Need to repair or repaint decorative coating on plastic parts and PVC cladding occurs much more often than it might seem at first glance. It could be a metal surface. plastic windows verandas, cases of home appliances, a soft inflatable boat, plastic elements of a body kit on a car and even protective covers made of fabric. It is not difficult to paint PVC plastic, but on one condition, if there is a special paint for PVC.

Difficulties in painting, how to paint PVC correctly

For coloring plastic, acrylic or acrylate paint for PVC profiles is used. As a rule, due to the high gloss or the specific “oily”, paraffinic texture of the PVC surface, ordinary acrylic paint on plastic lays down very poorly, rolls off in drops. Even the classic method of increasing paint adhesion by applying artificial roughness does not improve adhesion to the substrate.

Therefore, before attempting to apply paint to the window frame or plastic hinged parts, it will be necessary to thoroughly prepare the PVC surface:

- On the eve of using the paint, the PVC surface is cleaned of dust and dirt with soapy water and washed with clean water so that no traces remain. Ideally the best fit detergent for PVC parts, but an aqueous solution of isopropyl alcohol can also be used;

- The surface is treated with a special solvent-activator that improves the adhesion or adhesion of the paint to the smooth PVC profile;

- If water-based acrylic paint is used for painting, the PVC plastic can be lightly moistened with a hand spray gun and then applied with a brush or airbrush.

Important! It should be borne in mind that the quality of the painted surface depends primarily on temperature and humidity. The higher the temperature environment, the better the adhesion, and the faster the drying speed.

After about a couple of hours, the paint applied to PVC at a temperature of 20-23 ° C will stop sticking to the hands, and after 26-40 hours the drying process of the painted surface will be completed completely.

Water-soluble acrylic paints allow you to get the painted PVC surface of the most different colors and shades. According to the paint manufacturers, the tinting machine, which is used for tinting and color correction, can produce more than 2,000 color compositions.

Technology for painting household items made of PVC

The high quality of the painted surface can only be obtained by using specially designed products for painting PVC surfaces of any modification. More simple materials, such as frames and lining of plastic windows, can even be painted acrylic materials, but to obtain an exemplary glossy surface, a paint containing modifiers and a polyurethane varnish is required.

Therefore, to obtain a high-quality, perfectly smooth PVC texture, the following are most often used:

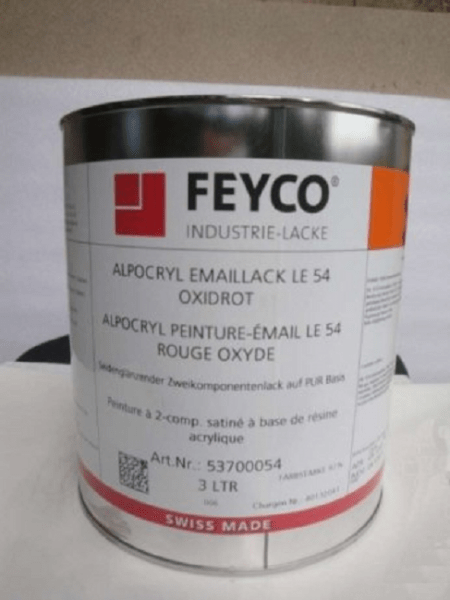

- Polyurethane paints and varnish compositions from Feyco AG, Switzerland;

- Acrylic-urethane paints "PaliPlast RP Base" used for industrial painting of PVC plastic.

Note! Painting compositions "PaliPlast" are produced both on a water basis and on a varnish basis.

Despite the fact that, after drying, PaliPlast water-borne compounds are not washed off with water and withstand repeated washing of windows and frames, it is necessary to periodically restore the protective layer with a varnish, for example, PaliPlast RP 022 Varnish.

Painting PVC plastic surfaces at home

The most demanded procedure for painting PVC plastics is the painting of frames of metal-plastic windows. Not everyone likes White color standard PVC cladding, or the owners want to make the windows of their shop or showroom more expressive, in any case, the coloring of the windows is not difficult if you use PaliPlast RP Base PVC materials.

