Widespread now open system heating has a number of serious disadvantages. One of them is direct contact with the atmosphere. As a result, a coolant flows through the pipes, in which there is air. Air bubbles can gradually cause corrosion of the metal elements of the heating system, as well as cause the “noise” of the coolant. All this can be avoided by just making a closed heating system of a private house.

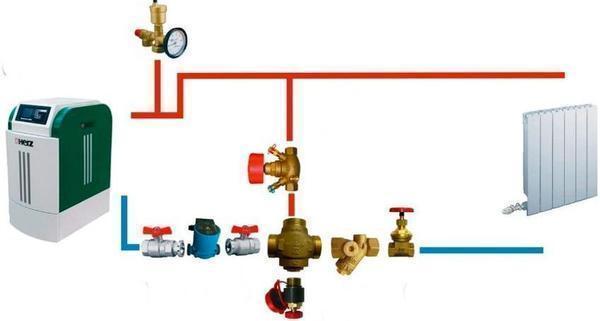

The main feature of such systems (and what does not have open circuit) - complete isolation from the influence of the environment. The closed heating system, which you can do with your own hands, includes the following elements:

- boiler;

- automatic air valve;

- thermostatic valve;

- heating radiators;

- expansion tank;

- balancing valve;

- ball valve;

- pump and filter;

- manometer;

- safety valve.

How does it work water heating closed type? If the temperature of the coolant rises, then excess liquid is squeezed into the expansion tank. When the temperature drops, the liquid returns to the system, i.e. pressure is maintained within a fairly narrow range.

For efficient circulation of the coolant, a pump is used (an open system may have natural circulation). True, there is also a minus here - in the absence of power supply, a closed system will not be able to function normally (lack of electricity for a country private house is a very urgent problem). But the advantages of using a “pump” more than compensate for the disadvantages - for both an apartment and a private house, installation of additional heating systems is possible. In particular, you can make a warm floor.

Circulation pump is installed on the return pipe ("return") in front of the heating boiler. An expansion tank is also mounted here. This arrangement of these important elements allows you to be uncritical about the diameter of the pipes used for installation and the observance of the slope, which open water heating must have.

As a result, less time and materials are spent on the installation of such a heating system (for example, it is no longer necessary to insulate the pipeline, since the expansion tank is installed next to the boiler). However, you should not "abuse" such advantages. This is especially true for the slope (it’s better to do it anyway) - if it is observed, the system will at least work in the event of a power outage, but it will still work, i.e. defrosting does not threaten her.

In the video below you can see a detailed example of the organization of closed-type heating using solid fuel and electric boilers.

The closed heating system is isolated from air penetration. However, its operation does not provide 100% tightness: air can fill the pipes, for example, when adding a coolant to the system. In this case, it will accumulate at the top points. You can get rid of it by means of a Mayevsky crane or float diverters operating on an "automatic". The air already dissolved in the water is removed using special separators installed directly in the pipeline.

Good results in terms of saving heat gives the use of a thermostat. It turns on the main consumer of electricity (pump) only when the temperature in the room drops below a predetermined limit.

How to choose a boiler for closed heating

The scheme of closed heat supply of a private house provides for the use of any type of fuel. It can be gas (the most efficient and profitable option), electricity, diesel or solid fuel.

It is necessary to pay attention to the power of the boiler. The approximate value for an insulated room with ceilings up to 3 meters high is 1 kW per 10 "squares" of a private house.

The figure above is very, very approximate. It all depends on many factors: the material from which the building is built, the quality of the insulation, the presence (absence) of a heated attic or attic. The efficiency of heating is affected by the number of windows and how well they were installed. Therefore, a competent thermal calculation is required, which a qualified engineer can do.

The heating boiler can be single-circuit, double-circuit or with a boiler. As practice shows, in general country houses have a small area and, consequently, a small need for hot water. From this point of view the best choice there will be a double-circuit boiler (its installation is simple), capable of heating about 10 liters of water to + 30C in half an hour. Boiler with storage boiler more comfortable - it constantly "has" ready-made several tens of liters hot water– no permanent filling required.

