Personal transport is an opportunity to quickly and comfortably get to your destination, even if it is hundreds of kilometers away from home. But car trips are not always as cloudless as we would like. Sometimes it can break, and at the most inopportune moment. To prevent this from happening, keep your vehicle in proper conditions.

However, sooner or later it will still have to be repaired, and this will require special equipment, and in particular a compressor for painting. After all appearance A car is as important as a good running gear. And besides, painting in a car dealership is very expensive and many people prefer to do it themselves using compressors. About what model of equipment to choose and what parameters to pay special attention to will be described below.

Compressor and moments of its use

Painting solution vehicle on its own leads to the need to purchase special device. And this is the compressor for painting cars. However, this unit has wider functionality and is not limited to applying various formulations. Using the device in combination with replaceable tools for the functioning of which requires compressed air, you can perform a variety of operations:

- purge;

- Application of various compositions;

- Grinding and polishing when used with pneumatic equipment.

The fastest way is not all the processes that will become available with the purchase of an air compressor for painting. In your own garage, there are many ways to use it. It remains only to choose a model that meets specific requirements, including those that meet the cost.

What unit is needed for painting a car

To answer this question, you need to familiarize yourself with all types of equipment and find out what their difference is. If you believe the statistics, then most often for work related to the repair and maintenance of vehicles, they choose air reciprocating compressors for painting. They are divided into two groups:

- Oily;

- Oil free.

Devices of the first type are considered one of the simplest in terms of design. They are reliable and easy to use.

We watch the video, types and their features of application:

Oil-free models are used to perform simple work. Therefore, for painting it is better to choose oil models. They are produced in two versions, which differ in the type of drive:

- Straight;

- Belt.

Of these, the most reliable compressors for painting the second type. They can be one or two stages. The latter create less noise during operation. In them, the flywheel is connected to the compressor head using a belt drive. The advantages of such devices include:

- Low engine speed;

- air cooling.

There are also compressors for painting screw and piston types. In the first, the air compression process is based on the simultaneous rotation of rotors arranged in parallel. During their operation, special chambers with a variable volume are formed. As it decreases, the pressure of the gas increases.

The equipment of this group is usually equipped with an automatic control system, allowing you to quickly set the device to a specific mode. Most often, screw compressors for painting a car are installed in car services or enterprises where uninterrupted operation is required for a long period of time.

Painting a car using such a device is carried out quickly and efficiently. In addition, the device is characterized by low power consumption and, compared with analogues, allows you to save up to 30%.

Piston models are inferior to screw models in some respects, but not in price. It is this parameter that often plays a decisive role, thanks to which devices of this class are the most common. The advantages of such devices include their simple design to keep maintenance to a minimum. differ from piston and on the principle of air compression. In them, this process is based on the operation of the electric drive.

Features to look out for

Each device is purchased for specific tasks. If you need a compressor for painting a car, then the following parameters should be considered:

- Performance;

- Power supply;

- receiver volume.

The most important parameter is power consumption. It must match the quality of the power supply at your facility. For old wiring, which used twisting of thin wires, you need to choose low-power models.

If you are going to do painting, you need to take into account that spray guns differ in such a parameter as air consumption, therefore, their consumption of a compressed mixture will be different. Therefore, when choosing equipment, you need to focus on its performance.

Watch the video, selection options:

Depending on the specifics of the device, a 220V air compressor for painting can produce up to 550 l / min. By correlating this parameter with the parameters of the spray gun, the desired model is selected. If these characteristics do not match, the unit will work without stopping, which will eventually lead to overheating and reduce the quality of work performed.

Since most units are equipped with an electric motor, they require a connection to the network. Based on the model, this can be a single or three-phase device. If 380 V is connected to your garage, then the unit is selected with the appropriate parameters, the same is true at 220 V. If the power supply is poor, when voltage surges are in the range from 160 to 230V, it is better to connect the compressor through a stabilizer.

When choosing equipment for painting work, you should think in advance about the required volume of the receiver. Experts recommend models from 50 liters. In some cases, purchasing a device with a large volume can partially compensate for its insufficient performance.

As for the injected pressure, this parameter is almost the same for all devices. The regulator allows you to set the desired value.

