Before you is the ZIL 130 compressor. This metal structure complex shape. Essentially the same engine. There are two pistons. They are rotated by the crankshaft. And it spins from a pulley, which is connected to a pulley located on the fan shaft using a V-belt.

There is also a lubrication system. She is combined. The oil comes from the engine lubrication system.

It is cooled by the coolant. The cooling system is connected to the main engine cooling system.

The ZIL 130 compressor is necessary for the operation of the brake system. It pumps air into the pneumatic system. It is installed on the right side of the motor on the head of the block. Its characteristics are:

- working volume - 214 cubic centimeters

- capacity 210 liters per minute

- power consumption - 2.1 kW

- rated speed - 2000 rpm.

As soon as the pressure in the pneumatic system reaches 700-740 kPa, the pressure regulator is activated, and no air enters the cylinders. At this time, the compressor is running, just like the engine is idling - in vain. Because air is not needed, but the motor spends power to keep it running.

What malfunctions occur?

- 1. Piston rings, crankshaft seals and bearings of the lower heads of connecting rods wear out.

- 2. The oil drain pipe is clogged.

These malfunctions are accompanied by noise and knocking during operation, as well as an increased amount of oil in the condensate.

The only thing that can be done in this case is to disassemble the compressor and replace the defective parts.

What should be checked during maintenance?

- How well the compressor is attached to the motor.

- How the nuts of the studs holding the head are tightened.

- Is the pulley holding firmly?

- How to tighten the belt (this must be done every day).

Also during maintenance, it is necessary to clean the piston valves, seats, springs, air channels. This is usually done every 50-60 thousand kilometers.

How to check if the ZIL 130 compressor is working properly?

- Start the engine.

- Wait until the pressure in the pneumatic system is 7-7.4 kgf/cm2.

- Stop the engine.

- Remove the hose that connects the air filter to the compressor (it's rubber). At this point, the pressure gauge should show a slight drop in pressure, and you will hear the noise that is created when something lets air through.

- Wait until the pressure drops to 5.5-6 kgf / cm2, and remove the pipe through which air enters, the spring and rocker.

- The stem socket and the stem itself must be removed. To do this, the nest must be raised up.

- Remove the fitting from the socket.

A compressor is required for the ZIL-130 brake system. The principle of operation of the modification is based on air injection. This happens in a closed pneumatic system. The device of this series is installed to the right of the motor. In order to disassemble the ZIL-130 compressor in detail, the technical characteristics must be considered. However, first of all, it recommends that you familiarize yourself with the device of the mechanism.

Compressor ZIL-130: device and model operation

The principle of operation of the compressor is built on the pumping of air. This is achieved through the movement of the pistons. The standard modification includes a wired crankcase that has channels. There is an oil seal in the central chamber of the system. A spring is installed to operate the supercharger. To prevent damage to the compressor from high pressure, there is a seal. A rod is also involved in the device. When it is retracted, air enters the valve.

Detailed modification parameters

The ZIL-130 compressor has the following: working volume - 214 cubic meters. centimeters, the capacity is 210 liters. The power consumption of the presented modification is no more than 2.1 kW. The maximum speed is 2 thousand revolutions per minute. Inside the pneumatic system, the pressure is maintained at around 740 kPa. The ZIL-130 compressor (market price) costs 22 thousand rubles.

Crankcase modification

Carter on air compressor ZIL-130 is installed with a rocker arm. Directly in front of the device there is a special shaft. As a rule, it is lubricated only at the base. The main problem of the crankcase lies in the wear of the struts. To correct this situation, you can disconnect the plug. Next, you need to inspect the drive shaft. To replace the crankcase, the cover is completely removed. If problems arise with the shaft, only the front part of the rocker arm is disconnected.

Delivery mechanism

The injection mechanism in the device is made in a very compact size. According to experts, the device can withstand high pressure. Thus, the price for the ZIL-130 compressor is quite justified. The saddle in the device has two outputs. The specified part does not come into contact with the rocker arm.

The injection mechanism is connected to the crankcase through a tube. The shaft of the model uses a small diameter. At its base there are two rings and lubricant for the ZIL-130 compressor. A short plug is installed at the end of the shaft. The exhaust valve at the supercharger is used with a protective sleeve. If there are problems with the air supply, the blower outlet is checked first. Next, the cap is unscrewed and the valve is completely cleaned. The next step, experts recommend checking the spring, as there is a lot of pressure on it.

crankshaft device

The crankshaft in this case is connected to the crankcase. The outlet channel is used with a small diameter. Cylinders on the ZIL-130 compressor are installed on the sides. It should also be noted that there are two overlays on the underside of the modification. The shaft is fixed on the clamp. Additional attention deserves the fact that the guides of this compressor are installed on the left side. When the shaft is shorted, experts recommend inspecting the supercharger completely.