Expansion tank for closed type heating

Most often, in the heating system of a private house, water plays the role of a coolant. As the temperature increases, the volume increases and the pressure increases. If a closed heat supply scheme is used, then the pressure can overcome a certain critical value and then the elements of the heating system will be destroyed.

To avoid such a development of events, the installation of a heating system for a private house involves the use expansion tank.

Features of the design of the tank of a closed type

Any tank of this type has two main parts: a body made of metal and an elastic membrane inside.

The scheme of its operation is quite simple - air is pumped into the upper half of the tank (in expensive modifications - inert gas), the lower part is filled with water from the pipeline.

When the coolant is heated, the pressure rises, while the membrane “bends”, condensing air or an inert gas. Safety valves are available to prevent dangerous situations. When the pipeline with water cools down, the air pressure on the membrane becomes stronger than the coolant pressure, and it fills the heating system. The expansion tank is installed next to the heating boiler. Membranes are of 2 types.

- Fixed - tightly fixed around the perimeter of the expander. Such devices can be found in the tanks of the heating system of a private house or a small enterprise.

These membranes will last a long time if you follow the recommendations for use. In the event of a rupture, it is impossible to change such a membrane - you will have to change the entire tank;

- Replaceable - they are made in the form of rubber pears, balls that must be filled with water. The installation of such a membrane is carried out on the tank flange. If a rupture occurs, then you can replace the damaged membrane with a new one with your own hands, without involving specialists.

When planning a heating scheme, it is important to first of all calculate the power of the heating boiler, take into account the number of radiators and the length of the pipeline.

Careful planning and calculation of the water heating system, and the installation carried out in accordance with the obtained data, will help you achieve productive, economical and efficient heating.

A water heating system that uses a membrane expansion tank and the coolant does not come into contact with atmospheric air, is considered closed and works under pressure. This scheme is the most common at the moment, because it has many advantages. In this article, we will analyze what a closed heating system of a private house is, its pros and cons, as well as service features.

What is a closed heating system?

An important feature of such a system is the absence of contact with outside air and the presence of a slight overpressure. As a rule, the circuit works with artificial stimulation of the circulation of the coolant using a pump. This allows you not to worry about observing large slopes of highways, as well as to accept smaller pipe diameters and lay them in the most convenient way.

As a rule, a gravity heating system with natural circulation of the coolant is made with an open expansion tank installed in the high point. A closed system is traditionally equipped with a circulation pump, which increases its efficiency and reduces material consumption.

Due to their features, closed-type systems have a lot of advantages:

- pressurized coolant heats up faster;

- the probability of airing the network of pipelines and radiators is very low;

- the coolant is not saturated with oxygen and does not evaporate into the atmosphere, which is very important when filling the system with antifreeze;

- installation of an expansion tank in a closed heating system is carried out on the return pipeline near the boiler, which is very convenient in terms of maintenance;

- there is no need to use pipelines of large diameters and lay them in plain sight, in this respect a closed system with forced circulation is the best choice for a private house.

There is only one significant drawback - dependence on the reliability of power supply, a closed heating system without a pump powered by the mains will not work. Fortunately, circulation units for individual systems have a small power consumption, and therefore, during a power outage, they can operate from an uninterruptible power supply for a long time.

Some experts argue that a closed system with natural circulation will help solve the problem of power outages. Recall that in this case the movement of the coolant occurs due to the difference in density and mass of hot and chilled water. The first, heating up in the boiler, as a lighter one, is displaced upwards by the cooled coolant coming from the radiators, which has a large mass.

Despite the fact that the pressure in a closed heating system (1.5-2 Bar) does not prevent the gravitational movement of hot and cold water its effectiveness is questionable. The fact is that the difference in convective forces is already small, and here you still need to overcome the resistance of the tank membrane, which stretches when the water expands. In order not to mess with these slippery moments, it is better to always put a pump on a closed system. If there is a need to mount a gravity circuit, then it must be made open.

