Woodworking machines can be classified depending on the range of tasks performed, namely:

- universal, combined, which perform a wide range of tasks. They can replace several specialized machines;

- specialized, carrying out a specific type of processing;

- special, processing only the same type of parts (for example, for lining).

Useful: sawmill equipment.

Wood: No. 1 natural material

Wood is and remains a natural material no. This construction material used for millennia for buildings and furniture of all kinds. The renewable material not only looks aesthetically pleasing, but also unlike other material with low density and high stability. This also makes it interesting for construction, as it is the only material that can take on both thermal insulation and static tasks. Accordingly, an entire industry has developed around the woodworking machine.

Special, in turn, are divided according to the type of operation performed into the following types:

- debarking (designed for cleaning from bark. They can be rotary, caliper and hydraulic. The former are most often used.);

- sawmill frames (they cut logs in the longitudinal direction with one or more saws. They can be general-purpose, intended for stationary workshops, and special - for precious woods and plywood production);

- band saws (used for cutting wood materials. They are divided into dividing, carpentry, log saws. The former can do vertical and horizontal cutting, the material is mechanized. The latter are only horizontal and manual feed);

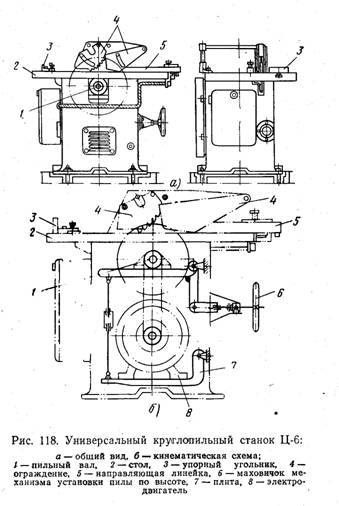

- circular saws (carry out cutting lumber, blanks and sheets of plywood or different kind plates. Can be for transverse cutting, longitudinal or mixed type);

- longitudinal milling (form the longitudinal surfaces of bar and panel parts. They are jointing, thicknessing and four-sided);

- milling (carry out milling various surfaces along the contours, cut spikes and springs, process the edges. They can be with a lower spindle and with an upper one);

- tenon-cutting (they form spikes and springs on adjacent parts when they are connected at an angle into boxes or frames. They are one-sided and two-sided);

- drilling, drilling-grooving and slotting (carry out making holes (through and not through), selecting sockets, removing knots that are sealed with plugs. They can be divided by type of cutting tool, type of specific operation, depending on the location of the spindles and on their number) ;

- turning (they are used for processing rotating parts. They can be center, face-turning and round-stick (centerless);

- grinding (used at the end of processing, smooth out any irregularities).

In woodworking machines, there are several ways to feed material. Accordingly, they can be cyclical or income. The former work on the principle of intermittent supply of material to the cutting tool or vice versa. In receipts, there is a continuous supply of material, that is, processing is in motion.

Also, to determine the type and subspecies of a woodworking machine, it is customary to use their letter indexing:

The term "woodworking" describes all the ways of making and modifying wooden surfaces. This includes both molding processes through machining and abrasion, as well as design methods for color or structuring woodworking.

The range of woodworking machines starts with simple hand tools and ends with big machines for industrial production. In most cases, the woodworking machine has a cutting or erosive effect on the material. Via various tools the material is brought into the desired shape. However, there are also molding machines that preserve the volume and mass of the material: wood can be bent into any shape under steam pressure. Its positive properties remain unchanged.

OK - leg,

R, 2R, RG - sawmill frames,

LB, LD, LS - band saws,

TsD, TsR, TsT, TsK - circular saws,

SF - jointer,

SR - planer,

C - four-sided longitudinal milling,

F - milling,

Shl - grinding,

SHO, SD - tenon-cutting for frame tenon,

ШП, ШЛХ, ШК - tenon-cutting for a box tenon,

SV - drilling,

SVP - drilling and grooving,

DC - slotting with a milling chain,

T - turning,

KP - round stick.The variety of woodworking machines is best explained by following the path of wood from a log to a finished product. The chainsaw marks the beginning of every woodworking machine. This is not without reason: here you can find all kinds of sawmills.

In addition, other forest machines help increase productivity and safety during the harvest. In order to cut the delivered tree trunk into working parts, stationary sawmills are used in the sawmill industry. The circular saws used here are especially large scale woodworking machines.

