Numerical systems program control

Basic principles of numerical control

The development of electronics and computer technology, the introduction of computers into production has led to the development and widespread use in machine tool building of numerical control systems (CNC) for metal-cutting machines, as well as other technological equipment.

Numerical control of metal-cutting machines is called control according to a program specified in an alphanumeric code and representing a sequence of commands written in a certain language and providing the specified functioning of the working bodies of the machine.

The fundamental difference between CNC systems and the previously considered ACS is the method of calculating and setting the control program and its transmission to control the working bodies of the machine. Detail drawing information is presented in analog-digital form, that is, in the form of numbers, various verbal instructions, conventional signs and other symbols that have a limited number of meanings, each of which has quite specific and unambiguous information.

In conventional ACS, the control program is embodied in physical analogues - cams, copiers, stops, jig plates and other means that are program carriers. This method task control program has two basic drawbacks.

First is caused by the fact that the information of the drawing of the part from digital (discrete) and unambiguous turns into analog (in the form of cam curves, copier). This leads to errors introduced in the manufacture of cams, copiers, the arrangement of travel stops on the rulers, as well as the wear of these software carriers during operation. Second The disadvantage is the extreme importance of manufacturing these software carriers with subsequent labor-intensive setup on the machine. It leads to high costs means and time and makes in most cases inefficient the use of conventional ACS for the automation of serial and especially small-scale production.

When preparing control programs for CNC machines up to its transfer to the working bodies of the machine, we are dealing with information in a discrete form, obtained directly from the drawing of the part.

The trajectory of the movement of the cutting tool relative to the machined workpiece in CNC machines is represented as a series of its successive positions, each of which is determined by a number. In CNC machines, it is possible to obtain complex movements of the working bodies not with the help of kinematic connections, but by controlling the independent coordinate movements of these working bodies according to a program specified in numerical form. Qualitatively new in CNC machines is the possibility of increasing the number of simultaneously controlled coordinates, which made it possible to create fundamentally new layouts of machine tools with obtaining wide technological capabilities with automatic control.

The control program must be calculated with any given accuracy and for any required law of movement of the working bodies of the machine. The control of machine tools directly from the computer is gaining more and more widespread use.

Classification of CNC systems

CNC systems can be classified according to various criteria.

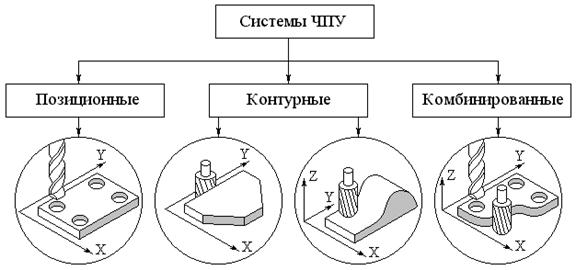

I. Based on the technological tasks of processing control All CNC systems are divided into three groups: positional, contour and combined.

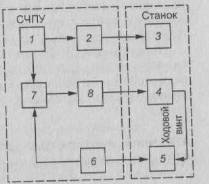

Positional CNC systems provide control of movements of the working bodies of the machine in accordance with the commands that determine the positions specified by the control program. In this case, movements along different coordinate axes can be performed simultaneously (for a given constant speed) or sequentially. These systems are mainly used for drilling and boring machines for processing parts such as plates, flanges, covers, etc., in which drilling, countersinking, boring holes, threading, etc.

CNC contouring systems provide control of the movements of the working bodies of the machine along the trajectory and with the contour speed specified by the control program. The contour speed is the resulting feed rate of the working body of the machine, the direction of which coincides with the direction of the tangent at each point of the specified processing contour. Contour CNC systems, unlike positional ones, provide continuous control of tool or workpiece movements one by one or simultaneously along several coordinates, which makes it possible to process very complex parts (with control over more than two coordinates simultaneously). CNC contouring systems are mainly equipped with turning and milling machines.

Combined CNC systems, combining the functions of positional and contour CNC systems, are the most complex, but also more versatile. In connection with the complication of CNC machines (especially multi-operational ones), the expansion of their technological capabilities and the increase in the degree of automation, the use of combined CNC systems is expanding significantly.

II. Availability feedback All CNC systems are divided into two groups: open and closed.

Closed CNC systems, in turn, are:

1) with feedback on the position of the working bodies of the machine; 2) with feedback on the position of the working bodies and with compensation for machine errors; 3) self-adapting (adaptive).

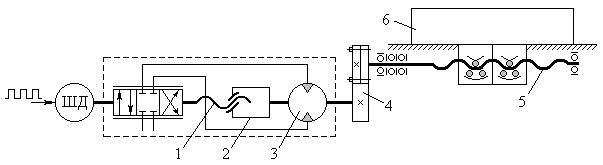

open CNC systems are built on the basis of power or stepper motors (SM). In the latter case, the stepper motor is usually used in conjunction with a hydraulic booster.

III. Classification based on the level of electronic technology.

Despite the relatively short period of use of CNC systems, they have already gone through several stages in their development, determined by the level of development of electronic technology.

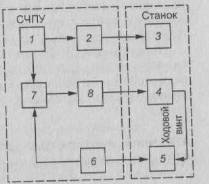

CNC systems currently used in industry class NC built on the basis of a digital model. In this system, the program (on punched tape) is entered into interpolator 3, further revised

the program is entered into the control system 2 machine 1. These CNC systems are called systems with a rigid program. The possibilities of operator intervention in the process of program processing are very limited on these systems.

In systems class SNC the device for reading the control program is used only once - to enter the control program into

storage unit 4 (memory). As a result, the reliability of the machine is increased due to the failure of the photoreader.

Feature of control systems CNC class is their structure corresponding to the structure of the control computer. With the advent of CNC class systems, the functionality of program control has expanded,

including storage of the control program and its editing directly at the workplace, advanced display options, dialog communication with the operator, etc. The input of the control program must be carried out on punched tape or manually. The second type of systems is called systems class HNC. The control program here is entered by the operator using the keyboard and stored in the system memory.

As well as autonomous systems CNC in industry use direct numerical control systems for a group of different machine tools from a single computer, called systems DNC class.

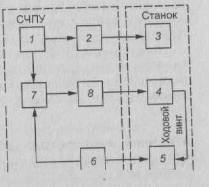

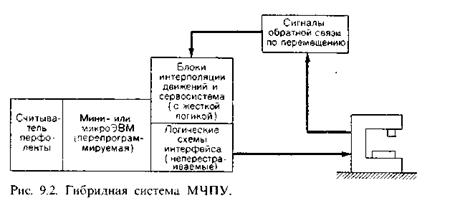

In this system, a medium or large computer (3) prepares programs for several CNC machines and transfers them to the CNC systems (2) of individual machines (1). Due to the very high speed of the computer, the system prepares programs for all machine tools of the group. The computer also performs additional functions for managing a semiautomatic device, for example, it controls automated transport and a warehouse. Machine tools are directly controlled by minicomputers with a small volume random access memory included in individual CNC systems.

In this system, a medium or large computer (3) prepares programs for several CNC machines and transfers them to the CNC systems (2) of individual machines (1). Due to the very high speed of the computer, the system prepares programs for all machine tools of the group. The computer also performs additional functions for managing a semiautomatic device, for example, it controls automated transport and a warehouse. Machine tools are directly controlled by minicomputers with a small volume random access memory included in individual CNC systems.

