- Air Compressor Services

When choosing oil for a compressor, every motorist must take into account that the machine is a complex mechanism, and for its competent Maintenance certain knowledge is required. Before deciding which oil to fill in the compressor, you need to understand some of the technical basics of its structure and functioning. The issue of increasing the power characteristics of the motor is one of the main ones that automakers set for themselves.

Compressor oil serves as a lubricant to reduce friction of parts, and also performs thermoregulation, providing the necessary temperature conditions.

Automotive Compressor Features

There are two solutions to the problem. The first is the production of an internal combustion engine (ICE) with a large internal volume. Such units are quite productive, but they are large and expensive to maintain.

The main task car compressor consists in the supply of air or gases under pressure.

Second and most suitable option- building a motor optimal sizes and maximum efficiency. This can be achieved by increasing the air supply to the combustion chamber of the internal combustion engine using special equipment - an air compressor.

According to the definition, this is a unit capable of creating a pressure at the inlet that exceeds atmospheric pressure. In the automotive industry, this is used to increase the power of the internal combustion engine. The compressor is added to the intake system of the machine in order to increase the air supply to the internal combustion engine, which contributes to the additional flow of fuel into the cylinders and, as a result, an increase in power vehicle.

There are several types of devices that differ from each other in design features and technical specifications, but the principle of operation is approximately the same. For example, the purpose of an oil compressor is to create pressure in the lubrication system.

Back to index

How to choose the right air compressor fluid?

Having dealt a little with the device of the unit, you can proceed to the next question. What oil to pour into the compressor for productive work and what functions does it perform? The search for an answer to it is updated with the advent of cold winter when all parts and assemblies of the vehicle are subject to increased load and the compressor is no exception. From a scientific point of view, compressor fluids are a synthetic or mineral compound. Their functions are:

- Improving the impermeability of air compression chambers.

- Reduced wear and friction of contacting elements.

- Heat sink.

The rules for the care and diagnostics of this equipment are usually prescribed in the service documentation, which indicates the permissible oil level, as well as how the oil in the compressor is changed and what liquid to fill in.

If for some reason this information is not available, you can use general recommendations regarding the choice of oil:

- If the car was produced before 1993, then it is most likely equipped with a KTS with an R12 type “cooler”. In this case, a mineral-based oil with good fluidity is used. Fills the entire working volume, reduces mechanical wear of parts.

- Cars manufactured before 1995 are equipped with the R134A unit. These compressors use PAG type oil.

- In the event that the car was initially filled with R12 fluid with subsequent conversion to R134A, it is recommended to use POE compressor oil with esters. It is important to take into account that PAG oil could have been initially filled in such a unit, therefore, in order to avoid damage, it is recommended to “flush” the compressor.

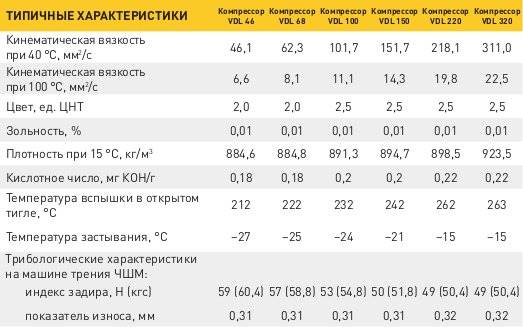

Having determined the type of oil, you need to determine its viscosity level, which is one of the main characteristics that affect the wear of compressor parts. For example, if the liquid has insufficient viscosity, it simply will not have time to cool the necessary elements. Since 1993, when PAG and POE fluids began to be used, it became necessary to change the viscosity of the oil (before that, compressor oils with the same viscosity were always filled). In the case of PAG, the indicator is 45 or 150, for POE a viscosity of 100 is provided.

Important! If you do not know what liquid is filled in the compressor, before buying it, contact a specialist who will replace it. Incorrect maintenance of the compressor is fraught with damage.

Compressor oil must have the following characteristics:

- High sealing properties. The effect is achieved by oil with an optimal level of viscosity. It is necessary to fill in a liquid that fills the entire working volume with the active parts of the unit.

- High resistance to oxidation. If a given property is not present, high temperatures will cause coke formation and, as a result, an explosion may occur.

- Water resistant. During compressor operation, gas may release liquid. Oil prevents it from getting on the parts of the unit.

- Resistance to gas dissolution. If the property is missing, the oil will absorb gas, thereby reducing its viscosity. Because of this, the load on the parts of the unit will increase.