Scheme of a closed heating system

In private housing construction, 2 types of schemes are traditionally used:

- single-pipe;

- two-pipe.

One-pipe, better known as "Leningrad", works satisfactorily in one - and two-storey houses a small area, when no more than 5 radiators are installed on each floor. The implementation of the scheme requires an accurate calculation of the pipe diameters and the number of battery sections, since the coolant cools down significantly after passing through each subsequent radiator. These requirements also need to be met by a single-pipe scheme of a closed-type heating system with an upper wiring, which is shown in the figure below:

Note. Regardless of the type of scheme chosen, a closed system must contain a security group, sometimes it comes with a boiler. The group consists of a manometer for pressure control, an air vent and safety valve for emergency water release. The unit is installed on the supply pipeline leaving the boiler, and without any shut-off valves.

The two-pipe scheme of a closed system is easier to calculate and install, and is famous for its good performance. After all, the coolant is delivered to all radiators with the same temperature, and when implementing a passing scheme, it also travels the same distance. An example of a two-pipe system is shown in the figure:

Some additions have a closed heating system with a solid fuel boiler. To avoid the formation of condensate in the furnace of the heat generator, the circuit is supplemented with a mixing unit with a three-way valve and a bypass line. The valve makes the water turn around bypass until it heats up to the set temperature, and only then it starts the coolant from the main into the boiler.

How to fill the system with coolant?

When the make-up connection is connected to the water supply network by means of a ball valve, it is quite simple to fill the closed-type heating system with a coolant. For this case, it makes sense to attract an assistant, especially if the house has several floors. One person operates the make-up valve, and the second is responsible for the release of air from the batteries. The faucet opens about a third so that the pressure is not strong.

The person in the boiler room monitors the readings of the pressure gauge, the recharge of the closed heating system is closed when the pressure reaches 2 bar. Now the assistant bleeds air from the radiators by means of Maevsky's taps, after which the pressure drops. The goal is to reach the design pressure by removing all air from the pipelines by gradually replacing it with tap water.

It is more difficult to pump the coolant into a closed system when there is no make-up from the water supply or it is necessary to fill in an antifreeze liquid. To do this, you need a special manual or electric pump and a container for the coolant from which it will be pumped into the system. First you need to open all the air valves on the radiators, and then fill the pipes through the drain fitting by connecting a pump with a check valve to it.

As the liquid is pumped in, it is necessary to close the Mayevsky taps, from which the coolant will flow. Having pumped up the system to 1.5 bar, it is necessary to remove the air, after which the pressure is brought to the working one. At the end, a trial run of the boiler and pressure adjustment are carried out, and, if necessary, air is bled.

Why does pressure drop in a closed heating system?

There is only one reason why the pressure drops - the lack of tightness, that is, leakage. The question is to find it. characteristic feature leaks are a puddle in a certain place or a brown spot when the water has time to dry. During the search, you should inspect the following nodes and elements:

- pipe connections and fittings: it happens that cracks occur in the latter;

- automatic air vents: a defective element with a stuck float will let water through;

- shut-off and control valves, safety valve;

- expansion tank: a crack in the membrane will cause a pressure drop, air in the system and frequent shutdowns of the boiler.

To eliminate leakage, one cannot do without partial or complete emptying of pipelines. At the end of the work, you will have to refill the water into the system, create required pressure and follow the pressure gauge for several days.

Conclusion

A closed heating system has a lot of advantages, hence its popularity. If the installation and commissioning is carried out correctly, then it does not require intervention in its work for a long time. Most of the malfunctions that occur can be easily fixed with your own hands, as well as system maintenance. It is advisable to check the performance of elements such as air vents, valves and an expansion tank annually.

When heating houses in the private sector, a closed heating circuit with forced circulation is mainly implemented.

The coolant in this scheme does not evaporate due to lack of contact with environment. This makes it possible use special formulations other than water that increase heating efficiency.

Closed heating system: what is it, principle of operation, pros and cons

These schemes use expansion membrane tanks. Sealed container divided into two parts by an elastic membrane.