Typical block diagram of a CNC system

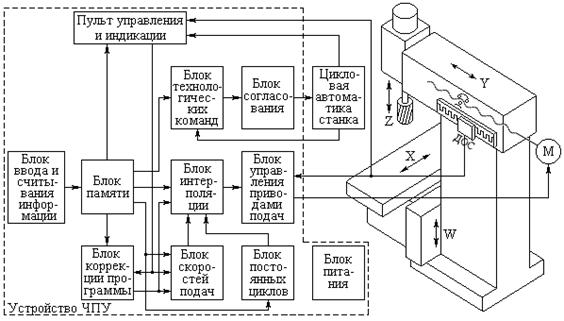

The figure shows a general enlarged block diagram of the CNC system. It includes the following main elements: CNC device; feed drives of the working bodies of the machine and feedback sensors (DOS) installed for each controlled coordinate. The CNC device is designed to issue control actions by the working body of the machine in accordance with the control program entered on the punched tape. The control program is read sequentially within one frame with storage in the memory block, from where it is fed into the blocks of technological commands, interpolation and feed rates. The interpolation block is a specialized computing device (interpolator) that formulates a partial trajectory of the tool movement between two or more points specified in the control program. The output information from this block enters the feed drive control unit, usually presented as a sequence of pulses for each coordinate, the frequency of which determines the feed rate, and the number determines the amount of movement.

Information input and reading block is intended for input and reading from the punched tape of the control program. Reading is carried out sequentially line by line within one frame with periodic pulling of a punched tape in front of a photo reader containing a photo reading head 11 with photo converters, and an illuminator,

consisting of an incandescent lamp 3 and a lens 4. Eight photoconverters provide information reading, and two are used to generate a sync pulse through the holes of the transport track. In other devices, another photoconverter is used, which is installed along the edge of the punched tape to control its breakage.

Pulling punched tape 9 is carried out by drive roller 7, to which it is pressed by roller 10, when the broach electromagnet (EMF) is turned on and armature 6 is pulled. braked by brake 1 and pressed against head 11 by clamp 5, which is retracted by lever 2 when punched tape is loaded. After reading the information of one frame, the punched tape is stopped by turning on the EMT brake and turning off the EMF electromagnet. Synchronization of their work is carried out by a control trigger (TG).

There are modifications to the input device.

Memory block. Since the information from the punched tape is read sequentially, and is used all at once within one frame, when reading it, it is stored in the memory block. Here, it is also monitored and a signal is generated when an error is detected in the punched tape. Since the processing of information proceeds sequentially by frames, and the time for reading information from one frame is approximately 0.1 - 0.2 s, a gap in the transmission of information is obtained, which is unacceptable. For this reason, two blocks of memory are used. While the information of one frame from the first memory block is being processed, the second frame is read from the punched tape and stored in the second block. The time for introducing information from the memory block into the interpolation block is negligible. In many CNC systems, the memory block can receive information bypassing the input block and reading directly from the computer.

interpolation block. This specialized computing device, ĸᴏᴛᴏᴩᴏᴇ forms a partial tool path between two or more points specified in the control program. This is the most important block in CNC contouring systems. The basis of the block is the interpolator, which, according to the numerical parameters of the contour section specified by the control program, restores the function f (x, y). In the intervals of X and Y coordinate values, the interpolator calculates the coordinate values of the intermediate points of this function.

At the outputs of the interpolator, control pulses strictly synchronized in time are generated to move the working body of the machine along the corresponding coordinate axes.

Apply linear and linear - circular interpolators. In accordance with this, the former produce linear interpolation, and the latter linear and circular.

A linear interpolator provides, for example, the movement of a working body with a cutter with a diameter between two reference points in a straight line with a deviation from a given contour by a value.

In this case, the initial information for the interpolator is the magnitude of the increments in coordinates and the processing time of moving along a straight line, ᴛ.ᴇ. , where S is the set tool feed rate.

The operation of a linear-circular interpolator can be carried out according to the method of the evaluation function F. The method essentially consists in the fact that when the next control pulse is generated, the logic circuit evaluates on which coordinate this pulse should be issued so that the total movement of the working body of the machine tool as close as possible to it to a given contour.

The interpolated line (see Fig. a) divides the plane in which it is located into two regions: above the line, where the evaluation function F>0, and below the line, where F<0. Все точки, лежащие теоретически заданной линии, имеют F=0.

The interpolation trajectory is a certain sequence of elementary movements along the coordinate axes from the starting point with coordinates to the end point with coordinates , .

If the intermediate point of the trajectory is in the region F>0, then the next step is taken along the X axis. If the intermediate point is in the region F<0, шаг делается по оси Y. Аналогично происходит работа интерполятора при круговой интерполяции (см. рис. б).

Feed drive control unit. From the interpolation block, the information is fed to the feed drive control unit, which converts it into a form suitable for controlling feed drives. The latter is done so that upon receipt of each pulse, the working body of the machine moves by a certain amount, characterizing the discreteness of the CNC system. With the arrival of each pulse, the controlled object moves by a certain amount, called the price of the pulse, which is usually 0.01 - 0.02 mm. Given the dependence on the type of drive (closed or open, phase or amplitude) used on machines, control units differ significantly. In closed-loop phase-type drives using feedback sensors in the form of rotating transformers operating in the phase shifter mode, control units are pulse-to-phase AC converters and phase discriminators that compare the phase of the signal at the output of the phase converter with the phase of the feedback sensor and output a differential error signal to the drive power amplifier.

Feed rate block- provides a given feed rate along the contour, as well as acceleration and deceleration processes at the beginning and at the end of processing sections according to a given law, most often linear, sometimes exponential. In addition to working feeds (0.5 - 3000 mm / min), this block provides, as a rule, idling with an increased speed (5000 - 20000 mm / min).

Control and indication panel. The operator communicates with the CNC system through the control and display panel. With the help of this console, the CNC system is started and stopped, the operating mode is switched from automatic to manual, etc., as well as the correction of the feed rate and tool sizes and changes in the initial position of the tool in all or some coordinates. This console contains a light signaling and digital indication.

Program correction block used to change the programmed machining parameters: feed rate and tool dimensions (length and diameter).

Block of canned cycles serves to simplify the programming process when processing repeating elements of a part (for example, drilling and boring holes, threading, etc.) a block of canned cycles is used. For example, such movements as fast withdrawal from a finished hole are not programmed on a punched tape - ϶ᴛᴏ is incorporated in the corresponding cycle (G81).

Block of technological commands provides control of the cycle of the machine (its cyclic automation), including the search and analysis of the cutting tool, switching the spindle speed, clamping and unclamping the moving working bodies of the machine, various interlocks.

Power Supply supplies the necessary constant voltages and currents to all CNC units from a conventional three-phase network. A feature of this block is the presence of voltage stabilizers and filters that protect the CNC electronic circuits from interference that always occurs in industrial power networks.

Feedback sensors (DOS)

DOS are designed to convert the linear movements of the working body of the machine into electrical signals containing information about the direction and magnitude of movements.

The whole variety of DOS can be conditionally divided into angular (circular) and linear. Circular DOS usually convert the angle of rotation of the lead screw or the movement of the working body of the machine through a rack and pinion gear. The advantage of circular DOS is their independence from the length of movement of the working body of the machine, ease of installation on the machine and ease of operation. The disadvantages include the principle of indirect measurement of the displacement of the working body, and therefore the measurement error.

Linear DOS directly measure the movement of the working body, which is their main advantage compared to circular DOS. The disadvantage of linear DOS is the dependence of their overall dimensions on the amount of movement of the working body, in addition, they are difficult to install and operate the machine.

According to the principle of operation, DOS are pulsed, phase, code, phase-pulse, etc. The most commonly used sensors are inductosin type, which are circular and linear, as well as resolvers.

The linear inductosyn consists of a ruler 1 and a slider 2. The length of the ruler slightly exceeds the value of the measured displacement, the ruler has one printed winding with a pitch of 2 mm, from which the induced voltage is removed. It must be solid (with a short stroke) or assembled from several plates (250 mm long). The slider is installed on the working body and moves relative to the ruler. It has two printed windings shifted by ¼ pitch. An alternating current with a frequency of 10 kHz is supplied to each winding, and the voltage on the first winding ![]() , and on the second

, and on the second ![]() , where is the specified offset angle.

