CNC machine is a numerical machine program management.

The CNC machine allows you to quickly get a product designed on a computer, and the CNC machine produces products much faster and more carefully than manually. Precise and highly adaptable, the CNC machine makes it possible to carry out projects that, using hand technology, would be unfeasible or unprofitable.

A good CNC machine should cope with a variety of purposes: milling, laser cutting, drilling, engraving, etc. with minor changes in the configuration of the machine. A CNC machine that is not adapted to the changing and increasing needs of today's production is hardly worth buying. The CNC machine must be multifunctional. However, the cost of a finished CNC machine is quite high. One way is to create homemade machine with CNC.

Making a homemade CNC machine

The easiest way is to make a CNC machine from MDF board. You will need an MDF board 1.5x1.5 meters and accessories for assembly.

The details of making a CNC machine at home are described in the article CNC (CNC) do-it-yourself MDF machine. This is the easiest machine to make. The article contains a link to a file with drawings, images and nomenclature of fittings and an assembly sequence. The latter is also presented as a video file.

CNC machine made of wood is easy to manufacture, but has a big drawback. It cannot be used to process steel, such a machine can handle aluminum, bronze, wood, plastic or foam.

Another constructive approach is to use aluminum profiles for the manufacture of the CNC machine. This approach can be found in the article CNC machine "in haste". Such a machine looks more functional, but its manufacture is much more difficult. When replacing aluminum profiles with steel ones, it is possible to achieve the processing of steel billets.

There is also a designer of the CNC machine "Kulibin". The designer includes all the details for assembling the CNC machine. By combining the guides in different ways, you can get various designs CNC machines. The designer can be purchased through the website's online store.

Places of communication CNC do-it-yourselfers

Most often homemade cnc machines are used in aircraft modeling. And this is no coincidence. The aircraft model does not forgive negligence of control and the slightest distraction from control is fraught with an unplanned meeting of the model with the ground.

In this case, usually the wing panels and the nose of the fuselage of an aircraft model break. They are easy to restore, and then the CNC machine comes to the rescue. Cutting 40 wing ribs and 20 fuselage parts by hand is simply tedious. And breakdowns during training (and after it) happen almost weekly.

Therefore, it is no coincidence that one of the places of communication is the forum of RC-Design modellers.

On the website of the designer Kulibin, you can see articles about various machines constructor based.

On VRI-cnc, you can download both CNC machine drawings and electronic filling diagrams.

As in industry, the term CNC is actively used. However, here it has nothing to do with machine control.

CNC is an approach to link building. It implies that all pages of the site must have an address, the reading of which will allow the user to understand what section he is in and what material he is studying. The abbreviation stands for "human-understandable URL".

When compiling such links, the webmaster seeks to clear it of information that is useless to the user. It can be:

- ID of materials;

- URL of the script page with GET request parameters;

- service names of directories and not only.

What is important to consider when forming the CNC

The NC generation template is designed based on the site type. Each case is different, but there are several standard solutions. For instance:

- domain/date/name — for news projects and websites, whose visitors value the relevance of information;

- domain/name — for root sections and static pages (Contacts, Delivery, Payment, etc.);

- domain / heading / title - for resources of a wide range of subjects and different target audiences;

- domain/language/name — for multilingual sites.

Optimal CNC address length

When designing the structure of the site, adhere to the following rule: the shorter, the more convenient. However, you should not go to extremes and shorten links to 10-20 characters unnecessarily. The NC address must remain legible and understandable. Otherwise, it will be no better than a URL containing unique content IDs and other technical data that neither the user nor the search engine needs.

The optimal length of the address of the internal page of the site is 60-80 characters. Such a link is convenient to operate, it is easy to remember.

Which is better: transliteration or Latin in CNC?

Let's say right away: for any modern search engine, the difference between Latin and transliteration. If the user searches for "news", then the same "Yandex" will highlight both links containing the word "news" and addresses that say "novosti".

In practice, these spelling methods are used on an equal footing and are often combined. So, the main sections, static pages and not only are called in English, but the added news, articles and materials are called transliteration.

