It is quite possible to make a circular saw, or, as it is also called, a circular saw, with your own hands - there are several options for this at once. Everyone who is used to doing everything with their own hands, of course, knows how necessary and useful this tool is, especially for giving.

Not everyone can afford to buy branded equipment today, but this does not mean at all that you should start denying yourself everything and saving up for a coveted circular. There is a much more economical option: a homemade circular saw made by yourself.

What should you look for when buying a rechargeable battery?

Undoubtedly, battery performance is one of the key criteria for purchasing a wireless device. Battery life has many features. She decides how much power the saw works and how long she can work with it. Lithium-ion batteries are mainly found with a capacity of 10, 8 volts or 18 volts. For battery powered circular saws, the Facts test compared models from both categories.

Saws are not meant to be used all the time, but they always work short term but at regular intervals. Therefore, batteries often do not last more than a few minutes, which is enough for a manageable amount of time. If you want to be on the safe side and don't want to suddenly become powerless, you can buy a second battery and swap it out if necessary. In connection with sawing, the charging time of the battery continues to play a role. The fall, especially on branded devices, is pleasant.

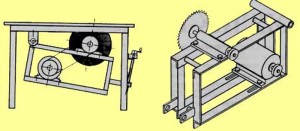

Samu circular saw, as well as a table for her, can really be made with minimal cost for the family budget, that is, with your own hands, using improvised means. Of course, one cannot do without certain tools here, but let's talk about everything in order. First of all, we make a table for a circular saw. Here it must be remembered that the most important quality of the table is its stability, since swaying during operation does not just interfere. They are also fraught with a very serious danger: the circle of the saw is sharp, and it rotates at great speed. Therefore, in order to protect ourselves from unnecessary injuries and injuries, we pay increased attention to the stability of the table.

Samu circular saw, as well as a table for her, can really be made with minimal cost for the family budget, that is, with your own hands, using improvised means. Of course, one cannot do without certain tools here, but let's talk about everything in order. First of all, we make a table for a circular saw. Here it must be remembered that the most important quality of the table is its stability, since swaying during operation does not just interfere. They are also fraught with a very serious danger: the circle of the saw is sharp, and it rotates at great speed. Therefore, in order to protect ourselves from unnecessary injuries and injuries, we pay increased attention to the stability of the table.

Some of them only take 90 minutes to fully charge. Nothing stands in the way of a major construction project. Charging with a suitable fast charger will cut the charging time in half. However, for now this is only available from the manufacturer and therefore only for batteries of this.

Especially in mobile devices, weight plays a decisive role. On the one hand, during transport, on the other hand, during operation. Modern cordless circular saws bring scales weighing more than 4 kg. Less is only possible with a mini circular saw solution where weights below 1 kg are achieved. However, if such a candidate is questioned, it should be checked first. The areas of application for cordless circular saws and mini circular saws are different.

In order to make a table frame with your own hands, you can take it to some old table or to make a prefabricated surface - either from a metal profile or from wooden bars. For the bed, it is important that its surface is even and preferably wide. The surface can be made from the following materials:

- plywood, plexiglass;

- fiberglass board;

- sheet of iron.

A combination of the above materials is also allowed. Here, as they say, at the discretion of the master.

In particular, large performance differences should be taken into account. Another important point. A distinction is made between cutting depths with a cutting angle of 0° and 45°. The 90° cutting angle achieved by some cordless circular saws is usually left outside. Depths of cut up to 40mm are usually sufficient for the home improvement sector, but of course you can also opt for higher depths of cut. Here it depends on how thick the material is processed.

What materials should be processed? Woodworking is not a problem for any cordless circular saw in the Facts test. However, if you also want to edit other materials, you should find out exactly which cordless portable circular saws allow more wiggle room. Many manufacturers leave recommendations in the product description. There, for example, read "particularly suitable for cutting laminate" or "ideal for cutting panels in the context of roofing and interior work."