, where is the specified offset angle.

When the slider 2 moves, a voltage is induced at the output of the winding of the ruler 1

where is the actual displacement angle, reflecting the actual movement of the working body, ᴛ.ᴇ.

If the working body is in a predetermined position, the voltage at the output of the line winding is zero. In the absence of this equality, the feed drive receives a signal for further movement.

DOS of the rotating transformer type (VT) are widely used in CNC machines.

Οʜᴎ are two-phase AC electrical machines, in which, when the rotor rotates, the mutual induction between the windings of the stator 2 and rotor 1 changes sinusoidally with high accuracy. Voltage is applied to the winding (a) of the stator, and to the winding (b) - , where is the displacement angle, reflecting the given amount of displacement. Voltage is removed from the rotor winding 1. The number of windings in the VT should be different, but most often VT is used with two mutually perpendicular windings on the stator and on the rotor. Such sine-cosine VTs are called resolvers.

In positional CNC systems, code feedback sensors are used to measure the absolute value of the displacement of the working body. As such a sensor, for example, a code disk of a circular photoelectric sensor with ten binary digits is used.

Each concentric ring of the glass disk consists of dark and transparent areas that do not transmit or transmit light to photodetectors. Rings correspond to certain digits: external - to the first, internal - to the tenth. The disk is installed so that its full revolution corresponds to the movement of the working body to the maximum value. In this case, each position of the working body corresponds to a single combination (code).

The figure shows a diagram of a pulsed linear sensor with a fixed diffraction grating 1, relative to which the movable auxiliary scale 2 moves. It is rotated relative to the main grating by an angle, in connection with this, when it moves by an amount, moiré fringes moving in the vertical direction are formed (3) , which periodically block the beam of light (4) passed through the grating to two photocells. When moving the auxiliary scale 2 by 1 step of strokes, one pulse comes from the photocells.

General principles of program coding

In CNC machines, all elements of the program: direction, magnitude and speed of given working and auxiliary movements, etc. are set in digital form - in the form of numbers arranged in a certain order and written in a certain way using some code. The code is a conditional record of a number or action, which allows, in a fairly simple way, to obtain an image of this number in a form convenient for use in PU systems. In the general case, any code used in program control systems consists of two basic elements: a movement code and an auxiliary instruction code. There are many different ways to encode.

Unitary code. The essence of this code is essentially that in it any number is expressed by one sign 1. To represent any number, you need to repeat this sign as many times as many times as the given number contains units. When used as a program carrier - punched tape, sign 1 is expressed by punching a hole, and with a magnetic tape - a magnetic stroke. The main drawback is the low recording density.

Decimal number system uses ten digits 0 - 9 to write numbers. To write numbers in the decimal number system, each character must have its own track, and each digit - a line. Writing numbers in decimal code is cumbersome.

Binary number system uses only two characters 0 and 1 for writing. To write a number in binary code, one corresponds to the presence of a signal, and at zero, there is no signal. This is convenient because the mechanisms most reliably distinguish between two stable states. For example, on punched tape: there is a punch, there is no punch. ; ; ; (2+1); ; (4+1); (4+2); (4+2+1); ; (8+1); (8+2) etc.

Binary-decimal number system.

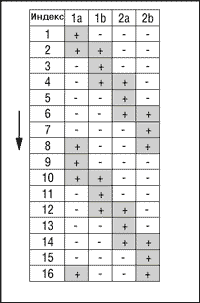

In this case, each digit of the decimal number is written with a binary equivalent, called a tetrad:

0 1 2 3 4 … 10 11

0000 0001 0010 0011 0100 … 0001,0000 0001,0001

International ISO code - 7bit

Despite the large number of types of processing and types of machines, a relatively limited set of commands encoded by certain characters or numbers is sufficient to communicate extremely important information.

To ensure the use of codes used in CNC machines, the unification of programming languages has been carried out on a large scale. To this end, the international organization of ISO standards has adopted a single international code for programming processing on CNC machines. In our country, there is a similar code (GOST 13052 - 74). The code establishes a set of specific characters, which are divided into numeric, alphabetic in uppercase letters of the Latin alphabet, and graphic. Each character has a unique expression, obtained by punching holes on a paper eight-track tape. 25.4 mm wide. The first track from the left (eighth) is for the parity and odd parity check feature. It is necessary that in each line of punched tape the number of punched holes be an even number. The remaining seven tracks represent the corresponding bit in the binary number system.

Each direction of movement of the working bodies of the machine tools is assigned the value of a certain coordinate and the corresponding address symbol, for example: X, Y, Z, W, etc. There is a single direction of the axes of the coordinate axes of metal-cutting machines. The positive direction of movement of the machine element is considered to be the one in which the machining tool (its holder) and the workpiece recede from each other.

Numerical control systems - concept and types. Classification and features of the category "Numerical control systems" 2014, 2015.

Lecture plan:

1. Numerical control of equipment and

his role in production.

2. The main advantages of using CNC machines.

3. The structure of the complex "Machine with CNC".

4. The concept of the CNC system and its main functions.

5. Positional, contour and combined CNC systems.

1. Numerical control of equipment and its role in production

The most important reserve for the growth of labor productivity in mechanical engineering is the reduction in the labor intensity of machining parts on metal-cutting machines. The main way to use this reserve is to automate the processes of machining parts based on the use of machine tools with numerical control (CNC), as well as automatic lines and automated sections based on these machines.

Automation of large-scale and mass production is ensured by the use of automatic machines and automatic lines. For small-scale and serial production, covering approximately 75-80% of engineering products, automation tools are needed that combine the productivity and accuracy of automatic machine tools with the flexibility of universal equipment.

Such means of automation are CNC machines. The CNC machine is a machine with a flexible connection, the operation of which is controlled by a special electronic device. The part processing program is written in numerical form on the program carrier and implemented using the CNC system. In this case, the accuracy of setting dimensions does not depend on the properties of the program carrier, but only on the resolution of the CNC system. The CNC machine does not require a long readjustment when switching to the processing of a new part. To do this, it is enough to change the program, cutting tool and fixture. This allows you to process a wide range of parts on the machine. Working in an automatic cycle, the CNC machine retains the properties of a universal machine with manual control.

The use of CNC machines places new demands on the design and processing of parts. The technological preparation of production (TPP) is changing radically: its center of gravity is transferred from the sphere of production to the sphere of engineering labor, it becomes more complex and increases in volume.

New elements of the technological process appear: tool path, path correction, processing control program, dimensional alignment of the position of the part and tool in the sledge coordinate system, tool setting outside the machine with high accuracy, etc.

The nature and volume of work of the technologist is radically changing. CNC machining makes it possible to formalize this process and apply computers and other means of automation of engineering work to the design of technological processes.

The introduction of CNC machining into production is a major organizational and technical event. It must be accompanied by a carefully thought-out plan of all the work arising from this task, including such a priority one as training the necessary staff and training specialists in the field of designing technological processes for machining on CNC machines.

Engineer-mechanic specialty 12.01.00 "Technology of mechanical engineering" must be able to solve issues on which the successful use of CNC machines in mechanical engineering depends. To do this, he must have a good knowledge of the technological capabilities of CNC machines and their technical equipment, a feasibility study for the feasibility of using CNC machines, methods for designing technological processes for processing parts on these machines, methods for developing control programs (NC), the procedure for compiling and processing technological documentation .

MACHINE AUTOMATIC CONTROL SYSTEMS

The automatic control system is a complex of devices and means of communication that ensures accurate and time-coordinated interaction between the working and auxiliary actuators of the machine in accordance with the control program developed on the basis of the accepted technological processing. Control program - ϶ᴛᴏ a sequence of commands that ensure the specified functioning of the working parts of the machine. . An element or a complex of elements that carry a control program is commonly called a program carrier

The classification of automatic control systems and their comparative analysis is given in the manual for independent work of students. Control systems with RV (with a camshaft), cyclic program control and tracking copying systems are also considered there.

