Not a single, both small and industrial enterprise for the production of steel products and woodworking is complete without milling machines. The milling process is the first and key process in the processing of steel and wood blanks.

The most popular among this category of units are horizontal milling machines.

Meanwhile, high processing speed itself can reduce the mounting requirements of the part. The cutting force is lighter, so clamping forces can also be lighter. This can become practical for machining a solid block part. Using an "image border" approach that leaves tabs around a piece to provide it with the rest of the block until processing is done and those tabs are cut off. With this approach, the only fastening components required are the clips that secure the block to the table.

These employees have functions including setting, loading, tool changing and chip removal. Only these changes allow the machine to occupy a smaller area. But the transition also frees up space. The one-off approach to machining leaves fewer storage fixtures. It also leaves fewer finished items to store because each horizontal cycle leaves only one piece to manage instead of three.

1 Features of horizontal milling machine

Horizontal milling machine - one of the first units used for processing metal blanks and various works on wood. With their help, milling, boring, grinding, and sometimes drilling are performed. However, the equipment and specifications similar units are approximately the same.

The horizontal machining center shown here has a rotary changer with tables on opposite sides. One table can be loaded while processing is performed on another table. The thrust-to-weight ratio for the process. In processing, as in an airplane, weight reduction leads to increased productivity. For the processing process, this "weight" takes the form of lead time requirements that inhibit flexibility and inventory requirements that tie up available capital.

High speed horizontal processing approach big parts can help the process to shed those kilos. First, the cycle time is shorter. This means that the store may deliver the finished part without prior notice from the customer. Meanwhile, optimal size batches for the machine is compressed from three pieces to one. The store can operate more efficiently when orders are small. If a customer orders only one part, for example, the shop is no longer left with a hard choice of either running a three-spindle machine at a level less than his full power, or storing additional items in the inventory until the client places another such item again.

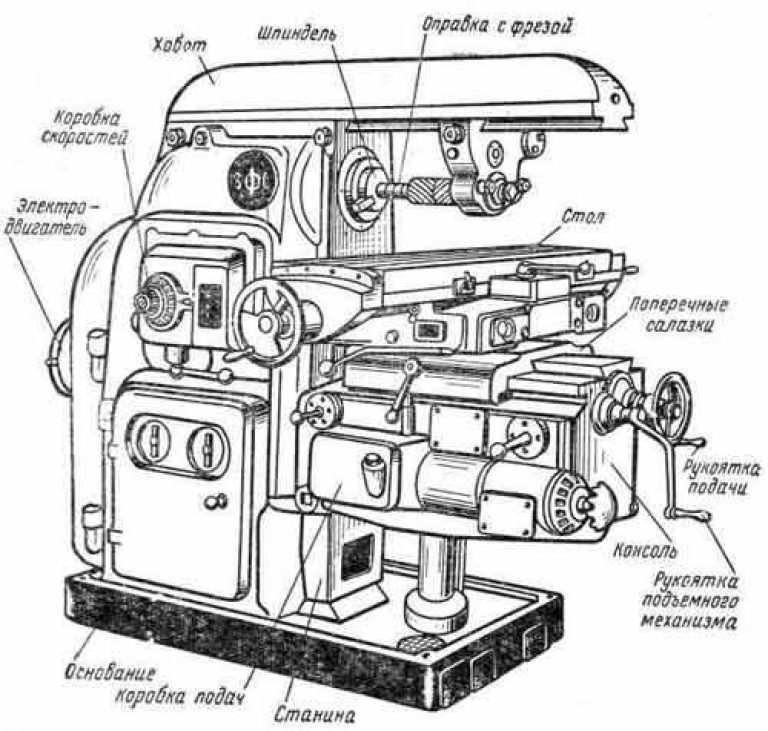

main feature horizontal console milling device - horizontal spindle arrangement. The working surface itself can move at different angles relative to the cutter.

Horizontally milling machine, like other industrial units, has not bypassed technical progress. In addition to the usual machines, where the operator performs all the work with the cutter, new units for metal and wood with CNC appeared(numerical program control).

