CNC machines are modern devices that allow you to work with a large number of workpieces and process them at a fast pace. To work with such a machine, you do not need to have special education. Having a minimum experience in this field allows you to effectively cope with such a device. In this article we will talk about how you can make money on a CNC machine.

Wood processing

CNC milling machines allow you to quickly and masterfully process wooden blanks. Such a device allows you to create curvilinear reliefs of traditional and non-traditional shapes. good machine for wood processing allows sawing wooden blanks, creating grooves and grooves on them.

Such devices are most often used:

- Furniture manufacturing companies. Allows you to create quite original products from the most different materials.

- Development of various forms for other industries.

- Production of souvenirs and original household items, gifts.

- Marketing area - production of logos, etc.

The broadest prospects for making money with the help of CNC machines open up in the field of developing the most different forms and models. The specificity of these devices makes it possible to produce the necessary (even rather complex) part or shape with the least expenditure of time and money. At the same time, they do everything quickly and efficiently. The made molds can be used for mass production of required goods.

Metal processing

CNC milling machines for machining metal products not much different from the same woodworking machines. On the other hand, such devices have a wider scope, and their products are in great demand in the modern market. There are several ways to make money with these devices:

- Create online ads on advertising resources. Write in detail there the products that you can produce, add to this ad the maximum number of photos of your products. Pay special attention to highlighting the benefits of your work. If you specify the price of your products, be sure to justify it. Specify the maximum amount of goods that you can produce in a certain period of time.

- Collaborate with other workshops. Feel free to seek allies. Among other masters, you can find not only competitors, but also potential and regular customers. They will not only buy your products for own production but they can also recommend it to their clients. In this case, the ability to show yourself and your products with the most better side, describe all the benefits of a possible cooperation.

- Try to specialize in a particular market segment. It is better to make one part that is in high demand than a lot of parts that are difficult to sell. With each new completed order, you will improve the quality of your products and acquire new customers. In this case, the correct analysis of the market and its potential place in it is of great importance.

Video: what can be done on a CNC machine?

Consider these recommendations before purchasing machines or before starting serious production. Try to get the maximum amount of information in the future area of \u200b\u200bits work. Feel free and don't be afraid to ask for advice on specialized forums and from people who have already achieved some success in this field.

A CNC router is a must for every craftsman who seriously works with wood. But how to choose it correctly and what to pay attention to? I am ready to accurately betray the technical points, as well as to conduct short review desktop CNC milling machines, which will surely help beginners make the right choice.

What are CNC milling machines

General information

Not so long ago, small-sized desktop woodworking machines were exclusively manual or automated. CNC blocks (computer numerical control), i.e. computerized control system, equipped only with equipment for large-scale production.

Recently, the situation has changed dramatically - desktop milling machines with emergency appeared on the market. This greatly expands their capabilities and increases productivity. After all, CNC allows the machine to perform any operation according to a given program without operator intervention.

In fact, desktop machines differ from industrial counterparts only in size and lower power. But in terms of functionality, they are practically not inferior to them. With their help, you can perform operations such as:

- Milling;

- countersinking;

- drilling;

- boring;

- sawing off;

- 3D wood carving, etc.

Unlike manual and automated equipment, CNC machines can work with workpieces that have a complex contour. And the work is carried out very accurately.

Varieties

Desktop machines differ primarily in the type of desktop. Depending on this, they can be:

- Console. The working table with the workpiece can change position relative to the router. As a rule, this design is found in overall machines capable of processing large parts;

- motionless. In this case, the table with the workpiece remains stationary, and the milling head is moved using carriages.

Another important difference between the equipment in question is the location of the milling head, which can be:

- horizontal;

- vertical;

- Changing.

The most functional last type of machines. These devices allow you to process the workpiece in all three coordinate axes, which greatly expands their capabilities.

Special mention should be made of copy machines, which can process the workpiece according to the template. Such devices are equipped with a special unit that scans the original part.