The development of electronics and computer technology, the introduction of computers into production has led to the development and widespread use in machine tool building of numerical control systems (CNC) for metal-cutting machines, as well as other technological equipment.

Numerical control is called control according to a program specified in an alphanumeric code and representing a sequence of commands written in a certain language and providing the specified functioning of the working bodies of the machine.

The fundamental difference between CNC systems and previously developed ACS lies in the method of calculating and setting the control program and its transmission to control the working bodies of the machine.

In conventional ACS, the control program is embodied in physical analogues - cams, copiers, stops and other means that are program carriers. This method of specifying the control program has two basic drawbacks. The first one is caused by the fact that the detail drawing information is converted from digital (discrete) into analog (in the form of cam curves, copier). This leads to errors introduced in the manufacture of cams, copiers, the arrangement of travel stops on the rulers, as well as the wear of these software carriers during operation. The second disadvantage is the extreme importance of manufacturing these software carriers with subsequent labor-intensive setup on the machine. This leads to large expenditures of money and time, and in most cases makes it inefficient to use conventional ACS for the automation of serial and especially small-scale production.

In CNC systems, all the way through the preparation of a control program up to its transfer to the working bodies of the machine, we deal only with information in digital (discrete) form, obtained directly from the drawing of the part. The trajectory of the movement of the cutting tool relative to the workpiece in CNC machines is represented as a series of its successive positions, each of which is determined by a number. All information of the control program (dimensional, technological and auxiliary) necessary to control the processing of the part, presented in text or tabular form using symbols (numbers, letters, symbols), is encoded (ISO-7bit code) and entered into the memory of the control system from computer or directly using the keys on the control panel. The CNC device converts this information into control commands for the actuators of the machine and controls their execution.

For this reason, in CNC machines, it became possible to obtain complex movements of its working bodies not due to kinematic connections, but due to the control of independent coordinate movements of these working bodies according to a program specified in numerical form. Qualitatively new in CNC machines is the possibility of increasing the number of simultaneously controlled coordinates, as a result of which it became possible to apply fundamentally new layouts of machine tools with obtaining wide technological capabilities in automatic control.

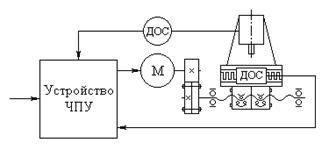

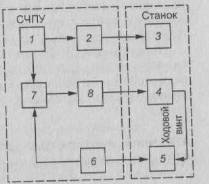

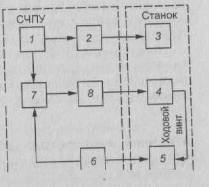

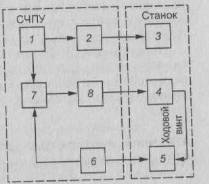

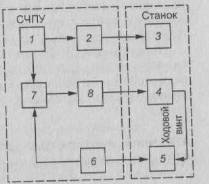

The general enlarged block diagram of the CNC system is shown in fig. twenty.

It includes the following main elements: CNC device; feed drives of the working bodies of the machine and feedback sensors (DOS) installed for each controlled coordinate. The CNC device is designed to issue control actions to the working bodies of the machine in accordance with the control program entered into the block for input and reading information. The control program is read sequentially within one frame with storage in the memory block, from where it is fed into the blocks of technological commands, interpolation and feed rates.

|

Rice. 20 Enlarged block diagram of the CNC system

Block of technological commands serves to control the cyclic automation of the machine, consisting mainly of actuating elements such as starters, electromagnetic clutches, solenoids, limit and travel switches, pressure switches, etc., providing the execution of various technological commands (tool change, switching spindle speeds, etc.), as well as various locks during machine operation.

Interpolation block- a specialized computing device (interpolator) - forms a partial trajectory of the tool between two or more points specified in the control program. The output information from this block, supplied to the feed drive control unit, is usually presented as a sequence of pulses for each coordinate, the frequency of which determines the feed rate, and the number determines the amount of movement. The specified feed rate along the workpiece contour, as well as the processes of acceleration and deceleration, are provided by the feed rate block. The program correction block is used to change the programmed processing parameters: feed rate and tool dimensions (length and diameter). The correction is entered from the control and display panel, which serves to connect the operator with the CNC system. The block of canned cycles allows you to simplify the programming process when processing repeating elements of a part, for example, when drilling and boring holes, threading, etc.

The feed drive of the working bodies consists of a drive motor, its control systems and kinematic links. The accuracy of movement of the working bodies of the CNC machine depends on the applied feed drive control scheme: open (without a system for measuring the actual displacements of the controlled working body) or closed (with a measurement system). In the second case, control of the accuracy of processing control signals for each controlled coordinate of the machine is carried out by a feedback sensor (DOS). The accuracy of this control is largely determined by the type, design and location of the sensors on the machine.

Classification of CNC systems

CNC systems can be classified according to various criteria.

1. Based on the technological tasks of processing control, all CNC systems are divided into three groups: positional, contour and combined.

Positional CNC systems provide control of movements of the working bodies of the machine in accordance with the commands that determine the positions specified by the control program. In this case, movements along different coordinate axes can be performed simultaneously (at a given constant speed) or sequentially. These systems are mainly equipped with drilling and boring machines for processing parts such as plates, flanges, covers, etc., in which drilling, countersinking, boring holes, threading, etc. ).

CNC contouring systems provide control of the movements of the working bodies of the machine along the trajectory and with the contour speed specified by the control program. The contour speed is the resulting feed rate of the working body of the machine, the direction of which coincides with the direction of the tangent at each point of the specified processing contour. Contour CNC systems, unlike positional systems, provide continuous control of tool or workpiece movements one by one or along several coordinates at once (Fig.), As a result, very complex parts can be processed (with control over more than two coordinates simultaneously). CNC contour systems are mainly equipped with turning and milling machines (for example, mod. 16K20F3, 6R13F3).

|

processing control tasks

Combined CNC systems, combining the functions of positional and contour CNC systems, are the most complex, but also more versatile. Due to the increasing complexity of CNC machine tools (especially multi-operational), expanding their technological capabilities and increasing the degree of automation, the use of combined CNC systems is expanding significantly (for example, mod. IR500MF4, IR320PMF4; 2206PMF4, 6305F4).

2. By the presence of feedback, all CNC systems are divided into two groups: open and closed.

Open-loop CNC systems are built on the basis of power or non-power stepper motors (SM). In the latter case, SD is usually used in conjunction with a hydraulic booster (GU). Although these systems are the simplest, in them, due to the lack of control over the actual position of the working body of the machine, the accuracy of movement will be affected by the errors of the stepper motor, hydraulic booster and transmission mechanisms of the feed drive (gear, screw-nut pairs, etc.).

The operation diagram of a stepper motor with a hydraulic booster is shown in fig. . When the SM rotor is rotated at a certain angle, the screw part 1 of the distributor is unscrewed from the currently stationary nut 2, moving the distributor, for example, to the left. In this case, the oil enters the cavity of the hydraulic motor 3, which through the gear 4 rotates the lead screw 5 of the drive of the working body 6. When the rotor of the hydraulic motor turns, the nut 2 turns (with the screw part of the distributor stationary) and returns the distributor back to its original position until the gap in it is blocked Hey. The latter will occur when the hydraulic motor rotor rotates exactly the same angle that the distributor from the stepper motor turned.

|

Rice. 22. Open-loop feed drive control circuit of a CNC machine

Open-loop CNC systems are equipped with a significant part of CNC machine tools (for example, mod. 16K20F3, 6R13F3, 6R11F3, RT-725F3, 1B732F3).

