disc is used when it is necessary to cut, in addition to wood, chipboard and various plastics. The presence of a large bevel ensures high-quality sawing without the formation of chips on the edges. The working elements in cross section have the shape of a trapezoid. Due to the presence of such a tooth configuration, the working elements of the disk are able to work for a long time without a visible deterioration in the quality of the cutting edges.

Conical working elements on the cross section have a conical shape. Most often, discs with such working teeth are used as auxiliary ones when pre-cutting the laminate. Discs with such teeth help to avoid the occurrence of chips when cutting the laminate.

Back to index

Principles and angles of sharpening the working elements of a circular saw

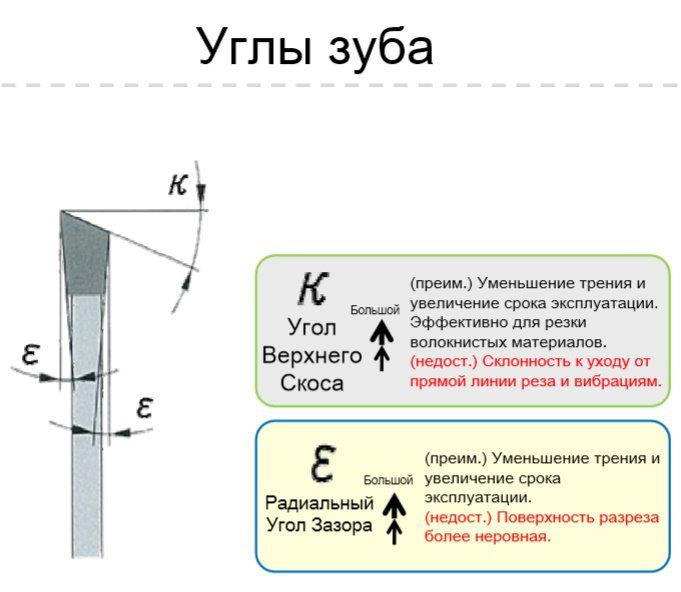

The working surfaces of the elements are sharpened at the four corners of sharpening. The sharpening angles and the shape of the cutting element are the main parameters of the disc, on which the quality of the work performed depends. The circular tooth has two main angles (back and front), in addition, the characteristics of the working element include the cutting angles of the front and rear surfaces. The characteristics of the sharpening angles depend on the purpose of the device for sawing, the material being processed and the direction of processing.

Circular saw designed for slitting material, sharpened at a large rake angle, for sawing in the transverse direction, a sharpening angle of 5-10 ° is used. A universal sharpening option is considered to be an angle of 15 °. The level of hardness of the material being processed affects the angle of sharpening of the working elements. The harder the material being cut, the smaller the sharpening angle the saw tooth should have.

During the operation of the tool, the upper cutting edge wears out to the maximum. As a result of the use of the tool for its intended purpose, the cutting edge is rounded. The rounding factor can reach 0.3 mm or more. Among the planes, the front one is subjected to maximum wear.

Proper sharpening should ensure the appearance of the edges, in which their rounding does not exceed 0.2 mm.

For this purpose, simultaneous grinding of the rear and front planes of the work items is used. This sharpening method is optimal. It is possible to sharpen only the front plane, but in this case, the sharpening process takes more time, and the tooth wears out faster due to the fact that it is necessary to grind the metal. With standard sharpening, it is necessary to remove metal with a thickness of 0.05 to 0.15 mm.

The complexity of sharpening saw blades with carbide teeth is due to the use of sintered tungsten-cobalt alloys for the manufacture of cutting inserts, which are subsequently attached to the disk by high-temperature soldering. But the main difficulty is caused by their geometry and the need to provide a certain angle when sharpening.

Tooth shape and sharpening angles

According to GOST 9769, a carbide tooth in its design has 4 planes - back, front and 2 auxiliary. According to the geometry of the cutting inserts are straight, beveled, trapezoidal and conical.

The front angle of sharpening determines not only the characteristics of the saw blade, but also its purpose:

- 15-25° - for ripping;

- 5-10° - for transverse;

- within 15° - universal application.

Also, the size of the angles is also determined by the hardness of the material being cut - the higher it is, the smaller the sharpening should be.

