Modern grinding machines are equipped with powerful engines and are able to perform many tasks. In particular, they have the ability to process wooden objects of various shapes. Many modifications are used for cleaning rounded surfaces. Models with horizontal guides are often used to work with pointed ends.

The powder coated crank is too long for the additional arm. The idea in grain milling is to mill the grain between two slowly rotating stones. The low speed, low temperature milling process protects the valuable and delicate natural grain nutrients we knew you might want. All of our mills are built with these slow turning features and we make them easy to understand and use. We left the noise and vibrations, so they only work with a whisper.

For processing metal objects, powerful devices are required that have tight belts. Pretty hard to make a tape grinding machine with your own hands. However, it should be borne in mind that there are various modifications that do not apply to complex devices.

Models for woodwork

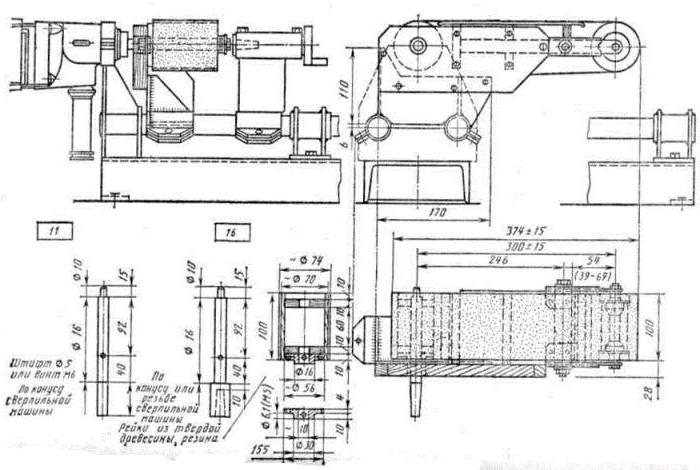

You can make simple woodwork with your own hands even without the use of an electric motor. In this case, it is more appropriate to consider drum modifications. First of all, a frame is installed for the stability of the structure. Next, guides are fixed on it. They are necessary to secure the workpiece. A shaft with a flywheel should be attached to the drum. Due to this, it will be possible to rotate the structure. In this situation, the drum should be selected with a small diameter.

The design of the belt units

But there is one thing, however, we have not abandoned our mills. Our motors and gears are built to specifications that meet or exceed the requirements of factories and industries. Our stainless steel milling stones or burrs are the result of costly research and development in which we have created virtually indestructible materials that rarely need to be replaced or serviced under normal use. The hardened sheet pile screws on our machines will never wear out.

Metal working devices

In order to make a metal grinding machine with your own hands, it is more expedient to select an electric motor with a power of at least 5 kW and a frequency of 55 Hz. Before starting work, it is important to take all measurements. In this case, much depends on the size of the metal blanks to be processed. After installing the bed, the guides are immediately fixed. In this situation, the beam is mounted on the frame.

We sincerely believe that we have designed and built the best home flour mill in the world! We know that our concept is different and our ideas in grain milling are also different. We think powder coated aluminum construction is superior to wood or plastics and we don't feel the mill should swallow a large number of grains to be good. A windmill that will be part of your family for years to come.

A good cup of coffee isn't easy, and if you love all things coffee, you're probably picky about your grinders. Coffee mills were not all created equal; material, size, function and warranty are just a few factors to consider when.

To adjust the position of the block, a lever with a return spring is used. The drive shaft of the model must be at least 5.5 cm in diameter. emery skin wide should be chosen. Handwheels are used to adjust the guides. If we consider tape modifications, then rollers will be additionally required for the machine. They must be attached above the frame.

What should you consider when looking for the best manual coffee grinder?

There are many hand choppers to choose from - you just need to make sure you pick the right one. If you're looking to grind on the go, you'll want to consider buying a coffee grinder that includes a sleek cylindrical shape that's easy to store and easy to grip.

Less when it comes to portability, however, if you're not into traveling with a hand sander, something nice and vintage-inspired might suit you better. Grinders can be supplied in all kinds of materials, but consider stainless steel or ceramic the best option because it is durable, easy to clean and looks great on the countertop next to your coffee machine.