Compliance with all rules and regulations, as well as following the right advice protect equipment from premature failure and prolong its service life.

In order to facilitate the movement of substances during execution production processes and domestic work, use high-pressure devices under the general name compressors. For industry, manufacturers produce a line of rotary (screw) compressors of different pressure levels - 5-12, 30-50, 150-300 bar, and for domestic and semi-industrial use - reciprocating.

Air piston compressors are divided into oil-free and oil. Oil free are used in medicine, pharmaceutical production and for domestic painting work.

compressed air in oil compressor installations are used for inflating inflatable products; refilling gas cylinders; for simplification of process of a car wash and on tire works. Air piston compressors blow through locks, car engines, heating pipes. They are used to operate pneumatic tools and refrigeration equipment.

Lubrication of air compressors

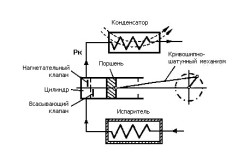

For trouble-free operation of oil-based air compressors, uninterrupted lubrication of rubbing parts is necessary, which is provided according to two schemes:

- Circular lubrication system of movement mechanism consisting of a crankshaft, bearings and a crosshead. This lubrication mechanism is provided by two gear pumps - starting and working, in front of which there is a pressure tank with a filter and a cooling coil. It is in this tank that special oil must be poured. Waste oil flows into a special receiver tank through special holes in the lower part of the compressor frame.

- Lubrication system for hydraulic seals of oil seals and cylinders. To ensure this system, 1 of 3 methods is used: a) crater oil spray, b) the introduction of atomized oil into the intake air stream, and, optimally, c) the supply of oil under pressure to the working surfaces of the seals and cylinders.

Oil for compressors not only lubricates the parts of the internal mechanism, but also provides the necessary sealing of the gas compression chamber.

Oils for air piston compressors

In addition to technological necessity, the use quality brands compressor oil will provide:

- long, highly efficient machine life and longer service intervals;

- reduction of carbon deposits and varnish formation;

- security overhead lines compressor from exothermic reactions in carbon deposits;

- anti-corrosion, deaeration, foam and wear-resistant protection of metal surfaces.

Groups

Compressor oils for reciprocating compressors classified according to their purpose into 4 groups:

Compressor oils for reciprocating compressors classified according to their purpose into 4 groups:

- Discharge temperature (T) less than 160 °C, with moderate air-in-oil compression.

- The temperature is less than 180 °C.

- Discharge temperature less than 200 °C, heavy duty.

- Temperatures over 200 °C, with particularly difficult working conditions.

Choice

For lubrication of compressor parts operating on the basis of compressed air, oil products produced according to or corresponding to GOST 1861–54 are used.

When choosing brands of oil, first of all, you should focus on lubricity index, as the main of the characteristics of lubricating fluids. The lubricity index characterizes the adhesion of oil to metal surfaces inside the compressor and the formation of a strong protective film. Oiliness directly indicates the range of conventional temperatures in which the oil product passes from a liquid to a solid state.

- K19 and KC19 - with low sulfur content for units using medium and high level pressure;

- K2-24, K3-20, K4-20 and K2-220 - with a single lubrication system for the movement mechanism and cylinders (seals), with the possible addition of multi-purpose additives, for heavily loaded compressor piston systems with high pressure;

- K3-10 and K3-10n - with a limiting air mixture discharge temperature up to a maximum of 200 ° C, with possible composite antioxidant and other additives.

Marking and international standards

![]() for example, brand KS-19p, where: K - oil product for compressors; C - the product is produced from sour oils; 19 - oil group; p - additional additive.

for example, brand KS-19p, where: K - oil product for compressors; C - the product is produced from sour oils; 19 - oil group; p - additional additive.

In the case of K3−10n: 10 indicates the kinematic viscosity of the oil at 100 ° C, and n indicates the addition of an additive that lowers the pour point.