Another option is to use Cyrillic characters as part of the CNC. However, this is only appropriate if the site domain is registered in the ".РФ" zone and other similar ones. Otherwise, the CNC address will contain a mixture of Latin and Cyrillic characters. This will make manual typing difficult, as you will have to switch keyboard layouts at least 1 time.

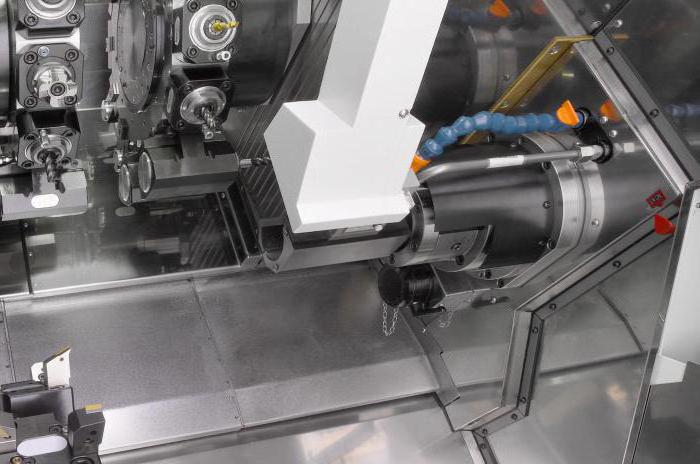

CNC machine tools (computer numerical control) are high-tech equipment in which actuators (drives) are controlled automatically. Drives controlled according to a specific program, actuate the working element of the machine - this is the principle of operation of CNC equipment. Depending on the purpose of the machine, the working element can be a spindle, drill, punch, etc.

The park of machine tools equipped with CNC is huge and diverse. It is enough to list only the most basic ones: these are turning, milling, grinding, metal-cutting, drilling machines, which are divided into many types and modifications. Complex and diverse production requires the same sophisticated equipment. However, with all the variety of types and models, the principle of operation of CNC machines comes down to the presence of software that sets the algorithm for the operation of the machine.

The CNC system includes:

- operator's console, which is designed to control the machine in manual mode when preparing the machine for work according to the program. It allows you to enter a machine control program, set its operating modes, with emergency turn off the machine for troubleshooting;

- the operator panel (display) displays current information about the operation of the machine and the program being executed. The operator can visually control the progress of the technological operation, see messages about accidents and problems that have arisen;

- controller, which is a microcircuit with the program of work of this machine. This device is used, for example, to set the trajectory of the movement of the working tool, for commands for performing technological operations, for changing control programs, etc.;

- ROM (read-only memory) is a permanent memory that is designed for long-term storage of system programs and constants that determine the configuration of a given machine; information in ROM can be read-only;

- RAM (Random Access Memory) is RAM, designed for short-term storage of files of system and control programs used at the moment; RAM is designed to store information that changes during the execution of the program, it is used both for writing and reading information.

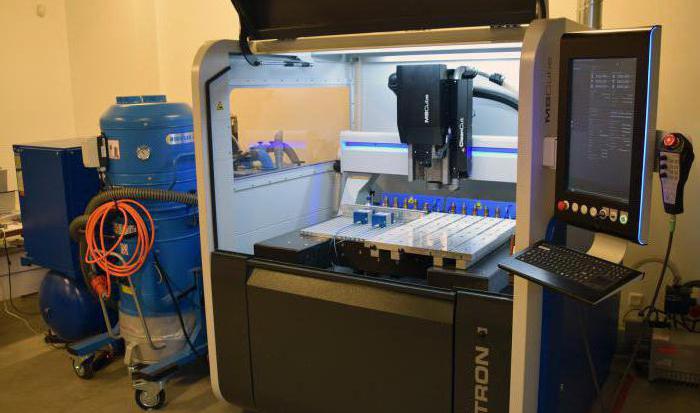

CNC machines do not require high qualification of a specialist - a machine operator, it is enough to train the staff in the methods of program management. CNC machines are modern equipment, allowing to ensure high labor productivity with excellent quality of work performed. The use of such machines significantly increases the overall level of production culture.

You can often hear about universal systems CNC. What is it, can be explained in simple words- smart machines capable of automatically carrying out the entire processing cycle of the part. The installer only needs to download the program and insert the workpiece.