You only need to seal the window, slopes, glass and rubber frame seal with plastic wrap with masking tape, and you can start painting according to the method described above. The easiest way to apply paint on a PVC profile is with a brush or roller, but best quality obtained using a low pressure spray gun. The viscosity of the paint is low, but the presence of mineral fillers can sometimes lead to clogging of the nozzle or poor spraying, so the paint solution must be cleaned of films and thoroughly mixed before use.

More difficult is the painting of decorative and protective elements made of PVC plastic on a car. Most often, these are moldings and linings inside the car. The size of the parts is small, so it is best to use spray cans to paint PVC plastic. The composition includes an activator and a solvent that provide good adhesion to plastic and rooted drying of the applied layer.

Dye not big details from PVC can be both with preliminary dismantling from the car interior, and directly inside the car. In the latter case, you will need to install a fan to carry the aerosol flow out of the passenger compartment and make an apron from polyethylene film, which will close the space around the PVC part to be painted.

Full-sized PVC parts must be dismantled, dusted with alcohol or window cleaner, and then spray-painted in thin layers, 50-70 microns thick.

Difficult options for coloring PVC plastic

Large parts of the body kit or spoilers can be painted with a spray gun or spray gun. Initially, you need to matte the surface with thick paper and micron-sized abrasive powder. Next, the plastic is thoroughly washed and dried.

Before applying paint, the surface will need to be wiped with a PVC cloth moistened with P646 solvent, and can be painted. If the thing is very thin and soft, then the first layer is best done with Feyco polyurethane varnish, after which the required number of layers of paint can be applied.

PVC pipes, structural frames, even glass and furniture can be painted in a similar way. In order to enhance the adhesion of the paint to a completely smooth and inert glass surface, Feyco proposes to add a special Fey (N) Vetro Zusatz 501 reagent to the paint. Polyurethane and epoxy compounds can be quite easily painted on metal, stone, plastic, wooden surfaces, while the quality of adhesion to the base is much higher than that of acrylic and water-dispersion materials.

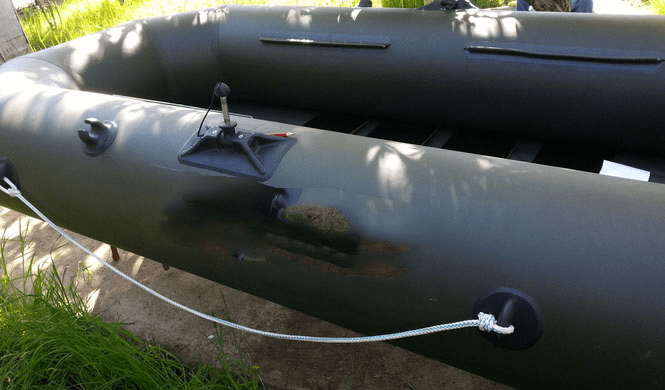

We should also mention the painting of soft PVC fabrics, for example, covers or the hull of an inflatable boat. Most polyurethane inks can be used on heavy PVC fabrics under one condition. Staining is carried out using a barrier subcoat of a 1:3 solvent-diluted FEYCO Universalprimer 2159 primer, with the addition of Fey (N) Vetro Zusatz 501. The sublayer is applied with a spray gun in a thin layer of 20-25 microns. Subsequent painting is carried out with conventional polyurethane paints.

If there is no particular desire to look for optimal recipes for staining soft tissues, a barrier layer can be made using spray paint for cars.

Conclusion

Painting polyvinyl chloride is not a difficult task if you use the right materials. Given the high durability of PVC plastic, the demand for special paints for decoration or repair is only increasing, so the technology of painting is improving, and, apparently, in the near future the problem with painting PVC plastic will be finally resolved.

The main reason to change the colors of the plastic is to give it a harmonious look with the interior of the room or the exterior of the building. At the moment there are more than 2000 shades that allow you to do this. There is only one thing left - to correctly apply the paint on plastic panels.

In the photo - painting plastic windows

The material during operation also turns yellow due to sunlight, losing its original appearance. In addition, its physical properties are also violated. In this case, coloring will protect the PVC plastic from such influences.

Tip: if you want to protect the metal elements in the apartment from corrosion, for this you use Zinga electrically conductive paint, which can prevent moisture from reaching their surface.