Drum modifications

You can make a drum grinder with your own hands manually or electronic type. If we consider the second option, then we should first of all make a frame from steel sheets. Next, a frame is laid on which the guides will be located. The next step is to take care of the electric motor. It must be located at the bottom of the bed.

Function - is it enough?

Connecting to Point #1 - If you plan to travel with yourself, avoid ceramics and stick with stainless steel. Accuracy and consistency are key; you will need a sander with functional applications that will produce the same results no matter where you are sanding. It's not good to have something that "just grinds", you'll need something that grinds to different tastes.

You should get the best bang for your buck and that includes an extended or lifetime warranty. Well-made products often offer a long-term or lifetime warranty, as their products are manufactured with precision and expertise.

Directly the tape position mechanism can be located in the side of the machine. Due to this, the working area of \u200b\u200bthe tool is significantly expanded. The casing in this case can be used plywood type. For greater stability of the machine, you will need to install legs. The carrier plate in the modification must be with a shield. After fixing it, it remains only to install the flywheel that regulates the position of the guides.

Beware of no warranty grinders - what are they trying to hide? This consistency is unmatched in the hand sander market. It's as easy as dialing, loading, shredding. Throw your beans into the bin, set the grind setting and turn the knob.

You have 15 grind settings, meaning you can brew for almost any brewing method. from cold brew to espresso. You won't be able to brew Turkish coffee, but most hand grinders have the same problem. But the best part is that you can choose a setting and use it over and over again - something you can't do with other hand sanders on the market!

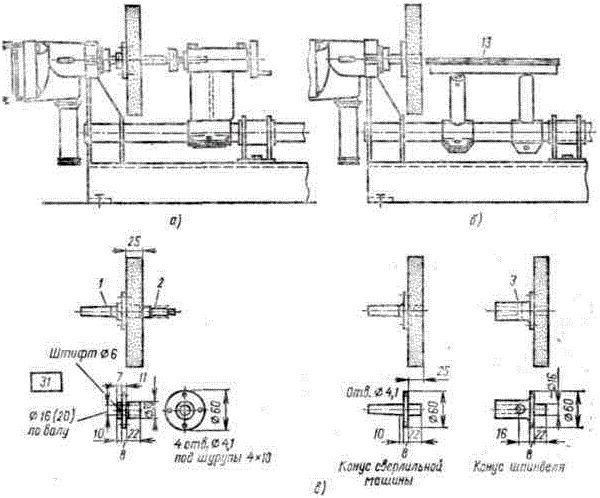

Spindle machine models

You can assemble a spindle grinder with your own hands only using electric motors. Quite often, experts recommend choosing models for 5 kW. The main element of the machine is considered to be the spindle mechanism. It must be installed on the bed. Directly guides are fixed in a horizontal position.

Slightly larger than some shredders, which means it's less portable and a little more expensive than some of the other options on this list. Best for: Anyone who understands the importance of a solid grind when brewing a great coffee. This is the best hand grinder on the market in terms of quality and performance - hands down.

Be sure to also check out its other color options, including stunning beech wood and black beech finishes. It's smaller than your typical electric sander, but in relation to hand sanders it's a bit bigger and bulkier, but style is added for its added size - especially the beautiful mahogany veneer.

After fixing the block, fix the longitudinal plate. Workpieces will be laid on it. Screws are used to fix the stand. The rollers in the design must be located on both sides of the spindle mechanism. The bearing plate in the structure must withstand heavy loads. Pulleys are used to increase the torque. In this case, the position of the guides is adjusted using flywheels.

With this handheld grinder, you'll be sure that the sanding function gives you consistent results every time and doesn't take away the heat from your delicate bean flavor that is usually generated from electric grinders. World class materials - if you love coffee, you will love mahogany, right? Slightly heavier than other grinders, which means its smaller laptop setup is unnumbered, so achieving the same results is tough. The conical burrs protect the integrity of the ground coffee beans. . With a 25 year warranty, a person interested in buying can rest assured that they have a high performance grinder for a long time to come.

