Mechanical restoration is a process during which the dimensions and configuration of workpieces and parts are changed. If we talk about metal products, then special cutting tools are used for their processing, such as cutters, broaches, drills, taps, cutters, etc. All operations are performed on metal-cutting machines according to the technological map. In this article we will learn what are the methods and types of mechanical processing of metals.

Processing methods

Machining is divided into two large groups. The first includes operations that occur without removing the metal. These include forging, stamping, pressing, rolling. This is the so-called using pressure or impact. It is used to give the desired shape to the workpiece. For non-ferrous metals, forging is most often used, and for ferrous metals, stamping is most often used.

The second group includes operations during which part of the metal is removed from the workpiece. This is necessary to give her required sizes. Such machining of metal is called cutting and is performed using the most common processing methods are turning, drilling, countersinking, grinding, milling, reaming, chiselling, planing and broaching.

What is the type of processing

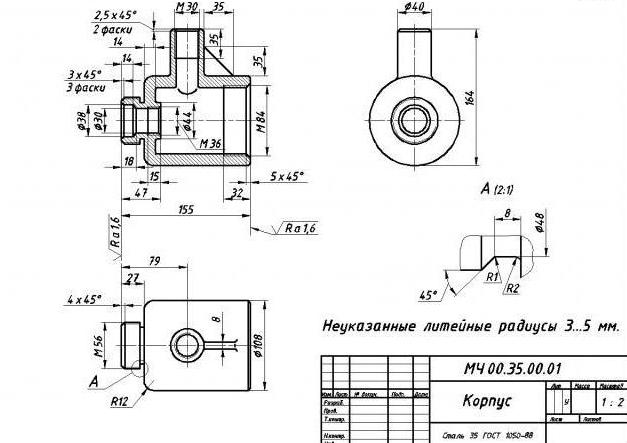

Manufacturing metal part from a blank is a laborious and rather complicated process. It includes many different operations. One of them is mechanical processing of metal. Before starting it, make up technological map and make a drawing of the finished part indicating all the required dimensions and accuracy classes. In some cases, a separate drawing is also prepared for intermediate operations.

In addition, there is roughing, semi-finishing and finishing machining of metal. For each of them, the calculation and allowances are performed. The type of metal processing as a whole depends on the surface to be treated, the accuracy class, the roughness parameters and the dimensions of the part. For example, to obtain a hole according to the H11 grade, rough drilling is used with a drill, and for a semi-clean reaming to the 3rd accuracy class, you can use a reamer or countersink. Next, we will study the methods of mechanical processing of metals in more detail.

Turning and drilling

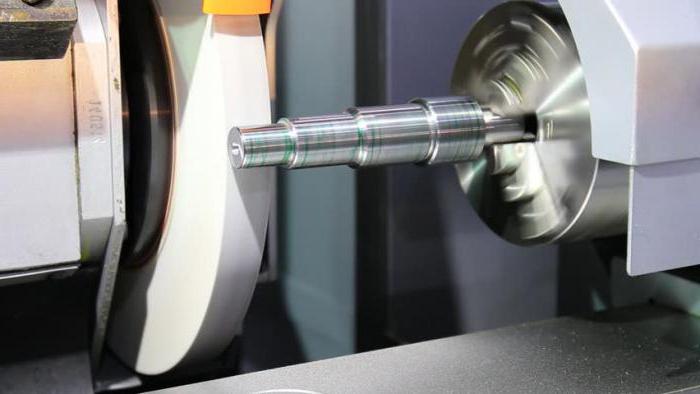

Turning is performed on machines of the turning group with the help of cutters. The workpiece is attached to the spindle, which rotates at a given speed. And the cutter, fixed in the caliper, makes longitudinal-transverse movements. In new CNC machines, all these parameters are entered into the computer, and the device itself performs necessary operation. In older models, for example, 16K20, longitudinal and transverse movements are performed manually. On lathes it is possible to turn shaped, conical and cylindrical surfaces.