Milling machine, milling tool, milling machine

A milling machine is a machine for processing metal, wood or plastic. The milling machine removes material with a milling tool rotating at high speed around its own axis while cutting off the contour to be made or move the workpiece accordingly. In the case of milling, the feed is performed vertically or obliquely to the axis of rotation of the tool, and in the direction of the axis of rotation and during rotation, the milling parts rotate around their axis, while the tool runs away from the contour.

Such a device does not require operator intervention in the process of processing workpieces. The operator of CNC machines must have the skills not so much to work with metal or wood as knowledge in the field computer technology and programs.

A 3D model of the future part is created on the computer, the trajectory of the cutter and other technical characteristics are drawn, the program is transferred to the machine, and the machine performs all work on processing the workpiece under CNC control without human intervention.

The main scope of the milling machine is metal processing. Since at least three feed paths are implemented, complex shapes can also be produced in good quality. Application examples are cutouts, chamfers, flat surfaces or profiles, complex bodies such as spindles, worms and gears, to massive milling parts for heavy cutting. Special milling machines are used in the processing of wood and plastics.

- Milling machines are used for machining metals.

- Feeding takes place vertically or obliquely to the axis of rotation of the tool.

- Milling is suitable for complex bodies such as spindles, gears, etc.

1.1 Basic equipment

At its base, this device has a frame on which the rest of the working elements of the unit are located. The frame must be as strong and vibration-resistant as possible, therefore it is made of cast iron or high-strength steel.

The following components and mechanisms are installed on the frame:

- Transmission. With its help, the speed of rotation of the cutter is adjusted;

- console. Device for moving the working surface of the console-milling unit along vertical guides;

- Desktop. This device is equipped with clamping mechanisms or vise for setting blanks for metal or wood. The desktop of the console milling machine is made in such a way that it can be moved in three directions: longitudinally along the guide rails; transversely by moving the slide itself along the console guides; vertically, by moving the cantilever-support mechanism along the bed guides;

- spindle. The main rotating device, on which there is a mandrel for fixing cutters;

- trunk. Housing element on which the suspension with a spindle is attached;

- the milling mandrel is attached to the end of the spindle;

- engine. Industrial units are equipped with a three-phase motor, household units are equipped with a two-phase motor. Engine power must be at least 1200-1500 W, to achieve the desired spindle speed. Horizontally milling machine for metal or wood must maintain a speed of rotation of the cutter from 400 to 4500 rpm;

- optional equipment. In addition to the equipment listed above, the machines can be additionally equipped with CNC boards, chip blowers, magnetic tables for clampless clamping of workpieces.

The basis of the milling machine is the machine body, which carries the other components. Therefore, heavy machines are built on a foundation. In the case of a small milling machine, the frame and stand form a unit, resulting in a high dynamic load capacity. A large milling machine is usually modular.

An important element of the milling machine is the milling head. This works the workpiece simultaneously from three sides. In a conventional milling machine, it carries the main spindle, which is designed vertically or horizontally, as well as a retractable nib. In a universal milling machine, the carriage and head have vertical and horizontal adjustment. This allows you to process the part in any angular position.

1.2 Cutters

It is very important that the horizontal milling machine allows quick change of cutters, since each cutting tool performs only its narrow-profile function. In addition, the attachment of the cutter should be as rigid as possible.

Any vibration or bending of the cutting tool will lead to damage to cutters and workpieces when working on metal or wood. For the strength of the cutter, the mandrel must be mounted on a hanger. The fastening itself is made using rings and nuts.

The basic shapes of modern milling machines were developed in the early days. . The corresponding workpieces are placed on horizontal clamping tables. If a cross table is installed, there is a problem with machines that the console tends to tilt in the end positions. For this reason, heavy and bulky milling parts clamped on the beds, as they rest on the entire surface.

A modern three- or five-axis machining center can produce many parts with small tolerances in a short time. But the old, ordinary milling machine is also used for individual production, small series and for educational purposes today.

