- Tool sharpening technique

- How to evaluate the sharpness of a tool?

- Conclusion, conclusions, recommendations

Every kitchen has a set of knives. Very often there is a situation where the tools lose their sharpness. If the knife is dull, you can use another one. But you need to remember that sooner or later all of them will cut badly, and therefore you still have to sharpen them. Many do not know how to sharpen knives with a bar. Why does a blade become dull over time? Regardless of the metal from which it is made, in the process of constant operation, its wear begins.

With prolonged use of knives, they require timely sharpening.

This occurs as a result of friction against the surface of another object, which contributes to edge wear. Often there are situations when the cutting edge breaks off. This is observed with increased lateral load, while the cutting edge begins to bend. The process of tearing off the smallest particles of metal occurs imperceptibly. If knives are used to cut hard objects at right angles, then the blade will dull much faster. Let us consider in more detail how knives are sharpened with a bar, the main stages of work.

Varieties of sharpening tools

by the most simple option sharpening a knife at home is sharpening with a bar.

To learn how to sharpen knives properly, you need to know the basic methods of sharpening. In the household, you can use various devices and tools:

- musats;

- whetstones;

- electric and mechanical sharpeners;

- grinding devices.

Choosing one or another tool, you do not need to save. A quality sharpening device will last for many years, while a cheap one can even ruin the blade. Grinding machines can be attributed to professional tools. They are used in repair shops. In the absence of skills, this method of sharpening is better not to use. The easiest way to sharpen a knife is to purchase a mechanical type sharpener. It is used for sharpening kitchen tools. If the knife has a thick blade, then this option will not work.

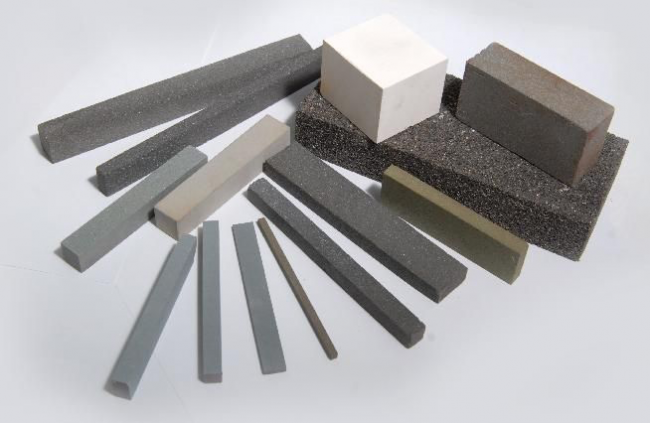

To edit the cutting edge, you can use musat. But they will be useless in a situation where the blade has already become blunt during use. The most popular today are whetstones. Sharpening knives with a bar is very simple and cheap. The bar is a stone, which consists of abrasive grains. Their number and size may vary. Bars of foreign manufacture are marked by which you can determine the grain size.