At the heart of the work closed systems CNC is based on the principle of servo control systems. As a drive motor M in these systems, DC motors are most often used.

Closed-loop CNC systems there are: 1) with feedback on the position of the working bodies of the machine; 2) with feedback on the position of the working bodies of the machine and with compensation for machine errors; 3) self-adapting (adaptive).

Closed-loop CNC systems of the first subgroup are of three types. In closed CNC systems of the first type (Fig. 23, a), an indirect measurement of the position of the working body is made using a circular DOS mounted on the lead screw. This scheme is quite simple and convenient in terms of installing DOS. The overall dimensions of the applied sensor do not depend on the magnitude of the measured displacement. When using circular DOS mounted on the lead screw, high requirements are placed on the accuracy characteristics of the screw-nut transmission (manufacturing accuracy, rigidity, absence of gaps), which in this case is not covered by feedback.

The use of precision-made ball screw pairs in feed drives of CNC machines and the creation of a preload in them to eliminate gaps and increase rigidity make it possible to widely use closed-loop CNC systems of the first type to obtain high accuracy of movement of working bodies.

|

Rice. 23. Structural diagrams of closed CNC systems:

a - closed with a circular DOS on the lead screw;

b - closed with circular DOS and rack and pinion;

c - closed with linear DOS

Closed CNC systems of the third type are equipped with linear DOS (Fig. 23, c), which provide direct measurement of the movement of the working body of the machine. This allows you to cover all the transmission mechanisms of the feed drive with feedback, which ensures high accuracy of movements. At the same time, linear DOS are more complicated and more expensive than circular ones; their overall dimensions depend on the stroke length of the working body of the machine. The accuracy of linear DOS can be affected by machine errors (for example, wear of guides, thermal deformations, etc.).

In all three types of closed CNC systems considered, only the errors of the feed drive of the working bodies of the machine are taken into account and do not take into account the errors of both the machine itself (deviation from the straightness of the guides and their wear, vibrations, thermal deformations of the base parts), and other elements of the technological system (elastic deformations, tool wear, etc.) that affect the accuracy of machining parts.

Closed-loop CNC systems of the second subgroup (Fig. 24) are equipped with additional feedback systems to improve processing accuracy, with sensors D that compensate for machine errors (thermal deformations, vibrations, wear of guides, etc.).

|

Closed CNC systems of the third subgroup are called self-adaptive (adaptive) control systems. Due to the presence of feedback not only on the position of the working bodies, but also on the parameters of the processing process (elastic deformations of the technological system, tool wear, temperature in the cutting zone, vibration), they provide automatic adaptation of the processing mode of the machine to changing processing conditions (fluctuation of the allowance on the workpiece , its hardness, etc.) to obtain a given machining accuracy, maximum possible productivity or minimum cost of machining.

Despite the relatively short period of use of CNC systems, they have already gone through several stages in their development, determined by the level of development of electronic technology. At the same time, the developers of CNC systems used various element bases: relay-contactor, transistor, microcircuits of a small and medium degree of integration, mini-computers and, finally, microprocessor sets and large memory integrated circuits (LSI memory).

|

Full text search:

Home > Abstract >Informatics

Introduction 4

Chapter I. The essence of building hardware-software complexes with numerical control 7

§1.1. Equipment with numerical control. Purposes, functions, existing solutions and models 7

§1.2. Stepper motor. Device, principle of operation, control 8

§1.3. Architecture of microcontrollers. Required parameters 12

§1.4. Software environment for the microcontroller 14

§1.5. Software environment for the CNC machine control module at the PC level 15

Chapter II. Implementation of the necessary control modules for the CNC machine 21

§2.1. Physical model of hardware 21

§2.2. Data analysis and structure of the drilling file with *.drl extension. 22

§2.3. Algorithm for reading data in the microcontroller coming from a PC via UART 26

§2.4. Formation of a drilling file for sending to the microcontroller 28

§2.5. Drilling operation 28

§2.6. Manual mode 31

§2.7. Burnout 32

§2.8. Modernization of the CNC complex 38

Chapter III. Analysis and testing of the complex 42

§3.1. Testing the CNC complex in computer simulation complexes 42

§3.2. Drilling module test 43

§3.3. Manual control 45

§3.4. Burnout 46

Conclusion 49

Used literature 51

Introduction

In the modern world, it is no longer possible to do without the use of the latest technologies in almost all areas. Basically, this is the introduction of automation systems into our lives, which make it possible to facilitate human work and increase both the scientific and technological level of knowledge. With the advent of computers, the introduction of such systems has become the most popular and relevant. This is due to the high demand for automatic control systems, both in production and in everyday life.

And in practice, software control of a particular device has received great application. Stepper motors are widely used in printers, automatic tools, disk drives, automotive dashboards and other applications requiring high positioning accuracy and microprocessor control. As is known, such control requires the use of special logic and high-precision drivers that can be implemented on a discrete element base, which increases the complexity of the circuit and its cost.

Machine tools with numerical control (CNC) deserve special attention. Their role today is great, because they can facilitate the work of a person due to their high accuracy, reliability and practicality.

Researchers, developers and system engineers need greater openness of control systems. This openness will make it much easier to design, build, and rapidly deploy functionality to meet the ever-increasing practical needs of programmable controller applications. While some of the robot control vendors provide customized development tools for their products, low-cost and non-proprietary solutions are preferred in terms of being able to quickly respond to market changes and reduce their life cycle cost. The most important success factors are the use of a common element base and open source software (if possible, freely distributed). In turn, software design should be focused on maximum portability and reconfigurability.

The purpose of this thesis is to create a software and hardware complex with CNC control that meets all the above requirements. The CNC complex allows you to perform many tasks that can be set depending on the imagination of the owner. The ultimate goal of this work is to create such control modules and hardware parts that will perform the following:

Hole drilling for PCB manufacturing, automatically controlled by PC;

Manual control of the CNC complex by means of a computer;

Transferring images from a PC to the processed material by heat treatment.

To implement such a software and hardware complex, it is necessary to solve the following tasks:

a) study mechanical technologies to create a working physical area of the machine;

b) understand the principle of management stepper motors;

c) study the architecture and operation of Atmel series microcontrollers;

d) study the mode of data exchange through the RS232 interface;

e) to develop the physical hardware of the complex with a minimum amount of necessary materials and assemblies;

f) to develop a control board for the physical part of the complex and interaction with a PC, directly through the RS232 interface, based on the Atmel microcontroller;

g) develop a program for the microcontroller that ensures the correct operation of the complex;

h) create a software part of the complex on a PC that provides the following operations:

drilling;

Burnout;

Manual control;

i) get acquainted with the latest computer simulators of electronic devices for testing the hardware and software complex.

Chapter I. Essence of building software and hardware complexes with numerical control

§1.1. Equipment with numerical control. Purposes, functions, existing solutions and models

For an introduction to the course of things, let's define the basic terms and meanings.

Computer numerical control or CNC- means a computerized control system that reads instructions into G-code(technical data format for CNC systems, described below) and for controlling machine tools and drives for metalworking machines. The CNC interpolates the movement of the machining tool according to the control program.

This is one of the many definitions of numerical control, taken from wikipedia, hereinafter CNC.

That is, the main distinctive functionality of the CNC is a computerized control system, which implies the presence of controlled equipment and a control terminal. In our case, the controlled equipment will be a multifunctional machine based on CNC control and a control terminal - a computer with a special software package.

To solve the problem, methods with their control algorithms for CNC systems are needed. To solve a specific problem, it is necessary to organize the interaction of the following elements of the complex:

The mechanical part of the complex;

Power keys for stepper motor control;

Autonomous power switch control terminal, controller with the possibility of autonomous operation without the participation of a computer and operator intervention;

Module for generating commands sent to the controller to control the hardware complex;

Data exchange interface between the control module and the managed controller;

Lines for receiving and transmitting information between the control module and the hardware complex.