Dyes for PVC in granules

Technology

Coloring of plastic PVC profiles water-based polyurethane acrylic system has a number of advantages:

- fast and high-quality surface preparation;

- drying takes place a short time at room temperature;

- hardening at a temperature of 20˚С - from 8 hours;

- manual and automatic spray painting;

- a wide range of decorative possibilities - texture "under the tree", mother-of-pearl, metallic.

Acrylic paint for PVC panels

Training

Below we consider the stages of manufacturing colored plastic profiles. And the most important step in this case will be the preparation of products for painting.

You must make sure that there is no dirt, silicone, greasy spots and other substances that will interfere with good adhesion of plastic to paint.

There is a small guide for this:

- remove dust, chips and crumbs with a dry cloth or compressed air;

- impregnate the rags with a special cleaner designed for polystyrene;

- degrease and clean the surface of the product from grease and dirt residues with your own hands, while removing static stress;

- wait 5-10 minutes for the cleaner to evaporate from the plastic surface.

Tip: use special activator cleaners for PVC for this. This liquid also creates micropores on the surface that help materials adhere to each other.

Paint for PVC plastic and internal works

Another way to achieve good adhesion is to sand the PVC and then prime it. However, this process is more laborious and requires some skills.

Tip: do not like the price of professional painters, get down to business on your own.

Choosing a paint

Remember that unless you are sanding and priming your plastic, you should only purchase paints that are specifically formulated for painting PVC.

- Choose a shade. To do this, you can use the NCS, RAL or Monicolor catalogs, where there is such a large selection that you can find suitable color won't be a problem.

- Determine what items, and how much, will need to be painted. This will make it possible to calculate the volume of paint for a certain area.

- Tinted to the desired shade at least 60 minutes before the start of work. The paint will be tinted according to a special recipe with the addition of pigments. The selected shade will be as close as possible to the color in the catalog. If possible, check the viscosity with a VZ-6 viscometer and adjust, if necessary, by adding pretreated water.

Paint for hard PVC products

Coloring

The process should be carried out in one layer at room temperature without prior application of a primer. When using a sprayer, the coating will turn out to be of better quality.

You can also apply paint with a brush or roller. The material dries in about 8 hours, depending on the temperature, but it can only be fully used after 72 hours.

Tip: If necessary, you can apply a second coat, but only when the previous one is completely dry.

If you use a gun for painting, make sure that the temperature of the paint, it and the plastic corresponds to the working room - not lower than 18 ° C, the humidity should not exceed 80%. It must also be dry and clean. It is recommended to apply with a working pressure of 2–2.5 atmospheres, nozzle size - 1.6–1.8 mm.

The desired film thickness is at least 60 microns, otherwise this will affect the adhesion strength to the base. With a layer thickness of more than 120 microns, the drying time will increase and this will affect the decorative effect of the coating.

Tip: there are enough items in the room that can be damaged during a fire. To protect them, use modern fire-retardant paints for metal Polistil, which are diluted with water.

Polyurethane paint PVC

How to dry

Drying painted surfaces ABS plastic occurs at temperatures above 40°C. They should be placed in a heated dryer no later than 5-10 minutes after staining.

If the wet film thickness is 80-120 µm, the temperature is 50°C, and the relative humidity is 65%, drying will take about 2-3 hours. It is not necessary to immediately check the degree of adhesion, it is better to wait 24 hours, complete polymerization occurs after 5-7 days.

Keep in mind that the drying time due to the high thickness of the wet layer, lower temperature, large dimensions of the product and high humidity, drying can increase significantly.

When storing finished plastic products, they must be protected with film or paper, protected from friction and impact on the painted surface. Also, they should not be exposed to moisture and negative temperatures for a long time until complete polymerization.

Conclusion

From the article it became clear that coloring PVC and ABS plastic is a simple task. It is only necessary to thoroughly clean the surface of any contamination, determine the color and the required amount of material (learn also how to paint old parquet on one's own).

You can apply it in a convenient way for yourself - spray or roller with a brush. Drying the first to produce at room temperature, the second at 40 or more degrees.

The video in this article will help you find Additional information on this topic.

Often there is a need to paint plastic windows or doors in accordance with colors interior, make PVC external communications less noticeable, or simply protect the material from fading and destruction. This requires a special paint for PVC, which will adhere firmly to the smooth surface of the material being processed.

