Parquet captivates with its naturalness and gives the interior a special flavor. But any surface made of natural materials becomes unusable without appropriate treatment.

One of the common methods of protection is the coating of wood with oil. The substance penetrates deep into the fibers and impregnates the surface structure over the entire area. This method is suitable for both common types of wood (oak, walnut, ash) and exotic ones.

Png" alt="(!LANG:Over time, the varnish cracks, but the oil is in perfect condition" width="550" height="205" srcset="" data-srcset="https://remontcap.ru/wp-content/uploads/2016/01/lakmaslo..png 300w" sizes="(max-width: 550px) 100vw, 550px">!}

Over time, the varnish cracks, but the oil is always in perfect condition.

Over time, the varnish cracks, but the oil is always in perfect condition.

The main advantage of the oil is its environmental friendliness, so the interior items impregnated with it can be safely placed in the children's room. Many believe that wood treated with such a tool contributes to the treatment of diseases. respiratory system, due to the fact that it "breathes" and fills the room with healing smells.

Why is oil better than varnish?

Wood oil coating has a number of advantages compared to, which is also often used for impregnation.

- The absence of a shiny film that appears on the varnished surface. The surface looks more natural, and the oil only emphasizes the color of the material.

- The wood treated with this tool is resistant to abrasion, high humidity and temperature fluctuations. Over time, the surface does not crack, and does not exfoliate. Damage and scratches are almost invisible.

- or furniture becomes soft and velvety, not the same as.

- The oil penetrates deeper into the wood, therefore, its protective properties are higher.

- Impregnation protects from moisture, but at the same time, leaves the pores of the material open, preserving its useful qualities.

- The coating is based on plant and natural components, which ensures its naturalness.

- If a fragment is damaged, it is not necessary to restore the entire surface.

Disadvantages of oil coating

Such impregnation has not only advantages, it also has several disadvantages;

- preparatory work should be carried out with special care, the floor must be polished with a special machine;

- the surface must be washed frequently and periodically treated with a protective oil or wax;

- furniture or floor treated with oil cannot be varnished in the future, it simply will not be taken on oiled wood;

- greasy spots it will not be possible to wash off or remove with a rag, only re-impregnation will remove them.

Oil application technology

Wood oiling can be done in two ways: cold or hot. The first option is simpler, in the second the degree of absorption is much higher. Everyone chooses the right one depending on the application, microclimatic conditions and their own preferences.

cold technology

Finishing should begin immediately and cleaning when the pores of the tree are open. This will ensure quick absorption and deeper penetration of the oil:

- if the surface is made of pine, birch or fir, it must be treated with an alkaline solution so that the material does not darken;

- the first oil layer is applied with a spatula, and it is better to make it thin;

- after 5–10 minutes, the excess should be removed with a rag;

- then the coating is polished with a special machine with a beige pad, after which the surface must be wiped with a cotton cloth;

- the product is absorbed in an average of 12 hours. During this time, you need to monitor the appearance of oil drops and remove them to avoid the formation of an unattractive crust;

- the second layer is applied and polished by machine;

- if necessary, a third layer can be applied and polished. It all depends on the degree of absorbency of wood, the higher it is, the more stages of work.

Jpg" alt="(!LANG: Surface treatment by polishing machine after oil application" width="552" height="414" srcset="" data-srcset="https://remontcap.ru/wp-content/uploads/2016/01/renew01..jpg 300w, https://remontcap.ru/wp-content/uploads/2016/01/renew01-768x576..jpg 174w, https://remontcap.ru/wp-content/uploads/2016/01/renew01-70x53.jpg 70w" sizes="(max-width: 552px) 100vw, 552px">!}

An important role in human life is played by such material as wood. Many seek, if possible, to have or make their own hands. wooden furniture, since she has presentable appearance and environmentally friendly. But, at the same time, wood is a rather capricious material, since it is very easy, without pre-treatment and protection, to be exposed to moisture and decay. For good and quality protection you can use oil to coat the wood.