There are industrial complexes that allow you to perform many tasks that require great precision and a large number of operations while maintaining strict standards. In such cases, such systems greatly simplify and speed up work in a particular area. Most of these systems are focused on the processing of various materials, ranging from gypsum to high-strength steel products. CNC is also used in the astronomical, aviation, and space industries. These are areas of activity in which accuracy and efficiency play a major role.

§1.2. Stepper motor. Device, principle of operation, control

Stepper motors are widely used in printers, automatic tools, disk drives, automotive dashboards and other applications requiring high positioning accuracy and microprocessor control. As is known, such control requires the use of special logic and high-precision drivers that can be implemented on a discrete element base, which increases the complexity of the circuit and its cost.

Small stepper motors are often used, for example, in automotive dashboards (instrument clusters) and perform the functions of rotating the arrows of the speedometer, tachometer, coolant temperature gauge and fuel level there. At the same time, compared to traditionally used galvanometric systems, there is no vibration of the pointer, and the accuracy of the readings increases.

DC motors (DC motors) start working as soon as a constant voltage is applied to them, . Switching the direction of current through the rotor windings is carried out by a mechanical commutator - a collector. Permanent magnets are located on the stator. A stepper motor can be considered as a DC motor without a commutator. Its windings are part of the stator. A permanent magnet is located on the rotor or, for cases with variable magnetic resistance, a toothed block made of a soft magnetic material. All commutations are made by external circuits. Typically, the motor-controller system is designed so that it is possible to bring the rotor to any fixed position, that is, the system is position-controlled. The cyclic positioning of the rotor depends on its geometry.

It is customary to distinguish between stepper motors and servo motors. The principle of their operation is largely similar, and many controllers can work with both types. The main difference is the number of steps per cycle (one rotation of the rotor). Servo motors require analog feedback in the control system, which is usually a potentiometer. The current in this case is inversely proportional to the difference between the desired and current positions. Stepper motors are mainly used in systems without feedback, requiring small accelerations during movement.

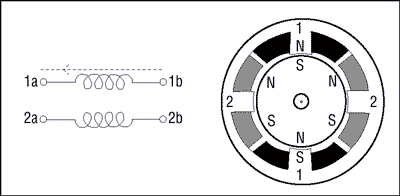

Stepper motors (SM) are divided into two varieties: permanent magnet motors and variable reluctance motors (hybrid motors). From the point of view of the controller, there is no difference between them. Permanent magnet motors usually have two independent windings which may or may not have a center tap (see Figure 1.2.1).

Fig.1.2.1 Unipolar stepper motor with permanent magnets.

Bipolar permanent magnet stepper motors and hybrid motors are simpler in design than unipolar motors and have no center tap windings (see Figure 2.2.2).

Fig.2.2.2 Bipolar and hybrid SD.

This simplification comes at the cost of a more complex reversal of the polarity of each pair of motor poles.

Stepper motors have a wide range of angular resolutions. Coarser motors typically rotate 90° per step, while finer motors can have 1.8° or 0.72° resolution per step. If the controller allows, then it is possible to use a half-step mode or a mode with a finer step splitting (micro-stepping mode), while fractional voltage values are applied to the windings, often formed using PWM modulation.

If only one winding is energized at any time in the control process, then the rotor will rotate through a fixed angle, which will be held until the external torque exceeds the motor holding torque at the equilibrium point.

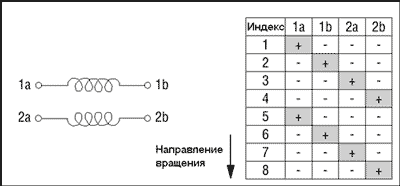

To properly control a bipolar stepper motor, an electrical circuit is needed that must perform the functions of start, stop, reverse and change speed. A stepper motor translates a sequence of digital switches into motion. The "rotating" magnetic field is provided by appropriate switching voltages on the windings. Following this field, the rotor will rotate, connected by means of a gearbox to the output shaft of the engine.

Each series contains high performance components to meet the ever increasing performance requirements of today's electronic applications.

The control circuit for a bipolar stepper motor requires a bridge circuit for each winding. This circuit will allow you to independently change the polarity of the voltage on each winding. Figure 3.2.3 shows the control sequence for single step mode.

Fig.3.2.3 Control sequence for single step mode.

Figure 4.2.3 shows the sequence for half step control.

Fig.4.2.3 Control sequence for half step mode.

§1.3. Architecture of microcontrollers. Required parameters

MK is a microcircuit (chip, stone, IC) - which, in response to external electrical signals, acts in accordance with:

With features provided by the manufacturer

With electronics connected to MK

- with the program that we loaded into it.

The ability of MK to act according to our program is the essence of MK.

This is the main difference between MK and "ordinary" NOT programmable microcircuits. AVR- this is the MK family from the company ATMEL

,

developed taking into account the features and convenience of writing programs in the C language. Why AVR?

These are not expensive, widely available, reliable, simple, fairly fast, counting most instructions are executed in 1 clock cycle - i.e. at 10 MHz quartz, up to 10 million instructions per second are executed.

A  VRs have developed peripherals, i.e. a set of equipment surrounding the processor-computer in one MK housing or a set of electronic devices, blocks, modules built into the MK.

VRs have developed peripherals, i.e. a set of equipment surrounding the processor-computer in one MK housing or a set of electronic devices, blocks, modules built into the MK.

To control the stepper motor, an intermediate power switch is required to amplify the current pulses and a controller that provides both control of the stepper motor and interaction with the PC. The most understandable and suitable in terms of the required parameters can be considered an 8-bit microcontroller from AVR - AT Mega 8 with 8 KBytes of in-system programmable Flash memory, which has the following distinctive features:

8-bit high performance low power AVR microcontroller; progressive RISC architecture; 130 high performance commands; most instructions are executed in one clock cycle; 32 8-bit general-purpose working registers; completely static work; built-in 2-cycle multiplier; non-volatile program and data memory; 8 KB of In-System Self-programmable Flash memory; provides 1000 erase/write cycles; additional sector of boot codes with independent lock bits; the mode of simultaneous reading/writing (Read-While-Write) is provided; 512 bytes EEPROM; provides 100,000 erase/write cycles; 1 KB built-in SRAM, programmable lock; ensuring the protection of user software; built-in peripherals; two 8-bit timer/counters with separate prescaler; one with compare mode, one 16-bit timer/counter with separate prescaler and capture and compare modes; real time counter with separate generator; three PWM channels, 8-channel A/D converter (in TQFP and MLF packages), 6 channels with 10-bit precision; 2 channels with 8-bit precision; 6-channel analog-to-digital converter (in PDIP package); 4 channels with 10-bit precision; 2 channels with 8-bit precision; Byte-oriented 2-wire serial interface; programmable serial USART; serial interface SPI (master/slave); programmable watchdog timer with separate built-in oscillator; built-in analog comparator; special microcontroller functions; power-on reset and programmable voltage drop detector; built-in calibrated RC generator; internal and external interrupt sources; five power-down modes: Idle, Power-save, Power-down, Standby and ADC noise reduction; I/O pins and cases; 23 programmable I/O lines; 28-pin PDIP package; 32-pin package; TQFP and 32-pin MLF package; operating voltages: 2.7 - 5.5 V (ATmega8L), 4.5 - 5.5 V (ATmega8); operating frequency: 0 - 8 MHz (ATmega8L), 0 - 16 MHz (ATmega8).

These parameters largely satisfy the requirements for the implementation of a hardware-software complex, in connection with this, it was decided to use this particular microcontroller, both in terms of technical parameters and in all others, including its prevalence and familiar command architecture. The purpose of each leg is indicated in Appendix 1 in Fig. 1.3.1.