How to properly operate

It is not enough to choose the equipment, it is also necessary to use it taking into account all requirements. This approach will achieve high quality work and extend the life of the device used for this.

Here are some tips for using:

- It is supposed to work in a short-term-repeated mode, if this does not happen, then the consumption is greater than the output;

- If it is necessary to use the equipment in the cold season, warm up the oil sump with a hair dryer or lamp;

- With intensive use of the device, the filter must be changed regularly;

- A complete cleaning of the unit should be carried out once every 5 months.

By fulfilling all these requirements, you can achieve long-term and high-quality operation of the equipment.

Domestic markets offer a wide range of equipment for the production of compressed air, which is used in almost all areas of human activity. It is represented by models of both Russian and foreign companies. Therefore, it is worth thinking carefully before deciding which compressor is best for painting a car.

There is a big difference in how technical specifications and the cost of the equipment. Sometimes the most important characteristic of a paint compressor is the price.

For domestic use, you can limit yourself to purchasing an Ekand Windsol-ico compressor. This is an oil model with a 50 l receiver, which is optimal for both car painting and summer cottages. The device is easy to operate, equipped with sensors and belongs to low pressure devices. At the same time, the compressor capacity is 270 l / min and it is connected to a standard electrical network.

Model Ekand Windsol

The advantages of the compressor of this brand include:

- Large volume receiver;

- High performance;

- The ability to control the pressure level using built-in pressure gauges;

- Equipped with wheels for easy transportation.

The cost of the equipment is 6,000 rubles, which makes it affordable for a wide range of consumers.

Over time, vehicles lose their original appearance and many car owners in these cases resort to painting their “iron horses”. Some trust this business to qualified specialists, while others try to restore the machine to its original appearance on their own. In this article we will tell you what a mini compressor for painting a car is, which one is needed and which one is better to choose for this.

The most common compressor designs

To begin with, we suggest that you find out what compressors are by their types. Currently, the most popular devices are piston type air compressors. It is these devices that are used in most modern service stations that offer car painting services. Piston equipment is divided into oil-free and oil. As practice and expert advice show, such devices are the most convenient to use and they do not need constant maintenance.

Oil-free devices are usually used for the most basic procedures, i.e. for pumping car wheels, blowing out various nozzles or non-professional painting.

As for oil devices, they are different. In particular, these compressors differ in terms of performance and usage. But one thing that they have in common is that the piston drive crankcase uses oil anyway. As for the differences, they can be belt or direct drive.

Belts are one of the most reliable. Firstly, this is due to the nuances in their design. The belt drive itself is directly mounted from the motor to the flywheel of the head.

As for the advantages of belt devices over drive ones, they are as follows:

- The motor runs at a slower speed.

- In the design, the diameter of the belt flywheel is slightly larger than the diameter of the motor shaft.

- Belts are equipped with a more reliable air vent system.

Where and how are they applied?

In fact, the scope of such devices is very wide. If the structure is equipped with specialized replaceable components that require compressed air to function, this greatly expands its capabilities. Basically, it all depends on your budget.

Consider several aspects where such equipment can be operated:

- When applying paint or primer to paint a vehicle. In this case, a spray gun should also be used.

- If purge is required. At specialized service stations, you can often see how craftsmen blow through various nozzles of various auto systems, jets, and so on with a compressor. In general, the compressor can be used wherever a good blowdown is required.

- When working with a wrench, screwdriver and other construction equipment.

- If you need to apply any composition (for example, anti-corrosion liquid). Using this device, it is possible to apply an anti-corrosion agent without problems even in the most hard-to-reach places vehicle.

- Often compressors are also used when working with pneumatic grinding or polishing devices.

However, in fact, there are a lot of ways to use it. In any case, if you decide to paint your vehicle, then using a compressor will be the best option. Which type to choose is up to you. Below we will consider the main characteristics and features of the use of oil-free devices.

Features of oil-free reciprocating compressors

Professionals have long known where oil-free devices are used and what are the features of their application. Now we will share this information with our users.

Oil-free designs are most commonly used in three types of compression units:

- spiral;

- piston;

- and screw.

The most efficient compressor operation can thus be achieved by using specialized materials, which have a low friction index. As we said at the beginning of the article, such equipment in practice is more expensive to manufacture. However, despite this, in terms of financial costs for the purchase of consumables, as well as regular maintenance, diagnostics and repairs, it is cheaper.