The crankcase is also checked, as it usually collects all the debris from the recycled oil. For the correct operation of the system, the pressure inside the unit is tested. It is also necessary to immediately clean all channels from the crankcase. This can be done using an ordinary ramrod. The seat is pre-lubricated. If the shaft is deformed, it must be replaced immediately. For spare parts ZIL-130 prices are quite reasonable. The tip of the part is welded on by hand.

plunger mechanism

The plunger mechanism of this compressor is used with a bearing row. Experts say that the part is able to withstand heavy loads at significant speeds. However, it is important to consider that the inlet valve needs to be cleaned frequently. In this case, the channel is quite often clogged. To check it, the crankcase is unscrewed. You will also have to remove the cover. An adjusting screw is used to adjust the plunger. A large screw can be installed when the overlay protrudes. In this case, it is necessary to select the appropriate protective ring. To solve the problems with erasing the lining, apply special means to seal the block. Some experts recommend periodically cleaning the tubules.

More motorists can expect problems with the base of the plunger. It is a regular plate, which is fixed on the thread. With a lot of shaking, the connection is broken pretty quickly. As a result, the plate begins to dangle. To correct this situation, it is recommended to first disconnect the cover. After that, it is important to immediately clean the outlet. The screw is loosened very slowly. In this case, you need to monitor the position of the bearing row.

Stuffing device

The stuffing box on the ZIL-130 compressor is installed with one seal. He uses a camera small size. At the bottom of the modification, two guides are installed. There are racks on the sides of the chamber. It should also be noted that there is one support in the upper part. The crankcase for the ZIL-130 compressor is placed on the right side.

Experts say that the oil seal does not need frequent maintenance. However, it should be borne in mind that the lining on the support can quickly wear off. In order to inspect them, only the front pillar is removed. Next, it is important to disconnect the block and the stuffing box plate. Then the master will be able to get the lining directly. If small cracks are visible on them, you can try using a sealant. However, experts recommend replacing them immediately with any deformation of parts.

Seal replacement

To do it yourself, it is important to carefully inspect the gland. As a rule, it collects a lot of soot. It should also be noted that the seals are erased due to overheating of the pad. This happens due to clogged tubules. To correct this situation, it is recommended to unscrew the protective cover of the compressor. After that, the rings are unscrewed. Then it remains only to push the rocker. New pads are installed on a well-cleaned surface. For new spare parts ZIL-130 prices are quite adequate.

Saddle inspection

The seat on the ZIL-130 compressor is installed under the discharge mechanism. To inspect it carefully, you need to remove the front connecting rod. After that, the piston moves directly. The next step is the protective cover. Its plate is fixed with four screws that can be unscrewed with a key. The cork in this case is screwed counterclockwise.

Then it remains only to get to the saddle, which is fixed on the nozzle. There should be an oil seal at the bottom of the device. In this case, the plate is checked separately. It is also worth inspecting the top of the saddle. It often collects soot. You can clean the case with gasoline. In this case, it is important not to damage the rocker.

Plunger repair

If the plunger breaks, compressor repair should begin by unscrewing the front crankcase. Next, the protective cover is unscrewed. After that, it is important to remove the two plates, which are clamped with rings. If they do not loosen, they can be knocked out a little with a hammer. The next step is to inspect the seal. As a rule, it accumulates a large number of mud.

If the supercharger is working properly, then everything inside the block should be clean. In this case, the valves are examined separately. To disconnect the plunger, it is recommended to use a large key. It is problematic to do this on your own due to the fact that it is necessary to constantly hold the piston. In this case, it is better to ask a friend for help.

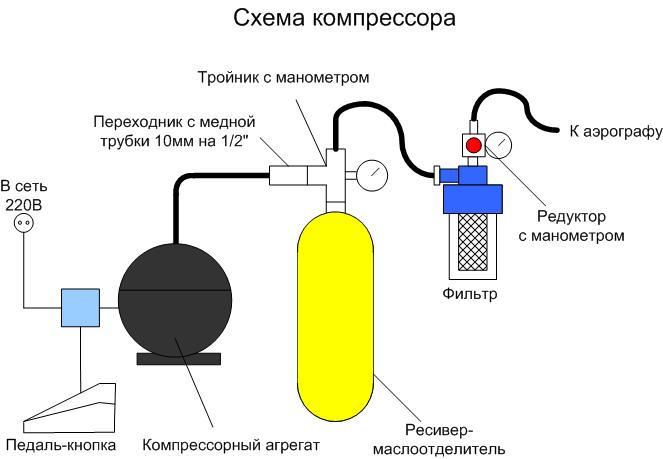

The best basis for creating with your own hands is the ZIL 130, the compressor of which is structurally most suitable for this. For body painting, the use of a compressor is important, as it improves the quality and strength of the applied layer, and increases productivity. In addition, it can be used to inflate tires, supply air to pneumatic tools.

Due to the considerable cost of the compressor, it is not advisable to purchase a device for a “one-time” painting of your car, and not everyone can afford it. Home craftsmen are capable of making such a device with their own hands.