§1.4. Software environment for the microcontroller

When writing a program for the microcontroller, a C compiler CodeVisionAVR was used.

CodeVisionAVR- an integrated software development environment for microcontrollers of the Atmel AVR family.

CodeVisionAVR includes the following components:

C compiler for AVR; assembly language compiler for AVR; generator of the initial code of the program, which allows to initialize peripheral devices; module for interaction with the debug board STK-500; module of interaction with the programmer; terminal.

The output files of CodeVisionAVR are:

HEX, BIN or ROM file for downloading to the microcontroller using a programmer; COFF - a file containing information for the debugger; OBJ file.

CodeVisionAVR is commercial software. There is a free trial version with a limited number of features.

As of April 2008, the latest version is 1.25.9.

Data taken from Wikipedia.

The program code was originally developed in the C language. The C language is characterized by conciseness, a modern set of flow control constructs, data structures, and an extensive set of operations.

Xi(English) C) is a standardized procedural programming language developed in the early 1970s by Bell Labs employees Ken Thompson and Denis Ritchie as a development of the B language. C was created for use on the UNIX operating system (OS). It has since been ported to many other operating systems and has become one of the most used programming languages. C is valued for its efficiency; it is the most popular language for creating system software. It is also often used to create application programs. Despite the fact that C was not designed for beginners, it is actively used to teach programming. Subsequently, the syntax of the C language became the basis for many other languages. Data taken from Wikipedia.

§1.5. Software environment for the CNC machine control module at the PC level

Borland C++Builder 6 software environment was chosen as the basis for writing the CNC machine control software module. Borland C++Builder is a recently released rapid application development tool by Borland that allows you to create C++ applications using the Delphi development environment and component library. This article discusses the C++ Builder development environment and the basic techniques used in designing the user interface.

We will not dwell on a detailed description of the current development environment for the control module, since there are many tutorials and reference books on working in Borland C++ Builder. When creating the complex, textbook materials were used, and.

Also, when developing, writing and improving the software package, previously acquired skills and articles from the Internet, taken from sources, as well as from various forums, were used.

When writing programs for both the controller and the control module, the PROTEUS package testing complex was of considerable importance - an electronic device simulator that supports AVR, 8051, Microchip PIC10, PIC16, PIC18, Philips microcontrollers

ARM7, Motorola MC68HC11, complete design system. The ability to test, from an idea to the results of the device and files for the board.

An important role in such systems is played by the successful creation of a CAM system designed to solve the problem of generating control programs for processing parts on CNC machines. That is, the formation of control data blocks from the source information. In the current work, the source information is image files, vector hole files that need to be converted to the required command format.

Currently, the CAM system is a complex software package. Over the past decade, several generations of CAM systems have changed.

According to experts, a modern domestic CAM system that can withstand the best Western models should have the following characteristics.

Advanced tools for importing geometric models.

If the representation of a geometric model in the STL or VDA format has certain disadvantages related to the accuracy of the representation of the model, and the STFP format has not yet found proper distribution, then the use of the IGES standard is quite capable of solving this problem. Currently, the IGES standard is generally recognized and provides the transfer of any geometric information. It is supported by all modern computer-aided design systems.

Support for 3D objects in NURBS representation.

Representation of curves and surfaces in the form of rational splines, or NURBS, provides high accuracy and compactness of data storage. In addition, the latest CNC racks will have built-in NURBS interpolation. For this reason, most of the existing systems that work with approximated objects will face the need for significant improvement.

Support for 3D models of any complexity.

Modern CAM systems allow you to create surface and solid models of high complexity (for example, car body parts). The processing of such models is possible in the absence of quantitative and qualitative restrictions in the CAM system.

Means of access to elementary objects of the model.

The real model consists of many surfaces. The system should allow to operate with separate surfaces (or their groups), which is necessary to achieve optimal technological solutions.

Means of modifying the geometric model.

For the processing of technological equipment, a geometric model of the product is used. In this case, it is often necessary to modify the original model. In the best case, the system should have full-fledged 3D modeling tools, but the fulfillment of this requirement significantly affects the cost of the system.

Functions for constructing auxiliary geometric objects.

The optimal organization of the processing process may require performing operations on limited areas of the model, or, on the contrary, select “islands” for which processing is prohibited. The system must have the means necessary to construct the contours of the boundaries. Modern systems have no restrictions, both on the number of such boundaries and on their nesting. In addition, contours can be used to control the path of a tool.

Wide range of processing methods.

The possibility of choosing the optimal processing method can significantly facilitate the work of the technologist and reduce the processing time on the machine. In the recent past, CAM systems could get by with surface treatment along isoparametric lines. Today, models for which this method is applicable are among the simplest. The processing of real models requires more complex algorithms that provide, for example, tool movement along curves obtained by crossing planes with quasi-equidistant surfaces.

Automatic cutting control.

The construction of quasi-equidistant surfaces makes it possible to exclude gouging when calculating the tool path. However, from the point of view of the mathematical apparatus, this is the most difficult part of the program, if we do not take into account the approximated models.

Means of automatic identification of zones of underworking.

The presence of such funds can significantly facilitate the work of the technologist.

Developed means of managing the parameters of technological operations.

The operation execution mode can vary significantly depending on the selected parameters. The variety of tuning tools allows even with a small number of processing methods to obtain a large number of processing options. However, a large number of adjustable parameters significantly complicates the development and use of the system; therefore, it seems necessary to have means of automatically determining the values of the parameters of a technological operation, depending on the dimensions of the model, processing method, tool, etc.

Support for various types of cutting tool.

The system should not impose restrictions on the shape of the tool used. The fulfillment of this requirement significantly complicates the algorithms for constructing the tool trajectory.

Means of modeling the process and the result of processing.

The system generates a model of the machined part and its photorealistic image. This allows the technologist to quickly control the results of work and detect errors in a timely manner.

Postprocessor with means of customization for an arbitrary format of the control program.

The task of translating data from an intermediate format (eg CLDATA) is not particularly difficult. However, the variety of numerical control systems gives rise to the problem of ensuring compatibility with arbitrary equipment. The customization tools must be available at the user level.

Means of dynamic visualization.

A characteristic feature of modern systems is the presence of advanced visualization tools for a three-dimensional model. The use of technologies such as OpenGL or DirectX makes it possible to achieve a generation speed of up to several frames per second without the use of expensive hardware accelerators, which allows you to dynamically control the angle and scale of the image. To solve this problem, it is necessary to perform triangulation of the original model, which is not always easy, provided that a wide range of representation forms of three-dimensional objects is supported.

Modern user interface.

The level of a modern system is largely determined by the organization of the user interface. At the same time, the extensive functional composition is in conflict with the organization of convenient access to controls and turns interface design into a real art. A serious problem with older systems is the support of numerous atavisms of the user interface.

The listed set of requirements does not claim to be complete, but allows you to form the most general idea of the modern system.

The most famous domestic CAM modules are SprutCAM, Compass-CNC, Gemma-3D, etc.

The use of such systems is not considered, since for the purchase of such systems one should make significant financial contributions, as well as purchase equipment that is designed specifically for a specific CAM system, which is also very expensive. Therefore, it was decided to develop our own CAM - a system that will meet the requirements for solving the task.

Chapter II. Implementation of the necessary CNC machine control modules

§2.1. Physical model of the hardware

First of all, methods for creating a hardware-software complex with CNC were analyzed. When designing the mechanical part of the CNC machine, parts used in dot matrix printers were used. In particular, these are:

Guides with carriages;

Stepper motors;

Power microcircuits for stepper motor control;

Connectors and cables.

Guides with carriages were converted instead of bronze bushings to pendulum bearings, since movement on bronze bushings with the necessary loads is not possible due to the friction force and low power of the stepper motor. The bearings provide free movement along the X and Y coordinates even under significant loads (see Fig.2.1.1).