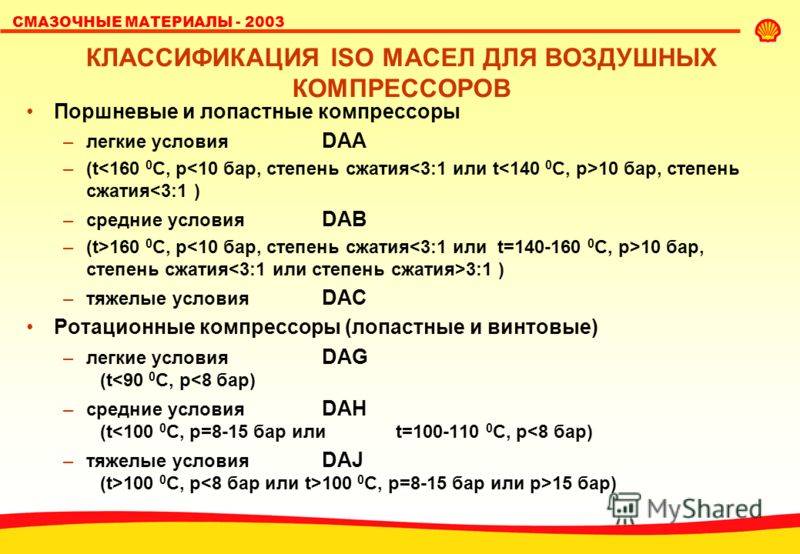

In the general technical world language DIN (German Institute for Standardization), compressor oils are designated as DIN 51506 ISO 6743/3 and are accompanied by an additional designation characterizing the degree of tension:

- VB or VB-l; DAG - discharge end temperature up to 140 °C (all types of compressors);

- VC or VC-l; DAA - end temperature up to 160 °C (stationary units) and up to 220 °C (mobile, mounted on vehicles);

- VD or VD-l; DAB - final compression temperature up to 220 °C (stationary and mobile compressor units). The letter l indicates the addition of additives.

Treat with care environment! Do not drain waste oil products, but hand them over to special disposal points.

Compressors are often used in various industries. With their help, nuts are screwed, blown and primed on different surfaces.

The brand abac compressor offers excellent quality and in different designs. This is a universal assistant to a person and in order for it to work well, it must be properly operated and maintained.

In order for the compressor not to fail, it must be serviced and oil changed in a timely manner. In order to change it, you need to know which one. Experts recommend changing the oil to types that are suitable for this unit.

Oil should be selected according to the following parameters:

- the oil must have a certain level of viscosity;

- thermal-oxidative capacity must correspond to the type of oil to be filled into the compressor.

Lubricating fluid should be bought from trusted brands and well-known manufacturers, which will improve the quality of the device itself.

A large amount of lubricant is consumed at high temperatures, which are formed during the operation of the compressor.

Today there are many types of oils. But there are several main types that are suitable for replacement:

- K-19;

- KS-19;

- Shell P-100;

- Mobil Rarus (this type is suitable for compressor brands such as Abac, Remeza, Fiac).

Shell Corena P 150 is an oil that has good performance and is recommended for use by many compressor manufacturers.

This type of lubricant is able to change the kinematic viscosity depending on operating temperature: from 150 sq. mm/s at 40 degrees, to 10.6 sq. mm/s at 100 degrees.

Replacement steps

When changing oil, for example, in a reciprocating compressor, oil should be added slightly above the required level, because such devices do not have a lubrication system. This will lubricate the entire system.

Oil changes must be carried out on time and in accordance with the manufacturer's recommendations. Therefore, during operation, you should carefully monitor its level in order to avoid damage to the compressor.

Air compressors are different and therefore, to select the appropriate oil for it, consult with specialists.

How to change the oil in the compressor, see the video:

Compressors are quite commonly used by many industrial organizations. They allow you to optimize the performance of many modern systems.

Main characteristics

The compressor is special device, which form compressed air under a certain pressure. This is used to solve many problems, including tire inflation, cleaning various surfaces from dust, etc.

Specialists distinguish several types of compressors:

- Mechanisms equipped with a vertical arrangement of cylinders.

- The compressors are assembled in a horizontal position. It should be noted that this category is divided into designs with one- or two-sided installation of cylinders.

- corner devices. It uses both vertical and horizontal arrangement of cylinders.

There are also other classifications of these products, among which it is necessary to highlight oil-free and oil compressors. The second type, for the optimal operation of all mechanisms, requires the use of special lubricants.

Choosing a lubricant

First of all, it should be said that when choosing oil for a compressor, it is necessary to pay attention to the recommendations of the manufacturer of this device. Often this is the best option and allows you to solve this problem very quickly.

It should be noted that the main criteria for choosing lubricants, is their viscosity and thermal-oxidative characteristics. At the same time, the higher the operating temperature of the compressor, the more oil will be consumed, which will lead to frequent replacement.