At the same time, the first letters are responsible for the type of machine and its purpose, and the subsequent ones - technological features. In addition to letters, there may be numbers. Oki indicate the maximum characteristic parameter.

A huge number of manufacturers of woodworking machines are represented on the Russian market. The most popular among buyers are Felder (Austria), JET (Switzerland), Belmash (Republic of Belarus), Stark (Germany), Makita (Japan).

Saws for workshops and construction sites

In workshops, on construction sites or as carpentry machines, significantly smaller but equally efficient saws get the job done. As a result, the material can be fed to a controlled saw blade which greatly improves the cutting accuracy.

What to look for when buying used cars?

Another version of the circular saw is used in the production of chipboard. Specialized solutions for processing wood products and much more - the world of woodworking equipment is huge.

Used car market

B. in the production of furniture - it's about efficiency. The pressure of innovation on manufacturers is very high. Due to efficiency gains, used machines and equipment are often sold long before they are retired to be replaced by new machines.Woodworking machines are presented on the market in a wide range. Some are designed for do-it-yourself wood processing, while other types can perform cutting, grinding, sawing and other processing operations in automatic mode, since their work is based on numerical program management- CNC. Consider what types of machines exist and what each of them is.

Wear and tear and dirt

Therefore, the market for used equipment is large, which leads to low prices. Although woodworking machines are less busy than machines in the steel industry, they are also less stable. In general, their wear is relatively low. The used woodworking machine usually does not reach the end of its life cycle by overloading, but by contamination.

Thicknessing and jointing-thicknessing machines

The dust generated during cutting is very fine and penetrates through every crack. It settles over time like a stubborn layer. For electronic components, this can lead to a short circuit. In warehouses, it provides increased wear. If this is left unnoticed for too long, the accuracy of the woodworking machine may suffer.

Woodworking machines, as the classification provides, are divided into a number of varieties. There is a certain list of technological characteristics on which the classification of woodworking equipment is based.

The most important thing when you buy a used woodworking machine is to take a critical look at its interior. Even if it is polished on the outside to a high gloss, the interior of the used car may differ. In particular, they are affected by spline machines: in addition to wood dust, they also have a permanent adhesive.

However, heavily used and barely used machines can also be repaired with patience and effort. Through professional cleaning, replacement of wear parts and the implementation of the necessary repair work virtually any used woodworking machine can be made afloat again.

Depending on the purpose, there are three types of machines:

- Universal. They are general purpose woodworking machines. They can be used to perform different kinds processing;

- Specialized. Their design and functionality allow you to engage in certain woodworking operations;

- Special. Focused on one specific function. Usually used in industries, factories, large workshops.

There is a classification depending on the way the workpiece is fed to the machine. Here they distinguish:

Dry ice lamp services are recommended here. They also insert the glued or wetted machine into working mode. This means that virtually any company can take advantage of an inexpensive but high quality used machine without having to pay the much higher costs of a comparable new machine.

Used cars at auction

For several years, used woodworking machines have increasingly been sold in online auctions. Europe's largest platform in this market segment is Surplex. Here, every day, well-preserved machines and plant equipment are under the hammer that comes from factory closures, restructurings and bankruptcies. The craftsman finds handy circular saws, chipping saws, band saws, grinders and carpentry machines on this platform.

- Cyclic;

- Checkpoints.

Depending on the application, all existing woodworking machines are divided into two categories.

- Household. They are not intended for continuous operation, have limited power and capabilities. The peculiarity lies in the presence of a thermal relay, which allows you to turn off the woodworking machine in case of excess loads.

- Industrial. Designed for large-scale processing, have increased power, wear resistance, high performance characteristics. With their help, work is carried out with large products, mass production of parts.

Both in industry and in everyday life, combined woodworking machines have gained wide popularity. But if for a garage or a home workshop it is enough to purchase mini woodworking machines, then a professional overall option is required for an enterprise or factory.

Participation in industry auctions provides some advantages. The offered machines are usually in good condition and come directly from the production. Thus, they have already proven their functionality and performance and can be quickly put into operation on a new site.

Last but not least, every industrial auction offers a realistic opportunity to purchase a high quality used car, especially favorable. It is true that there are usually realistic market prices in an auction. However, again and again significant deviations are observed. This also applies to some new machine in use, which bears any comparison with the corresponding new car, but often added to a portion of the original price.