Principle of operation

The latest versions of machine tools are inconceivable without CNC systems. What it is? The abbreviation contains several meanings: H - numerical, P - software, Y - control. It can be seen from the decryption that the reading of the state of individual machine components occurs in code form. Ones and zeros are relentlessly processed by the central processor.

There are two types of controller used at the heart of the CNC. What it is? Everything works like a desktop computer. Only one controller is used to track the position of the machine axes. The second reads the status of peripheral devices, sensors, security systems.

Modern CNC machines are equipped with an additional computer. It is required to implement complex tasks with one click, and also visualizes the current process. The hard disk stores all the data that will not be lost in the event of a sudden power outage.

Figurative description of equipment operation

Metal cutting is currently associated with the acronym CNC. What it is can be explained using the example of a conventional drill:

- By hand, you can process the workpiece with a drill from any side. Similarly, on the machine, if there are several axes, you can bring the tool from any coordinate.

- The CNC system carries out the simultaneous movement of the axes. Volumetric movement is copied, and, accordingly, products that are ideal in geometric shape are obtained.

- Hands cannot measure micron displacements. CNC machines constantly monitor the position of the cutter, making corrections when the load changes automatically.

Abbreviation

For CNC decoding:

- N (numeric) - all mathematical operations are performed in binary code. Circular and linear movements are converted into quantitative values with a certain step (often there is an accuracy of 0.01 microns).

- P (software) - all stages of the process are written in the form of simple cycles. The task of the operator is to select certain parameters according to the detail drawing. Processing after loading into memory does not require human intervention. Sometimes corrections are made at the end of the cutting cycle.

- U (management) - the processing process is fully automated. Imperceptibly there is a control of loadings on axes, position of circular and linear gauges. Mechanical backlashes, predetermined workpiece hardness factors and the effect of ambient temperature are also taken into account.

In the abbreviation CNC, the decoding is more extensive: the control system is capable of simultaneously conducting tens of hundreds of operations. Complex structures can have more than 12 axles. The movement accuracy of each is more than 0.01 microns. Parts produced on such machines are used in spacecraft, microsurgery, precision mechanisms.

Areas of use

Numerical control is often introduced into old equipment, where the mechanics, acceptable in terms of tolerances, have been preserved. These can be woodworking machines to create printed circuit boards for working with metals. Almost any design can be equipped with CNC systems, where there are at least 2 controlled axes.

On modern CNC machines, it is almost always installed. It can be:

- plasma cutters;

- piercing mills;

- hydraulic presses;

- milling and turning structures;

- portals;

- where there is coordinate processing;

- 3D printers.

Complex machines with visualization do not require deep knowledge of technical components from the operator. He can fully concentrate on the execution of the technology. The main task is to select the right tool, select the attachment points to the part and control the resulting dimensions.

The machine takes care of most of the mathematical calculations. So to perform a cut along a circle, it is enough to specify the center, radius and direction. If the cutter goes along the contour, then only the end point of each section is indicated.

Control commands

CNC programs have standard view practically on the system of any manufacturer. Machine codes are understandable to the hardware and are easily transferred from one machine to another. The visual design is often different.

Machines can be supplemented with unique applications for the rapid creation of part programs. Such developments are present in the systems of Heidenhain, Siemens. The so-called canned cycles make life easier for the operator.

More simply, NC programs are created on your own PC and transferred to the machine using a USB flash drive. However, many manufacturers still have strict rules for writing codes. But this system compatibility barrier is easily overcome by installing additional software.

Applications for writing control programs are supplied with the machine and are available on the Internet. Also, they can always be bought from the authors. Hacked versions are illegal, but they are also found in the public domain.

What systems exist?

Currently, several CNC systems are widespread in the Russian Federation: Fanuc for small-sized machines, Heidenhain is easy to create programs directly from the operator's console, Siemens is chosen due to its versatility and the ability to quickly upgrade the machine.

The listed firms are the most sold. There are a number of other systems: Balt Systems is a domestic company with a foreign past, Okuma is an Asian competitor (Japan), Mitsubishi Electric, Schneider Electric (France).