Primary requirements

The main requirement that such paint must meet is high adhesion. Unlike wood, plastic has a smooth, slippery surface and a very hard, dense structure that does not high level adhesion between materials.

Also, the coloring composition must have the following characteristics:

- water resistance;

- strength;

- resistance to mechanical stress;

- resistance to UV rays;

- preservation of color throughout the entire period of operation;

- the absence of toxic and toxic substances in the composition that can be released when heated;

- resistance to temperature changes;

- long service life;

- wide range of colors;

- the ability to give the object a certain texture.

The ease of application of the composition also plays an important role, since plastic windows are often painted by hand.

Polyurethane-acrylic compound

Water-based polyurethane-acrylic paint for PVC has all these qualities. It is distinguished by the uniformity of the coating, resistance to defect formation, high drying speed, and allows self-tinting. With its help, you can create textured effects by introducing special additives into the base composition.

The wide color spectrum of such paint has more than 2000 shades. In addition to traditional tones, among them are:

- nacre;

- metallic;

- composition with the addition of sparkles.

In this case, painting the PVC profile will give the room or the facade of the building originality and uniqueness.

Preparatory work

Before you do windows, doors or other surfaces with your own hands, you should carefully prepare it. For this you need:

- Remove mosquito nets, blinds, curtains, ebbs and other items that will interfere with the work.

- Free the surface from mechanical impurities.

- Remove grease stains.

- Seal rubber seals and other fittings with construction tape to avoid paint ingress.

- Glasses should be covered with plastic wrap.

For more effective cleaning, degreasing and removal of static electricity, you can use specialized cleaners-activators for PVC. They are applied to a cloth napkin, which is used to wipe the surface to be treated. After that, it is necessary to allow the solution to completely evaporate, which takes from 5 to 10 minutes, and only then proceed to painting.

If the surface has roughness, scratches and other irregularities, they must be puttied and then sanded with a fine sandpaper. Finally, cover the entire surface with an even layer of primer. If you have certain skills, you can do it yourself. But if there is no experience, then it is better to resort to the services of professionals.

Application technology

Windows and other PVC products are painted with a spray gun. Before pouring polyurethane-acrylic paint into it, it is necessary to add a suitable color to it and mix thoroughly.

After opening the can, sometimes a film can be found on the surface of the coloring composition, which must be removed. It contains solid particles that do not dissolve when mixed and clog the nozzle of the spray gun.

If the paint has been frozen, then it should be discarded, because after exposure negative temperatures it loses its properties.

For coloring, it is better to choose dry, but not very hot weather. Do not work at temperatures below +5.

Window paint is applied in a thin uniform layer with a thickness of 80 to 120 microns. At the same time, there is no need to pre-paint over corners, edges and hard-to-reach areas. The composition perfectly holds and does not flow down from vertical surfaces. The paint begins to adhere tightly to the surface after 2-3 hours. But its complete drying continues for another two days.

In industrial conditions, forced drying is used for two hours at a temperature of plus 50.

Aerosols

Spray paint can be used to paint a small area of PVC. This container is convenient in that it reliably protects the contents from the ingress of air, therefore, prevents the formation of a film on its surface.

Other benefits of this paint include:

- ease of transportation;

- the possibility of staining hard-to-reach places and small details;

- no need to use additional tools;

- increased level of adhesion.

Often spray paint used for painting PVC parts in car interiors.

Even application of paint requires certain skills and experience, so it is worth a little practice before proceeding with the staining procedure.

Cover protection

While acrylic paints adhere well to PVC surfaces, they can be further protected with a water-based plastic gloss varnish. In addition to protecting, it also performs a decorative function, giving the product a shine.

This material can be used to process painted plastic window sills and windows in kitchens where they are exposed to aggressive factors.

The varnish is applied with a brush and does not require special skills. Therefore, these works are easy to do with your own hands.

To protect window sills in the kitchen and pipes passing close to open flames, which are often used for metal surfaces, are also suitable.

Important Points

When purchasing paint for processing plastic windows, you must first calculate the required amount of material. To do this, you need to measure the surface that will be processed. The exact calculation will be made by sales consultants.

The cost of polyurethane-acrylic coloring composition is quite high. However, the low material consumption and long service life without additional processing fully justifies the costs.