Basic sharpening rules

Basically, the main cutting edge is subject to wear - it is rounded up to 0.3 mm. Carbide teeth should not be allowed to wear beyond this value. This leads to a decrease in productivity and an increase in the time for subsequent sharpening. Dullness is determined by the teeth and the cut (the quality of the cut worsens).

- With the correct performance of the work, the maximum operational resource of the saw blade with soldering is ensured - up to 30 sharpenings. Therefore, sharpening should be done along the front and back plane of the tooth.

- First of all, the front plane is sharpened.

- Soldering during sharpening should be in contact with the surface of the abrasive wheel with the entire plane.

- It is recommended to sharpen the teeth in short strokes (within 3-5 seconds), which will prevent them from overheating. Since with increasing temperature, the microhardness of the abrasive decreases, and hence the effectiveness of sharpening.

- The thickness of the removed metal should not exceed 0.15 mm.

Materials and tools

To sharpen discs with carbide teeth, you can use diamond wheels and silicon carbide. To provide smooth surface without nicks, it is recommended to use abrasive with the highest grit. Otherwise, the notches will crumble during operation, which will lead to a rapid blunting of the soldering.

It is best to sharpen on specialized machines with the ability to adjust the angles of the saw blade. To adjust its position in the horizontal plane (in the case of teeth with a bevelled front plane), special devices with pendulum goniometers.

But the purchase of special equipment for home use when the need for it arises no more than 1 time in several months, it is not advisable. And to hold saw blade hands in exact accordance with the required angle - this is something from the realm of fantasy.

There is only one way out - to build a stand, the surface of which will be located on the same level with the axis of the abrasive wheel. This will ensure that the position of the back and front plane of the tooth is perpendicular to the grinding material. And if you show your imagination and fix one side of the device pivotally, and on the other make supports in the form of bolts with the possibility of screwing in and out, you can also control the angle of inclination relative to the horizontal plane. And the accuracy is verified by a pendulum goniometer.

To ensure the angle required for sharpening the front and rear planes of the soldered teeth, stops can be equipped on the stand that will fix the saw blade in the desired position.

Any cutting tool tends to become dull during operation. This also applies saw blades, which must be sharpened regularly in order for the sawing of wood to occur quickly and efficiently.

The easiest way to sharpen teeth on a circular saw is to use a regular file. But when working with your own hands, on bringing the cutting tool into working condition, there are many difficulties that only good specialist with sufficient experience. Much easier, faster and more efficient to use for this operation homemade machine for sharpening circular saws or sharpening machine for circular knives.

If there is a home-made electric sharpening machine for circular saws, regardless of whether it is a factory tool or home-made, you should know the basic principles for using such equipment. Especially when there is a need to sharpen the teeth of saw blades that have different geometry and sharpening angles.

1 Tooth shapes on saw blades

There are several of them, and they appeared as a result of optimization impact of the cutting edge on the material being cut, which can have different properties.

The main tooth shapes are:

- straight - used for longitudinal sawing, when high quality is not necessary;

- oblique (beveled tooth) - has a variable right and left angle of inclination of the posterior (sometimes also anterior) plane. It is used for sawing both in the longitudinal and transverse directions. The most common shape for circular saws. This configuration is convenient to use when cutting boards with double-sided lamination, as it does not give chips along the edges of the cut;

- trapezoidal - characterized by a long period of retention of the cutting edge in a sharp state. Usually on saw blades, teeth of this shape alternate with straight teeth, somewhat rising above them. Trapezoidal teeth, in this case, make rough sawing, and straight teeth - fine;

- conical - this form of teeth is used in auxiliary operations. For example, a layer of laminate is cut to prevent the appearance of splinters during the main sawing.

The front edge of all teeth is flat, but in some types of circular saws it is concave.

![]()

This allows you to perform high-quality finishing cross-cutting.

1.1 Sharpening angles

Sharpening of the teeth of a circular saw is carried out taking into account the four main angles that are formed at the intersection of the planes:

- front corner;

- back corner;

- bevel angles of the front and rear planes.

as a helper, the angle of sharpening is also taken into account, which is given by the front and back angles.

Sharpening angles depend on the purpose of the saw:

- for longitudinal sawing, a rake angle of 15 to 20 degrees is suitable;

- with cross sawing - from 5 to 10 degrees;

- with universal use, on average - 15 degrees.

Sharpening angles are important to take into account not only in the direction of the cut, but also in terms of the hardness of the wood - the harder it is, the smaller the front and rear angles should be.