There are several types of compositions for these purposes. Protective oil can be purchased at hardware stores or you can make your own impregnation for wood.

Many, especially novice craftsmen, ignore the wood protection process. But this approach brings with it many problems. It is no secret that wood absorbs moisture quite well. It is because of this property that undesirable consequences appear. Wooden products can dry out, crack, start to rot and so on.

After a lot of effort has been put into the manufacture of a piece of furniture, in the end you don’t want to get such a result. Therefore, in order to avoid damage to the product, you need to take time to protect it.

Oils and waxes are commonly used for impregnating wood surfaces. They are able to reliably withstand such negative factors as moisture, mold, fungus, rot and different kind insects. Along with this, they are able to increase the degree of strength and increase the service life of the product.

Oil use

In the list of oils with which they process wooden surfaces, includes the following types:

- tung;

- teak;

- tar;

- linen.

Wood processing oil has the following properties:

- antiseptic;

- the ability to penetrate deeply into the structure of the material;

- make wood more elastic;

- protect the tree from drying out;

- leaves the pores of the wood free, which allows the material to breathe and regulate the degree of humidity;

- it is not harmful to human health, it is environmentally friendly.

Advice! Experts do not recommend impregnation sunflower oil, although in desperate situations this is also an option. The fact is that there are quite a few polyunsaturated fatty acids in sunflower. This also applies to olive oil.

With the help of wax

The use of wax is a centuries-old method that was used by great-grandfathers to protect wood. It protects it very well from moisture. Wax easily penetrates into the pores of the wood, and also gives the surface a matte finish. But, waxing has one drawback. Due to the fact that the pores are filled, the process of "breathing" of wood is completely absent.

Important! You should listen to the advice of masters who say that it is better not to work with pure wax, but to add a certain amount to it. vegetable oil, for example, linen. Also, other components, such as turpentine, will not interfere.

On the video: how to prepare a composition of wax and linseed oil.

Oiling Features

The best option for protecting wooden products is wood processing oil. It has many positive characteristics:

- ecological qualities;

- appearance impregnated products;

- giving the product a matte sheen and velvety to the touch;

- ease of work;

- low price of the composition;

- the possibility of restoring the damaged surface.

The disadvantages of these protections should also be noted:

- very capricious in care, since finishing should be done every 4 months, followed by high-quality polishing of the surface;

- greasy spots are clearly visible on the treated surfaces, which can be removed during re-treatment.

Benefits of Using Flaxseed Oil

Impregnation of wood with linseed oil gives it an original look, completely restoring the structure. Provides long-term operation of the product and reliable protection against moisture and dirt. You can also achieve the desired shade by adding the desired dye to the composition.

Linseed oils for wood are able to protect wood from rotting, fungus and mold damage, allowing you to fully preserve its texture and embossed pattern. One of important factors- this is the ability to preserve the tree's ability to breathe, while providing a surface reliable protection from water, increase resistance to drying, peeling, discoloration and cracking.

The construction industry provides a wide range of compounds that can protect wood products, but most of them are not natural and can adversely affect the health of the consumer. Linseed oil absolutely safe, is an environmentally friendly material, has the strongest waterproofing characteristics.

Linseed oil for wood impregnation has additional benefits:

- the ability to provide reliable closure of the pores of the material;

- the presence of a high degree of water-repellent characteristics;

- giving the product originality and preserving a natural shade;

- polymerization of the composition under the influence of some external factors, which significantly increases the degree of all its inherent qualities.

Stages of wood impregnation

Linseed oils for wood processing are used in two ways, it all depends on personal preferences and the size of the treated surfaces:

- Soaking is only suitable for small items (decorative figurines, dishes, etc.);

- Lubrication (rubbing).

The following steps will tell you how to treat a tree with linseed oil impregnation.

Preparatory stage

Before you start coating wood at home, you must first carefully prepare the surface to be treated. If this is a newly made product, then the surface is simply sanded with high quality using sandpaper small fraction. impregnate wooden crafts with a large area, for example, the facade of a house or previously exposed surfaces, is a little more difficult.