Before making a table cover, you need to think about what kind of load it will have in the process of work, respectively, the thickness should correspond to the level of load. In addition, one more important point should be taken into account - in some do-it-yourself circular saws, the drive is attached just to the table cover, so it is recommended to make it lifting. This option makes the design of the frame simpler, while making it easier for the master to access the power tool.

Such compositions are a good guide on the way to the right cordless circular saw. Even more detailed is the Circular Saw Fact Test. Since practicality is also being compared here, the interested party gets valuable advice on which the sawing model can convince in practice and whether it is suitable for his project. In addition to wood, cordless circular saws can be used to cut metals, plastics and composites. To do this, the saw needs the right speed, a powerful battery and the right saw blade for the material.

A corner is quite suitable as a guide bar: whenever you set the desired size, it will need to be attached to the plate with clamps. However, a more convenient option with a sliding bar is also possible here. If you stop at this option, then remember that the guide bar should be placed perpendicular to the plane in which the circular saw rotates, and the sides of the table top must certainly be parallel. A sliding sled can be made from an angle piece (aluminum or steel) that slides along the edges while maintaining a right angle. Some craftsmen make wooden sleds, but in this case, the machine bed becomes less durable and at the same time more cumbersome.

Electronics for speed and speed. The harder and thicker the material being cut, the higher the speed of the cordless circular saw should be. The speed is given as idle speed. This is because they change during the sawing process and due to various factors, the same meaningful values. Cordless circular saw speeds range from 500 to 000 rpm, although higher speeds are also on the market. For processing various materials It is recommended to use a cordless circular saw with electronic speed control.

Bulgarian, drill and circular saw - choose options

Now let's go directly to the saw itself. You can assemble a circular saw with a powerful electric motor, a pulley system and a belt drive, but such a saw will be quite expensive. But there is more cheap option- almost everyone has such a power tool as a drill, circular saw or grinder. On any of these tools, you can attach a cut-off circular saw. In addition, their compact size can be attributed to their advantages here. Using such tools as an electric drive in order to cut not very thick boards is a very good solution.

Now let's go directly to the saw itself. You can assemble a circular saw with a powerful electric motor, a pulley system and a belt drive, but such a saw will be quite expensive. But there is more cheap option- almost everyone has such a power tool as a drill, circular saw or grinder. On any of these tools, you can attach a cut-off circular saw. In addition, their compact size can be attributed to their advantages here. Using such tools as an electric drive in order to cut not very thick boards is a very good solution.

At this motor speed, material requirements can be adjusted individually. Selecting the correct speed also affects the cutting result. If too low a speed is selected, the saw blade must literally “eat” itself through the material, resulting in an unclean cut and scuffs or scratches. In the worst case, the saw blade gives up and gets stuck in the material. This can cause significant damage to the point of failure of the cordless circular saw.

The saw blade continues to make a decision about the success or failure of the sawing. As a rule, a cordless circular saw is equipped with a universal carbide saw blade. As the name suggests, it is suitable for various works by sawing. Woodworking is again no problem with this saw blade. It gets more difficult with other materials, with more complex cuts that deviate from a straight line and precise cuts. The cutting direction, tooth alignment and number of teeth must be taken into account.

It will be most convenient to use circular saw, since it has the maximum size of the useful part of the disk, while a drill or grinder, due to the design of their body, does not physically allow using the entire area of \u200b\u200bthe disk. The power tool can be attached to the table with plastic clamps. Here you should also pay special attention to the reliability of fastening - an uneven cut will not be the biggest problem if the fasteners turn out to be unreliable.

The greater the distance between the teeth, the more inaccurate the cut. This also applies to larger teeth. This is achieved using saw blade with larger, widely spaced teeth, higher cutting speed. Although many of the smaller teeth slow down the cutting speed, they cut much cleaner and more accurately.

In addition, it depends on the orientation and shape of the teeth. The aforementioned universal blades are equipped with mutually aligned teeth. They can be used for transverse and longitudinal cuts. When working on sensitive surfaces, smaller working saw blades are used that do not tear any material and do not leave a clean cutting edge. For harder materials, the saw blade must be made from a harder metal.