2 Equipment for sharpening saw blades

These are grinding machines for circular saws, which constructively made in the following variations:

- when sharpening, only the saw moves (the engine with the grinding wheel is stationary);

- both a sharpened saw and an engine with a circle can move;

- only the motor with the grinding wheel attached to it moves (the saw blade remains stationary).

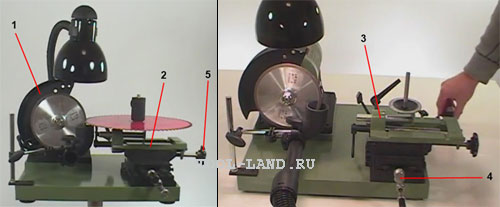

As standard example A grinding machine can be a device that consists of two components - an engine with a grinding wheel mounted on its shaft, and a caliper on which a sharpened circular saw is attached.

To ensure angular sharpening in this device, a system must be provided that allows you to change the angle of inclination of the blade (for teeth with a beveled front plane).

2.1 Machine JMY8-70

The JMY8-70 electric grinding machine, which is made in China, has enough a large number of positive feedback. Some craftsmen take his device as a basis when they assemble a home-made machine for their own needs with their own hands.

The JMY8-70 machine is designed for sharpening circular saw blades that made of hard high-speed alloys. On the machine, it is possible to process the front and rear plane of the teeth, as well as to perform angular sharpening.

Main advantages:

- has a diamond grinding wheel, the diameter of which is 125 mm;

- equipped with an inclined saw holder, which allows for angular sharpening;

- the body is made of cast steel used in the aviation industry;

- installed on rubber gaskets, which significantly reduce the impact of vibration on the material being processed;

- It has a simple adjustment that even a non-specialist can handle.

The manufacturer upon shipment completes the machine detailed instruction, which describes in detail all the possible functions of the device and how to perform them.

Specifications:

- the grinding wheel has dimensions - 125 × 10x8 mm;

- the grinding wheel can be rotated up to 20 degrees;

- diameter of the sharpened saw — from 70 to 800 mm;

- grinding wheel rotation speed - 2850 rpm;

- weight - 35 kg.

2.2 Homemade grinder

A lot of people, when working with their own hands, use carbide circular saws not regularly, but from time to time. Therefore, buying factory equipment does not make economic sense. A homemade grinding machine is a great solution that will allow you not to contact third-party organizations.

The main argument is that when sharpening a circular saw on a conventional grinding wheel with your own hands, it is very difficult to maintain the required sharpening angles. Therefore, a device is needed allows you to fix the saw blade in a specific position in relation to the grinding wheel.

A home-made machine, on which you can sharpen circular saws with your own hands, may consist of the following components and parts:

- a fixed electric motor with the possibility of mounting a grinding disk on its shaft;

- table-stand, the surface of which is located at the same level in height with the axis of rotation of the grinding wheel;

- tilting the stand with hinges on one side and rotating (height-changing) screws on the other. This will allow you to perform angular sharpening along the front and rear planes;

- clamps to secure the saw blade. To do this, a groove is made on the surface of the stand for the mandrel on which the saw is installed. The movement of the mandrel, along with the disk, along the groove will allow you to maintain the required angle of sharpening the teeth;

- a device for moving an electric motor or a stand for angular sharpening of circular saws with different diameters;

- the presence of stops for reliable fixation of the tool during work.

2.3 Sharpening circular saws

The sequence of operations when sharpening the front plane of the tooth of a carbide saw blade:

- the saw is placed on the mandrel and fixed with a conical sleeve with a nut;

- it is set clearly horizontally using a pendulum goniometer, while the bevel angle of the front plane is equal to zero;

- moving the mandrel horizontally with the disk installed, the specified front angle of sharpening is set. In other words, the disk moves in such a way that the front plane of her tooth fits snugly against the surface of the grinding wheel;

- using a marker, a mark is made - from which tooth sharpening began;

- when the electric motor is turned on, several movements of the saw are made back and forth with pressing the surface to be sharpened against the working surface of the grinding wheel;

- the thickness of the metal removal is regulated by the clamping force and the number of translational movements;

- after the first tooth is sharpened, the saw is removed from contact with the grinding wheel and rotates around its axis by one tooth, which will be the next when sharpening;

- the operation is repeated according to the number of teeth on the saw blade.