When the temperature rises, the valve opens and the excess liquid moves into the tank.

When the temperature drops, the coolant enters back into the system, due to which a stable pressure is maintained in the latter.

Non-pressure tank can be completely filled with liquid, so the pressure maintenance installation must be more compact than a conventional tank. It allows you to adjust the specified parameters in the circuit and automatically feed the structure.

closed circuit consists of the following elements:

- from a sealed membrane tank;

- from batteries (radiators);

- from the heating boiler;

- from the circulation pump;

- from pipes;

- from connecting elements (valves, taps, filters).

Closed heating circuit has a number of advantages:

- the possibility of using any coolant;

- durability of the structure due to complete tightness;

- no extra noise

- opportunity self installation systems;

- high speed of movement of the liquid, providing maximum heat transfer;

- no need for thermal insulation for the highway;

- reducing the financial cost of heating the house.

The disadvantages include dependence on electrical energy and the need to purchase a membrane tank big size, the price of which is quite high. The problem of volatility is solved by installing uninterruptible power supplies or small generators that provide emergency power.

Construction schemes, use in apartment buildings

Used in private homes one-pipe or two-pipe heating circuit.

Single pipe scheme used in rooms with a small area where heating is required no more than five radiators.

Photo 1. Scheme of a closed heating system with a single-pipe circuit. Each of the radiators is connected in series.

All batteries are included in the circuit in series, so the last heater will always be colder than the first. The obvious advantage of such a scheme is less pipe consumption.

If one battery fails, the rest will continue to operate normally. when using bypass. Single pipe system is horizontal and vertical. The horizontal one does not allow you to adjust the amount of coolant, therefore, when laying it, bypasses are installed. A vertical single-pipe circuit is in most cases used in high-rise buildings.

Two-pipe (two-circuit) scheme heats rooms more evenly. The liquid from the heat generator to the batteries circulates on two circuits. Radiators in this case are connected in parallel. The coolant has the same temperature in all batteries. This method requires much high costs, but it makes it possible to regulate the temperature in each room.

Payment

In order to choose the right circulation pump and pipe diameters, carry out hydraulic calculation of the heating circuit. It allows you to identify hydraulic pressure losses in specific areas and minimize operating costs.

Attention! It is advisable to install a circulation pump in the return pipeline. In this case, the service life of the device will increase, since an already cooled coolant will pass through it.

Calculations are carried out by a specialized specialist using thermotechnical calculation and after selection of batteries. As a result of the calculations, the pressure value necessary for the circulation of water by the circulation pump will be obtained. After this stage, the value is calculated to determine the volume and selection of the membrane tank.

You will also be interested in:

How to start a coolant in the system?

When filling a closed circuit there should be no air pockets.

If the heating circuit is connected to the water supply using a tap, then in order to fill it you need periodically open the valve and release the displaced air from radiators.

This process continues until all excess air is gone and the pressure reaches the required design value.

To fill a circuit that is not connected to the water supply pump and tank required from which the coolant will be pumped. Before applying it, you need to open all the taps on the radiators. The drain fitting is connected to the pipe, and the structure is filled with the help of a circulation pump.

Important! When filling the heating circuit with coolant it is necessary to close the taps in time to prevent leaks.

Setup and launch

After starting the coolant into the structure check all circuit connections. Before this, the air from the pump must be downloaded, otherwise the operation of the device may be disrupted. Next, you need to bypass all the batteries and do the same procedure, slightly opening Mayevsky cranes.

The air descends until water flows out of the radiators. After that, the pressure value is checked by the measuring device. If she below 1.5 atmospheres, then the liquid is added again, and the process of deaeration of the equipment is resumed.

Then the system is pressurized. The pump pumps the coolant into the pipes until the pressure increases in 1.5-2 times.

The heating structure is left in this state for 15 minutes, after which the pressure is measured again. If the readings of the measuring device have changed, it means that there is a leak somewhere.

