The catalog of the online store "77 Volt" presents a wide range of pipes for laying cables, sold at affordable prices in Moscow. The use of plastic pipes in electrical installations ensures fire safety. Non-combustible material is used for the production of products. Smooth and corrugated pipes allow you to protect the cable from adverse effects environment and accidental mechanical damage.

Today you can buy inexpensive pipes for laying cables and use them to create a reliable and safe heating system. Here you will find products made of PVC and HDPE, which have different diameters and characteristics. The company's specialists will advise you for right choice products, taking into account the features of operation.

Varieties of pipes

For pulling the cable, a smooth and corrugated pipe, made of PVC and HDPE, can be used. The most popular option for protecting wiring are PVC products, which are divided into two types:

- Lungs. They are used when performing electrical wiring in raised floors, strobes, in plasterboard walls and above false ceilings. These are quite flexible structures that allow solving cable laying tasks most efficiently, in compliance with fire safety rules.

- Heavy. They have great strength, they are designed for use when pouring into concrete, laying in cement screed. Used in open space. If the laying of the cable network is carried out in hard-to-reach places, it is recommended to use this type of pipes.

Our company offers to order pipes for cable laying from the HDPE warehouse, the cost of which you can check in the price list. In production, low-density polyethylene is used. This is a low-flammable plastic, which is environmentally friendly, because it does not contain harmful substances. One of the main advantages is a wide operating temperature range and resistance to acids, gasoline and oils.

We have discounts on purchases, sales of PVC and HDPE pipes for cable laying.

Table for selecting the minimum diameter of the corrugated pipe for cable laying

| Cross-sectional area of the wire, sq. mm | Number of wires, pcs. | External diameter pipes, mm |

| 1,5 | 2/3/4/5 | 16/16/20/20 |

| 2,5 | 2/3/4/5 | 16/16/20/25 |

| 4 | 2/3/4/5 | 20/20/25/25 |

| 6 | 2/3/4/5 | 20/25/32/32 |

| 10 | 2/3/4/5 | 25/32/32/40 |

| 16 | 2/3/4/5 | 32/32/40/40 |

| 25 | 2/3/4/5 | 32/40/50/50 |

| 35 | 2/3/4/5 | 40/50/50/63 |

| 50 | 2/3/4/5 | 50/50/63/63 |

| 70 | 2/3/4 | 50/63/63 |

| 95 | 2/3 | 63/63 |

| 120 | 2 | 63 |

| 150 | 2 | 63 |

Selection table for the minimum diameter of steel cable pipe

| Group of complexity of laying wires (cables) | Pipe route configuration | Number of bends at corners | The greatest length of the route, m | Pipe laying complexity code | ||

| 90-120 deg. | 120-150 deg. | (90-105) + (120-150) deg. | ||||

| 1 | straight track | - | - | - | 75 | B |

| 50 | V | |||||

| 2 | One or two bends | 1 | 2 | - | 50 | B |

| 30 | V | |||||

| 3 | Two or three bends | 2 | 3 | 1+2 | 40 | A |

| 30 | B | |||||

| 20 | V | |||||

| 4 | Three or four bends | 3 | 4 | 1+3 or 2+2 | 20 | B |

| 10 | V | |||||

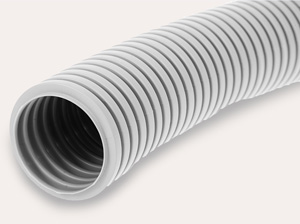

For the safe laying of power and low-current electrical networks, flexible PVC pipes. A corrugated pipe for a cable is its protective casing, which, at the same time, is considered an ideal dielectric that protects structures and people from electric current in case of damage and breakdown of the cable or fire due to a short circuit. The peculiarity of corrugated pipes is that they have incredible flexibility, which makes their installation simple and convenient. At the same time, labor costs are significantly reduced and the possibilities of laying cable networks are expanded.

Varieties of corrugated pipes for electrical networks

Corrugated pipes are widely used by professionals and home craftsmen for laying electrical and telephone wires, television, as well as computer and power cables. Corrugated pipes are produced:- from PVC (or polyvinyl chloride) - self-extinguishing plastic compound;

- from HDPE (or low-pressure polyethylene), having a high rate of flexibility;

- from LDPE (or high-density polyethylene), as a rule, for concealed installation in structures made of non-combustible materials or as an external corrugation for the manufacture of two-layer pipes;

- from PP (or polypropylene), for conductive channels in monolithic construction;

- made of PA (or polyamide), with a high degree of protection against the ingress of water.

Polymer pipes with corrugated profile are intended for both hidden and open laying of wires and cables. By design, they are:

- single-layer, where the outer and internal surfaces have a common wall;

- two-layer, when there is a corrugation on the outside, and a flexible, smooth surface is located inside.

Corrugated PVC pipes differ according to the version.

- Lightweight corrugated pipes are laid inside buildings, they have the greatest flexibility, have thin walls and are able to fit compactly on any bends, repeating their contour. They are often used for installing cables under wall and ceiling sheathing.