When applying the paint an important factor is to strictly follow the instructions. The high environmental safety performance of the presented paints for PVC makes it possible to use them in residential premises, children's and medical institutions, public catering facilities.

HideWhen the design of the room has changed, and the standard color of the plastic is not suitable, and it is not possible to replace the windows, PVC painting will help. . This can be done in several ways, which we will discuss below.

Why paint plastic windows?

Painting may be required in the following cases:

- The frame burned out in the sun, lost its original color, turned yellow and looks unattractive. The absence of a paint layer can lead to a violation of the physical properties of the profile, so it is recommended to paint it.

- The paintwork layer will be able to protect the window from the harmful effects of the environment.

- The design of the room has changed, and the original color of the profile has ceased to harmonize with the room.

- The facade was repainted, the windows began to look unfavorable.

The use of paint of special brands, such as Zinga, will protect the metal elements of windows from corrosion.

Varieties of dyes for PVC

Not every paint will adhere to a smooth plastic surface. It is for this reason that painting takes place with the help of special dyes that adhere well to plastic. . A water-based paint for PVC is widely used. It has the following features:

- The surface does not require complex preparation before painting.

- The paint dries at natural temperature.

- At 20 degrees, hardness will be gained in 8 hours.

- When choosing how to paint PVC, you can use both manual application and use a spray gun.

- Materials can have a different texture, a wide range of colors is offered.

Dyes for PVC in granules

The choice of acrylic paint

Acrylic paint for PVC panels

Acrylic substances are more expensive and quality materials. In addition to the difference in price, they have the following features:

- The surface needs careful preparation before painting. To do this, remove dust and other contaminants from it. This can be done with compressed air, napkins, alcohol.

- The surface must be degreased and wait until it dries.

- With the help of a special rag, dirt is removed from the surface, static stress is removed.

Paint for PVC windows will lie on the surface better if the frame is treated with a special cleaner for plastic. It allows not only to clean the surface, but also contributes to a good bonding of materials at the molecular level.

What tools to choose for interior work with plastic?

Paint for PVC plastic and interior work

Paint for can differ not only in composition, but also in the ability to endure difficult operating conditions. Therefore, all materials can be conditionally divided into universal, suitable for indoor and outdoor work, and those that can only be used indoors.

It is quite possible to cope with the work on your own. You do not need to pay for expensive services of painters.

If you purchase ordinary paint, the plastic will have to be sanded, then it will need to be primed. It may lose its glossy appearance, as roughness will remain after grinding. Unnecessary manipulations can be avoided by using the appropriate type of paint.

Methods for painting plastic surfaces

Paint for, provided that the work is carried out indoors, should be applied at room temperature. This will contribute not only to comfortable work, but also to the rapid drying of the paint.

The first coat can be applied without a primer. The sprayer will help to better paint the surface.

If you do not have a sprayer, you can apply the material to the surface using a conventional paint brush or roller. If you are going to apply a second coat, you must wait until the first is completely dry.

When using a gun for painting, the operating temperature is set to the appropriate room: for example, not lower than 18 degrees. Humidity should also be taken into account - no more than 80%. There should be no dampness and dust in the room, it is recommended to spray at a pressure of 2 atmospheres, use a gun with a nozzle size of 1.6–1.8 mm.

If the painting of PVC windows does not take place in an empty room, it is recommended to cover the furniture with a special film. Otherwise, drops of paint may fall on it and spoil the surface.

Drying after coloring

In most cases, it is not necessary to dry the paint, it dries itself at room temperature, but if the room is cold, you can speed up the process using a heat gun. It is not recommended to heat the room more than 40 degrees. The gun must not be aimed directly at the painted surface, and warming up should be carried out no later than 10 minutes after applying the paint.

Painting a PVC profile at home does not cause problems. To do this, you just need to purchase the appropriate paint and take precautions so as not to stain surfaces that do not need to be painted.

Greetings comrades. I won’t open America if I say that the furniture is made of MDF, Wall panels and other forms of application of this material have firmly entered our lives. But what if you don't like their color? Painting MDF panels can make a difference, but not all paints are suitable for this. And if so, then for sure you want to ask: which ones are suitable and what is the price of the solution? This is what we will find out now.