Otherwise, the operating pressure is returned to the system by draining excess coolant.

Final step - starting the heat generator, which is already prepared for use and included in the network. A low temperature is set on the thermostat of the equipment ( 40-50°C), time is given to warm up the entire volume of the coolant. After that, all radiators are checked. If the upper parts of the batteries are colder, then the air is bled again.

Thereafter increase the temperature of the liquid(up to 70-80 °C) and leave the heating circuit for a while. If in this mode the heat appliances continue to operate normally, and the temperature of the liquid in the return pipe at 20 °C colder than heated, the system functions properly and does not require additional settings.

Features of the heating circuit with a membrane expansion tank

The circulation pump in a closed circuit allows you to organize the structure according to any scheme, regardless of the hydraulic resistance index. Forced circulation gives the ability to use different options for organizing heating:

- sequential arrangement of radiators;

- collector circuit;

- warm floor.

Diaphragm expansion tank and circulation pump can be located together with the heat generator in the same room. This reduces the total length of the pipelines, so when organizing the heating circuit, it is not necessary to install pipes of large diameters and pay attention to the angles of inclination.

Photo 2. Scheme of the structure of a membrane tank for a closed heating system. The arrows indicate parts of the structure.

Why does pressure drop?

Pressure drops can be caused by:

- malfunctions of the heat generator (heating boiler);

- coolant leaks;

- excess air;

- aluminum radiators.

Leakage may not be visually noticeable. To discover her use special tools: thermal imagers or ultrasonic devices. It is necessary to carefully check the sectional connections of the radiators, because their surface may be covered with corrosion. Rusty smudges indicate damage to the batteries.

To find a leak need to press the nipple located on top of the expansion tank. If, when pressed, water and air are released, then we can safely conclude that there is a leak.

Closed type heating with safety group

Safety block in the heating circuit- a set of devices that prevent the occurrence of emergencies. Any heating structure operates at certain pressure values. Depending on the heating or cooling of the coolant, this value varies. The safety group monitors it and, if the maximum allowable value is exceeded, discharges a certain amount of liquid from the circuit.

In the private sector within the city or outside it is not possible to connect the house to central heating, so the owners of cottages are engaged in installation autonomous heating. Installation of open and closed heating systems is possible

Autonomous heating is a system of interconnected elements that heat up when connected to a heat source. It can be both oven and water or electric heating- it all depends on whether the residents are there permanently or come periodically.

Properly installed water heating can be powered by any source of energy - gas, solid fuel, working off.

The heat supply of the closed type consists of pipes, a boiler, a circulation pump, a battery and an expansion tank. All elements are sealed - water does not evaporate during heating and circulation.

Differences between closed and open heating systems:

- An open autonomous heating system provides for the installation of an expansion tank in the very high place- in the attic under the roof, in a closed one, it can be placed anywhere.

- Unlike an open heating system, a closed heating system is hermetically sealed and isolated from air currents.

- In the open heating system wide pipes are used, which are installed at a certain slope for better circulation. For a closed system, pipes of smaller diameter are needed.

- For a closed heating system, it is important to properly install and adjust the pump.

Circulation pumps ensure uniform distribution of the coolant through the pipes, increase the productivity of the system and help save fuel consumption.

Closed heating system: advantages and disadvantages

Hermetic heating system with a pump operates under pressure and in full atmospheric isolation, which leads to less oxidation of metal elements.

System advantages:

- The coolant is water, it does not evaporate, it is constantly in the system. If necessary, antifreeze can be used, which allows the system not to freeze, even if it is turned off for a short time.

- The use of a circulation pump allows the system to work faster and, accordingly, heat the room faster.

- The expansion tank can be placed in close proximity to the boiler, which makes the system more compact.

- With the help of special taps, you can adjust the temperature in the room or disconnect one or another room from the system if not needed.

- When installing the system, pipes of small diameter are taken.

- The tightness of the system eliminates the appearance of air pockets in the radiators.

Among the minuses is the fact that the system will not be able to function without electricity. When the power supply is turned off, the pump will stop working.