The scanning unit transmits the data to the CNC, after which the router reproduces an exact copy. Accordingly, for copying, you don’t even need to set any parameters of the original part with your own hands.

Therefore, when choosing, you first need to decide on the type of workpieces and the type of operations that will most often be performed on the equipment, which will allow you to choose the optimal type of machine.

What to look for when choosing

When choosing a compact CNC machine, be sure to pay attention to the following points:

- Device dimensions and table dimensions. This parameter determines the maximum size of parts that you can process;

- Type of power plant. Can be stepper or servo driven. The first is more powerful, but provides less processing accuracy;

- Power and speed. As a rule, this indicator is usually in the range of 1.5-2.5 kW. The rotation speed can reach 24-25 thousand revolutions per minute.

Ideally, the power and speed should be adjustable, which makes the machine more functional; - CNC block. It is desirable that the CNC unit can be connected to a computer. This simplifies the work and increases its equipment capabilities.

In particular, connection to a computer allows you to download ready-made two-dimensional and three-dimensional models. Moreover, download models for CNC milling machine possible on the Internet;

- cooling type. Machines can be equipped with an air or water cooling system. If the equipment will be actively used, it is better to purchase a water-cooled model, as it is more efficient;

- Positioning accuracy of the cutting element. The error of milling processing depends on this parameter. Accordingly, the smaller the error, the more accurate the details are, so it is desirable that the positioning accuracy is no more than 0.1 mm.

When buying a device, pay attention to the compatibility of the CNC unit with operating system your PC. Some older models may only work with Windows XP.

This is the whole basic instruction for choosing a machine. Otherwise, you should pay attention to the manufacturer of the equipment and its functionality.

Machine overviews

Finally, consider some popular and relatively inexpensive machine models that have proven themselves well. These include:

Volzhanin-1

Volzhanin-1 is a small domestic-made milling and engraving machine. It is able to work in three planes, which allows you to perform both two-dimensional and 3D milling.

Characteristics. This machine has the following features:

As a result, the machine allows you to work with any type of wood, polymeric materials, plexiglass and even non-ferrous metals.

Price. Volzhanin-1 costs about 300,000 rubles. Keep in mind that all prices are current in spring 2017.

Zaxis

Zaxis is another compact Russian-made milling and engraving machine. It has less power than Volzhanin-1, but is not inferior to it in terms of functionality, besides it costs much less.

The manufacturer draws attention to the high reliability of the device due to the use of high-quality components of Italian, Russian and Chinese production.

Characteristics:

Zaxis can work with all types of wood, polymers and non-ferrous metals.

Minimo 6090TT - multifunctional desktop machine with large working area

Minimo 6090TT

Minimo 6090TT is a milling and engraving machine from a Chinese manufacturer. This unit has a large enough working field along three axes. In addition, the manufacturer draws attention to a simple and intuitive interface that simplifies the work with the machine.

Characteristics:

The scope of the apparatus is the same as that of the machines described above.

Price. Minimo 6090TT costs 195,000 rubles.

LTT-K6090

LTT-K6090 is a fairly powerful milling machine made in China, which is popular due to its reliability and functionality. Like all of the above brothers, it is capable of performing both two-dimensional milling and three-dimensional.

Characteristics:

Price. The price of LTT-K6090 is about 240,000 rubles.

Aman 3040 Lite

Aman 3040 Lite is a mini milling and engraving machine made in China. It differs from the counterparts described above in more compact dimensions and lower spindle power.

Characteristics:

The design of this machine allows you to install a more powerful spindle - up to 1.5 kW.

Price. The price of the device is 118,000 rubles.

That, in fact, is all desktop models CNC milling machines that I wanted to tell you about.

Output

Now you know what differences desktop CNC routers can have, and what you need to pay attention to when choosing them. Watch the video in this article for more. If you have any questions - write comments, and I will be happy to answer you.

