Turn your laser pointer into a cutting laser with a DVD burner emitter! This 245mW laser is very powerful and is the perfect size for your MiniMag!

Please note that not all laser diodes (not all DVD or CD-RW models) are suitable for making this laser cutter.

CAREFULLY! As you know, lasers can be dangerous. Never point at a living creature! This is not a toy and should not be treated like a regular laser pointer. In other words, don't use it for presentations or animal play, don't let kids play with it. This device should be in the hands of a reasonable person who is aware of and responsible for the potential danger that the sign represents.

Laser cutting of metal and its application

Another risk factor for the self-assembly torch is the high voltage laser feed. The voltage is typically between 000 and 000 volts at about 50 mA. This voltage in this current can be quite life-threatening. When building a laser cutter, you should be aware of these hazards and take appropriate precautions to reduce the risk as little as possible. Full self-development of a laser cutter is not only technically and budgetary risky, but also because of the dangerous potential. Anyone who has left the factory again will be glad that professional laser cutters for the hobby area are already around € 000.

Handle laser radiation with extreme care. Any hit in the eye, due to refraction in the lens, has time to burn out a few cells in the eye. A direct hit will cause loss of vision. The beam reflected from the mirror surface is also dangerous. Scattered is not so dangerous, but still does not add visual acuity.

With a laser cutter, you can carry out interesting experiences. Lighting matches is not the most effective option. You can burn through paper by directing the beam at balloon you can see how it pops. Preferably a bead dark color, green or blue, red does not burst. A focused beam leaves a rather deep groove on black plastic, and a small spot of white or mirror color appears at the focus point in transparent plexiglass. If such a diode is attached to the head of the plotter, then you can engrave on plexiglass.

Gas lasers, mainly CO2

At 330 ohm we have a laser cutting service. While laser cutting offers many benefits such as good cutting accuracy, repeatability, and economy, there are a few things to consider before starting a project. These considerations are important if you want to use our service or use a laser cutter at home.

Laser cutters only support vector files

Simple photographs or non-vectorized drawings are not enough to create an object by laser cutting, because they do not contain the information necessary for cutting or engraving machines. You need a vector file. You can find files already made in vectors on dedicated websites or ask a designer to make them. Regardless of the software you use, you must not forget the design principles that must be followed, depending on the material you want to use.

For starters, you'll need a faulty DVD-RW (with faulty mechanics, not a laser). Although not every DVD can be broken, for example, Samsung is not suitable at all, there the diodes are unpackaged and the crystal is not protected by anything, it is disabled by simply touching the end. LG is best suited, only different drives have different diodes in power.

Find the right material for your project

Lastly, make sure your design is in the correct format so you can submit it to a laser cutting service. Each project is unique and each project must find its right material to become an object. To do this, you need to know the properties of each material. On the contrary, if your budget is tight or you want to try a design prototype, a box might be a good choice.

Converts user-friendly laser cut design into laser cut proof

You must also consider the incision the laser creates as the material passes through and how your material will react to the heat of the laser. Once your design is ready, reformulate it! Is it suitable for laser cutting? Narrow details, extra detail, etched wide surfaces can damage the end result of your item or increase the price of your design. Keep in mind that if you optimize the line of work, you will get faster cuts and save money.

The power of the installed diode can be determined by the following characteristic of the drive: you need to look at what speed it writes dual-layer discs, if on the tenth, then the diode power is one hundred and eighty - two hundred, if on the sixteenth - two hundred and fifty - two hundred and seventy.

If there is no faulty DVD drive available, then first try to purchase a separate laser on the radio market. If it does not work out then we get a faulty DVD from junk dealers.

What materials and mechanisms will be required

First, intelligent designers will find The best way make the most of the materials. Take a close look at your design and discard anything that might be considered redundant. You must also remove double lines. The laser, as powerful and precise as it can be, has no brain and doesn't know that you don't want to cut the same line twice! This may seem obvious, but be careful when creating your design in software. The sources must also be vectorized, otherwise they will not be included in the template.

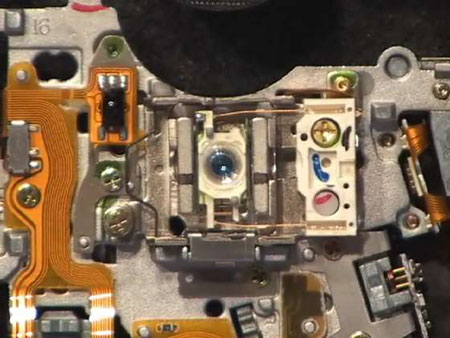

although DVD drives are different, each has two rails on which the laser carriage moves. Remove the screws, release the guides and remove the carriage. Disconnect connectors and flat ribbon cables.