Algorithm of preparatory work:

- Get rid of the old coating, that is, varnish or paint. Several methods can be used here. Try to take off old paint with a spatula and a metal brush. If it does not lend itself, then you need to use a building hair dryer.

- Surface sanding. For this process, sandpaper with varying degrees of abrasive coating is used. You should start with a larger one, gradually reaching the smallest one. The surface is ready if, after running a hand over it, we do not feel any irregularities.

- Remove dust with a soft brush and cloth. The key to high-quality oiling with linseed oil for wood, a well-cleaned surface from dust.

The lubrication process

Oiling prepared wood can be done using the oiling method. Oil is applied either with an ordinary soft rag or with a brush that has a natural bristle. Although painting with a brush is only suitable for small areas. As for the facade of the house, ceilings and other things, it is only necessary to apply oil to the tree with a rag.

Linseed oil for wood is applied according to the following algorithm:

- Pre-stir the composition and pour the required amount into a clean bowl.

- Moisten a cloth and wipe the surface with it. It is necessary to apply the composition along the wood fibers.

- After treating the wood with linseed oil, it is necessary to allow the surface to dry for about 20 minutes, then remove the excess with a clean rag.

- The impregnated product with oil for wood coating is left for some time to dry, and then the wood is re-coated with linseed oils.

Soaking process

Wood processing by soaking, as mentioned above, is only suitable for small products. The very process of soaking a tree with oil is quite simple: oil is poured into a clean container, and then a prepared, dust-free product is placed there. You can keep it as long as you like.

After the product has been impregnated for some time, it is removed and placed on paper in an inclined state. This will allow excess linseed oil to drain off. When you get rid of the excess, polish the surface with a clean and soft cloth. Next, leave the product to dry.

If pure linseed oil was used, then drying will last three weeks. To speed up drying it is necessary to use white oil with wax.

The technology of oiling wood with linseed oil is quite simple, but it will reliably protect it from the effects of negative factors. And, if you compare it with various kinds of industrial compounds, then you can cover the tree with oils without harm to human health. The processing of wooden products is a process that should not be neglected.

Features and rules for applying oil (2 videos)

Impregnation for wooden coatings (38 photos)

All photos from the article

Despite the fact that at present the construction market is literally oversaturated with synthetic and mineral materials for rough and finishing works, nevertheless, oil impregnation for wood remains relevant to this day. Indeed, in our house or apartment there will always be design components, furniture or various utensils that are made of solid wood or other lumber such as chipboard, OSB or plywood.

Therefore, we will now talk about which compounds are suitable for impregnation, how it is done, and in addition we will show you a video in this article.

Impregnation

What is it for

Note. The main goal, which is achieved in the end result, when impregnating oil for wood is used, is to extend the life of the product.

- Let's start with the fact that the impregnation of wood with used oil, and even better with linseed oil, is much more effective than opening it with varnish, since the varnish can crack, and water will certainly penetrate into the cracks, besides, it wears off very quickly under mechanical stress. In addition, the structure of the oil-treated wood does not change, for example, if it is a knife handle or a rifle butt, then they will not slip - they will retain the slight roughness inherent in wood.

- Products opened with oil have a soft sheen that does not disappear with time even with partial abrasion - the fact is that the composition penetrates deep enough and constant grinding from the touch of hands will not harm this in any way.

- In addition, the instruction recommends treating wood with various antiseptics, but in this case this will not be necessary, since the impregnation tightly clogs all pores and the formation of microorganisms that cause mold and decay.

Methods of application - rubbing and boiling

- One of the most common ways in which wood is impregnated with transformer oil or linseed (hemp) oil can be called rubbing it into the surface and this is done using fine sandpaper (P400) and a cloth made from natural fibers. This procedure is carried out 3-4 times in between for complete drying of the surface, which may take 1-2 days.

This, of course, is very long, but the effect is excellent. A rag is used first to apply liquid to the surface, and then at the final stage - for grinding, and this is possible to cover fairly large areas.

Note. There is also a way to smear the surface paint brush or maklavitsa, but this technique is used only for painting. In such cases, drying oil is applied to the surface.