In domestic saws, sintered tungsten-cobalt alloys of VK grades (VK6, VK15, etc., the figure means the percentage of cobalt) are used as the material for cutting plates. BK6 has a hardness of 88.5 HRA, BK15 has a hardness of 86 HRA. Foreign manufacturers use their alloys. Hard alloys VK consist mainly of tungsten carbide cemented with cobalt. The characteristics of the alloy depend not only on its chemical composition, but also on the grain size of the carbide phase. The smaller the grain, the higher the hardness and strength of the alloy.

Fasten hard-alloy plates to a disk by high-temperature soldering. As a material for soldering, at best, silver solders (PSr-40, PSr-45) are used, in the worst case, copper-zinc solders (L-63, MNMTs-68-4-2).

Carbide tooth geometry

Carbide tooth has four working planes - front (A), back (B), and two auxiliary side (C). Intersecting with each other, these planes form cutting edges - the main one (1) and two auxiliary ones (2 and 3). The given definition of faces and edges of the tooth is given in accordance with GOST 9769-79.

The following types of teeth are distinguished by shape.

Typically used in fast rip saws where quality is not a concern.

Oblique (beveled) tooth with the left and right angle of inclination of the rear plane. Teeth with different angles of inclination alternate with each other, which is why they are called alternately beveled. This is the most common form of the tooth. Depending on the size of the sharpening angles, saws with alternately beveled teeth are used for sawing a wide variety of materials (wood, chipboard, plastics) - both in the longitudinal and transverse directions. Saws with a large angle of inclination of the rear plane are used as scoring saws when cutting boards with double-sided lamination. Their use avoids chipping of the coating at the edges of the cut. Increasing the bevel angle reduces the cutting force and reduces the risk of chipping, but at the same time reduces the tool life and strength of the tooth.

The teeth can have an inclination not only of the rear, but also of the front plane.

A feature of these teeth is the relatively slow rate of blunting of the cutting edges compared to alternately beveled teeth. They are usually used in combination with a straight tooth.

![]()

Alternating with the latter and slightly rising above it, the trapezoidal tooth performs rough sawing, and the straight one following it - finishing. Saws with alternating straight and trapezoidal teeth are used for cutting boards with double-sided lamination (chipboard, MDF, etc.), as well as for sawing plastics.

Cone tooth saws are auxiliary and are used to cut the bottom layer of the laminate, preventing it from chipping when the main saw passes.

In the vast majority of cases, the front face of the teeth is flat, but there are saws with a concave front face. They are used for cleaning cross cutting.

Tooth sharpening angles

There are four main sharpening angles of a circular saw, which, along with the shape of the tooth, determine its characteristics. These are the front angle (γ), rear (α) and bevel angles of the front and rear planes (ε 1 and ε 2). The taper angle (β) has an auxiliary value, since it is set by the front and back angles (β=90°-γ-α).

The values of the sharpening angles are determined by the purpose of the saw - i.e. for cutting what material and in what direction it is intended. Rip saws have a relatively large rake angle (15°-25°). For crosscut saws, the angle γ usually ranges from 5-10°. General purpose saws designed for crosscutting and rip sawing have an average rake angle - typically 15°.

The sharpening angles are determined not only by the direction of the cut, but also by the hardness of the material being cut. The higher the hardness, the smaller the front and back angles should be (less sharpening of the tooth).

The front angle can be not only positive, but also negative. Saws with this angle are used for cutting non-ferrous metals and plastics.

Basic sharpening principles

The main wear of a carbide tooth occurs along its main (upper) cutting edge. In the process of work, the latter is rounded to 0.1-0.3 mm. Of the faces, the front wears out the fastest.When sawing massive workpieces, the side edges are also subject to rapid wear.

The saw must not be overblown. The cutting edge rounding radius should not exceed 0.1-0.2 mm. In addition to the fact that when working with a very blunt saw, productivity drops sharply, it takes several times more time to sharpen it than to sharpen a saw with normal bluntness. The degree of dullness can be determined both by the teeth themselves and by the type of cut they leave.

Proper sharpening of circular saws is to simultaneously ensure the proper sharpness of the cutting edge, to ensure the maximum number of sharpenings, which in the optimal case can reach 25-30 times. For this purpose, it is recommended to sharpen the carbide tooth along the front and back planes. In fact, the teeth can be sharpened along one front plane, but the number of possible sharpenings is almost two times less than when sharpening along two planes. The figure below clearly demonstrates why this happens.