Below we briefly consider how friction is reduced using the example of oil-free screw equipment. As a rule, in the production of such devices, air seal o-rings are used, as well as viscous oil seals. in addition, the design of such equipment has a large vent designed for discharge into environment. This can be negative from an environmental point of view, especially since filters are rarely installed on such equipment, but nothing can be done about it.

As for the features:

- Oil-free equipment is equipped with reliable wear rings made of special alloy steel for air sealing. It should also be noted that such equipment is equipped with additional stops made of stainless iron with a reduced coefficient of friction.

- In addition, the design also uses viscous seals made of copper material. This creates a positive pressure that will push the oil mist to the lubrication side of the seal.

- Of course, like any other equipment, oil-free compressors have their drawbacks. However, most modern manufacturers could still keep them to a minimum. In particular, the sound level of such equipment is much higher than in the case of oil devices. However, the structures are equipped by manufacturers with additional soundproofing elements.

- Very a large assortment equipment. Today, the domestic market offers many models designed to solve certain problems. In this case, you must understand for yourself what you need and where you will use the compress. If for garage use, then pay attention to one type, if for a car service, then its parameters will be different.

- Perhaps the most main feature what buyers pay attention to is the price. Oil-free equipment costs an order of magnitude lower, especially if you decide to purchase a piston unit.

Recommendations for the selection of compressors of any design

What is needed and how to choose a compressor for painting a car - you will learn further.

ALREADY SHARE

Today on the market you can find a compressor for painting cars from a variety of manufacturers. They differ in price and features. To choose suitable option, you need to know the features of this tool, how to use it and accurately determine its practical necessity.

1 Compressor for car painting - design and purpose

Paint specialists distinguish several types of modern compressors, which differ from each other in such indicators as:

- design features (piston or screw),

- the amount of oil in the compressed air (oil-free or oily),

- the presence of a belt drive and drive,

- power and type of power source (from 220 to 380 volts),

- dimensions of the air storage tank,

- air flow performance.

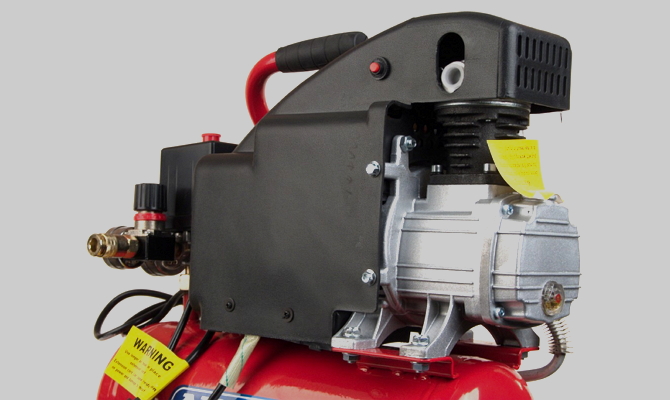

Screw compressors are devices where air is compressed by rotating casing rotors, which are parallel to each other. Thus, during continuous rotation, special air cells are created, which gradually decrease in volume, and the pressure in the system increases.

Screw compressor for car painting Recommended reading:

- – effective and simple!

- - testing a popular product

- What exist?

As a rule, compressors screw type equipped automated systems management and control, so it is quite easy to set them up for the desired mode of operation, which depends on specific conditions. Screw compressors can provide an uninterrupted supply of compressed air for a long time, so they are used in professional workshops for painting cars and other equipment.

Due to the thoughtful and at the same time simple design, such devices have a high price, but this disadvantage is compensated by ease of use and practicality. Other benefits of screw compressors include:

- low energy consumption (compared to other types of compressors),

- no pressure drops during operation,

- low noise level.

Low noise unit

Piston type compressors - this type is more common among ordinary motorists because of the affordable price. Due to the simple design, various faulty parts can be easily replaced without opening the case. The pressure in such systems is pumped due to the built-in piston drive.

The drive can be direct or belt. In the first case, the installation will be noisier and less productive, so experts recommend choosing oil compressors with a two-stage belt drive to eliminate noise and increase productivity. In addition, the belt-driven compressor motor rotates at a lower frequency and has more reliable system cooling.

