Dedicated to the owners of planers, jointers and electric planers.....

Each owner of planers, planers and electric planers faced the need to sharpen knives for their equipment. Having a specialized small sharpening machine planer knives It will not be difficult for you to do this. It will also be true to turn to where your planer knives will be sharpened quickly and inexpensively.

How can I sharpen with a sharp stone and suitable grit? Soak the stone in water for 5-10 minutes before using. When there is no more acne, you can remove it from the water. Please note that the stone is always wet during pruning. The powder that comes out of the stone during the cutting process must remain in the stone and thus form a mass. Always start with the thickest part of the stone. Place the sharpening knife at an angle of approx. 15° from the body with light pressure on the entire surface of the stone.

Repeat this procedure until burrs appear. Now change the sides of the blade and exactly repeat the point # It is very important that the angle between the blade and the stone is constant. To get a very thin and sharp blade, repeat this procedure on the thin white side of the stone. Finally, rinse the stone thoroughly and clean the knife with a neutral detergent so that it is completely free of excess. 360 grit for cutting wire alignment.

Is it possible sharpen planer and planer knives at home???

Maybe. And you can sharpen planer knives on a sharpener. Yes, on the grinder. But only for this you need a modern low-speed grinder (or rather, even a grinding machine) with water cooling. The best option is use . Naturally, such knives are not sharpened by hand. To sharpen them, we use a special tool.

For high-quality sharpening of planer knives, a smooth and not greasy grinding stone is required. Align the sharpening stone with the tool for leveling and straightening the grinding stone that comes with the Tormek T7.

After straightening, we smooth the grinding stone with a whetstone for cleaning and leveling the grinding stone.

We recommend using our magnets or blocks. Up to a certain point, knives can be kept sharp through a rifle. Thus, the cutting wire always remains sharp. However, after some time it is convenient to sharpen the knife through a sharpener, and thus thus obtain the cutting wire as the initial and ideal cutting angle.

Why do they exist different colors knife cables? The main purpose of this decree is to ensure uniform hygiene standards in the European Union in order to ensure public health and maintain consumer confidence in the food system without any inconvenience. Any contamination or contamination in food product that could endanger the health of consumers is considered an unacceptable threat.

Having prepared the grinding stone, let's start sharpening the planer knives. We remove the universal stop and install the special stop that comes with Tormek SVH 320.

We screw into it a screw that regulates the angle of inclination of the knife to be sharpened relative to the grinding stone. With this screw, we will be able to set the required sharpening angle in the future.

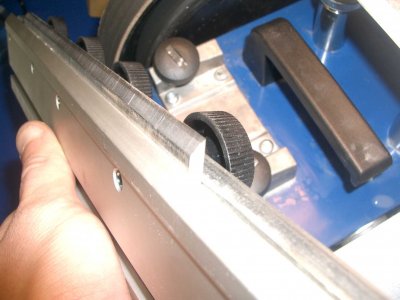

We take the blade holder supplied with the SVH 320 and install our planer knife into it.

Tormek recommends sharpening blades and knives with a width of at least 13 mm. The length of the knife is not so important, because. it is possible to rearrange the long knife in the holder. However, this can be argued, because. I have doubts about the convenience and quality of sharpening long knives with rearrangement. It is very important to correctly install the knife in the holder, because. otherwise it will be sharpened with a warp. When installing the knife in the holder, we rest the back of the knife against the stop and clamp it with the screws of the holder.

What is the advantage of the alveoli in the blade? Air cushions are formed through the alveoli, which prevent food from sticking to the blade. With this type of blade, you get excellent thin slices of salmon, ham, etc. They present the cutting wire on only one side of the blade because only one side of the blade is suitable for cutting. The food has a short blade contact time with minimal friction. This type of knife is ideal for filleting meat or fish through a long and thin cut, for which the angle should not be too steep during cutting.

For precise setting and control of the set sharpening angle with a marker, paint over the sharpened chamfer of the knife.

Now, by the nature of the sharpening stone marks on the painted blade, we can estimate the angle of inclination and correct it in the required proportions.