The only solution to the problem of a power outage may be the installation of an autonomous generator, but this additional source expenses.

When not correct installation pipes of the system, which will cause a violation of its operation. Therefore, after installing all the elements of the heating system, it is very important to check it for leaks.

Closed heating system: single-pipe scheme

You can assemble a closed heating system with your own hands, having decided which scheme - one-pipe or two-pipe, will be used during installation.

The single-pipe heating system is closed and is considered optimal for small cottages.

All heating devices - radiators, are interconnected in turn. When installing the system, you need to use a powerful pump that will help the coolant get to the end point of the system faster.

The expansion tank performs a number of important functions in the system. About what it is for and how to choose it correctly, you can read on

In this system, it is not possible to install coolant return risers. During use, it is impossible to regulate the supply of heat in certain rooms; if the temperature in one room decreases, the temperature throughout the house will decrease.

V high-rise buildings it is best to use a vertical one-pipe system, while the connection is made from the highest point. It is not recommended to connect more than 10 heaters in a riser. As a rule, on the 1st floor, the batteries heat up weaker than on the last one.

What is a two-pipe closed heating system

In a closed-type two-pipe heat supply system, the carrier (water, antifreeze) goes up the riser and is connected directly to a separate radiator. The heating system is characterized high rates- water is distributed through the batteries with the same temperature, then goes down the riser back to the heating boiler.

For a private house, a two-pipe horizontal wiring of the heating system is used.

With this heating scheme, it is possible to regulate the flow and temperature on each radiator by installing a thermostat on the battery. All other batteries will not be affected by the disconnection of one cell. Experts recommend installing for each radiator to be installed to expel excess air when starting the system before the heating season.

In a two-pipe closed type heating system, there is no need to install hydraulic pump- the coolant is distributed through the pipes independently.

When choosing between two heating schemes, it must be borne in mind that for all the efficiency of a two-pipe scheme, it requires 2 times more materials - pipes and fasteners.

Types of closed heating system of a private house (video)

A closed-type heating system has many advantages, hence its popularity. With the correct installation of the system elements and the subsequent operation of the heating, the owner will not need to intervene in the work for a long time. It is important to periodically clean the expansion tank and air outlet to avoid malfunctions.

The principle of operation is as follows: the coolant (water) is heated in the boiler to the required temperature and flows through the pipeline to the radiators. The latter give off heat and heat the room. The water cools down, returns to the boiler and thus a constantly repeating cycle is obtained. The movement of water can be natural or forced, which distinguishes the heating systems we are considering.

open system

A feature of an open heating system is that the coolant moves through the pipes in a natural way. This is due to the difference in density between cold and hot water (the latter has more). Therefore, a hydrostatic head is created which directs the coolant to the radiators. The most commonly used heat carrier is ordinary water. The structure of an open heating system includes a heating boiler, an expansion tank, direct and return pipes and radiators. natural circulation, at which the radiators heat up, occurs as follows. Water reaches a high temperature, tends to rise at the outlet of the boiler, is pushed out by cold water. When heated, the structure of water expands, its excess appears. That's what the expansion tank is for. excess water sent to avoid a break. The coolant cools down in the expansion tank, returns to the heating system. The expansion tank is installed as high as possible, in the attic, which is not heated. The tank is open, a constant supply of oxygen is provided. Constant monitoring of the tank level prevents air locks in the pipeline. It is necessary to monitor the slow heating of the water, since the circulation of water is slow. If you bring the temperature to the maximum (boiling point) - there is a risk of rapid wear of the entire heating system. If you do not use heating in winter, it is necessary to drain the coolant to preserve pipes, radiators and the boiler. Installation of an open heating system must be carried out strictly according to the instructions, otherwise there will be a risk of leakage and freezing of water in winter period. We present the following recommendations:- It is necessary to install the boiler as low as possible in relation to pipes, heating devices;

- It is necessary to insulate the expansion tank when installed in the attic. This prevents the water from freezing;

- Due attention is paid to the slope when installing the pipeline;

- It is recommended to avoid numerous bends, bends and bends;

- It is important to use the least number of connecting elements;

- The pipe is installed largest diameter at the outlet of the boiler.