2 Ways and options for using the compressor

Household compressors are used in a wide variety of industries, but among motorists they are used when painting car body parts. Before choosing a compressor for painting cars at home, you need to know all the parameters of painting work, for example, the volume and timing of painting, the required output quality, the number of paintings per day, etc.

Before choosing a compressor, it is necessary to make the right choice of an airbrush - the main tool with which paint is sprayed during operation.

Choosing a paint spray gun The choice of a compressor involves taking into account the performance of the spray gun (maximum pressure, the amount of "passage" of air at a time, etc.). Miscellaneous systems have different requirements by the amount of air consumed. The most efficient HVLP spray guns have low outlet overpressure but very high air flow.

As for piston-type compressors, when choosing them, it is also recommended to take into account performance margins (at least 20 percent). If work is carried out at low temperatures (up to 5 degrees), then when using a piston compressor, there may be problems starting the engine, since the oil in the crankcase thickens and the engine does not have enough power to scroll the cylinders and piston. To avoid this, warm up the oil pan before painting.

Painting work can be divided into household and professional. In the first case, we are talking about a simple painting of some body part (wing, mirrors, handles, pillars, etc.) without the need to comply with standards and requirements. Professional painting uses efficient tools, special technologies, paints and other materials.

Home paint compressor Thus, for simple painting, a piston-type oil compressor with a two-stage belt drive is suitable, the performance of which does not exceed the maximum amount of air consumed by the spray gun, while not more than 250 liters / min. The power of the device can vary between 1.5–3.5 kW with a pressure of up to 8 atmospheres. If you are painting in the garage, it is also recommended to equip the compressor with a special air filter that prevents solid particles and oil residues from entering the surface to be painted. In addition, you can purchase a special air dryer, which removes the water vapor that occurs during the compression process.

For more professional painting, reciprocating compressors are ineffective, even though they are more attractively priced. In this case, it is better to use oil-free type screw compressors with low power. They are economical, productive and do not require the purchase of additional parts and filters, and the output is clean air without impurities of oil and moisture. As a rule, a standard paint shop at a specialized service is equipped with a mobile screw-type installation with a power of up to 5.5 kW, a capacity of up to 620 liters / min and a pressure of up to 15 atmospheres. Air intakes on such models can reach 200–300 liters in volume, while the installation itself has all the necessary filters and a refrigerator to remove moisture.

3 Compressor selection - main criteria

When choosing an air type compressor, it is necessary to pay attention to the following criteria:

- inlet and outlet pressure,

- device power,

- source of power,

- versatility,

- manufacturer,

- warranty period,

- receiver size, etc.

Selecting the volume of the air compressor receiver Pressure is one of the main selection criteria. In reciprocating systems, a constant pressure must be maintained in the range of 5.5–6.5 bar. At the same time, it should be remembered that an increase in pressure leads to greater energy consumption, which should be taken into account when purchasing a compressor for reusable production work.

Mechanism for production reusable works An important factor is also the versatility of the do-it-yourself painting device. The optimal design will allow the compressor to be used in various conditions(in the garage, in the open area). Some compressors are able to operate from the car's on-board network and can be used not only as painting tools, but also as a universal pumping device, etc. Therefore, the choice of a compressor requires taking into account the power source and voltage from which the compressor can operate. The volume of the receiver does not play the most important role in the selection process, therefore, universal models with a tank volume of up to 100 liters are suitable for living conditions.

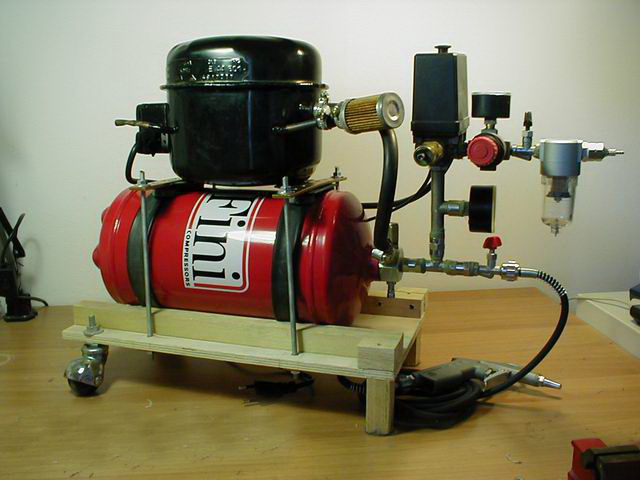

4 Homemade compressor - an easy way to make

The simplest and effective method make a compressor with your own hands - make it from an old car chamber. For this you will need:

- car camera with or without a tire,

- car pump with a connected pressure gauge,

- additional nipple,

- repair kit (awl, rubber, etc.)