- How to do homemade circular?

- Large homemade circular saw

- Pendulum circular with electric motor

- Circular mini saw: instructions for making

- Base for mini circular

- Engine installation

A handmade circular saw is great way save a lot of money and at the same time acquire fairly high-quality and reliable equipment. A properly assembled homemade circular saw is in no way inferior to a factory saw and is also capable of sawing logs of even very large diameters.

Saw blades can be purchased separately and as a set separately. Changing a saw blade should be as easy as possible. Check spindle locks that provide this. Equipment and useful accessories. There are a number of useful accessories that are included or available as an option. Many saw models now have a guide to guide the circular saw safely. Almost every winner circular saw battery powered has this, or at least a combination with one.

Several models do not have a guide and cannot be used with this guide. The disadvantage is not necessary. Those who do not need a guide or do not know how to help themselves by other means can do without them. For long, straight cuts, a guide rail is required. An integrated laser can also be useful here, which also has some battery powered circular saws.

A circular saw is used to cut timber evenly.

How to make a homemade circular?

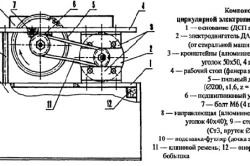

In order for the circular saw to easily cut large logs, it is necessary to equip it with a truly powerful electric drive. In addition, for this purpose, a belt drive, a shaft and an engine with high strength traction. All handmade circular saws consist of two parts: upper and lower.

A suitcase or other container for storage or transport should of course be taken for granted with a cordless circular saw. After all, it is designed for mobile use. In practice, however, it looks different, and there are actually battery-operated portable circular saws that come without such a "shell". This is how you look closely! The same goes for the charger and battery: their presence is not self-evident.

Cordless circular saws allow you to perform various sawing jobs and are completely independent of the power connection. This and the absence of a problematic cable greatly increase the portability and flexibility of a cordless circular saw compared to a manual or stationary electric powered circular saw.

In the lower part there is always various electrical equipment, namely:

- saw motor;

- transformer;

- device that starts the circulation.

In the upper part of the circular saw set:

More and more tools help us to perform more specific tasks, more precisely, as well as milling machines, multi-tools or mini-tools. However, the circular saw and jigsaw are the main cutting tools. In this post, we will show you what are the differences between a circular saw and a jigsaw in terms of the work to be done. This way you will have no doubts about what is best for each job.

What are the differences between a circular saw and a puzzle? Both the circular saw and the puzzle can perform different types cuts, but both of them don't behave the same with every cut. Thus, we will show you the differences between them depending on the use you can give them.

- pulley;

- cutting disc.

Back to index

Large homemade circular saw

When making a frame for the top of the saw, it is best to use metal corner 25 mm wide. In this case, the rectangle, which will be the frame of the upper part of the homemade circular, should have dimensions of 600x400 mm. Further, four pipes are welded in the corners of this quadrangle, the diameter of which should be 17 mm and the height should be approximately 2.2 m.

These two tools can do just that. In the case of a puzzle, straight cuts can be made if we can rely on a cutting guide or we can follow the previously marked line. In this case, we are very dependent on our experience with the tool.

The problem that can arise is to make straight cuts with thick wood. In this situation, the puzzle is at a disadvantage because when making these cuts, the leaves experience temperature problems due to the much friction they suffer, becoming more susceptible to possible damage such as warping or breaking the blade.

After that, two corners must be strengthened on the frame, on which the bearings will later be fixed. The distance between these corners directly depends on the length of the shaft. To fix the bearings, as a rule, clamps are used. It is best if the bearings mounted on a homemade circular are of a closed type. So you can not be afraid that wood chips will fall into the space between the balls, rings and separator. Don't forget to also cut the threads at the very end of the shaft so that you can later install a cutting disc on it.

Another problem that can occur when cutting thick materials is the possible deflection of the bottom of the sheet with the machine part itself. Although in this case the sheet chosen for the work to be done has a strong influence, it is very possible that this can happen to us when trying to follow the marked line.