This type of knife is only suitable for right-handers. What are the advantages of a knife with more than 1 layer of steel? An oxidized carbon steel knife from our grandmother's time is probably dwindling to the present day. Knives from carbon steel today are not used for hygiene reasons. But in order to maintain the advantage of carbon steel in cutting performance, we must define an ultra-thin layer of this material between two layers of high corrosion protection using a sandwich procedure.

What is Damascus steel and what are its benefits? Traditionally Damascus steel blades were assembled together and stacked, one layer after another. Thanks to various materials used in the manufacture of these knives today achieves incredible blade hardness. Considering that in ancient times the main goal was to prevent the destruction of brittle materials, today the main characteristic of Damascus steel is that the various properties of different steels combine favorably, resulting in an excellent finish and great cutting ability.

We install the holder with a knife on the stop fixed on Tormek. Lower the holder with the knife with the adjusting screws of the stop until it touches the grinding stone.

With the adjusting screw for setting the angle, we set the angle of the knife relative to the stone. By manually rotating the grinding stone, by the nature of the marks on the painted blade, we determine whether it is necessary to adjust the angle of inclination of the holder with the knife. We make adjustments if necessary.

So, having set the required angle, we proceed directly to sharpening. For a fixed removal of metal from a knife being sharpened, there are two sliders on the stop with a scale division of 0.1 mm. It is assumed that the sharpener can adjust the amount of removal in exact proportions. Be sure to securely fix the fence after each feed with two clamping screws so that there is no vibration of the fence during sharpening.

Everyone has forged knives are there rivets? Rivet knives are commonly found in kitchens, but they don't have to be high quality knives or forged steel. These beliefs go back to the past, when the cable manufacturing process involved handicraft work and was therefore only carried out in the case of a knife of lasting value.

All our knives are made in Portugal. Traditionally, rivets were used to hold pieces of cable together. Due to the great effort involved in production, this process has come to be regarded as a sign of quality, but also for reasons of hygiene, in which the handle and blade are combined, in this case, the rivets have no function to correct.

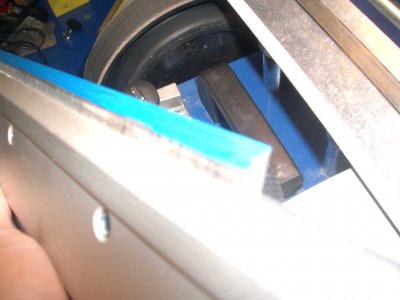

Sharpening of the knife is carried out by moving the holder with the knife to the right to the left relative to the grinding stone.

It is not permissible for the knife to be sharpened to go beyond the edge of the grinding stone. It is recommended to stop the holder 12 mm before the edge of the circle. To eliminate errors, stops are provided that can be moved and set the required holder stroke. We did not use these stops, relying on our experience.

Why is it so hard to sharpen a serrated knife? The distance between the teeth is fixed. In some cases, this serra must be removed, completely worn out and thus thus form a new serra. How do you recognize a forged knife? The reinforced knife is recognized for its reinforcement. Sometimes also continuous blade steel on the handle. Try blowing the blade and cable together.

If a shadow appears, the blade is welded. Procedure in case of complaints? We guarantee the manufacture of our products with strict quality control. However, there may be some reason to complain. In this case, you must follow the steps below. First, go to the store where you purchased the product and explain the situation. If this is not possible, file a complaint directly.

It should be noted that during the sharpening of the planer knife, water accumulates and distributes on the knife blade from the grinding stone, which leads to water runoff onto the body of the sharpening machine and onto the floor. And there is a lot of this water. Therefore, it is necessary to regularly add water to the Tormek water tank. To reduce water spillage on the body, it is recommended to place a 6 mm high pad under the right leg of the machine (under the honing leather wheel).

However, this measure does not completely eliminate the ingress of water on the body of the Tormek T7. However, Tormek T7 has good protection and he is not afraid of such water baths.

Attach short description problems and full address. If you do not receive an answer to your question, please contact us directly. One of the oldest instruments, it retains its appearance, its conformation and its usefulness since ancient times. It remains unbeatable for the result on the tree as it passes, the charm of the harmony of movement and the beauty of the waste that produces. Wood must be worked with sharp tools and this principle is worth more than ever for hand planing. planer for a tree.