Model with cam rest

You can make a do-it-yourself belt grinder with a cam steady with your own hands quite quickly. Manual modifications are very rare. In this case, the motor should be selected with a power of 5 kW and a frequency of at least 55 Hz. The grinding type drum must be installed on the working platform. Fixing it occurs on the bed. To adjust the position of the guides, flywheels are used as standard.

What makes this product a great travel companion? For one, the portable easy-to-grip cylindrical shape makes it easy to lift, bike, pack into a suitcase, or get stuck in a car. Even better; made of stainless steel material, which makes it easy to clean, practically does not destroy and keeps the temperature very well. The adjustable grinder produces precise grinding wheels for fine, course or grinding wheels in between and has a neat little dial that ensures you remember that perfect grinding you just produced.

The tape in this case is selected small size. To protect the electric motor, many experts recommend using a casing. In order to fix the workpiece, a powerful support is needed. The lunette itself plays the role of a feeding device. It should be fixed next to the drive shaft. Different control units are installed on the devices. In this case, many experts advise choosing high-quality CNCs that are able to regulate engine speed.

Easy to use with versatile features - Achieve the perfect finish for most types of beer Portable design is perfect for coffee enthusiasts on the go. Best for: This is a coffee grinder perfect for those who want to take their coffee with them when traveling or when exploring the beautiful outdoors. Not only is this portable product easy to use with simple features such as sanding strength and versatility, but it offers the user the opportunity to enjoy a great cup of coffee wherever they are.

Devices with horizontal rails

Assembling a grinder with horizontal guides with your own hands is a very difficult task. In this case, a wide frame is required. In this case, the block must withstand heavy loads. Legs are used directly to fix the working platform. The rails of the model must be above the bottom frame. The tape position mechanism is fixed near the electric motor. Gearboxes are also often used in these devices. In order to install the side plates, you will need a welding machine.

Many wood splitters are afraid of chopping. And "fear" might be too much kind word. I had several village specialists who sent me grinding tools. Other village workers spend hundreds of dollars on elaborate tool stands or other grinding contraptions to ensure that the tool doesn't catch fire, steal their spouse, and then go on a triumphant kill.

Devices with sliding supports

Grinding is easy, fast and completely necessary. You don't need a lot of money to learn how to grind. For some woodworkers, the fear of shredding applies to electric grinders. They've heard stories about how a high-speed grinder will destroy their tools. So they spend extra money on a slow grinder and fantastic grinding wheels.

Models with vertical rails

You can make a grinder with vertical guides with your own hands using welding inverter. In this case, the tape must be fixed on the drum. Directly, the electric motor for the configuration is selected with a power of about 7 kW and a frequency of 55 Hz. The beam of the model must be rigidly fixed at the base of the machine.

Here's the truth: any dry grinder can remove character from your tools and soften the steel. Should you grind away the discoloration until you're back to good steel? Finish your sanding job, sharpen the edge and get back to work. Yes, the steel is softer and yes, it won't have an edge either, but it's still a workable tool. In the end, you will work out softer steel and return to good.

And now, thanks to hillbilly Bill Anderson, I have a nice hand grinder that's great for the home. If you can grind a machine, then gain the skills to use a hand grinder, this is the cake. It doesn't require much coordination.

The pulley for her is selected with a head. A small plate is required to stop the workpiece. A place for the roller mechanism should be provided next to the guides. All this will allow you to easily change the position of the workpiece on the desktop.

Longitudinal rest machines

Do-it-yourself grinding machine with a longitudinal lunette can be mounted in different ways. Electric motors are most often selected with low power. The flywheels in this case are fixed at the base of the bed. Bearings are used to adjust the pulley. The plate will be required for a machine with a steel stop. The carrier plate of the model is used with a small thickness. The gearbox is most often used rack type. To adjust the position of the guides, you need a lever. Directly the lunette is installed on the edge of the support beam. You can use screws to fix it.

Belt sander

And hand crushers work fast. In addition, the manual coffee grinder is variable speed. You can work as fast or slow as you like. Hand crank grinders are widely available, fairly inexpensive, and fit modern grinding wheels.