Remember that when designing assemblies

Finally, we strongly recommend reducing bitmap engraving as much as possible, as this is the most time-consuming operation. One of good features laser cutting is that parts that are cut can be easily assembled. To do this, you must plan for the minimum space between each part of the assembly.

It took some time, but it the only way prepare such a project. If you want parts to fit together and make sure they stay connected, you absolutely need to add them to nodes. Knots are small protrusions located in the grooves or tongues of the piece to compensate for changes in material thickness and kerf. The nodes are compressed when the parts are assembled and they concentrate the friction at certain points rather than the entire surface of the groove. This way the grooves can be larger without detaching, allowing the pieces to stay together.

After removing the carriage from the drive, start disassembling the device by unscrewing the screws. There will be a lot of small screws, so please be patient.

Disconnect the cables from the carriage. There may be two diodes, one for reading the disc (infrared diode) and the actual red diode, with which the burning is carried out. You need a second one.

Installation of laser cutting of metal - the principle of operation

To make sure the pieces stay fixed, you should place nodes on each side of the slot opposite the other. Depending on the length of the slot, you can place multiple nodes. This minimizes the stress that can occur if nodes are misaligned or missing. They should be smooth and long enough to make blocking easier. Depending on the density of the material, the width of the knots can be increased or decreased. The higher the density of the material, the smaller the width of the knots.

A printed circuit board is attached to the red diode using three screws. Use a soldering iron to CAREFULLY remove the 3 screws.

You can test the diode using two AA batteries, taking into account the polarity. You will have to pull the diode out of the case, which will vary depending on the drive. The laser diode is a very fragile part, so be extremely careful.

Both methods are a powerful tool useful for designers who now need to design, prototype, iterate quickly and quickly. And it's a real pleasure to create products that combine these two methods. Sometimes it can even match your design idea better than 3D printing. If you want to learn more about laser cutting, stay close to our social networks because soon we take courses on this subject.

What is laser cutting and laser cutting?

laser cutting, industrially applied to metals, began in the early 80s and is today positioned as one of the main alternatives for cutting sheet metal. Laser cutters are devices that use one of the effects of quantum mechanics, induced or stimulated emission of particles, to create a coherent beam of light that interacts with a piece to produce a piece with the size, shape, and clarity we desire.

This is what your diode should look like after "freeing".

Remove the sticker from the body of the purchased AixiZ laser pointer and unroll the body to the top and bottom. Inside the top is a laser diode (5 mW), which we will replace. I used an X-Acto knife and after two light strokes, the native diode came out. In fact, with such actions, the diode can be damaged, but I have previously managed to avoid this. Using a very small screwdriver, knocked out the emitter.

Benefits of using laser cutting

Buy second hand laser cutter

The advantages of laser cutters over traditional cutting systems such as punching machines in terms of accuracy, safety and results have made this type of technique gain an important presence in workshops dedicated to the industrial process of metals. However, while the demand for this type of cutter has made their prices more affordable, purchasing them can be an important economic cost. To minimize this potential problem, many workshops and individuals are considering purchasing a second hand laser cutter.

I used some hot glue and carefully installed the new DVD diode in the AixiZ case. With pliers, I SLOWLY pressed the edges of the diode towards the case until it was flush.

Purpose of laser equipment

The price of a used laser cutter on sale can be much lower than new car, and this does not mean that the results will be worse. They can be used for both decorative parts and mechanical components, bearings, boxes, gears, etc.

Before you turn to buying a machine, it is good to understand the basic parameters of choosing a laser cutting machine. There are other types of lasers for cutting other materials. The machine can be used for. It can also be used on paper, cardboard, heavier cardboard box or cardboard. engraving on the same materials or leather. It is also possible to record on some metals such as aluminum if they are surface treated. There are two alternatives for cutting metal.

Make sure the polarity of the diode is correct before you install it and connect the power! You may need to shorten the wires and adjust the beam focus.

Install the laser pointer in a suitable two-battery flashlight. Insert the batteries (AA) into place, screw on the top of the flashlight (diffuser), including your new laser pointer! Plexiglas must be removed from the reflector. Attention!! Laser diodes are dangerous, so do not point the beam at people or animals.