- Heavy (or reinforced) corrugated pipes are much stronger, their walls are thicker, and they are laid in a concrete-cement screed, concrete base floors, underground and outdoors.

For the convenience of pulling wires through electrical corrugated pipes, they are equipped with metal probes in the form of a steel cable, which is connected to the cable and pulls it out with reverse side. In this case, the installation of the electrical network is much faster. But manufacturers produce corrugated pipes without broaches. They do not differ in quality, but their price is somewhat lower.

Corrugated pipes for electrical networks are produced with diameters of 16-63mm. Manufacturers supply them with a length of 15-20-25 meters, as well as 50 and 100 meters, as a rule, in coils packed in sealed shrink bags. polyethylene film. Rigid corrugated pipes are sold in lengths of 2 or 3 meters.

In addition to plastic pipes, corrugated stainless steel pipes are produced by the industry, but their cost is much higher, so they are used much less often for laying cables.

Advantages and characteristics of corrugated pipes

Regardless of the version, corrugated flexible pipes made of self-extinguishing PVC:

- durable (service life exceeds 50 years) and do not lose their properties over time;

- moisture resistant;

- low flammable;

- resistant to shock and compression, rotting and corrosion;

- provide reliable protection of cables in a wide temperature range (from -20 to +55 degrees);

- environmentally friendly and safe;

- they are light in weight, therefore they are problem-free during transportation and storage;

- chemically resistant;

- make it possible to quickly replace a cable that has become unusable;

- universal;

- easy to install.

The dielectric strength of corrugated PVC pipes reaches up to 2000V with an insulation resistance of 100 ohms.

Selection of PVC corrugated pipes for cable

V plastic pipes it is possible to lay cables for various purposes, ranging from low-voltage networks to power ones. The size of the protective electrical casing is selected depending on the diameter of the electrical wire, the number of cables to be pulled and their purpose.

If it is necessary to supply electricity to lighting fixtures, a corrugated pipe with a diameter of 16 mm will be enough. To power switches and sockets, it is better to use a casing with a diameter of 20 mm, and if several wires are located inside the pipe, corrugated pipes with a size of 40-63 mm should be chosen. For any of the options there is a corrugated PVC pipe, the price and quality of which will be acceptable even for the most demanding customer.

A corrugated pipe should be chosen with a metal probe, which is a rigid steel wire that provides trouble-free cable pulling through a plastic casing. The monetary savings when buying a pipe without a probe will turn out to be insignificant, and labor costs will be greatly reduced.

Anyone can lay corrugated pipes on their own home master. But one should take into account the factor that not everyone understands the intricacies of connecting electrical wiring. For this, it is better to invite a specialist.

Corrugated pipes are laid in strobes, when installing suspended or sheathing systems, as well as in an open way, performed mainly in house systems.

Corrugated PVC pipes for cables can be laid inside or outside any building structures, as they are fireproof. But if it is possible to install them inside non-combustible or slow-burning materials, then it is better to choose a safer option. You should also avoid open way gaskets in places of direct exposure to ultraviolet rays.

Mount the electrical network in the casing as follows:

- initially open or in a closed way lay a corrugated pipe for the cable;

- the end of the electrical wire is twisted with a steel broach (probe);

- gently pull the cable from the other side of the corrugated pipe, which, if necessary, is cut with any available cutting tools (knife, scissors, saw).

With hidden laying, corrugated pipes are fastened in the body of the main building structure using cement mortar, and when open - they are mounted to the base with special clamps.

An excellent protection against damage is the corrugation for wires and cables. This device will be needed when pulling the cable underground or when conducting electrical wiring inside the building. Corrugated pipe is an important attribute of any concealed wiring. How to choose it correctly, we will tell in this article.

The safety of the entire building depends on the quality of such products.

Corrugated pipe for cable is used for mounting all kinds of lines, as well as for various options wiring: disguised, underground and outdoor. They differ in their device, technology and raw materials.

Can be used the following types materials:

- HDPE is a flexible wire;

- polyvinyl chloride refers to self-extinguishing types of raw materials;

- pnd is used for hidden lines. It is laid in concrete structures or brick;

- polypropylene is a plastic backbone that is used to install the cable;

- polyamide provides good waterproofing.

If the wiring is laid on combustible types of material, then a heat-resistant metal corrugation is used. Pipes may have different designs. With a single-layer version, the highway has one wall between the outer and inner surfaces. A two-layer product has an inner layer that is placed in a protective case.

Corrugation for wires is in demand due to many advantages:

- long service life;

- does not pass moisture;

- fire resistance;

- increased resistance different types loads;

- does not give in to corrosion;

- light weight.

Important information! To easily place the wires inside the protective case, a probe is provided in the kit. This is a device for mounting the cable in place.

Why are corrugated metal pipes for electrical wiring so popular?