Before sanding systems existed, man modeled wood with stones and irons, gradually stroking the pores, which was not necessary to obtain the desired detail. However, with so much experience gained over millennia, today it is planing that puts us more to the test in woodworking. The reasons for this fact can be found in the nature of the tool, the hand planer for wood, which requires respect for at least two basic rules. The first is a rule that applies to any processing, but in this case there are no possible tolerances: you must experience!

Another annoyance when sharpening a planer knife was that the SG 250 stone was constantly clogged, which reduced sharpening efficiency and increased sharpening time. I had to clean it regularly with an SP-650 sharpening stone cleaning and leveling stone. Of course, what material the knife is made of is of great importance. In our case, a knife made of HSS steel was sharpened and given stone had to be constantly corrected. When sharpening knives made of tool (softer steel), there is a more intensive removal of chalk and sharpening is faster. It is recommended to use a different stone for sharpening HSS knives.

Entity type and grain orientation are, in fact, a "dramatically" important variable in planing, more so than in many other woodworking processes. Thus, learning to plan wood also involves the acquisition of certain technical knowledge of the essence, as well as the ability to evaluate the part itself or the orientation of the fibers, the presence of knots, cracks or other causes of weakness and breakage. The second fundamental rule is that the tool is valid, has a high constructive level and above all has a very well sharpened and well adjusted cutting edge.

So, after 20 minutes of sharpening, we have an even, smooth, beautiful bevel of the knife with a stable, even burr on the cutting edge.

The knife needs finishing. We finish the planer knife on a Tormek T7 leather wheel using a finishing and polishing paste.

First, we bring the working plane of the knife, then its chamfer. We make sure that there is no burr on the cutting edge of the knife. Once the burr is removed, the knife is sharpened and ready to go.

After sharpening, we checked the geometry of the knife. The knife had a strict parallelism of the cutting edge and back. Even despite the rather large sharpening angle, the knife sharpened by us perfectly cut a sheet of paper.

Even though a planer is an extremely simple and important tool, it must guarantee a reliable and durable cutting edge. Sharpening the knife of a hand planer deserves a separate treatment, given that, observing all the premises, if not, then it is completely useless to continue working. Obviously sharpening does not mean manual planing for a new wood, because most of the time you are buying, the first thing to do is sanding and sharpening the blade, and the second is to repeat as often as possible.

Which manual planer to use wood?

Aircraft are classified into three categories that define the base's intended use: aircraft, satellites, and bags. Real planes are those that are used to grind surfaces, or make them flat, even, uniform. In fact, other divisions can be found in this category. The 25cm to 35cm long roughing planer is flat but the cutting edge is slightly convex to remove the solid thickness of material. The finishing planer, used for work to surfaces, has a straight edge with rounded edges to avoid scratching the workpiece.

Let's summarize:

1. To sharpen planer knives no need to have complex and expensive machines. It is enough to have a Tormek T7 and special device Tormek SVH 320

2. After sharpening on the Tormek T7, you get a high-quality sharpened planer knife with the same geometry.

Identified shortcomings:

1. At the entrance of sharpening from the knife being sharpened, water pours abundantly on the desktop and machine body, which causes some discomfort. Even resorting to certain tricks, it is not possible to completely get rid of this inconvenience.

2. The Tormek SG 250 sharpening stone is regularly oiled and needs to be cleaned and leveled with a Tormek SP-650 whetstone. There is an assumption that if you use a Tormek SB 250 stone, this trouble will be eliminated.

The cooper platform is characterized by a curved sole, with which it is possible to process concave parts, such as planks for construction wooden barrels or vats. A planer recorder, most often of metal but also of wood, provides registration screws that allow easy adjustment of the blade protrusion and slot opening. The veneer, usually thin, is characterized by the same width of the knife and a very small hole, because the chips after the gap are forced out of the side holes.