- If the area of the house is 50-100 square meters. m - you need to use pipes with a diameter of 40 mm. The larger the total area of \u200b\u200bthe heated room, the larger the diameter.

- The pipes that go to the radiators have a similar diameter to the riser. Pipes that lead to radiators may have a smaller cross section.

- The recommended slope of horizontal pipes is 0.005-0.01%. It runs from the boiler towards the radiators.

Advantages/disadvantages of an open system

The main advantages of an open system are:- Heating uniformity. Heat enters all heated rooms, creating a comfortable and cozy atmosphere.

- Silent operation. Achieved by the absence of a circulation pump.

- Long operation. The pump can fail, it does not exist in an open system.

- Independence from electricity. Will not be disturbed by fluctuations in the network and a complete power outage.

- High equipment prices. In an open system, large diameter pipes are used.

- Complicated installation. It is necessary to calculate the slope of the horizontal pipe sections.

- Risk of water freezing in an open expansion tank.

- Danger of corrosion of pipes, radiators. An open expansion tank allows oxygen to enter the system.

- Changing the coolant level. Constant monitoring of the expansion tank is required.

- The impossibility of using antifreeze.

- Long time to heat up.

Closed heating system

The main difference between a closed heating system is the use of a circulation pump, which moves the coolant. Otherwise, the principle of operation is the same as in an open system. In a closed pipe system, radiators heat up much faster.

- The expansion tank is installed directly in the room. At the same time, the cost of pipeline elements is reduced and the coolant does not freeze.

- Using pipes of smaller diameter does not mean at all that you need to install pipes with a minimum cross section. This way to save money can have a destructive effect on the entire heating system. There is a risk of increasing pressure in the pipeline, and the pump may not be able to cope with this.

- Particular attention must be paid to the correct installation of the pump. The rotor is located horizontally relative to its own axis. This contributes to quiet operation and less friction with the coolant.

- The circulation pump and expansion tank are installed in front of the boiler inlet.

Advantages/disadvantages of a closed system

The main advantages of a closed system are:- Ease of system installation.

- lower cost heating structure. It is provided due to the possibility of using pipes with a smaller diameter.

- There is no need to control the level of the coolant. The tightness of the expansion tank does not allow the coolant to evaporate.

- Possibility to regulate the temperature. This occurs with an increase / decrease in the amount of supplied coolant.

- Possibility of floor heating. A special additional element is connected to the heating system.

Heating wiring: types and features

Regardless of the chosen heating system, you need to know that there are the following types of wiring: single-pipe, two-pipe and beam. Their use is influenced by the place where the main pipe passes, the methods of connecting radiators, risers of the supply function, and the location of the risers.Single pipe wiring

Single-pipe wiring is horizontal and vertical. Horizontal does not allow adjusting the amount of coolant. Therefore, when using it, bypasses are installed. Vertical wiring is used mainly for multi-storey buildings.

Two-pipe wiring

The two-pipe type of wiring is the most common. Each radiator has two pipes - supplying coolant and draining chilled water. The pipeline is made in the form of a star, plume or beam.

Beam wiring

Allows you to adjust the heating of each individual radiator. Requires complex installation, several distribution manifolds and the highest pipe costs.

Thus, we examined the device, the main features, advantages and disadvantages of a closed and open heating system. The choice should be based not only on your wishes, but also on the possibility of installing the system in the house. Therefore, it is very important to seek professional advice from a trusted specialist. Calculation and installation of the system must be carried out by specialists of licensed firms. Based on the recommendations presented, we wish you the right choice and installation of a heating system!

History of sky lanterns

Job description: concept, purpose, structure, procedure for compiling and formalizing Purpose and content of job descriptions for managers

Interview questions What job are you going to work on?

What to do if the boss criticizes all the time If the boss does nothing

How to understand: will the kitten be fluffy?