Machine dimensions can be classified as follows. The cover protects from the laser and also helps to prevent gas emissions from environment. A laser with higher power has greater durability and also cuts faster. They are ideal models for creators; Large dimensions: above 120 cm, the machines are usually "open", that is - it does not have a cover to protect against laser or gases. Now that we know the main characteristics of laser cutting machines, the question is: which machine meets the needs of the creators?

Have you ever thought about the fact that you can engrave yourself on a leather purse or smartphone case, put a photo on wooden surface? Or maybe you have always wanted to cut details from various materials for creating beautiful crafts or housings for robots? But all this can be done with the help of compact desktop laser engravers and cutters. Let's look at a few of these devices.

Let's take a look at this in the next article. Electronics repair has all but disappeared; in the event of a break, they often give us no choice but to buy a new phone. Revaluation of the means of production: Karl Marx dreamed of it, and a researcher from the Massachusetts Institute of Technology. To do this, they have a whole apparatus of digital production tools, in particular machines that, when applying layers of plastic on top of each other, convert the file into a very real object - a laser cutter that can cut wood or iron, digital cutters, etc. students love it, so much so that they return to the lab in their spare time to give their creative imaginative wings and make their own projects come true.

What can a laser engraver/cutter be used for?

With the help of an engraver, you can create commemorative inscriptions and drawings on various objects. The engraver can accurately draw on materials such as paper, cardboard, leather, fabric, felt, wood, plywood, hardboard, plastic and acrylic. It is also possible to engrave on aluminum and glass and make printed circuit boards using some tricks. However, you need to remember that you will not be able to engrave on metal and ceramic products.

This minor marketing lacquer contributed to its growth by imposing the "sign" of the link. Designed for easier access to machines, the first lab was reserved for students; but the door quickly opened, expanded access, and helped democratize personal digital production on a global scale. In this way, prototyping, apanagia of the industry and experts as designers became available also to individuals. And handiwork, often seen as a tedious task, became attractive.

"We're talking about creating, not consuming." This is Gershenfeld's credo, against the economic logic that has chosen growth and consumption as indestructible and inescapable dogmas. Doing it yourself implies necessarily assigning objects; which represents a real revolution in the context in which we live today, the purchase of thinner devices filled with patented technologies that cannot be changed or improved, and is also prohibited because they belong to someone.

The cutter will allow you to cut out the necessary contours from paper, cardboard, leather, fabric, felt, wood, plywood, hardboard, plastic and acrylic with great accuracy. When working with durable materials such as plywood, the cutter will replace your jigsaw, and when working with the rest of the listed materials, scissors. However, you need to remember that you will not be able to cut transparent and metal objects.

Not to mention that some of these devices are designed to go to waste after a certain period, in the best "disposable" style supported by the theory of programmed obsolescence. your button washing machine does not work? With a computer-aided design program, you create a design, small design, and then the 3D printer models the material and creates a tangible object. Do you need a shelf for your home that you won't find in any store? Simple: you buy wood and make shelves made with a laser saw.

When working with a laser cutter / engraver, do not forget that the laser is not a toy. During operation, it is imperative to protect your eyes with the help of special glasses, which sometimes come with the device, and sometimes they need to be purchased separately.

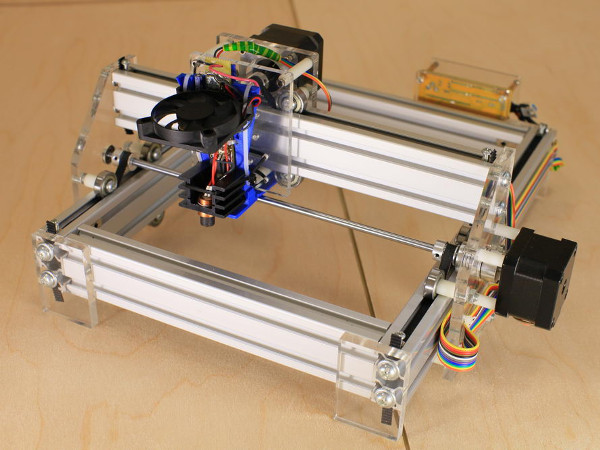

Endurance DIY

Endurance DIY is a small desktop laser engraver / cutter from the Russian-American company Endurance with a size of only 31x25 cm and a working area of 210x297 mm.