Horizontal planing or cross planing with a manual wood planer

It is used to make joints, wells or moldings. The pliers are a planer characterized by molding the sole and the knife to make frames or moldings right on the edge of the piece. A manual wood planer must be carried with two hands, even if the front handle is not available. The bottom of this page, while for the top of the wood planing, the back of the tool needs to be very soft, making the hand slightly dominant in front. The manual wood planer can also be used to round the edges of the board, and the work, especially if the part is large, is simple, indeed, it is good way get the sensitivity of the tilt of the instrument. The layout of the head, which is created by bringing the planer across the direction of the wood fibers, creates certain difficulties.

Jointer and jointer have long been one of the most popular carpentry tools, they have not lost their relevance today. The question of how to sharpen jointer knives is of interest to many specialized specialists, since a tool fully prepared for work allows you to achieve best quality work. The first thing to do is to remove the knife and chipbreaker, which must be unscrewed before work. A used tool must be cleaned of contaminants, such as resin, it is best removed with gasoline.

The most obvious is the fact that the fibers are sheared and thus provide greater resistance to the passage of the blade. In addition, when presenting oneself "in a bundle", there are often areas of weakness of the entity; this leads to the classic exit from the chunk. An alternative solution to the problem is to firmly block the piece of scrap wood on the face with respect to the exit from the plane. The wood must remain flush with the planed surface in order to hold the fibers of a good piece, sacrificing its benefit to the job.

By hand, using stones, or with the help of a water grinding wheel, sharpening is an operation that must be done with the utmost care, especially on new aircraft knives. In fact, there are very few of them, those that are sold quite sharply. With stones, more steps are made with a gradual degree of grinding, depending also on how damaged the knife line is. The skin pass is complete and is about to complete the job.

To sharpen a knife of a planing and jointing type, it is better to use specialized devices. The procedure is also carried out manually, in addition, the device for sharpening jointer knives can be assembled independently. When working, you need to follow a number of rules, you can use several technologies. Regardless of which sharpening option you use, you need to follow the instructions as accurately as possible. Otherwise, you can achieve poor-quality work of the tool, the functions of which cannot be used 100%. If you are thinking about how to sharpen jointer knives at home, then use ordinary whetstones, although ideal option there will be a choice of professional grinder with cooling function.

Preparation for sharpening knives

Sharpening of jointer knives can be done better if you choose a fixture with low speed and high quality. If you want to use a grindstone, then it must be leveled initially. After editing the device, the stone must be smoothed with a bar.

Now set the appropriate angle of inclination, this is done by rotating the screw that secures the canvas. Next, you need to use the holder, which is included in the standard equipment of the machine, where the planer knife is fixed. Work should begin with knives no wider than 13 mm. The length is not important, since the tool is fixed in a convenient position in the holder.

In order to fix the knife well, hold it in the selected position and tighten the screws tightly.

To control the angle of sharpening the jointer knives, a marker is used to mark the chamfer of the knife. You can understand the accuracy of adjustment by turning the stone manually.

Tool sharpening

Sharpening jointer knives is a simple process, you only need to move the holder from side to side relatively grindstone. Try not to let the blade go over the edges of the stone. Fix the holder 12 mm from the end of the circle. When carrying out work, it is necessary to establish the supply of water cooling. Be prepared for the fact that you will need to regularly replenish the supply of fluid in the reservoir and prevent the reservoir from draining. To secure the work, you need to ensure that moisture does not flow onto the floor under your feet.

sharpening planer knives quite a lengthy procedure. Periodically check the cleanliness of the grindstone, as it can quickly become clogged. To clean it, you need to use a special bar as soon as pollution is detected. By the way, the choice of stone largely depends on the type of instrument. The planer may include knives made of various types hardness, so choose your whetstone carefully.

Usually knives for planer sharpened for 20 minutes, after which it is necessary to perform fine-tuning. This procedure is carried out using a special paste. Polishing is carried out so that the blade does not have the slightest roughness, burrs, otherwise work with such a knife will not be complete. Check the effectiveness of sharpening by cutting a piece of paper with it. If the cut is made neatly, then the knife is completely ready for work.

Other tools sharpening materials:

Living and dead water: myth or reality, what is the power of living and dead water?

Craniosynostosis, or premature fusion of the bones of the skull Frontal crest in a child

Beautiful hair How to achieve hair density at home: useful tips

Why mosquitoes bite some people, but not others

How to achieve beautiful hair