Rice. 2.1.1. – the use of pendulum bearings for travel carriages.

All parts were securely fixed on a chipboard sheet. To ensure the movement of the machine spindle along the Z axis, parts from an ordinary CD drive were used, in which a worm gear was used to move the laser over the disk (see Fig.2.1.2.).

Fig.2.1.2. – use of parts from the CD drive for the Z axis.

All the cables of the stepper motor and the spindle motor were routed to the connector that will be connected to the machine control board. The control board was assembled on the basis of the AT Mega 8 microcontroller on a circuit board with a programming connector and the necessary electronic elements and microcircuits (see Fig. 2.1.3.).

To test the hardware of the machine, a stepper motor control program for the microcontroller was written. The program algorithm consists in actuating all elements of the machine without the participation of a PC, that is, according to the commands embedded in the microcontroller.

Fig 2.1.3. – general view of the hardware complex with the circuit board.

Now there is a hardware and software part that controls the CNC machine in three coordinates without using a PC according to the algorithms and coordinates previously “stitched” into it.

§2.2. Data analysis and structure of the drilling file with *.drl.

At the first step, the hardware and software part was developed for drilling holes on the board for mounting microcircuits. To do this, an algorithm was developed that understands a specific technical data format for drilling holes. To accomplish the task, the data format with which the software package will work was determined. After analyzing the information on the Internet about CNC machines, the following conclusions were drawn: basically, all machines work with the help of purchased CNC control drivers and the “VriCNC” programs attached to them, which are developed abroad and cost a lot of money. But also from the received demo versions of programs and “samples” for the CNC, it was found that in most cases the generally accepted “Gerber” format working with G-codes is used to control the machines. Using resources it was obtained:

G-code is the name of the programming language for controlling NC and CNC machines. Created by the Electronic Industries Alliance in the early 1960s. The final revision was approved in February 1980 as the RS274D standard. During development, due to a huge lack of control over all the many functions and tools of machine tools, several CNC machine manufacturers adopted G-code as a standard. Additions and innovations in the G-code were made by the manufacturers themselves, so each operator must be aware of the differences between machines from different manufacturers.

Below is a simple Gerber file illustrating the structure and content of the format:

Then a search was made for applications that work with a similar format. Attention was focused on a common program Sprint layout designed for PCB designers. This program has the ability to export the results in the Gerber format we need. Now we can draw the necessary boards and export the result for drilling holes in *.drl format with G-codes.

Next, a method for analyzing the data structure in the resulting file was developed and the necessary data for drilling holes with a CNC machine were selected from it. Initially, it was decided to use several commands to work with the machine, which would indicate the necessary parameters, for example, these could be single-byte commands that would indicate that:

There will be a drilling operation;

There will be data on operating variables;

A block of coordinates will arrive;

End of operation.

A dialogue between the PC and the MK is also organized. Which provides an ordered two-way communication between each other with the ability to cancel the current operation.

Positioning by the machine is carried out based on the received coordinates in the format “X123456Y123456Z123…”. That is, the first three numbers make up the integer part of the number, the second three numbers make up the fractional part of the number, and the Z coordinate has only the integer part. But in the future, given the factor of distance per step of the stepper motor on the plane, only the number of steps for each coordinate and the necessary commands will be sent.

So, about the data structure in the *.drl file.

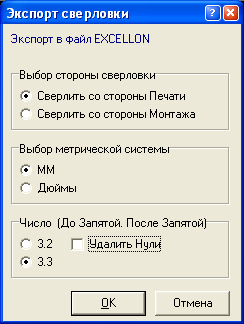

In a programme Sprint layout a board design with three holes was created. The inner diameter of the holes is set to 1 mm. The size of the fee is not critical. Then from the menu File->Export file->"Format Excellon" the drill export wizard is called. Set to "drill from print side" or from mounting side (inverted horizontally). The metric system of measurement is selected. In the "Number after the decimal point" field, the value 3.3 is selected and the checkbox for deleting zeros is unchecked, as shown in fig. 2.2.1.

Rice. 2.2.1. – Export files for drilling.

This is in order to prepare the file in advance for more convenient conversion in the application for sending to the CNC. Pressed OK, the file name is specified and saved. For example, 123.drl. Then, opening the resulting file with any text editor, we have the following:

To accomplish this task, you need the following:

Reading data from a file into an array line by line;

Analysis of each readable line for the content of the text;

If the code G05 (command for drilling) is encountered, then we continue the analysis and read the coordinate data in 3.3 format and enter them into an array of numbers for the subsequent formation of a drilling view pattern.

If the code M30 (end of program) is encountered, then we complete the analysis of the file.

Here is an example of the implementation of this task in C ++ in the C ++ Builder environment:

§2.3. The algorithm for reading data in the microcontroller coming from a PC throughUART

To control the CNC machine using a microcontroller, a set of commands and data was formed that will be “understood” by the controller, a PCMK dialogue is provided. This is necessary in order to bypass the cause of the lack of memory on the MK. After all, the transferred volume can be much larger than the amount of RAM on the MK. To do this, it was decided to form a receive buffer on the MK of 255 bytes (255 characters - this is with a margin of 2-3 times) and after transmitting a data line, wait for confirmation of the execution of the previous command and a signal to allow the transfer of the next line. After analyzing all the necessary conditions, it was decided to develop an algorithm for receiving data on the controller, since the possibilities for implementing various methods are more limited on it.

The controller was initially programmed in the Code Visio AVR environment in C language. To avoid frequent reprogramming of the MK, the program was tested in the Proteus complex. However, during operation, differences in the output results in the proteus and, in fact, on the hardware, were often observed.

To solve the problem, the functions and procedures available in Code Visio AVR for working with input / output via UART were analyzed. The analysis was carried out on the basis of the task. It is necessary to receive a line from a PC, separate it from another line, read it, analyze it for content, if this is a command, then proceed further to the analysis of coordinate data. The main thing here is to choose the format of the received data correctly so that it is most convenient for using the available functions. At first, it was not possible to “correctly” read the data lines coming to the MK, since it is necessary to accurately determine the last character of the line. And also the reception and transmission in the MK is organized on interruption. And the data is stored in the same buffer, of which there are two - one for receiving, the other for transmitting. On the Internet, and in scientific sources, to solve the problem, functions were found that scan the received data, automatically highlighting the lines. For example, a function such as scanf(), which reads data from the input stream in the format specified in the first parameter and stores them in variables, the addresses of which are passed to it as the following parameters. For instance:

scanf(“% d,% d/ n”,& x& y); - we read two numbers in decimal form, which are separated by a comma, into the variables X, Y, respectively. But, as mentioned earlier, there is a problem regarding finding the end of lines, and this function does not work correctly with data that comes from the PC. It was decided to create "their own" procedure that generates strings from the incoming data. Below is the implementation of the string generation algorithm:

|

su=getchar(); if (su=="\n") sscanf(su,"G%d\n",&op); |

Let us describe this algorithm in more detail. We do not work directly with a receive character interrupt. The buffer is formed independently by interrupts and you should not load the buffer formation function with unnecessary operations. We, when we need it, calmly read characters from the buffer ( su[ ii]= getchar(); ) to the string su using the index array, and at the same time check the incoming character for the presence of a line terminator. If there is one, we scan the line for all the data we need, which may be in the received line. With the help of the procedure sscanf ( su ," G % d \ n ",& op );, which in this case scans the string su for the presence of the character 'G' and, if present, places it in a variable op the number in the string after the 'G' character.

Thus, it was possible to analyze the incoming data on the MC from the PC and perform various actions based on the received data. Several procedures have been added to the program code for the microcontroller to ensure the operation of such operations as drilling, machine initialization. All operations are controlled from a PC. Subsequently, burnout operations and manual control mode (Robot) were implemented.

§2.4. Formation of a drilling file to be sent to the microcontroller