(CNC) is equipment designed for machining various sheet materials using a special tool - a cutter. Milling processes the most various material: plastic, graphite, aluminium, copper, cast iron, steel or wood.

Milling cutters are metal tools various shapes With several cutting teeth. The shape of the cutter is:

- conical,

- cylindrical,

- end,

- end and other types.

The material from which the cutting part is made must be much stronger than the material being processed, therefore, hard alloys of high-speed steel are selected for milling cutters, mineral ceramics or diamond can also be used. In addition, cutters differ in design and type of teeth: they can be:

- solid (or monolithic, the so-called "finger cutters"),

- with welded cutting element,

- prefabricated or with soldered cutting element.

Rotating at high speed, they process the material, cutting, drilling, cutting and engraving it in accordance with a given program under the control of a CNC operator.

Depending on the location of the working tool, milling can be horizontal or vertical. Universal machines have become widespread, making it possible to mill complex parts at any angle using different cutters.

The cutter, fixed in the collet, is the main element in direct contact with the material being processed. A collet with a cutter fixed in it is installed in the spindle, which ensures the rotation of the cutter. In turn, the spindle with the cutter is mounted on a movable beam - a portal that moves the spindle and cutter in three coordinate axes above the material being processed, mounted on the desktop. The movement of the portal, as well as the movement of the spindle along the portal, is provided by three microstepping motors. Portal, bed, motors, spindle and cutter are the mechanical part of the milling machine. Each engine provides the movement of the portal and the spindle along its axis according to a given program.

The control stations of CNC milling machines are an electronic part of the equipment and are supplied with the machine. Software machine processes vector images from graphic files, translates them into G-codes that control the operation of microstepping motors. Thus, for the manufacture of a particular part, it is necessary to build it in a graphic editor such computer program, such as AutoCad or Corel Draw. After installing the developed program in the RAM of the machine (random access memory or RAM), the operator can start working by first selecting the necessary modes and parameters in accordance with the technological task and the material being processed.

Numerical control allows you to automate complex technological processes processing of certain materials. The CNC machine does not require any complicated actions from the operator during operation. The machine works according to the program laid down in it before the start of the processing process. The program is entered by the operator from the remote control designed to control the machine in manual mode. When emergency The remote control is used to turn off the machine. All current information about the operation of the machine is displayed on the operator panel, which visually controls the execution of technological operations.

CNC milling machines are high-tech modern equipment, capable of providing the necessary labor productivity and excellent quality of material processing. The use of CNC machines increases the level of safety and culture of production and does not require virtuosity and high professionalism from the machine operator.

On this page of the site we will try enough plain language explain how work on a CNC machine For example jewelry modeling.

I am sure that almost any interested person will be able to master the methods of work.

However, do not forget that any technique requires attention, ... and patience.

First:

If you are not familiar with AutoCAD, then you will first need to learn the basics of this graphic editor. The fact is that it is on this platform that we design the trajectory of the movement of machine tools and create a working file for it. To this end, we have developed several embedded software modules.

Tutorials are required to learn with AutoCAD. There are a lot of them. Many are available on the Internet, freely available. To get started, you can read, for example, - AutoCAD for students.

You can use different versions of AutoCAD. True, we, for example, use the Mechanical Desktop R6 Power Pack. Suitable for our purposes the best way. And in case of difficulties with the installation or with the study of this program, we can provide all possible assistance.

Second:

To study the device of the machine and characteristics. For initial acquaintance we can provide 2 instructions.

We provide full-time and (or) distance learning. Basic course included in the cost of the machine.