The last pass when sharpening saw blades is recommended to be done along the back plane of the tooth. The standard amount of metal removal is 0.05-0.15 mm.

Before sharpening, it is necessary to clean the saw of impurities, such as resin, and check the sharpening angles. On some saws they are written on the disc.

Equipment and materials for sharpening saw blades

Depending on the material from which the teeth are made, circular saw blades can be sharpened with CBN, green silicon carbide, or diamond (PCD) wheels. So, CBN wheels are able to sharpen high-performance high-speed steel wheels, diamond wheels and green silicon carbide wheels - hard alloy cutters.When using abrasive wheels (especially diamond wheels), it is desirable to cool them with coolant.

One of the significant disadvantages of diamond is the relatively low temperature stability - at a temperature of about 900°C, the diamond burns out.

With increasing temperature, microhardness abrasive materials decreases. Increasing the temperature to 1000°C reduces the microhardness by almost 2-2.5 times compared to the microhardness at room temperature. An increase in temperature to 1300°C causes a decrease in the hardness of abrasive materials by almost 4-6 times.

The use of water for cooling can lead to rust on machine parts and assemblies. To eliminate corrosion, soap and certain electrolytes (sodium carbonate, soda ash, trisodium phosphate, sodium nitrite, sodium silicate, etc.) are added to water, which form protective films. In normal grinding, soap and soda solutions are most often used, and in fine grinding, low-concentration emulsions are used.

However, when sharpening saw blades at home with a low intensity of grinding work, they do not resort to cooling the circle so often - not wanting to spend time on this.

To increase the productivity of sharpening with abrasive wheels and reduce specific wear, you should choose the largest grit that provides the required surface cleanliness of the tooth being sharpened.

To select the grit size of the abrasive, in accordance with the stage of sharpening, you can use the table in the article about sharpening bars. For example, in the case of using diamond wheels, wheels with a grain size of 160/125 or 125/100 can be used for rough sharpening, and 63/50 or 50/40 for finishing. Wheels with a grit size of 40/28 to 14/10 are used for chipping.

It is necessary to strive to ensure that the surface of the tooth is very smooth. If there are notches on the surface of the tooth, then the protrusions will crumble when the saw is used, and it will become dull very quickly.

The circumferential speed of the circle when sharpening carbide teeth should be about 10-18 m / s. This means that when using a wheel with a diameter of 125 mm, the engine speed should be about 1500-2700 rpm. Sharpening of more brittle alloys is carried out at a lower speed from this range. When sharpening carbide tools, the use of hard modes leads to the formation of increased stresses and cracks, and sometimes to chipping of the cutting edges, while wheel wear increases.

When using machines for sharpening circular saws, a change in the relative position of the saw and the grinding wheel can be realized different ways- moving one saw (motor with a circle is stationary), simultaneous movement of the saw and the engine, moving only the engine with a circle (saw blade is stationary).

A large number of grinding machines of various functionality are produced. The most complex and expensive programmable complexes are capable of providing a fully automatic sharpening mode, in which all operations are performed without the participation of a worker.

In the simplest and cheapest models, after installing and fixing the saw in a position that provides the required sharpening angle, all further operations are turning the saw around its axis (turning on the tooth), filing for grinding (introducing into contact with the wheel) and controlling the thickness of the tooth removed from the tooth. metal - are made by the worker manually. Such simple models it is advisable to use at home, when sharpening circular saws is episodic.

An example of the simplest machine for sharpening circular saws is the system, a photograph of which is shown in the photo below. It consists of two main units - an engine with a circle (1) and a caliper (2), on which a sharpened saw is installed. The turning mechanism (3) is used to change the angle of inclination of the blade (when sharpening teeth with a beveled front plane). With the help of the screw (4) the saw is displaced along the axis of the abrasive wheel. This ensures that the required value of the front angle of sharpening is set. The screw (5) is used to set the limiter in the desired position, preventing excessive entry of the wheel into the interdental cavity.