Automotive pump with connected pressure gauge In our case, the chamber acts as a receiver, and the pump builds up pressure. First you need to check the chamber for leaks, for this you need to pump it up with a pump and check for air leaks. If there is a leak, the rubber must be vulcanized. Next, we make an additional hole for the nipple through which air will escape. The native nipple should also be left, it will serve as a valve that holds excess pressure.

Checking the chamber for leaks Next, we connect the spray gun and determine the required pressure level in the receiver using the barometer built into the pump. The paint can be sprayed onto any flat surface, it should be applied evenly. Once you have determined the correct pressure, loosen the pump hose slightly so that the homemade compressor does not change pressure (especially if the pump does not have a bleed mechanism). After work, make sure that no moisture gets into the camera, otherwise the paint will turn out blurry.

A homemade compressor is much more efficient than a can of spray paint, and given the cost of professional kits, it is sometimes advisable to do it yourself. There are other ways, but they require more details(motor, adapters, gearbox, etc.) and professional knowledge is indispensable.

If you need to paint a car, and you decide to do it yourself in the garage, then you need a car painting compressor - a device that compresses and supplies air under pressure. Therefore, in addition to applying paints, varnishes and primers, it is used for inflating tires, blowing, removing contaminants from the engine, working with pneumatic tools, treating cars with an anti-corrosion compound in places where you can’t get to without using a compressor. There are several types of devices that use compressed air. Which of them is better suited for the needs of the motorist?

Types of compressors

- piston;

- screw;

- diesel.

Piston compressors for car painting

Widely used in industrial and non-industrial facilities, as well as in everyday life. It is this type that is considered optimal for paint and varnish work. Their advantages speak for the choice in favor of these devices:

- a wide range of goods at different prices, so that everyone can buy such compressors for painting cars;

- unpretentiousness in service;

- long service life, with timely care of the mechanism (it is required to replace piston rings, seals and valves as they wear out);

- relatively small weight and size;

- the ability to work in extreme conditions: household models can function in any temperature conditions and with a high level of air pollution.

The reciprocating air compressor is the ideal choice for those who need small capacity at high pressure.

This type of units can be divided into two groups according to the type of connecting rod-crank mechanism:

- crosshead - the movement of the connecting rod is transmitted through the crosshead (slider) to the piston;

- without crossheads - instead of a slider, the piston itself is used. This design leads to rapid wear of the mechanism, but it also has its advantages. Crossheadless reciprocating compressors, due to their low weight and small size, are considered the best option for portable installations.

Also, devices may differ in the number of cylinders:

- single-cylinder;

- multi-cylinder.

There are mechanisms of single and double action, depending on how many functioning cavities the cylinder has. In single-acting mechanisms, air is compressed when the piston moves in one direction, and double-acting means simultaneous suction and injection of vapors from different sides with each piston stroke.

Air reciprocating compressors for car painting are oil and oil free. No special experience or professional maintenance is required for their operation.

Oil type compressors are divided into two subspecies:

Oil units, due to their design, are considered the most reliable today, and are well suited for self-painting cars.

Screw compressor for car painting

Screw compressors are becoming increasingly popular among motorists. This type of mechanism has the following advantages:

- power;

- profitability;

- durability;

- high level of performance;

- have an automatic control and monitoring system;

- are almost silent and almost do not vibrate.

Such units function thanks to two helical rotors, one of which is connected to the motor, they are able to work continuously for a long time, and do not overheat.

The cost of screw compressors is an order of magnitude higher than piston compressors, but this choice will reduce other costs due to energy savings - about 30% compared to other types of similar equipment.

Diesel Mobile Compressors for Painting

Compact Diesel Compressor

Compressors of this type are designed to work in the construction industry. They have high performance, mobility, are equipped with durable engines that consume fuel optimally. They can also be used in auto repair shops, but for a simple car owner they will not fit the price.