Of course, the best will be natural materials that are obtained from flax and hemp, hemp, olives, soybeans and sunflowers, but flax is still the undisputed leader among all plants - such impregnation or boiling is of the highest quality.

Sunflower can be called the most ineffective, since there are few polyunsaturated fatty acids, but working out, of course, is in the very last place for obvious reasons.

Let's take a look at the simplest and most common treatment, oil-based wood stain, which can be used on objects large and small, as well as on ceilings, floors and walls.

The real method goes back far into the past and has probably existed for as long as the carpentry and carpentry craft itself - fortunately, there has always been where to get the components, because flax and hemp grow in abundance not only in Russia, but also in most of the globe .

The main purpose of this action is the waterproofing of lumber, that is, the upper part of the workpiece is impregnated, where all the pores and cracks are clogged (they turn out to be hydrophobic), which makes it impossible for moisture to penetrate, and therefore excludes rotting and the occurrence of conditions for the vital activity of microorganisms.

Let's look into the details of how to saturate a tree with linseed oil and take four planks of oak, maple, ash and beech for this - here we can see how different textures appear after processing. Of course, applying linseed oil (which we will use) is easier just with a paint brush, and not with a cloth napkin, which we will do to save time - in practice, you can also act in this way.

We generously lubricate each of the boards with a brush, not trying to particularly rub the liquid into the surface, and after we have already covered all the planes, we begin to rub the contents with a napkin made of natural fibers (wool, linen, cotton) or fine sandpaper (zero).

The time of such a process is not limited - it all depends on the porosity of the structure - the larger the pores, the faster their ability to absorb liquid, and the rubbing process simply speeds up this process. It turns out that you can spend 20-30 seconds on one plank, but you can also spend 2-3 minutes - here the duration only increases the quality, since the sawn timber is being sanded at the same time.

It is important to take into account one nuance - when rubbing, you need not only to remove excess oil from the surface of the material being processed, but to try to rub it inside the wood - this is somewhat reminiscent of a back massage using a cream or gel, when it is desirable to spend the entire composition.

Therefore, you need to continue processing until the surface of the lumber is almost dry. As we have already said, for high-quality wood processing, you will need to repeat this process three to four times, but for this you need to wait for the final drying of the previous layer, which can take from one to two days at room temperature and moderate air humidity in the room.

If fine sandpaper can be used when rubbing the impregnation over the first and second layers, then this is not permissible for the last coating - only a napkin made of natural material(preferably wool). It is with a napkin that you polish the product completely and the longer you do this, the more beautiful the surface will look.

Flaxseed oil is a natural substance obtained by cold or hot pressing of flaxseeds. Pure oil can be used as a stand-alone topcoat, but it is ineffective in the untreated state due to its low polymerization (drying) ability.

Speaking about the impregnation of wood with linseed oil, as a rule, they mean the use of drying oil. This is a modified heat treatment and the addition of chemical additives that accelerate the polymerization process. Drying oil is also called "boiled" or "boiled" linseed oil.

Features of finishing with raw oil and drying oil

When processing wooden products with pure linseed oil, you should be prepared not only for long-term drying, which can take up to 3 days (for each layer), but also to know a number of important features. The raw product is actively absorbed into the structure of the wood, so the coating of wood with linseed oil has to be done in 5-7 or more layers. Drying on the outside, it polymerizes poorly inside, which is why a dry-looking product can leave oil stains for a long time. Exposure to ultraviolet significantly speeds up the drying process. In the sun, treated wood can dry in 6-8 hours, but the tone of the coating will change: it will become yellowish or even slightly brown.

Drying oil, due to the high polymerization rate, has completely different properties: it dries quickly, is not so actively absorbed, and does not change its color. This makes it more practical to use. Regardless of the conditions, the answer to the question of how long the drying oil dries is unequivocal - no more than a day (at 20 ° C). This sets it apart from raw linseed oil. In the future, speaking about this type of finish, we will mean linseed drying oil.