Music from this video can be downloaded for free. Larry Williams' grinding and sharpening resources on "Old Street" tools is the ability to grind. If there's one thing that separates a good cup of coffee from a great one, it's freshly frozen coffee beans. And there is no greater feeling than using a manual coffee grinder to grind your own beans.

Version with rolling bearings

With the help of rolling supports, you can also make a grinding machine with your own hands. The advantage of these configurations is their versatility. Workpieces in this case can be processed at different angles. The assembly of the machine should begin with the installation of the bed. For the working platform are used steel sheets. It is more expedient to solder guides in a horizontal position.

You've probably seen automatic coffee grinders in the market or your local barista. While automatic grinders help speed up the brewing process, manual grinders make you slow down and enjoy the bean-to-cup experience.

Our Favorite Coffee Grinders

Hand grinders are a little more difficult to use and don't create the smoothest grind compared to automatic grinders, but they have their advantages and feel like such a simple luxury in the world of specialty coffee. If you're on the road and have to bounce from hotel to hotel, it can be difficult to find a quality fresh cup of coffee. The hand grinders are small and easy to carry with you, so you can enjoy your favorite specialty coffee no matter where you are. Hand grinders are much more affordable than their automatic ones. copy machines, making them ideal grinders for people on a budget. Using a hand grinder to grind your own coffee is perhaps the The best way slow down and truly enjoy the process of making coffee from bean to cup. In addition, they are suitable for use. Grinding machines are a completely unique gadget. If you have a manual coffee grinder, this can be one of the most unique devices you will have in your kitchen because they are so aesthetically pleasing.

- Hand grinders are ideal for travelers.

- Brewhouses helped you slow down and enjoy the moment.

Flywheels for them are installed last. The drive shaft in the structure must be under the frame. The belt positioning mechanism is installed near the electric motor. Guards are used for the safe use of the machine. After fixing the flywheels, it remains only to fix the casing to protect the mechanism from dust.

Devices with sliding supports

With sliding supports, making a machine is quite simple. In this case, the guides can be installed in a horizontal position. The working platform for these configurations is mainly made of a small width. Directly the supports of the machines must be located on the edge of the upper beam. However, first of all, you should make a frame for the tool. For this, metal profiles are selected. You can also use pipes quite successfully. The top beam is attached to the frame.

Electric motors are used with a power of about 7 kW and a frequency of 50 Hz. Corners are used to adjust the position of the pulley. The guides of the model must be fixed on the plate. Ball bearings are used for free rotation of the bearings. The tape position mechanism is fixed near the electric motor. If we consider the classic model, then the drive shaft is installed under the guides. Thus, the maximum rotation of the spindle is achieved. Guards are used to protect the operator during work. It is also possible to install a hand rest on the edge of the working platform.

Model for 5 kW

At 5 kW, how to make a grinding machine with your own hands? Such devices are most often made with a spindle mechanism. The upper beam of the models can be located on the bed. Pulleys are most often used guide type. The belt positioner must be installed close to the motor. The modifications differ in the type of upper blocks.

Every person who has had to deal with wood processing knows the importance of the final polishing of the finished product.

This also applies to holders for various agricultural implements, and wooden furniture, and building elements (doors, windows, window sills) and any other wood products. Sanding allows you to remove burrs, as well as bring smoothness and shine to the wood.

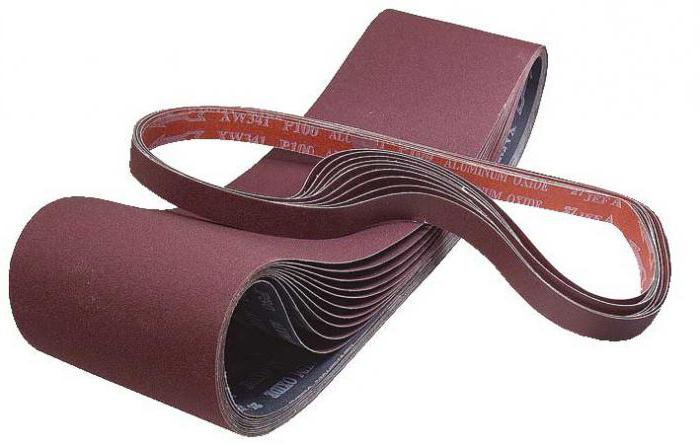

Of course, grinding work can be done with a regular piece sandpaper or a special attachment for drills or angle grinders. But this takes a lot of time and does not ensure the ideal shape of the product. Therefore, for such purposes, various grinding machines were created.