Diesel Mobile Compressor

What you need to know when buying

When choosing a machine for painting a car, you should pay attention to the following indicators:

- the amount of compressed air produced is calculated in liters produced per minute. Different spray guns, depending on the design features, consume different volumes of air. Therefore, when purchasing an air compression machine, it is better to correlate its performance with the requirements of the spray gun. Otherwise, the quality of painting will deteriorate greatly, and the compressor will quickly fail due to constant overheating.

- the maximum indicator of pressure injected into the receiver for all reciprocating oil compressors is approximately 8–12 Atmospheres (atm).

- the receiver must be at least 50 liters in volume.

- power supply and power required for operation. Before you buy the unit you like, you need to make sure that the wiring in the room can withstand the power of the compressor. Check for twists on the wires going from the garage to the shield. If problems are found, they must be corrected, since the consumption is too a large number electricity with poor wiring can cause a fire. Also, if the mains voltage varies from 160 to 220 volts, the machine will not work normally. To check this, take a reading with a voltmeter to alternating current three times a day. Ideally, the voltage should be even and not fall below 200 watts. Otherwise, you need to install a stabilizer.

Criteria for choosing compressor models for car painting

Which of the existing models to choose depends on your goal, so we will consider several options.

- For cosmetic work. If you want to touch up a car fender or decide to learn auto painting, opt for the most inexpensive option with the following characteristics: a piston oil compressor with one cylinder, a capacity of 130 l / m., a 25 liter receiver and a pressure of 8 atmospheres. They won’t be able to paint the whole car, but it’s more than possible to cover up a scratch on their own.

- An apparatus that compresses air for skilled workers. If you already have some experience in this area and want to try painting the entire side of the car (or front / rear), we advise you to choose a single-cylinder piston-type compressor with an oil fill, a 100 liter receiver, a pressure of 10 atmospheres, which gains 330 l / m. This option will allow you to periodically carry out good work. D For a complete painting of a vehicle, such a compressor will not work - it will not be able to get enough air.

- The compressor for high-quality painting of the car. One of the best options for carrying out paintwork is an oil belt compressor, productivity - 515 l / m, receiver for 200 liters, pressure 10 atm. Such a unit can work for a long time, you can even paint a truck with it. But it will be much more expensive to pay for a belt model with such characteristics than for previous options.

- The unit for carrying out professional work. If you are painting cars by occupation, you should choose a quality compressor, as cheap option may not paint the surface well enough. A low-power screw compressor is suitable here (capacity 240–620 l / m, pressure - 10 atmospheres). It is reliable, economical, can work for long periods of time and, despite the high price, will quickly pay for itself even in an average workshop.

Whichever machine you choose, it needs maintenance. How to properly care for the device is described in the instructions that came with the device you purchased, but there are several universal recommendations:

- the compressor, when air is sucked in, captures water with it, which accumulates in the receiver. The condensate must be drained at least once a week, depending on the frequency of use. With timely draining of condensate, corrosion of the receiver and rapid wear of the filters are prevented.

- The air filter prevents debris and dust from entering the piston chamber. Regular cleaning (washing, blowing) or replacement with a new air filter is necessary.

- oil level needs to be monitored. Periodically, the old oil is completely drained and new, only specialized

- do not allow the unit to become heavily soiled. Check the condition of the belt drive, electric motor, bearings. Check the cylinder head bolts every 4 months. Also check the relief valve.

- check belt tension and wear approximately every 200 hours of operation.

When deciding which device to choose, you should remember about safety. Pay attention to the manufacturer, the presence of a pressure gauge, a place to install an air regulator and an inlet air filter.

The compressor is an important device that any motorist should have if he does not want to overpay in the workshop. A right choice will allow you to carry out high-quality work independently.

How to understand: will the kitten be fluffy?

What kind of light alcohol can be drunk for pregnant women: the consequences of drinking

Why do the legs swell in the ankles and ankles of the feet in pregnant women: causes and methods of treatment

The wedding of Prince Harry and Meghan Markle: scandalous and secret details of the marriage (photo) The future marriage of Prince Harry year NTV

How to close white plums for the winter