Material feature

Sawing, cutting, milling, drilling, perforating and, of course, painting. It is for this set of qualities that MDF made from wood waste is valued. All these operations are not particularly difficult, with the exception of the staining process - if you do not know the characteristics of the material, it will take a lot of paint for furniture from MDF, and the result will disappoint you.

Reason 2:

- The material is highly hygroscopic, it absorbs coloring compositions like a sponge;

- When stained, wood pile rises from the interaction of the coloring composition. The result is an unattractive and rough surface to the touch.

What suits

It is clear that these problems can be solved in production, because in construction stores all MDF products are qualitatively painted and smooth to the touch. Is it possible to achieve such an effect with your own hands?

Important!

Looking ahead, I will say - it will definitely work.

The secret lies in the preliminary application of an insulating primer that impregnates the MDF and creates a high-quality base, as well as in grinding the surface before applying the final coloring layer.

We will return to the process of surface preparation. The main thing is to first figure out how to paint MDF at home. We need special formulations with high covering power.

These include:

- acrylic enamels and paints in the form of aerosols.

- enamels made on an alkyd-urethane, alkyd or oil base;

- polyurethane enamels.

Acrylic enamels

This group is considered environmentally friendly, since it is a water-dispersion composition based on acrylate or latex copolymers. Most manufacturers recommend their use in residential areas and even children's rooms.

Another plus - good protection surfaces from moisture and temperature changes, which is quite important for furniture and sliding MDF screens in bathrooms.

On sale most often you can find the following compositions:

| Name | Options | price, rub. |

| Belinka AQUA EMAIL | The composition is endowed with good hiding power, and when applied creates a glossy film. The manufacturer allows the composition to be applied over old paints and varnishes. Be sure to use an insulating primer. Among the features of this composition can be identified:

This composition can be recommended for products located in direct sunlight. If you doubted whether it is possible to paint MDF wall panels that have faded in the sun, then applying Belinka AQUA EMAIL in 2-3 layers will make them resistant to UV exposure. |

590 for 0.75l; 1720 for 2.5l |

Some of the compositions presented can also be used as an insulating primer. For such purposes, the manufacturer recommends diluting them with water in a ratio of 70% paint and 30% drinking water.

Before you paint white door from MDF under a tree, it is obligatory:

- first apply a base coat of light paint, after which you can apply dark tones;

- using a special rubber brush, without waiting for the second layer to dry, treat the surface to obtain a wood structure.

Captain Evidence informs: if you choose how to paint MDF panels small size, then it is not advisable to purchase paint in a large-capacity package.

And since the smallest volume is 0.9 l, it is worth taking a closer look at acrylic paints in cans.

It is also important that when applying such compositions, wood fibers do not rise on the surface, which simplifies painting.

Important: before painting MDF with an alkyd spray, the surface should be primed.

Alkyd and alkyd-urethane enamels

One more is enough large group coloring compositions, allowing you to paint MDF surfaces. If you do not know how to repaint MDF furniture with your own hands, then for self use I can recommend products from the following manufacturers:

Important: Do not forget that all alkyd compounds have a pungent odor, which, moreover, is quite toxic in the drying process.

It is important to organize staining in a ventilated area using personal protective equipment.

Polyurethane enamels

Polyurethane compounds are primarily interesting for their wear resistance and durability. Agree that if you spend money on expensive paint, then its service life should be maximum. In the case of the type in question, manufacturers guarantee at least 20 years!

So, what can be purchased from this group in our country? Below we will take a closer look at some of these compositions:

Coloring process

We figured out the compositions, and now you know whether it is possible to paint MDF panels and with what exactly.

It's time to puzzle you with some of the nuances of the upcoming process, telling you how to paint MDF:

- Any surface must be pretreated with primer. It fills the pores of the material, preventing further absorption of the finish coating (paint);

- After applying the primer and drying, the surface must be sanded to remove the raised wood drag. It is best to use a grinder for these purposes;

- The surface should be cleaned of dust, and only then apply the first coat of paint;

- Repeat the sanding process again to remove the raised fibers from the surface again;

- Then apply a second coat of paint;

- To give a complete appearance the surface should be polished.

Chocolate biscuit: the secrets of cooking in a slow cooker and oven

Chemical composition and nutritional value

Apple chips at home

Braised cabbage with white beans, recipe

How to reduce the ass, hips and stomach at home?