With a circular saw, we have more advantages in this regard. When starting the cut and inserting the disc into the wood, the disc itself serves as a guide, since the width of this is much larger than the problem of deformation of the cutting blade, and therefore the irregular cut disappears.

The lower part of the circular saw should be made much more massive, which will provide it with the necessary stability and reliability. Therefore, in the manufacture of the lower frame, you need to take a corner with a width of at least 40 mm. Further across the frame, it is necessary to fix two more additional corners, on which the engine of a home-made circular will be held in the future. The most suitable motor for a do-it-yourself circular saw is an asynchronous three-phase motor with a power of at least 1.5 kW and 1500 rpm. The pulley creek should have enough big size, approximately 80 mm, and should be mounted directly on the shaft itself. In addition, you will need to weld a rather small metal platform to the frame, on which the launcher will be placed. Large pipes 2.2 m long, which were previously welded by you in the corners of the frame, are necessary for high-quality tension of the belt so that the metal lambs tighten the thin pipes.

In this case, the circular saw is at a clear disadvantage compared to the jigsaw. A circular saw practically does not allow curved cuts, as the size and hardness of the blade do not allow this. With the puzzle, we only have to mark the line to be cut using the sheet marked for curved cutting and follow the line. The blade for this job is thinner and thinner than others and allows us to make sharp turns without problems.

This task is very common to perform on wooden boards, such as the sink hole on a bench. For this job, using a circular saw can be a little tricky. This causes the safety system to avoid hand contractions, making cutting difficult. It is designed in such a way that the disc opens at the beginning of the cut and closes again at the end.

Now, in the finished supports made of pipes, it is necessary to insert both the lower and upper parts of the homemade saw, and then tighten and tighten the belt with metal winglets. Starting the motor in this model of the circular with your own hands is carried out using starting capacitors. In order to load the motor and increase its torque, a 220/36 400 W transformer can be used.

Back to index

Pendulum circular with electric motor

![]()

It is quite easy to make a homemade circular saw to cut logs and blocks of wood, the thickness of which corresponds to the power of the electric drive installed on it. If you intend to work with large and very thick pieces of wood, then you should equip your homemade saw a truly powerful electric motor, as well as install a shaft and a belt drive on it. best solution in this case, a special pendulum bed will be installed.

When making a pendulum circular with your own hands, only very strong steel corners should be used as the material for the frame. Next, on the finished steel frame, you will need to place all the mechanisms necessary for the normal operation of a homemade circular saw. With this design, you can personally, without any special effort, set the height of the flight of the cutting disc, while avoiding excessive design difficulties.

Back to index

Circular mini saw: instructions for making

Back to index

Base for mini circular

For the manufacture of such homemade products you will need:

- two metal plates;

- wooden beam;

- spindle from a bicycle;

- star;

- chain.

The mini-circular must stand on a solid and stable table, since any rocking can be dangerous to human health and, moreover, interfere with the normal operation of the saw. Before proceeding with the manufacture of a machine from a hand-held circular saw, it is necessary to make a special table. In this case, metal goats and an ordinary old one can be used as a bed. kitchen table. First you need to connect the goats to each other with a wide wooden board at least 50 mm thick, and then fix the kitchen table on this base.

You can make the tabletop itself from two metal (preferably steel) plates with a cross section of about 4 mm. In addition, for this purpose, you can use thick wooden blocks.

It is important not to forget to leave between metal sheets a small gap, the size of which is usually 10-12 mm.

In this case, it is necessary to ensure that the edges of the metal plates are perfectly parallel with respect to each other. Now that the table is completely ready, you can begin to attach the circular saw itself to it. It is important to note that it should be fixed from below, and in such a way that its cutting disc is directly in the gap between two sheets of the tabletop.

How to cook ham in the oven at home

Pain in the lower abdomen during pregnancy, reasons for what to do Can the lower abdomen hurt if pregnant

Protein for muscle gain

The best vitamins for men according to customer reviews

How to lose weight on a vegan diet?