Third:

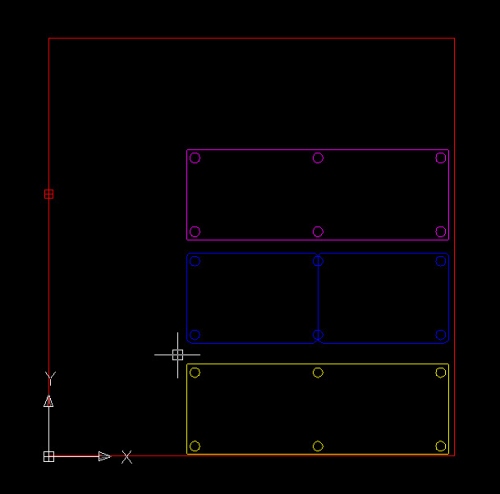

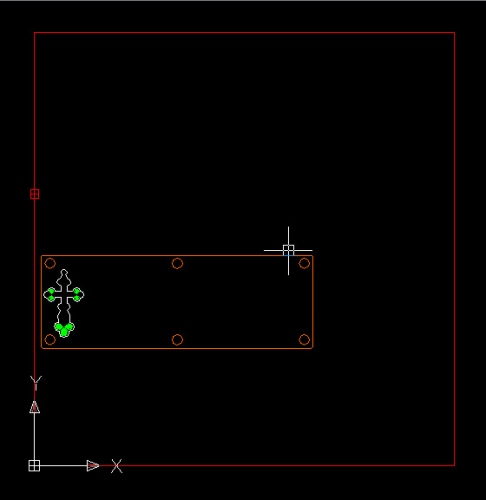

Together with the machine, we will provide the files necessary for work. All machine settings will be made and fixed in your computer, in the AutoCAD DWG file. This means that the boundaries of the working field will be set, seat for interchangeable plates, and the real settings of each tool of the machine (milling cutter, scriber, engraver) will be fixed (see fig. No. 1).

Together with the machine, we will provide the files necessary for work. All machine settings will be made and fixed in your computer, in the AutoCAD DWG file. This means that the boundaries of the working field will be set, seat for interchangeable plates, and the real settings of each tool of the machine (milling cutter, scriber, engraver) will be fixed (see fig. No. 1).

Having received the machine, you can immediately start modeling the product that you want to receive.

First of all, it is necessary to determine the geometry of the product. It is very good if you have (get) this information along with a perforated stamp. Otherwise, you will have to work quite hard with an electronic barbell and other meters ...

Having dimensions products, we use a milling cutter to make a seat for the product.

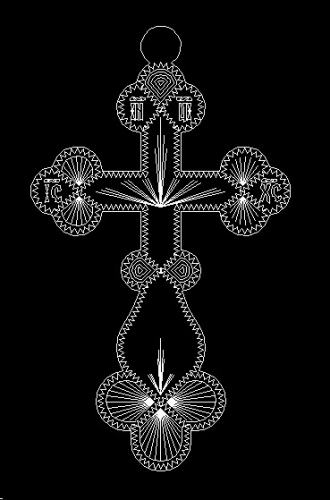

Now about the design of the future product. For example, it may look like it is presented in fig. No. 2.

This is a variant of a body jewelry cross. In this case, with the help of AutoCAD primitives (segments, arcs, polylines, splines ...), a trajectory of movement of working tools was created. To achieve the best artistic effect, this trajectory is made three-dimensional.

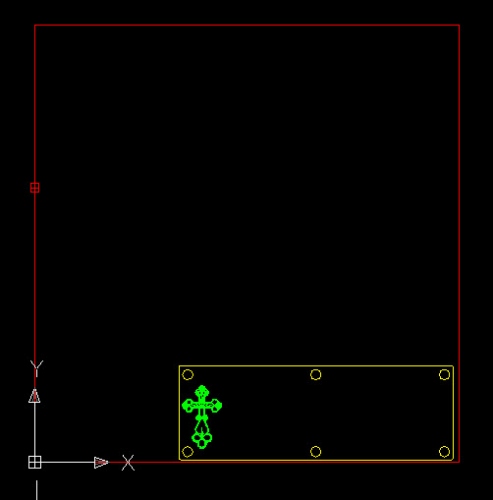

Now a few words about drawings No. 3 and No. 4. Here we have separated the primitives that define the operation of each of the two tools. And for convenience further use, created two separate files.