Where is the best place to apply this finish?

Impregnation of wood with linseed oil does not provide solid protective film resistant to scratches and abrasion. But this kind decorative finishes valued for something else, first of all, - environmental friendliness, antiseptic properties, the ability to emphasize the texture of wood and keep it from cracking.

Linseed drying oil is used for finishing products used indoors. It is optimal for covering furniture surfaces that are not subject to intense abrasion, wooden walls and ceilings. She is being treated wooden utensils, Kids toys. As a decorative and protective finish, it is appropriate to apply linseed oil to the surface of precious woods to maximize their natural qualities.

How to coat wood with linseed oil?

Training. The oil is applied to a dry and sanded surface. The moisture content of the wood must be at least 15%. Work is recommended to be carried out at a relative humidity of not more than 80%. When applying the composition to oily wood species, the prepared surface is additionally wiped with white spirit.

Application. To work, use a brush, swab or lint-free cloth. The composition is evenly distributed on the surface, and allowed to penetrate into the structure of the tree for 15-30 minutes. Excess oil that is no longer absorbed is wiped off with a cloth or swab along the fibers. Keep the oil evenly distributed on the surface to avoid staining.

Each new layer is applied after complete polymerization of the previous one with preliminary grinding. The number of necessary layers (in the case of drying oil from 1 to 4) depends on the characteristics of the product and the type of wood (small-vascular species require fewer layers due to low absorbency).

The time of complete drying of each layer is up to 24 hours.

How to restore the oil coating?

Over time, the surface impregnated with linseed oil changes its color, begins to look dry or wears off. This coating is short-lived, but this disadvantage is compensated by the ease of its restoration. When applying a second layer, the oil will hide all scratches and return the external attractiveness of the wood. If desired, linseed oil can be tinted with pigments, reaching the desired color shades. For products not subject to intensive use, the restoration procedure is carried out every two to three years.

What is oil wax and how to make it yourself?

Linseed oil with wax is an effective decorative and protective coating that gives wood high moisture-proof properties and increases its wear resistance. The impregnation adds a silky sheen to the surfaces and enhances the natural qualities of the wood. Suitable for processing light and dark woods. Completely natural impregnation is optimal for finishing wooden floors, stairs, doors, furniture and other items subject to intense wear.

Linseed oil and wood wax are easy to make yourself. The easiest way: add grated beeswax to the oil heated in a water bath and bring to a homogeneous consistency. The classic proportion by weight is 1:1. The ratio of wax and linseed oil can be varied, creating compositions of varying degrees of viscosity: from thick mastics to liquid impregnations that penetrate deep into the wood structure.

How to avoid spontaneous combustion?

The process of oil oxidation upon contact with air is accompanied by an increase in temperature, which can lead to spontaneous combustion of steam-oil rags, swabs, sponges, etc. All consumables that were used for wiping linseed oil should be thoroughly dried outdoors in a straightened state before disposal, and it is better to soak in water or immediately burn them. Sealed containers are used to store the dispenser and other tools in contact with oil.

In order not to lose the quality characteristics of wood, it is recommended to process it only with natural compounds. Various natural wood oils have been used since the 12th century. Linseed oil ranks first in its characteristics, as it not only protects the wood, but also gives it a soft velvety shade. How to use linseed oil for woodworking, the main stages and subtleties of work in one small article.

When choosing how to treat a wooden floor or stairs, first of all, environmental friendliness and protective properties of the impregnation are taken into account. Impregnation of wood with natural linseed oil has a number of advantages:

- The old product acquires an aesthetic appearance, as small cracks, abrasions and irregularities are masked.

- Absorbing into the porous surface, the composition gives it water-repellent properties.

- After drying, dust and dirt stick to the surface less.

- Emphasizes the natural texture of wood.

- The oil has antiseptic properties and protects the surface from fungus, mold and blue stain.

- It is deeply absorbed into the wood and will last at least 50 years.

- Protects wood from cracking and drying out.

- Wood does not stop "breathing".

- Hypoallergenic and suitable as decoration in children's rooms and kitchens.