The device uses lasers own production L-Cheapo, which, by the way, have universal fasteners that allow you to mount the laser on many 3D printers and CNC devices. The working wavelength of the laser is 445 nm, the engraving accuracy (grain) is 0.1 mm, and the cooling is air. The engraving speed, as well as the speed and depth of cut, depends on the laser power, which can be three options:

| Power | 2.1W | 3.5W | 5.6 W |

| Maximum engraving speed | 20 mm/sec | 40 mm/sec | 50 mm/s |

| Maximum cutting speed for 1mm thick cardboard | 3 mm/sec | 5 mm/sec | 6 mm/sec |

| Maximum cutting depth of plywood specimen | 3 mm | 5-6 mm | 7-8 mm |

| Maximum cutting depth of acrylic sample | 3 mm | 4-5 mm | 5-8 mm |

When purchasing this desktop laser engraver/cutter, you can choose one of the listed laser powers. The price will depend on this: a device with a 2.1 W laser will cost you 29,900 rubles, with a 3.5 W laser - for 37,400 rubles and with a 5.6 W laser - 49,400 rubles. Comes with engraver/cutter and power adapter. Please note that goggles are not included.

To control the Endurance DIY laser engraver / cutter, you can always download the full software package on the manufacturer's website.

Full description, a large number of See photos and videos on the manufacturer's website.

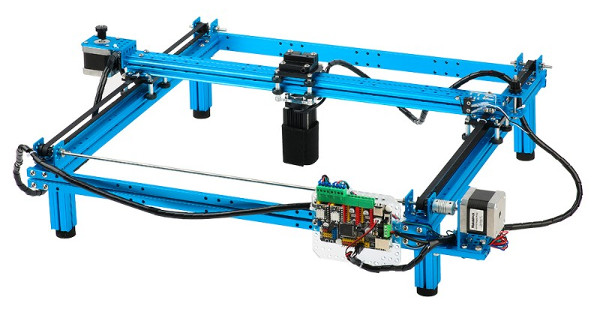

LaserBot

This laser engraver/cutter is manufactured by the Chinese company Makeblock. It uses an Arduino-compatible microcontroller. By the way, in addition to this, the company produces Arduino-compatible robot designers, which I wrote about earlier in the article "".

This unit comes with a 1.6W 445nm laser. The working area here reaches 383×367 mm. Engraving accuracy is the same as the previous device - 0.1 mm. The maximum speed of the laser head is 200 mm/sec.

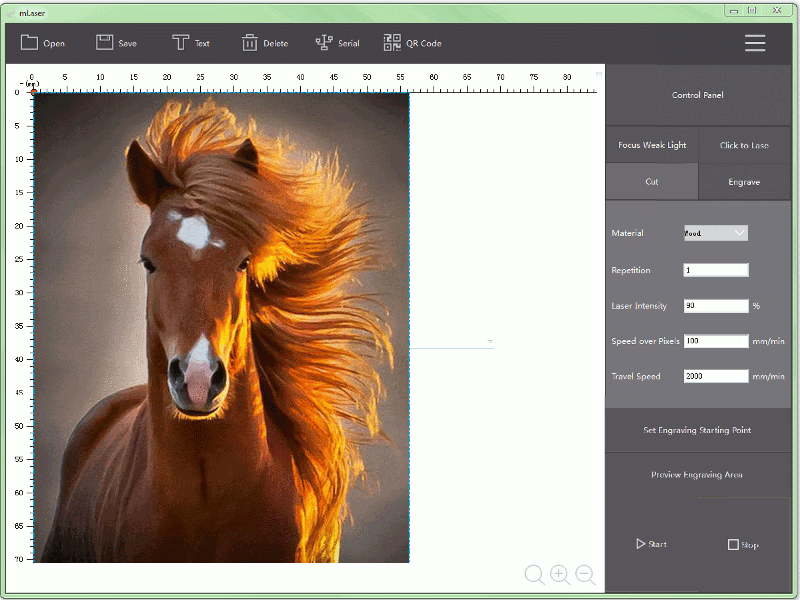

For this cutter/engraver you will be able to use mLaser's proprietary software, which contains a simple and an expert mode. The program supports raster and vector drawings in PNG, JPG, BMP, SVG and DXF formats.

The cost of such an engraver/cutter is about $350, excluding shipping and tax. You can order it on the manufacturer's website. Complete with the device and power adapter you will receive goggles and 4 sheets of colored paper.