Make it yourself or buy a ready-made device

Today's market for pressure boosting and air injection devices is replete with variety. For various purposes, screw, piston and other types of compressors are produced. Those who have made a choice in favor of a ready-made device should choose the type of mechanism with the required technical specifications and at the best price.

Of the variety of products offered, of course, it is better to choose products famous brands. Their main disadvantage is their high cost. Big money spending will pay off only when you practice professional repair cars.

If you buy a cheap device of an unknown brand, you need to be prepared for unpleasant surprises. Inexpensive products are often made of poor quality material, the engine fails, and warranty repair lasts several months.

A do-it-yourself unit made from Zilovsky (ZIL 130) is considered by many craftsmen to be more reliable. According to numerous reviews, such a device has good performance, strength, wear resistance.

In addition, a repair kit for a Zilovsky compressor can be bought at every auto parts store. A self-made high-quality device that works for a long time and works properly will delight its owner and become the envy of many motorists.

After studying the instructions for making a device from the ZIL 130 compressor with your own hands, you can conclude: buy a pig in a poke or make the device yourself.

Step-by-step instructions for making a paint compressor from Zilovsky

To create a device that pumps air, compressors are used:

- ZIL 130;

- ZIL 157;

- KamAZ;

The KamAZ device has good performance, is durable and reliable, but requires serious improvement, and GAZ, MTZ are inefficient. Therefore, for the manufacture of a device that pumps air, many people choose a Zilovsky unit with their own hands.

Consider an example of such an assembly. Let's take as a basis the ZIL 130 compressor, a propane cylinder of 50 liters. For a network of 220 volts, a 2–3 kilowatt motor is needed, when using 3 phases, the power may be less. The frame is made of a steel corner; bolts, self-tapping screws, sealant, clamps are required for fastening.

For a car enthusiast who has little experience in welding and metalwork, it will not be difficult to make an air injection device based on the ZIL 130 compressor with your own hands if you follow our recommendations.

A compressor for painting a car is the most important equipment for. Let's say right away that an acceptable compressor costs not so little, and not everyone can afford to buy this for a one-time. That is why many motorists who are going to refresh the paintwork of their iron horse, looking at the prices of this miracle unit, come to the conclusion that since the hands do not grow from the same place as the legs, then you can try your luck and make something similar with your own hands.

And we, in turn, not for instruction, but for the sake of ideas, will give you an example of this kind of work.

In our case, the ZIL-130 car compressor, a propane tank and a 2-3 kilowatt engine are taken as the basis. It is these components that we cite in view of their availability in our country and for the reason that the compressor from ZiL is structurally the most suitable for our alteration.

Here are its brief characteristics:

- two-piston;

- piston diameter 60mm;

- volume 12 cm3;

- weight - 14kg;

Here's what we need to make a compressor for painting a car:

- compressor with ZIL;

- an empty propane tank;

- 2-3 kW motor;

- metal corner;

- hoses, clamps, sealant and every little thing;

- at least familiarity with the basics of plumbing, welding and turning.

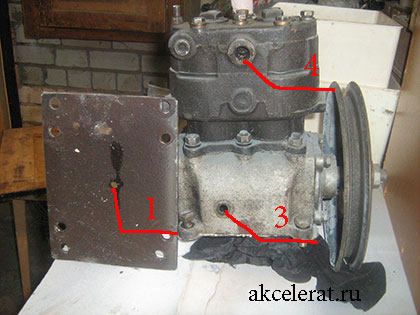

The compressor from the ZIL car has no bottom, so we make it from a 5 mm thick steel sheet. We seal the structure with paronite 2 mm thick and sealant on both sides to prevent oil leakage.

The most difficult stage in our offer is the refinement of the compressor lubrication system. To do this, you need to disassemble it, get the connecting rods, but do not forget to mark where they stood. We drill the connecting rods together with the insert: three holes of 3 mm each and countersink with a diameter of 10 mm. Everything is shown in the picture.

We carry out this whole procedure so that our compressor does not wedge: in our case, the lubricant is not forcibly supplied, as in a car, but is scattered around the crankcase and lubricates the crankshaft through these holes.

![]()

- Drain plug of any size;

- Oil outlet, if the pressure is excessive;

- Plug for filling hole of any size;

- Adapter for connecting the air system and the painting area, 3/8 thread. The tube is taken copper, because the place where the compressor is connected to the head is very hot - the hoses will burst, the plastic will melt.

We drill hole 3 below the center of the crankshaft by 10 mm.

We install fitting 2 in this hole, it is advisable to take the tube from the carburetor, since it is petrol and oil resistant. A couple more tips: we process the propane cylinder by welding only by filling it completely with water, for this we unscrew the bronze valve; if there is not enough air volume for painting, install additional receivers.

The meaning of the name diamond is sonan

Pirantel instructions for use for

What is a genetic passport What does a genetic passport include

Nebilet - a powerful tool in the fight against hypertension

Solution, aerosol Berodual: instructions for use for inhalation