- processing of horizontal surfaces by a milling machine 6r81, and its other analogues, is performed using a cylindrical cutter;

- the device performs vertical work on metal or wood with the help of end or disk cutters;

- combined processing requires the change of several cutting tools with different functionality.

To improve the accuracy of execution milling work for metal or wood milling machine 6m82 It is recommended to equip with a CNC board.

One car, many options

The various milling machines cannot be clearly delineated. Flow transitions predominate. However, a major distinction was made on the following criteria. Listed below are some common options no claim to completeness. Standard milling machine with two spindles, swivel head and adjustable longitudinal and transverse guides.

Choice of cutter for work

Milling machine for automatic complete processing. Vertical and horizontal options. Further difference in the body of the machine. The stationary machine prevents tilting movements. For heavy and bulky milling workpieces. The milling unit is guided along the cross beam between two stands.

2 Types of machines

Note that console milling machines are both domestic and professional. They allow you to process workpieces weighing from a few grams to thousands of kilograms.

Based on the size of the equipment, console milling machines for metal or wood are divided into three groups:

High Speed Milling Machining Center

Scans models or stencils, transfers the template to the router, and also cuts any contours into the workpiece without numerical control. Extremely high speed and feed rate, which results in a layer thickness significantly lower than with other grinding methods.

Other metalworking machines

Universal gear system with which all tooth numbers, profile offsets and arbitrary helix angles can be realized. Long milling machine, milling machine, milling machine, milling machine, switch milling machine, drum switching milling machine, etc.

- the first group - light equipment weighing up to 1 ton;

- the second group - medium equipment whose weight is in the range from 1 to 10 tons;

- the third group - heavy units, weighing from 10 to 100 tons;

- There is also a fourth group special machines whose weight exceeds 100 tons.

Any of the above units can be equipped with CNC.

Woodworking machines

Milling Machine, Milling Machine, Chain Milling Machine, etc.

Used milling machines: like new

The service life of a milling machine in industry and crafts is often 20 to 30 years. Regular Maintenance and maintenance, many of the old machines still work the same way as they did on the first day. Therefore, buying a used milling machine - instead of an expensive new car- can be a reasonable economic decision. However, the substance of the milling machine used should be carefully checked before purchase.

The second criterion for dividing console-milling units into groups is the control method. The machine control can be manual, semi-automatic or CNC automatic.

- Manually operated machines require full control from the miller. He must install the workpiece, turn on the machine, bring the cutting tool, adjust the trajectory and speed of the cutter, turn off the machine, remove the part.

- Semi-automatic devices are configured to perform a specific cyclic task. The operator sets the workpiece and starts the machine. The unit automatically performs the programmed cycle and stops. The worker must then remove the part from the latch and turn off the machine.

- Automatic units are equipped with CNC. In this case, the milling machine must be able to use not so much the machine as the computer and related programs. Its task is to create a 3D model of the future part and draw the trajectory of the cutter, as well as other technical specifications machine work. After transferring the numerical code to the machine, installing the workpiece and starting the unit, he will independently perform all the work. The task of the operator is only to observe his work.

Milling machine auction: bidding as commandment reasons

In the case of older models, it is also important to ensure that the software is compatible with new computers, and the licenses are transferred to the buyer. Large-scale industrial events take place here on a daily basis, in which numerous machines and equipment are sold in an online auction, including many milling machines. The benefits are clear: the machines come directly from production, so they don't need start-up time. They are usually available immediately, in good condition and surprisingly cheaper.

2.1 Rules for the operation of horizontal milling units

V technical passport for any model of a console milling machine, the rules for its installation, assembly, and operation features are prescribed. However, there are also general rules relating to any type of manual or CNC equipment. These requirements relate to the organization of the technical process and the observance of safety rules by workers.

To be here is almost a commandment of reason. famous brands milling machines are presented with changing models at almost every online auction. If you do not find the machine you are looking for, we encourage you to register with the Surplex program to receive the newsletter. Then you will immediately know if the required milling machine is available in one of the following online auctions.