If you need such an engraver/cutter but with a more powerful laser, you can purchase turnkey solution from the Endurance company, about which it was written above. The cost of a LaserBot with an L-Cheapo laser with a power of 2.1 W will cost 39,900 rubles, a power of 3.5 W - 44,900 rubles, a power of 5.6 W - 56,900 rubles. Details about this kit.

Dobot Magician

The next device allows you to do much more than just engrave, because it is a robotic arm to which, in addition to a laser, you can attach a 3D printing head, a claw, a pencil or brush, a suction cup and much more. But cutting materials, unfortunately, will not work due to the low power of the laser that comes with the robotic arm - only 0.5 W. However, if you have a strong desire, you can attach a higher power third-party laser here.

![]()

To date, the robotic arm is sold in two versions: Dobot Magician and Dobot M1. The Dobot M1 is a very accurate (0.02mm) industrial version, but it's very expensive ($2999) and so I won't cover it here. Dobot Magician is a desktop robotic arm that is suitable for home, educational institutions, and small industries. The cost of the complete set, which includes the Dobot Magician with laser and goggles, is $1,159, excluding shipping. In addition to the laser, this includes a 3D printing kit, a claw, a joystick, a suction cup, a drawing kit, Bluetooth and Wi-Fi modules.

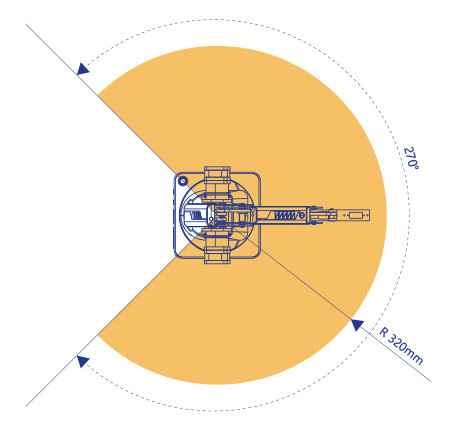

The technical characteristics of the assembled robotic arm with laser are as follows: positioning accuracy 0.2 mm, laser power consumption 0.5 W, laser type 405 nm (blue laser), maximum coverage 320 mm, maximum rotation angle 270°, see Fig. drawing below.

Order Dobot Magician and see all specifications available on the manufacturer's website.

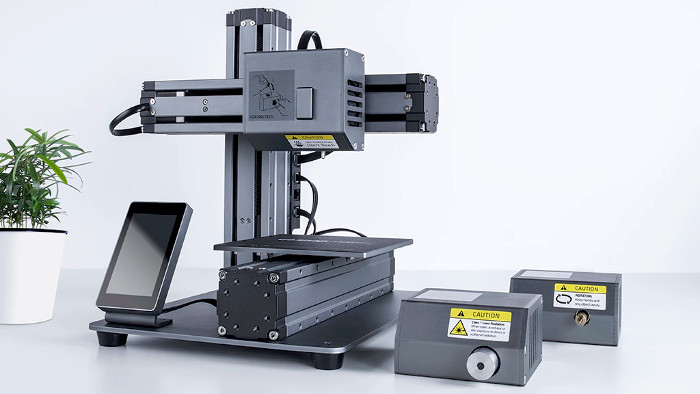

snapmaker

This device is also multifunctional: in addition to engraving, it can carry out 3D printing and woodcarving. For each of these three processes, Snapmaker has a separate head. Unfortunately, you will not be able to cut materials, because. the laser included is weak, only 0.5 watts.

The 3D printing and laser engraving kit costs $369, not including shipping. A set with all three heads will cost $439. Goggles are included. To order Snapmaker or find out more, visit the project's Kickstarter page.

The advantages of this device include also quick assembly and disassembly (only 10 minutes).