Back to index

Tool sharpening technique

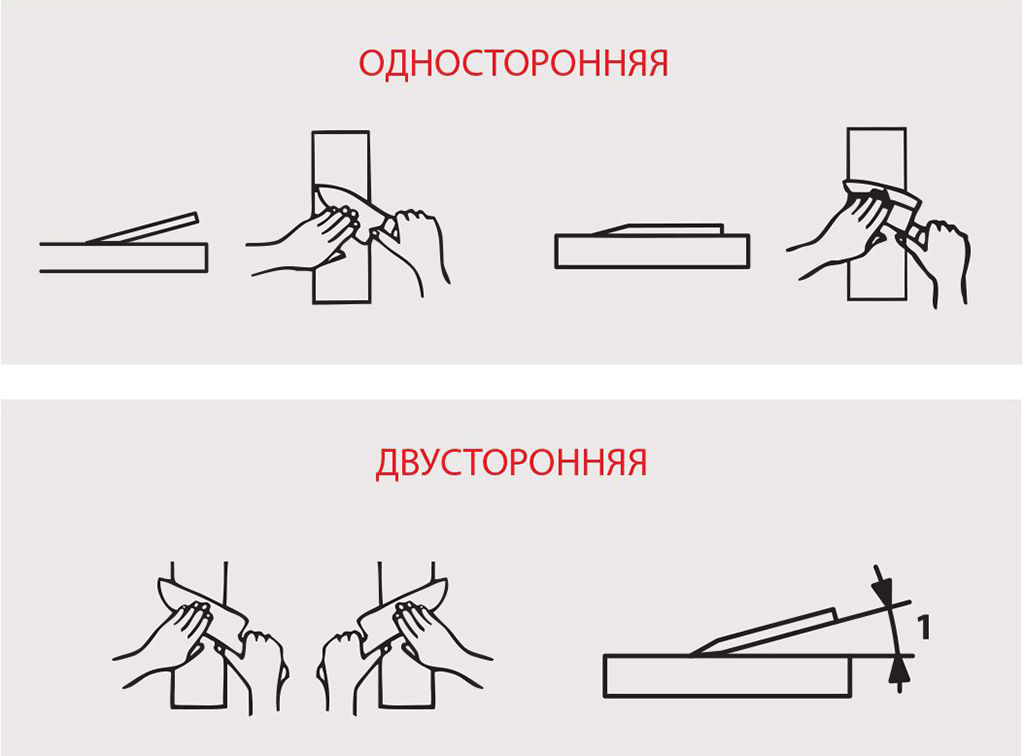

How to sharpen knives at home? To do this, you need to know a few basic rules. Firstly, for work you need to have at hand not one, but two whetstones at once. The first should have a coarse-grained structure, and the second - fine-grained. In this case, one bar will be needed for sharpening, and the other for grinding. Secondly, before sharpening the knife, the blade must be moistened with water or special mineral oil. Thirdly, the angle of inclination of the tool to the whetstone is of great importance. Fourthly, the work is carried out in such a way that the grinding tool lies, and the blade moves on its surface, and not vice versa.