Depending on the situation, the needs of the buyer, each woodworking unit has its own undeniable advantages. Therefore, you need to focus on the list of tasks that the machine should be able to perform when processing wood.

Types of machines

Woodworking machine is:

Woodworking machines for efficient processing

In general, industrial auctions provide an opportunity to buy used machines from leading manufacturers inexpensively without compromising the quality of the offered woodworking machine. Wood as a material for woodworking machines. Wood combines many properties not found in other materials in this range. For example, wood is the only material that combines properties that can be used for both static and insulating purposes.

- planer;

- Format-cutting;

- Circular;

- Sawing;

- Slotting;

- Turning;

- Milling;

- drilling;

- Combined;

- Tape;

- edge banding;

- Grinding;

- Electrocleaver.

What are the advantages of the machine?

In addition, wood is easier to process than stone due to its lower density and hardness. For wood and wood-based materials, there is a large selection of woodworking machines or simplified wood machines. Video: Modern woodworking machine in action.

Used woodworking machines and tools can be a useful alternative to newly purchased machines. In addition to older devices, you will also find. The woodworking machines used are available from various international suppliers. The offer includes used wood machines from different manufacturers and years of construction. The product descriptions on the operator pages help you choose the right machine.

In addition to the fact that you have to choose a woodworking machine of the type that suits you, working with equipment is usually accompanied by the additional purchase of a workbench and a chip blower. The workbench has different sizes, which predetermines the possibilities for placing the machine on it. The larger the dimensions, the larger the machine you will be able to deal with yourself.

You can often buy used woodworking machines at attractive prices. The wood is injected into the desired shape in several stages. These steps are also carried out by carpentry machines. They make the necessary boards and beams from a round and irregularly shaped trunk. There are many used woodworking machines in the area. The most frequent here are guns, circular saws, chain saws.

Woodworking machines for various tasks

There are woodworking machines for various purposes. They are available from simple three axle systems up to seven axles. With them, single and small series can be made into any desired shape. All desired shapes can be made wooden blanks. Particularly efficient woodworking machines are profiling machines. They are used to make specially shaped blanks in series. These include window and frame machines. Chip presses process the accumulated sawdust that occurs when working with wood into high-quality chipboard.

Woodworking work can do without a chip extractor, that is, a vacuum cleaner. But so that after processing there is no dirt left, it does not have to be removed with your own hands, it does not clog the technological holes of the machine during cutting, it is better to choose an effective vacuum cleaner and do not forget to use it periodically.

What type of woodworking equipment suits you best? Here you should not rely only on video reviews of popular models, customer reviews or prices. On average, a woodworking machine will cost at least 5-10 thousand rubles, but there are also models for 5-10 thousand dollars. Again, it all depends on your processing needs. Therefore, we will consider each of the presented types separately.

Wooden machines for the perfect surface

They are made at different levels of quality. Particularly when processing chipboard importance has a surface design. Again, there are different woodworking machines. As homogeneous and easily processed as these predecessors, they are not visually pleasing to look at. This is done on special machines for sanding veneer. The plates are covered with soft and postforming machines. Modern woodworking machines can also be used unlimitedly in the coating of profiles and round edges.

- planer. He is also a planer-planer for wood. The shortest, but understandable name for everyone is the thickness gauge. This woodworking machine performs two operations - planes, giving the product the desired size, and aligns to obtain flat surface. It looks like a do-it-yourself planer. But unlike rough cutting with a planer, the planer provides excellent quality woodworking.