The main purpose of metal corrugations for wiring is to protect wires from various damages. In residential premises, metal corrugated wire is used for cables that run along combustible surfaces. These are various electrical wiring over suspended structures, in utility buildings and wooden buildings.

Additional protection is important when the cable comes into contact with pipelines. This is important when crossing heating mains and gas pipelines. Laying electrical wiring inside a metal case is done in several steps:

- the wires are pulled inside the protecting line;

- installation of the structure on surfaces and the supply of wires to the shield boxes;

- connecting cables.

The protective line is laid on a variety of surfaces using clips. You need to fasten through the distance to prevent sagging. Pay attention to the installation of cables and wires inside electrical appliances. Condensate must not collect in the corrugation. When entering into the design of electrical panels, a variety of couplings are used. Fittings are used to connect elements.

Metal differs from similar options in increased strength. The following options are also provided:

- plastic corrugation has excellent specifications;

- the street version is used for wiring outside, it is resistant to aggressive environmental manifestations;

- an automobile pipe is used to save wires in cars;

- the product for pulling the cable in the ground is wear-resistant and can be used for a very long time;

- modern options include PVC construction;

- heat resistant version elevated level strength and not subject to thermal stress.

Note! Before laying, you need to measure the length of the corrugated pipe in advance and cut off the necessary pieces.

How to work with corrugated pipe?

It is difficult for beginners to understand how to correctly run a wire through a corrugated pipe for electrical wiring. Although there is nothing complicated about this, you only need to follow certain steps:

- the required length is measured in place and cut, and then the wire is cut with side cutters;

- you need to hold the broach so that it is not lost in the pipe;

- a tourniquet is made, which should be tight;

- the tourniquet, conducted into the corrugation, must be attached to a metal broach;

- the joints are wrapped with electrical tape.

After placing the wiring, the corrugated pipe is fixed every 20 cm with special fasteners. Clamps are first attached to the corrugation, and then to the surface. A special tool is used to pull the cable through the corrugation.

Note! If you plan to place a pair of wires in the corrugated pipe, they should be inserted in one go. Also, when connecting to a cable, you need to make sure that part of the corrugation fits into the outlet, and there is no open wire in sight.

What to consider when choosing a corrugated pipe

When choosing corrugations for wires, you need to consider some recommendations. pay attention to color scheme material. It is better to choose a color uniform and without inclusions. Since heterogeneity indicates that the product is made from recycled plastic.

To facilitate the installation process, do not save too much and choose a tube without pulling. This is important for small diameter pipes.

When purchasing fixtures, do not forget about special fasteners for installing pipes. In this case, you can use clamps, clips and dowels.

Various types of cables are used in the corrugation for electrical wiring, so it is important to choose correct dimensions, which depend on the cross section of the wires. For computer lines, a pipe with a cross section of 16 mm is suitable, and for connections to sockets, a pipe of 20 mm is used. For power structures pipes with a diameter of 25-55 mm are suitable.

In the table you can see how to choose a corrugation, taking into account the color scheme.

According to fire safety, this material is divided into three categories:

- for installation on non-combustible surfaces made of concrete or brick, any pipes are used;

- in frame buildings, LDPE and PVC corrugations are used;

- for laying in combustible structures, pipes with fire resistance are used. On such surfaces it is forbidden to use plastic.

The price of a metal corrugation for a cable

The average price for a corrugation for a meter cable varies from 10 to 800 rubles. Price metal pipe will be higher.

In the table you can see the price for specific corrugation models.

| Image | Product | price, rub. |

|---|---|---|

| Corrugated pipe 32 mm T Plast 50 m | 660 |

| PVC pipe B 16mm with a broach 100 m | 450 |

| Pipe 20 mm (100 m) | 487 |

| Corrugated pipe. PVC with probe d 16 | 560 |

| HDPE pipe d 16 with probe | 1350 |

| Flexible pipe for PVC cable 50 mm, 15 m | 525 |

To create a safe and durable wiring when choosing a corrugated pipe and its installation, follow our tips:

- if possible, do not use sharp corners;

- when used in long networks, connect pieces of corrugation using transit boxes;

- in monolithic structures, the corrugation is mounted before pouring, and the wiring is pulled after solidification;

- when carrying out hidden wiring, strobes are made in advance, where the pipe will be laid;

- external wiring is hidden behind suspended or plasterboard ceilings.

Testing the corrugation of HDPE and PVC pipes for cable (video)

You may also be interested in:

Wiring in wooden house do it yourself: step-by-step instruction for the implementation

Wiring in wooden house do it yourself: step-by-step instruction for the implementation

How to correctly transfer meter readings for electricity: different ways and their benefits

How to correctly transfer meter readings for electricity: different ways and their benefits

History of sky lanterns

Job description: concept, purpose, structure, procedure for compiling and formalizing Purpose and content of job descriptions for managers

Interview questions What job are you going to work on?

What to do if the boss criticizes all the time If the boss does nothing

How to understand: will the kitten be fluffy?