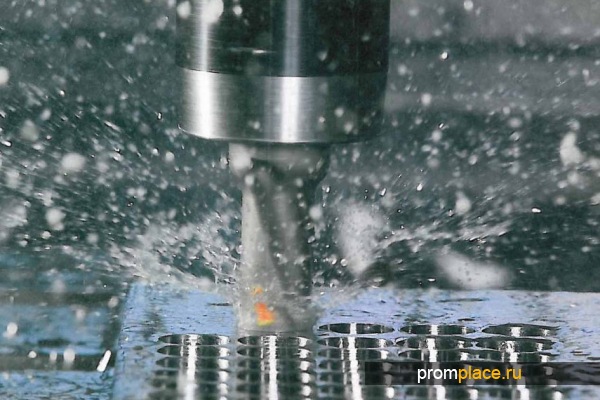

Drilling is an operation that is performed to obtain holes. The main working tool is a drill. As a rule, drilling does not provide a high accuracy class and is either rough or semi-finishing. To obtain a hole with a quality below H8, reaming, reaming, boring and countersinking are used. In addition, after drilling, cutting can also be performed internal thread. Such machining of metal is performed using taps and some types of cutters.

Milling and grinding

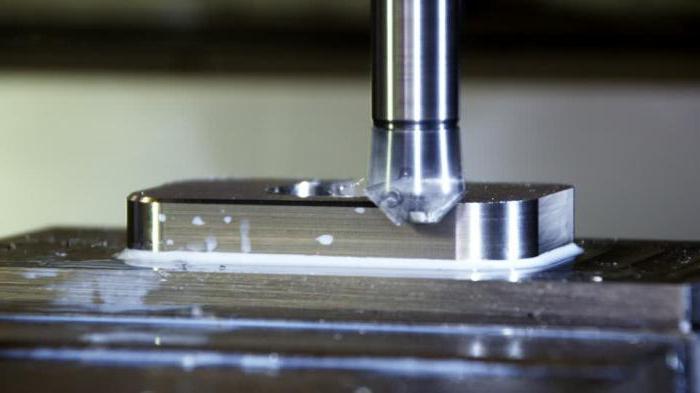

Milling is one of the most interesting ways of metal processing. This operation is performed using a wide variety of milling cutters on milling machines. There are end, shaped, end and peripheral processing. Milling can be both rough and semi-finishing, and finishing. The smallest quality of accuracy obtained during finishing is 6. With the help of cutters, various dowels, grooves, wells, undercuts are machined, profiles are milled.

Grinding is a mechanical operation used to improve the quality of roughness, as well as to remove an excess layer of metal down to a micron. Usually, this processing is the final stage in the manufacture of parts, which means it is finishing. For cutting, abrasive wheels are used, on the surface of which there is a huge number of grains that have different shape cutting edge. During this processing, the part is very hot. In order for the metal not to be deformed and not chipped, cutting fluids (LLC) are used. Machining of non-ferrous metals is carried out with the help of diamond tools. This allows you to ensure the best quality of the manufactured part.

Most machine parts are made by machining. The blanks of such parts are rolled products, castings, forgings, stampings, etc.

The process of machining parts by cutting is based on the formation of new surfaces by deformation and subsequent separation of the surface layers of the material with the formation of chips. The part of the metal that is removed during processing is called the allowance. Or, in other words, the allowance is an excess (in excess of the drawing size) layer of the workpiece left for removal by a cutting tool during cutting operations.

After removing the allowance on metal-cutting machines, the workpiece acquires the shape and dimensions corresponding to the working drawing of the part. To reduce the labor intensity and cost of manufacturing a part, as well as to save metal, the size of the allowance should be minimal, but at the same time sufficient to obtain good quality parts and with the required surface roughness.

In modern mechanical engineering, there is a tendency to reduce the volume of metal cutting by increasing the accuracy of the original workpieces.

Basic methods of metal cutting. Depending on the nature of the work performed and the type of cutting tool, the following metal processing methods are distinguished by cutting: turning, milling, drilling, countersinking, slotting, broaching, reaming, etc. (Fig. 12).

Turning- the operation of processing bodies of revolution, helical and spiral surfaces by cutting with cutters on machines of the turning group. When turning (Fig. 12.1), the workpiece is given a rotational movement (main movement), and the cutting tool (cutter) is given a slow translational movement in the longitudinal or transverse direction (feed movement).

Milling- a high-performance and widespread process of processing materials by cutting, performed on milling machines. The cutter receives the main (rotational) movement, and the workpiece receives the feed movement in the longitudinal direction (Fig. 12.2).

drilling- the operation of processing the material by cutting to obtain a hole. The cutting tool is a drill that performs a rotational movement (main movement) of cutting and an axial movement of the feed. Drilling is done on drilling machines(Fig. 12.3).