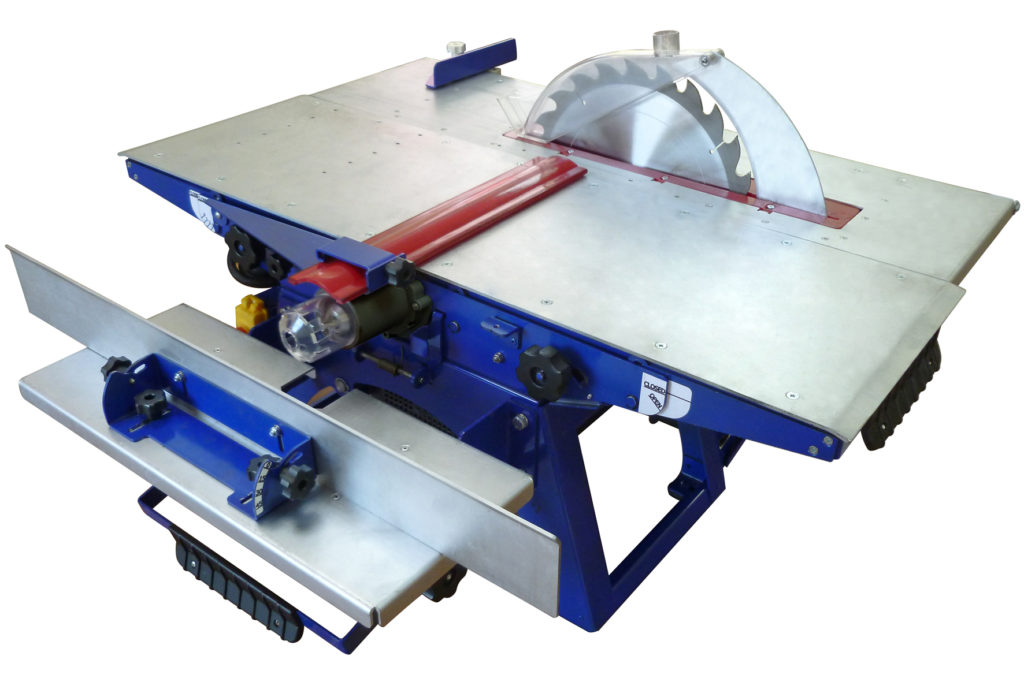

- Circular. This is about circular saws designed for do-it-yourself work. Excellent tool for cutting, sawing wood. Working with such woodworking equipment is accompanied by high cutting accuracy. This type of woodworking machine is preferable to hand saws.

- Format cutting. This wood cutting machine provides angular, longitudinal, transverse cutting of wooden blanks and wood-based materials.

- Sawing. Such a woodworking unit has several varieties - disk machines for cutting, longitudinal sawing machines, sawmills, etc. Their main task is to divide one large workpiece into several smaller parts. Work can be done by hand or automatically, depending on the model. It is quite possible to assemble a sawmill with your own hands, using drawings and video guides. Moreover, many drawings provide for the use of a conventional circular, from which a full-fledged apparatus is assembled.

- Dolbezhny. This unit is clearly not designed for cutting. Its drawings and device provide for a powerful drive. This is due to the fact that serious loads are applied to the electric motor for drilling, grooving and other operations. Therefore, when choosing a slotting woodworking machine, pay attention not only to the dimensions, but also to technical specifications devices.

- Turning. The most famous version of woodworking equipment, which serves for a wide range of operations performed. Namely, drilling, carving, facing, making grooves, turning, etc.

- Milling. An equally popular unit that allows you to work with your own hands or use the CNC module for automatic operation. Milling devices perform outdoor and internal surfaces, planes, grooving, threading, etc.

- Drilling. From the name it becomes clear for what purposes this woodworking unit is needed.

- Combined. This woodworking equipment is capable of combining several units at once in one device. Depending on the modification, the device has a certain set of functions. But the greater the number of working tools, the lower the overall quality of processing. Therefore, it is recommended to choose units where no more than 2-3 functions are assembled.

- Tape. Tape devices, they are also saws, provide cutting wood of different parameters, as well as figured cutting of products.

- Edge banding. These devices are designed for decorative operations in the processing of wood. The most demanded sphere of their application is furniture production.

- Grinding. The grinding machine brings the surface of wooden blanks to perfection, removes all irregularities, gives smoothness.

- Cleaver. Electrical machines for chopping firewood, they perfectly replace axes, with which you have to harvest firewood for the winter with your own hands. Widespread among owners of private houses where there are fireplaces.

It is quite simple to choose and work with your own hands on machines for cutting, sawing, sharpening, drilling and other operations. Based on your own needs and planned woodworking activities, the purchase of a suitable machine becomes a matter of technology.

Finally, the parts are assembled to form end products on frames and assembly presses. Despite all the automation, it takes a lot handmade. However, these woodworking machines are a particularly efficient assembly of cabinets, shelving and other furniture.

The influence of the Internet on a person

Types of seizures Tonic-clonic seizures in children

Profession Internet project manager

best remedy for prostatitis

Symptoms and treatment of mastopathy of the mammary glands