Saw blade sharpening process

Sharpening a straight tooth along the front plane. Sharpening of a straight tooth of carbide saw blades is carried out in the following sequence.The saw is mounted on a mandrel, clamped with a conical (centering) sleeve and a nut, then set in a strictly horizontal position by means of a mechanism (3). This provides a bevel angle of the front plane (ε 1) equal to 0°. On machines for sharpening disks that do not have a built-in angular scale in the tilt mechanism, this is done using a conventional pendulum goniometer. In this case, you should check the horizontalness of the machine.

By turning the screw (4) of the mechanism that provides horizontal movement of the mandrel with a circle, the required front angle of sharpening is set. In other words, the saw moves to a position in which the front plane of the tooth fits snugly against the working surface of the circle.

The marker makes a mark of the tooth from which sharpening begins.

![]()

The engine is turned on and the front plane is sharpened - by putting the tooth in contact with the circle and several movements of the saw back and forth while simultaneously pressing the tooth against the circle. The thickness of the removed metal is regulated by the number of sharpening movements and the force of pressing the tooth against the abrasive wheel. After sharpening one tooth, the saw is removed from contact with the wheel, rotated by one tooth, and the sharpening operation is repeated. And so on until the marker mark makes a full circle, indicating that all the teeth are sharpened.

Sharpening a tooth beveled along the front plane. The difference between sharpening a beveled tooth and sharpening a straight one is that the saw must not be installed horizontally, but with an inclination - with an angle corresponding to the angle of the bevel of the front plane.

The angle of inclination of the saw is set using the same pendulum goniometer. First, a positive angle is set (in this case +8°).

After that, every second tooth is sharpened.

After sharpening half of the teeth, the saw blade angle changes from +8° to -8°.

And again, every second tooth is sharpened.

Sharpening on the back plane. To sharpen a tooth along the back plane, it is necessary that the saw blade sharpening machine allows you to install the saw in such a way that the back plane of the tooth will be in the same plane as the working surface of the abrasive wheel.

If there is no machine for sharpening saw blades

Sharpening circular saws on functional and convenient specialized machines does not require special professional skills. A little practice - and sharpening will go without any problems. But most people use carbide saw blades occasionally, as needed. Spending a significant amount on a special sharpening machine, which is used for several hours a month, does not seem reasonable to everyone.Accurately maintaining the required sharpening angles, holding the saw in the hands on weight, is an impossible task even for a person with a unique eye and an enviable hardness of hands. The most reasonable thing in this case is to make the simplest sharpening device, which makes it possible to fix the saw in a certain position in relation to the circle.

The simplest of these devices for sharpening circular saws is a stand, the surface of which is flush with the axis of the grinding wheel. By placing a saw blade on it, it is possible to ensure the perpendicularity of the front and back planes of the tooth with respect to the saw blade. And if the upper surface of the stand is made movable - fixing one side hingedly, and the other - resting on a pair of bolts that can be screwed in and out - then it can be installed at any angle, making it possible to sharpen an oblique tooth along the front and rear planes.

True, in this case, one of the main problems remains unresolved - holding the same front and rear sharpening angles. This problem can be solved by fixing the center of the saw relative to the abrasive wheel in the desired position. One way to implement this is to make a groove on the surface of the stand for the mandrel on which the saw is mounted. By moving the mandrel with a circle along the groove, it will be possible to maintain the required front angle of sharpening the tooth. But for sharpening circular saws with different diameters or sharpening angles, it should be possible to either move the engine or the stand and the groove with it. Another way to ensure the required sharpening angle is simpler, and is to install stops on the table that fix the disk in the desired position. At the end of the article there is a video demonstrating such a device.

Sharpening quality control

The sharpened teeth must be free of cracks, chips, visible risks from the grinding wheel. The radius of rounding of the cutting edge should be no more than 0.015 mm. Visually, this can be defined as the absence of glare on the cutting edge.GOST 9769-79 establishes certain tolerance values for sharpening parameters. The end runout of the tops of the teeth should not exceed 0.2 mm (for saws with a diameter of up to 400 mm), the radial runout should not exceed 0.15 mm. The runout is checked using a conventional dial gauge.

Deviations of sharpening angles should not exceed:

- for front angle - ±1°30";

- for the rear corner and bevel angles of the front and rear planes - ± 2 °;

Video:

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Chocolate biscuit: the secrets of cooking in a slow cooker and oven

Chemical composition and nutritional value

Apple chips at home

Braised cabbage with white beans, recipe

How to reduce the ass, hips and stomach at home?