Linen is used to cover any wood products: in the processing of houses, in the decoration of furniture and decorative elements from oak, teak, pine, spruce, fir. Due to its composition, the oil is easily combined with various tinting emulsions. Can be applied alone as a finish and protection or under further varnishing.

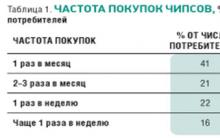

Of the minuses, the price stands out, which depends on the manufacturer and the volume of impregnation purchased. The table below shows the most popular manufacturers of linseed oil for finishing work:

Which wood oil to choose depends on the material possibilities. An unrefined product from any manufacturer is suitable for wood processing. Imported linen compositions are more expensive, but have additives in the form of beeswax or artificial polymers. They reduce drying time and make work easier. The consumption of each manufacturer is different and depends on the density of the product.

To tint the surface, impregnation with colors is purchased. This can be found in the catalogs of the manufacturer Tikkurila, the price is from 750 rubles / l. Tinted translucent with various natural shades. Using colored oil, you can tint an inexpensive type of wood, such as pine, you can give the appearance of oak or mahogany. After processing, it will be difficult at first glance to distinguish inexpensive material from a similar premium class.

Application technology

Usage for each manufacturer is listed on the label. But there are standard ways:

- Dive - when wooden element immersed in a hot composition and left to soak for several days. Then it is taken out and dried on a warm surface.

- Vacuum impregnation - the product is placed in a special device, where, under the influence of vacuum, the oil penetrates deep into the wood.

- Two-layer application - performed with a brush or a piece of foam rubber when decorating the premises.

Let's take a closer look at the two-layer application, which is suitable for processing wooden floors, stairs and walls.

Two-layer application

To complete the finish, you will need tools and materials:

- Butter.

- Wax.

- Wide brush - flute.

- Sanding paper of the finest fraction.

- Cotton rag.

- A piece of pure suede.

Previously, the product is cleaned of the old coating, the surface is polished with sandpaper. Dust is swept away with a soft brush. Prepared wood absorbs oil better, and the protective properties of the coating will be higher.

The oil is brought to a boil twice before work. Thermal preparation will shorten the drying time of the impregnation. You need to cook a linen product in a water bath, in small portions. As soon as the oil boils for the first time, it is removed from the heat and allowed to cool. Then the procedure is repeated. Before application, the hot agent is stirred so that the color is more uniform. Modern wax formulations can not be preheated, but they will take longer to dry. Use hot impregnation with caution, wearing protective gloves.

- A brush or sponge is impregnated with linseed oil, which is applied liberally, with blotting movements, to the wood. Movements are performed along the fibers.

- Within two hours, the surface of the wood is impregnated.

- A second layer of hot impregnation is applied. Surfaces are allowed to dry for 2-3 hours.

- A soft rag is taken, with which excess impregnation is removed from the tree.

- The surface is polished with wax or varnished.

Beeswax is heated in a water bath and hot rubbed into the wood until the surface acquires an even sheen. But it is not necessary to cover the impregnation with wax, you can apply the old fashioned way polishing - with a thick suede cloth. Suede rub the surface to a shine, in a circular motion. But giving shine to wood is a long and painstaking process. Large areas can take several weeks to process.

Using linseed oil to protect wood in your home, the application technology is followed. You will have to work with a heated product, so take care to protect your hands and eyes. By impregnating the wood, the oil will protect it from moisture, the sun, fungi and mold. Small cracks will disappear on the surface, and the pattern will become clearer. To decorate inexpensive oak or mahogany wood, impregnations with tinting effects are used, which can be purchased at any specialized store. For simple processing, the most inexpensive unrefined oil will do. From above, it is advisable to wipe the surface with wax or polish it with a suede cloth until it shines.

Mars space program

The history of the origin of zero What is the name of zero

Gloria planet (anti-earth) - exposing all revelations Is it true that there is a planet behind the sun

20 cases of alleged reincarnation

The secret of the "sun stones": how the Vikings got from Norway to Greenland almost blindly