CNC abbreviation has been used for many decades among production workers in everyday working dialogues as a common technical term and does not arouse any interest, since in fact they all know what it means and what it is about. However, for an ordinary layman who accidentally entered into such conversations, the decoding of “NC” may not be available, and the interlocutors will probably not clarify their terminology, or will grin in response to an incorrect question.

What is CNC

All ever heard the phrases: “CNC machine”, “CNC operator”, “CNC milling”, “CNC programs”, “CNC codes”. Naturally, many were interested in the question of what CNC is. So! Literally, the abbreviation CNC stands for Numerical Program Control. However, it will be easier to fully capture the essence of the three words if you analyze each of them separately.

Control- means that some intricate mechanism (machine) will be given commands that it will perform with a given accuracy. For example, move the milling unit a certain distance to the left, right, forward, backward, up, down, or tilt it to a certain angle, turn it on or off. The parameters of the actions of certain units and assemblies of the machine are set using Numbers. To execute several consecutive commands, the numbers are combined into special algorithms - Programs that are entered into the memory of the machine control unit. That is, decoding CNC means a machine or unit that operates under the Control of Numerical Programs.

Areas of use of CNC machines

Currently in fact, in all areas of industry, machine tools with numerical control are used. No one machine building plant does not do without the use of modern high-tech equipment for the manufacture of complex parts made of metal, plastic and other materials. V light industry widely used CNC machines for patterns of matter, leather. In construction, they are used for the manufacture of panels for prefabricated panel houses.

in the furniture industry milling machine CNC allows you to achieve amazing results in the manufacture of furniture facades from MDF, plastic, solid wood for the kitchen, living room or bedroom. Many jewelers use CNC engraving machines to make precious metal jewelry.CNC can be found in any office. According to its principle, a printer or fax works.

Basic principles of working with CNC

To obtain the finished product using a CNC machine, it is necessary to perform several preparatory operations. At the first stage, according to pre-prepared drawings in special computer programs a product model is created in 2D or 3D format. Then the parameters of the working tool (cutter, cutter, laser) are set to the program, and the computer calculates the trajectories of the tool. After choosing the optimal trajectory, the resulting vectors are translated into an alphanumeric code - the Control Program, understandable for a specific CNC machine model. There is a kind of decoding of CNC codes into a language understandable by the machine.

Control program is entered into the operating memory of the CNC machine's processor. After its launch, the processor in a certain order gives commands to power units and assemblies to perform certain operations to change the position of the workpiece or cutting tool.

CNC software

Certainly, the sequence of machine actions can be set manually by entering the positioning coordinates of the tool relative to the workpiece from the control panel. This is easy to do if you work with simple products or you need to perform fairly simple operations. However, the modern market requires more and more complex products, which are quite problematic to manufacture without the use of a computer and graphic programs.

No one The engineering and technical department of a modern industrial enterprise cannot do without a set of special programs for working with drawings and graphic models of products. A whole series of software has been developed for working on CNC machines. For example, in the furniture industry, the Type3 and ArtCAM programs have gained the most popularity. With their help, it is enough to simply create a graphical model of the workpiece and, right there, create direction vectors and parameters of the processing tool.

On the other side, according to pre-prepared sketches, you can create a 3D model of the product, and by setting the processing parameters, get a finished control program for processing the workpiece on a CNC machine. If suddenly there are difficulties with working with complex graphic reliefs, software manufacturers offer a wide range of ready-made solutions from vectors to volumetric models.In conclusion, I would like to note that working on CNC machines requires high qualifications, broad knowledge in electronics, mechanics and computer technology and requires in-depth study. However, the purpose of this article is to explain what the CNC decoding means, and other details of interest can be easily found on numerous Internet resources.

How to understand: will the kitten be fluffy?

What kind of light alcohol can be drunk for pregnant women: the consequences of drinking

Why do the legs swell in the ankles and ankles of the feet in pregnant women: causes and methods of treatment

The wedding of Prince Harry and Meghan Markle: scandalous and secret details of the marriage (photo) The future marriage of Prince Harry year NTV

How to close white plums for the winter