Classification of supplied horizontal milling machines

Milling machines and machining centers are important company components in many manufacturing enterprises and factories for the production of various products, such as gears or engine blocks, in single or series production. With over 100 years of experience, we support you with our team specially trained in this field. Our activities include the purchase and sale of used milling machines, horizontal, vertical and universal machining centers and are distributed throughout Europe.

The first task of a production engineer is to correctly select and prepare the installation site for the unit. It is selected depending on the dimensions and weight of the machine. It is also important to have vibration compensation for the unit from the side of the platform on which it is installed. The floor under the machine must be rigid, usually it is poured from durable reinforced concrete. Additionally, supports with compensation cushions can be installed.

Our services for machining centers and milling machines

This allows us to offer you a wide range of choices. Our competent staff is at your disposal to provide you with the best possible service for your purchase or sale. This package includes the removal of the milling machine or processing center, the insured transport on the desired date and commissioning in your company. We will be happy to make an individual offer tailored to your needs in order to integrate the acquisition of your new used machine into your operational sequence.

Assembly and maintenance of any unit must be carried out by a specialist. Operation of the unit with the slightest technical malfunctions strictly prohibited!

Also, the general operational requirements of horizontal milling machines include:

Our competent team will guide you through the entire organizational process from machine selection to the operation of your new machine in your production facilities. In addition to used machining centers and milling machines, we also offer a wide range of products that can be purchased and sold through the same services.

The use of computer numerical control systems in machine tools allows for increased productivity compared to conventional machines and has made it possible to perform molding operations that cannot be performed with a high degree of dimensional accuracy in conventional machines.

- Operator of a horizontal milling unit must work in special clothing. Using the same protective gloves or gloves is strictly prohibited.

- All work on the machine must be performed by the milling machine in protective glasses.

- If the workpiece for milling weighs more than 20 kg, it is installed on the work table using lifting mechanisms.

- If abnormal vibration or oscillation occurs, the machine must be stopped immediately. Most often, such a violation in the work is caused by improper installation of the cutter.

- Often, on devices of a horizontal milling type, an additional chip blower is installed. But even in this case, the worker must carefully clean the machine from chips and dust.

OOO Mir Stanochnika offers to buy imported equipment for metal processing in Moscow. Each product is of high quality production and assembly. We are ready to offer favorable conditions for the purchase and independently deliver the goods to the facility.

Showing all 7 results

CNC horizontal metal milling machine has found wide application in various fields production. It is used for processing large workpieces. In addition, the machine is often operated as a boring machine to create holes of different depths and diameters.

In this type of equipment, the cutting tool is located horizontally, that is, parallel to the floor. The workpiece is fixed on a special table that rotates around its axis, thereby expanding the capabilities of the machine.

Advantages of horizontal milling machining centers:

- Horizontal spindle. Thanks to this, chips do not accumulate around the work surface.

- High speed. Automatic feed tool and blanks allows you to exclude a person from the process of processing materials with a CNC horizontal milling machine.

- High accuracy. The error in the final product is hundredths of a millimeter.

- Ease of use. The machine only needs to set the operating parameters and feed the workpieces.

Benefits of purchasing CNC horizontal milling machines from us

The company World of the Machine Tool provides customers with the maximum convenient conditions purchases of CNC machines:

- Help with choosing. We will offer a CNC horizontal milling machine and accessories for it at a favorable price, based on the needs of a particular enterprise. To do this, our specialist will study the drawings of manufactured parts.

- Delivery of equipment.

- A wide range of products, the presence of most machines in stock.

- Formation commercial offer within a working day after contacting the company.

How to understand: will the kitten be fluffy?

What kind of light alcohol can be drunk for pregnant women: the consequences of drinking

Why do the legs swell in the ankles and ankles of the feet in pregnant women: causes and methods of treatment

The wedding of Prince Harry and Meghan Markle: scandalous and secret details of the marriage (photo) The future marriage of Prince Harry year NTV

How to close white plums for the winter