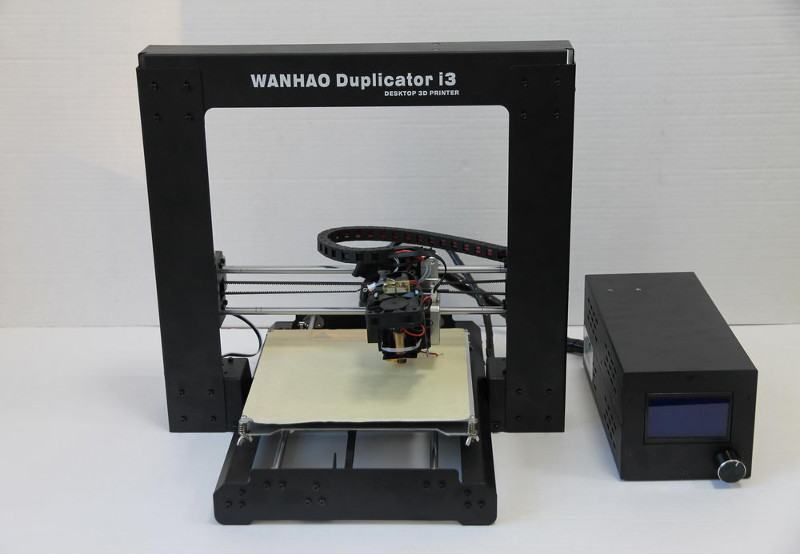

This kit is also offered by Endurance. Here, the Wanhao DuPlicator i3 3D printer is used as a platform, on which the L-Cheapo laser will be installed. Thanks to this, you can not only engrave and cut, but also use the 3D printer for its intended purpose.

The dimensions of the working area here are 200x200 mm, and the engraving accuracy is 0.1 mm. A set with a 2.1 W laser will cost you 49,900 rubles, with a 3.5 W laser - for 57,400 rubles, with a 5.6 W laser - for 69,400 rubles. Delivery and installation is free only in Moscow. Details on the kits can be found on the official page. And don't forget to get safety goggles.

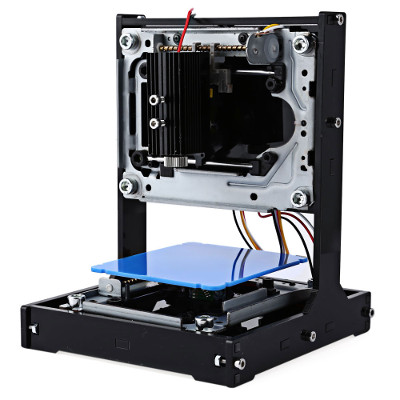

Engraving machines Neje

These kids only know how to engrave, because there is a low laser power. But it is impossible to bypass them, because the price for these machines on the Internet starts at about 3,500 rubles. The small Neje engraving machine is perfect for a first introduction to laser engraving technology at home. In the first picture below, the NEJE DK-5 Pro machine (smaller size), and in the second picture, the DK-8-KZ machine (neater view).

The NEJE DK-5 Pro is slightly smaller (its size is 13.0x13.5x16.5 cm) than the NEJE DK-8-KZ (its size is 14.5x16.0x19.0 cm). But the NEJE DK-8-KZ machine has a neater look and can be equipped with a 0.5 or 1 W laser. The NEJE DK-5 Pro laser machine can only have 0.5W.

The engraving area of both machines is only 38x38mm, so you won't be able to make large paintings or engrave the entire surface of a smartphone case.

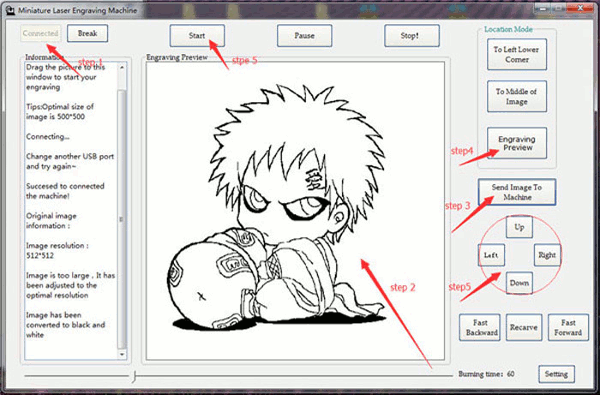

The program for these engravers is simple and free. It can only work with 512×512 pixel bitmaps in JPG, BMP and PNG formats.

The engraver comes with goggles, 2 USB cables (one for power, one for data transfer), a hex wrench, a microSD memory card (contains driver, software, etc.) and a quick start guide. The package contents may vary depending on the store where you buy the engraver.

Outcome

I hope this article helps you make right choice when buying an engraver / cutter. If you know of any other interesting devices for engraving and cutting, write about it in the comments.

The legacy of the Atlantean civilization

What is the dream of the red stone

Dream interpretation of the royal family. The king dreamed. Old Russian dream book

What to do to increase hemoglobin during pregnancy: products, pills, general recommendations Products to increase hemoglobin in pregnant women

The concept of negativism: symptoms and features of manifestation in children and adults