Planing- a method of machining planes or ruled surfaces. The main movement (rectilinear reciprocating) is performed by a curved planer, and the feed movement (rectilinear, perpendicular to the main movement, intermittent) is the workpiece. Planing is carried out on planing machines (Fig. 12.4).

chiselling- a method of processing planes or shaped surfaces with a cutter. The main movement (rectilinear reciprocating) is performed by the cutter, and the feed movement (rectilinear, perpendicular to the main movement, intermittent) is performed by the workpiece. Slotting is carried out on slotting machines (Fig. 12.5).

grinding- the process of finishing and finishing of machine parts and tools by removing a thin layer of metal from their surface with grinding wheels, on the surface of which abrasive grains are located.

Rice. 12

The main movement is rotational, which is carried out by a grinding wheel. With circular grinding (Fig. 12.6), the workpiece rotates at the same time. With flat grinding, the longitudinal feed is usually carried out by a workpiece, and the transverse feed is carried out by a grinding wheel or a workpiece (Fig. 12.7).

Stretching- a process, the productivity of which is several times greater than that of planing and even milling. The main movement is rectilinear and less often rotational (Fig. 12.8).

In many areas of industry, a process such as mechanical processing of metals is indispensable. Machines, machine tools and tools are constantly being improved, operations are carried out faster and faster from year to year. On the manufacturing enterprises work machines specialized and general purpose. With the help of such machines, it is easy to cut blanks of sheet, profile or other types. Methods for separating the material are also widely used:, cutter, band saw and others.

Technological processes of mechanical processing of metals

Machining of metals is a rather complex process, which results in parts of certain sizes and given shapes. There are two ways of mechanical action on the material. The first method is expressed in the removal of the top layer from the working surface. In this case, the depth can be different depending on the requirements for the dimensions of the part. In the second method, the material is not damaged in any way during the initial impact, it can only be pressed, stamped, forged, rolled. As a rule, this method of exposure is followed by the stage further work above the detail.

A complex of technological operations for giving a certain size and shape to parts provides different kinds mechanical processing of metals. The main ones are turning, milling, planing, grinding and drilling. Now all operations are carried out on modern multifunctional machines. So, the same machine can perform successively different functions. To do this, you just need to install the programs correctly and apply them in time. the right tools. Many names of tools speak of their purpose: a drill for drilling, a milling cutter for milling, and so on.

All types of mechanical processing of metals are diverse, they have their own differences and nuances. The most modern way that meets high-tech requirements is processing on lathe. They are automatic, semi-automatic and CNC. As a rule, milling is used to process shaped or flat surfaces. different types: end, end or shaped.

Now many modern industries offer metal machining services. There are also a lot of machines for carrying out these works, but time dictates its own conditions, so the machines are constantly being improved. So, primitive machines have almost everywhere been replaced by automatic lines. Dynamically developing enterprises are trying to expand production as much as possible with the help of high-tech equipment. Thus, with a high degree of probability, it is possible to guarantee the high quality of products and the minimum order processing time. Any production wins if it accepts for priority good production of quality products, regardless of the volume of the order and its complexity.

Equipment for mechanical processing of metals

As a rule, metal machining services are performed quickly and in full compliance with all standards when qualified personnel take up the work. In addition, each promising enterprise provides optimal conditions for work: sufficient availability of production facilities, necessary equipment. It should be noted that in order to successfully and quickly complete the order, the staff needs to provide machine tools, welding and technological equipment.

So, to perform the work, you should choose the right equipment for the mechanical processing of metals. Of course, for the main work - chip removal, the turning and milling direction is responsible. The most common equipment in this area is CNC turning centers and centers. Modern models make it possible to manufacture parts that meet the highest requirements regarding geometric parameters product and surface roughness. The advantages of new models of machines are: accuracy, speed, improved parameters of working areas.

The equipment for mechanical processing of metals is currently presented in a wide range. Among the variety of models, there are both the most popular and quite rare (relatively frequent applications). For example, a carousel machine that can process a part with a diameter of up to nine meters. Such a machine is not used often and not everywhere. Quite in demand are jig boring machines that provide high-quality boring at any angle and boring machines with rotary tables. Each enterprise, whose field of activity is mechanical processing of metal, tries to have milling, gear-hobbing, radial, horizontal and vertical drilling machines available.

How to cook ham in the oven at home

Pain in the lower abdomen during pregnancy, reasons for what to do Can the lower abdomen hurt if pregnant

Protein for muscle gain

The best vitamins for men according to customer reviews

How to lose weight on a vegan diet?