Most often in domestic conditions and in conditions small scale production they use a drum grinding machine, the device, the principle of operation and the possibility of making it with our own hands, we will consider in this publication.

1 Drum grinder - device, principle of operation

The drum grinder got its name from the rotating cylinder - the drum, which, in fact, performs the function of grinding.

In addition to the grinding itself, which allows you to remove burrs and give wooden surface perfect smoothness, such devices also perform a calibration function. Drum grinder or any other type allows you to adjust wooden detail to the right size with millimeter precision.

This machine is used for finishing sanding and grading of flat and long wood products, such as wood panel surfaces, chipboard, fiberboard, etc., doors, window sills, and so on. The use of such a device for processing cylindrical parts is not possible.

1.1 Main components

Drum grinder appearance and a set of basic components has no fundamental differences from any other machines.

The basic package of such a device includes the following elements:

- The bed is the part of any machine to which all other elements are attached.

- The engine performs the function of driving the moving parts of the machine. Most often, drum sanders for wood are equipped with two motors. One rotates the drum itself according to the principle of a drill, the second sets the feed tape in motion.

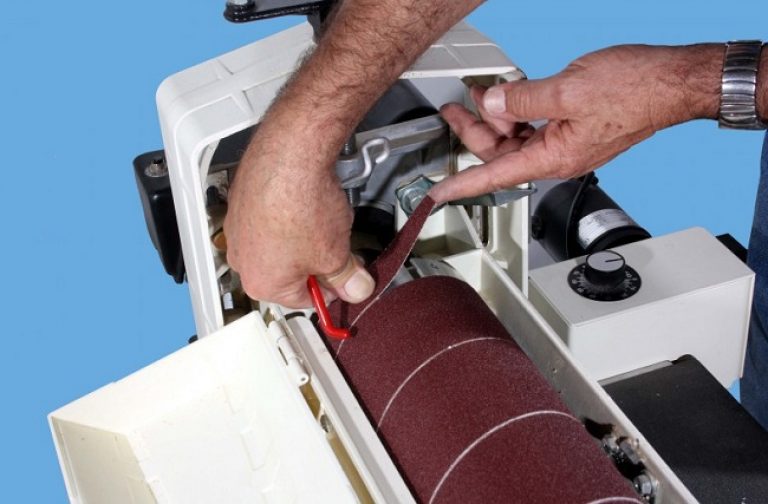

- Grinding planer drum, on which the emery belt is wound and attached. It is necessarily equipped with a tensioning mechanism, with the help of which, when the tape is heated, it is automatically tensioned. The rotating drum with sanding belt directly smoothes the woodwork.

- Feed drum with conveyor belt. This part of the machine on wood makes its own wiring wooden product on the grinding drum. Thanks to flat surface conveyor and the same distance from the belt to the drum over its entire plane, the product is evenly adjusted to the desired dimensions.

- The mechanism that regulates the speed of the conveyor belt.

- Fixing racks of the grinding drum, equipped with a ruler. The ruler and screw fixation on the racks allow you to set the required thickness, under which the product must be adjusted.

- The protective cover covers the grinding drum to prevent injury during operation.

- Machine for removing dust and chips.

1.2 How it works

Such a grinding machine works on the principle of a drill. Its grinding part rotates the engine at high speed - an average of 2000 rpm.

The sander can have different weights, different sizes, sanding drum length, conveyor belt length and width, maximum and minimum drum installation height, etc.

Choice technical parameters device depends on the features for which it was purchased.

After installing the machine, you need to calibrate the grinding drum to avoid eccentric rotation and unnecessary vibrations. In addition, a non-centered drum will not be able to clean the products evenly.

To do this, we take two beams of the same height, install them on the feed belt, lower the drum on them and fix them in this position. Next, set the height of the mechanism, depending on the size of the part to be ground.