|

|

Fourth:

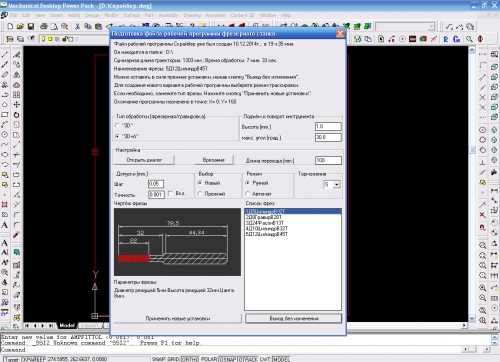

Now everything is ready to calculate the working files for the machine. For example, let's first perform such a calculation for a scriber. To do this, open the desired file and run the corresponding function of our software module AutoCAD adaptations. The initial view of the dialog box of this function is presented in Fig. No. 5. Next, you need to perform a few simple sequential steps. These actions are determined by the calculation function algorithm. One of the main tasks here is to specify the sequence of processing primitives. As a result of the dialogue, if necessary, you can change the direction of movement on the desired sections of the trajectory. After the end of the calculation, a working file for the scriber will be prepared. This file has the extension lpm. This format is developed by us and "understandable" only by our machine controller.

Fifth:

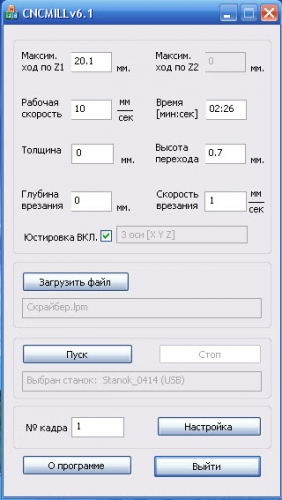

The prepared working file can now be immediately processed. To do this, open the dialog box of the machine control driver and load the file. Appearance driver submitted in Fig. No. 6.

The control of the machine is quite simple. The main task of the operator is to set the desired tool depth. To do this, he has at his disposal an electronic indicator of the Z coordinate. It shows the current position (distance) relative to the zero point sensor in Z. The task of the operator is to find the distance from the zero position to the tool touching the surface of the product and add the desired depth. For example, according to the electronic indicator, the contact with the workpiece was fixed at a value of 20 mm. The cutting depth is usually 0.1 mm. Therefore, the maximum depth will be 20.1 mm. We enter this data into the program window (Max. travel in Z) Thus, we connect the program and machine zero. This parameter very easy to adjust, if necessary, along the tuning pass.

Outcome:

Almost anyone can become a machine operator. Engraving time for one side of the middle cross is approximately 2-3 minutes. In particular, for the considered product, scribing front side took 2 min. 26 sec. Time spent processing reverse side was 1min.58sec. The work of the engraver lasted 1 min. 32sec. The result is shown in fig. No. 7 and No. 8.

|

|

More than 70% of products in mechanical engineering are manufactured in small-scale and mass production. An effective remedy automation of small-scale and serial production is the software control of metal-cutting machines.

In CNC machines, the control of working bodies during processing is carried out automatically according to a previously developed program without the direct participation of the worker. Program control is such a control system that provides automatic operation of machine mechanisms according to an easily readjustable program. The automatic machine works according to a program set by cams or a copier. The changeover of machine tools - automatic machines and copying machines for the manufacture of another part is difficult. Therefore, it is advantageous to use them only in large-scale and mass production.

The fundamental difference between a machine with a numerical program management(CNC) from a conventional machine consists in setting a part processing program in mathematical (numerical) form on a special program carrier (punched tape or magnetic tape). Hence the name - numerical control.

Can't understand the meaning of life

Mate Brewing Methods

Trollface quest games Black humor games

Dark spots in photos?

Rules of the game Bald in VK. Scrabble nerd. The purpose of the game Balda