- K-19 and KS-19;

- Shell P-100 and Mobil Rarus.

There are other substances that can only be used with a specific compressor model. When buying oil, you must first consult with specialists or store consultants who will help you choose the best option.

To optimize the consumption of this substance, operate the compressor only under optimal conditions. And how to change the oil with your own hands, you can peep in this video:

Air compressors are designed for continuous operation. Due to the presence of high circumferential speeds, the working parts of the unit heat up intensely. This not only reduces their service life, but also causes a deterioration in the characteristics of compressed air, which is unacceptable for supplying most types of pneumatic equipment. Therefore, the selection of the optimal brand of oil is a very important and responsible task.

Characteristics of oils used in the operation of compressor units

There are varieties of reciprocating compressors that do not require oil. They are used when it is necessary to obtain compressed air without impurities and with the most reduced relative humidity at the outlet. To seal the piston units of such units, rings made of composite materials are used. In such compressors, carbon deposits do not form on working parts (which is their main advantage). But for the price, such compressors definitely lose to oil ones.

The optimum lubricating medium must meet the following requirements:

- Reduce compressed air heating as much as possible as compressor run time increases.

- Possess properties that change little with increasing temperature and pressure.

- Have a minimum coke number - the percentage of solid carbon residue that is formed during the thermal decomposition of the oil.

- Possess stable physical and chemical properties, in particular flash, drop, solidification and melting parameters.

All characteristics of domestically produced oils are regulated by the relevant state standards. Thus, the permissible flash and ignition temperatures are determined by GOST 6356 and GOST 4333, the stability of the chemical composition is determined by GOST 11063, and the tendency to form oil soot is determined by GOST 10585.

Upper limits that determine the suitability of an oil for use in piston air compressors are considered:

- humidity - not higher than 1.5%;

- sulfur content - no more than 3%;

- ash content (or coke number) - not higher than 0.14%;

- flash point – not less than 100…110 °C;

- self-ignition temperature - not lower than 350 °C.

Important indicators are also oxidation stability, corrosiveness and the minimum content of mechanical impurities.

How to choose oil for a piston compressor

Usually, the recommended oil grades are set by the machine manufacturer. However, sometimes you have to fill in substitutes or foreign analogues. In such cases, the performance of the unit and the viscosity of the oil serve as the initial data for selection. It is recommended to choose a product with the greatest stability of the initial viscosity, because otherwise the specific consumption increases, the processes of thermal decomposition are intensified, and, as a result, the heat-shielding characteristics of the substance are reduced.

An important point is the composition and purpose of additives that are added to improve antioxidant, antiwear and anticorrosion properties.

The oils that are used in the machines in question are divided into synthetic and mineral. The former are less dependent on external operating conditions, and therefore are less often replaced. Most mineral (cheaper) products require the addition of additives.

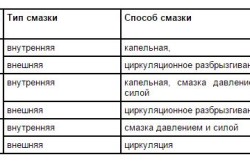

The lubrication scheme used in this compressor will also affect the choice. It can be circular, when the design of the unit has a pair of gear pumps, and spray, when the supply is provided using nozzles.

All brands of compressor oils of domestic production have the letter K (compressor) in their designation, the following components symbol are the viscosity of the oil, the presence or absence of additives, as well as the type of feedstock used to obtain the product.

For example, in the designation of the KZ-12p brand, the number 12 will mean the kinematic viscosity of the substance, mm 2 / h at 100 ° C, and the letter "p" will indicate the presence of an additive. It is permissible to fill such a product if the operating temperatures do not exceed 200 ° C (experimentally established that the specified parameter during testing should not exceed more than 2 times the maximum thermal level that occurs inside the operating unit). The presence of the letter C in the designation indicates that the substance was produced from petroleum products with a high sulfur content: this will lead to the need for more frequent replacement of the cutting fluid due to the rapid formation of soot.

The European DIN system (Deutsches Institut für Normung) establishes the following product classes that can be filled into reciprocating air compressors:

- VB DAG - suitable for installations in which the thermal regime does not exceed 140 ° C;

- VC DAA – the product can be used up to 160…200 °C;

- VD DAB - it is advisable to operate the oil up to 220 ° C.

If you find an error, please highlight a piece of text and click Ctrl+Enter.

Chocolate biscuit: the secrets of cooking in a slow cooker and oven

Chemical composition and nutritional value

Apple chips at home

Braised cabbage with white beans, recipe

How to reduce the ass, hips and stomach at home?