We turn on the installation. For the first pass it is better to set the minimum speed of the feed belt, for the final - the maximum - 3 meters per minute.

The grinding drum should gain momentum, like a drill. After that we put wooden beam to be processed onto the conveyor belt. The passage of the beam under the drum occurs automatically.

We repeat this action the required number of times until our part comes into the desired shape and acquires the specified dimensions.

If the sides of the product are of different sizes, the height of the drum must be adjusted for each change in parameters.

2 Types of machines

If we talk about grinding machines in general, their classification is based on two parameters: the scope and the functions performed.

According to the field of application, the machines are:

- circular grinding machines. Are intended for processing of the details having round section;

- surface grinding. Their task is to grind flat parts. The drum machine also belongs to this type;

- internal grinding. These mechanisms are used to process internal surfaces products. Drills are often used for this purpose;

- specialized. Designed for processing complex surfaces - threads, grooves, teeth, etc.

Various machines can perform different functions:

- pruning and cleaning;

- sharpening;

- grinding.

2.1 We make a drum machine with our own hands

It is difficult to make a drum grinder for raw wood with your own hands, but it is quite possible.

To do this, we take a list of necessary elements and look for suitable material and spare parts.

And so, we need:

- Bed. For these purposes, any stable workbench or table is suitable, to which other elements of the machine can be screwed. It is better if the bed is metal. If you have to use wooden structure, it needs to be qualitatively strengthened with your own hands.

- Electric motor with a power of 200-300 watts. The speed should be 1500-2000 rpm. Better if it is single phase asynchronous motor. For these purposes, the mechanism from the old washing machine(in this case, we also take pulleys with a belt from it), drills, grinders, etc.

- Sanding drum for wood. This is perhaps the most important and most complex part of the machine, on which the quality of the work performed will depend. We will talk later about how and from what to make a home-made grinding drum with our own hands.

- Drum stands. The device that fixes the drum and regulates its height can be made of wooden beams. The height adjustment mechanism can be made by hand in two versions. First option - through holes on the racks through which the drum will be attached. This option is simpler, but it only allows you to work with a fixed adjustment step of about 1 cm. The second option is long screws mounted perpendicular to the drum. In this case, by tightening the screws, we will be able to raise the grinding device, releasing - to lower it. In the second variant, height adjustment is possible with an accuracy of up to a millimeter.

We will not make a conveyor belt with our own hands. It's possible, but not necessary. Submission for homemade machines is usually done manually.

2.2 Making a drum

Before proceeding with the manufacture of the drum itself, you need to clearly understand what functions our machine will perform. The fact is that the smaller the size of the cylinder, the easier and faster it will be rotated by the engine from the drill.

To make a grinding drum, we need a piece of anything that has a cylindrical shape, the desired length and diameter. It can be a wooden beam with a round section, a PVC pipe, metal pipe and much more.

We will consider as a material pvc pipe for making a drum with your own hands.

- Take the right size cut plastic pipe. We also need a metal pin that acts as an axis, wooden or plastic plugs that match in diameter with inside diameter pipes, screws, rubber, glue.

- We take the plugs and make holes in them that correspond in diameter to the thickness of the rod.

- Holes in the plugs must be exactly in the center. The slightest eccentricity of the drum will lead to incorrect operation of the machine.

- We tightly plant the plugs into the pipe and fix it with self-tapping screws.

- Insert the pin into the holes in the plugs. The axis should protrude from the cylinder by 2-3 cm on each side. It is she who will act as an attachment to the adjusting racks.

- We glue rubber on the drum. To her it will be easier to attach the sanding belt.

2.3 Assembling the machine

To assemble the machine you need:

- Install the racks on the frame.

- Attach the drum to them so that the height of its rise can be adjusted.

- Connect the motor to the drum using a belt or chain drive.

- You can get to work.

2.4 Homemade drum sander (video)

How Jacob Wrestled With God - Bible Interpretation

Prayer for the taming of an evil heart

Happy birthday dear pastor Julia

Venerable Seraphim of Vyritsky, who repeated the pilgrimage of Seraphim of Sarov

Icon of the All-Seeing Eye of God - meaning, what helps, history