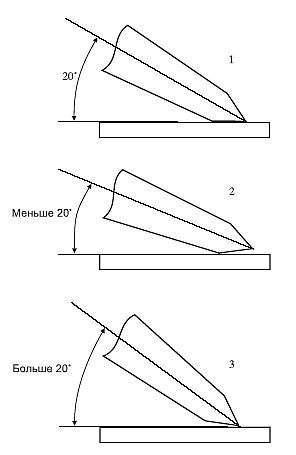

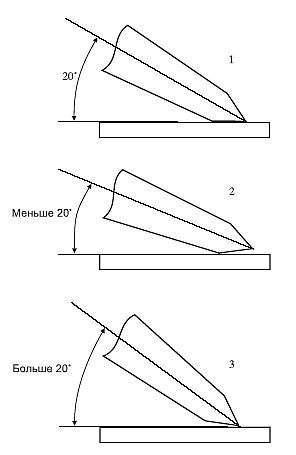

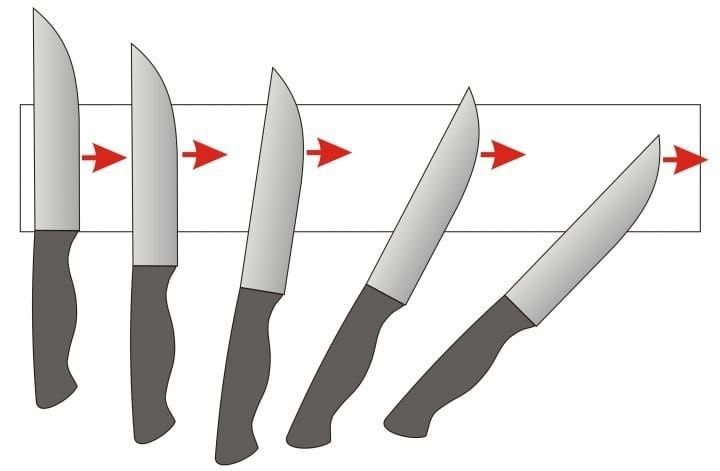

The angle of sharpening may be different. It is in the range from 15 to 45 degrees. Its optimal value is 20-25 degrees. The angle largely depends on the nature of the material from which the tool blade is made. If you sharpen the knife at a small angle, it will soon become dull again. This is due to the rounding of the cutting edge. How to sharpen a knife, always keeping the same angle of inclination? Everything is pretty simple. First, it is recommended to fix the grindstone on a flat surface. The blade is best positioned transversely. After that, you need to move it along the bar, observing the correct angle of inclination. It is advisable to do this only in one direction, for example, away from you.

Back to index

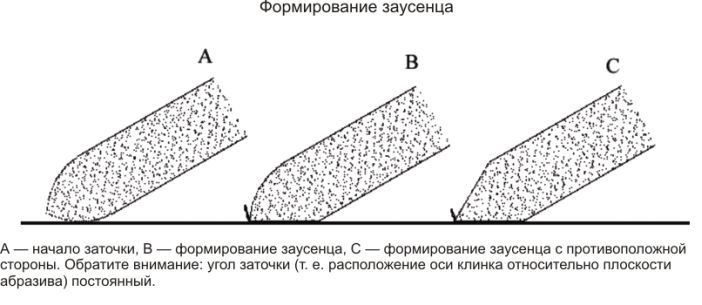

The movement of the blade on the whetstone

You need to sharpen your knife properly. It is recommended to move the blade along a bar moistened with water or oil. It is necessary to sharpen until burrs appear along the metal blade. Sharpening is carried out on both sides. Each time the burrs will be directed in one direction. They are easy enough to identify, for this you need to swipe your finger on reverse side tool. At the beginning, it is necessary to sharpen the knife with a coarse-grained bar, then with a finer one. This will reduce the size of the burrs.

You need to use a fine-grained bar twice. After resharpening, some kind of leather product is used, for example, an old belt, the back of which resembles suede. This will ensure that the blade is polished. Of no small importance during the work are the dimensions of the whetstone. It is desirable that its width is 5 cm, and the length is 2 times the size of the blade. The instrument must be guided smoothly.

The blade must be placed across, and the movement of the blade itself must be directed towards the cutting surface.

In fact, there are a lot of things with which you can sharpen knives, but from the whole variety sharpening tools 4 main ones can be distinguished:

- Sharpening stones;

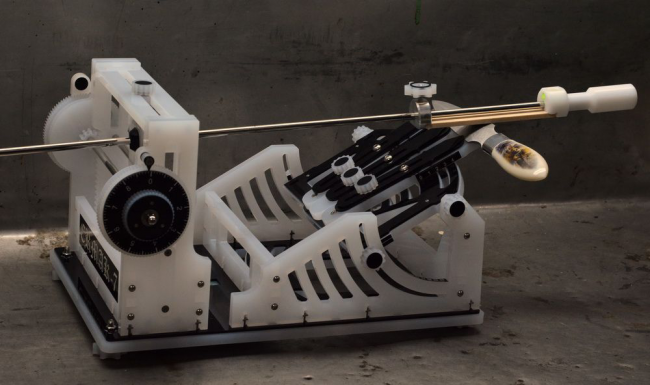

- Grinding machines (manual);

- Knife on knife.

We will not consider sharpening on emery, since it is not suitable for domestic use, but is used mainly in production.

Consider in order their advantages and disadvantages, as well as the technique of working with them at home, starting with the simplest.

Grinding stone (beam)

Speaking of grindstones, let's immediately decide what we are considering the best option of all the stones available today, and this is undoubtedly the so-called "Water Stone" - a special mineral, which is shaped into an even beam (brick), the length of which is slightly longer than the length of a large kitchen knife for chopping meat. It exists in two versions - from natural rock, and artificially made, there are still disputes about their effectiveness, but artificial, in any case, is cheaper.

This device is used mainly in everyday life, while in industry all points are machined only on emery.

Why is it called water? Because before use, the stone must be wetted to increase its effectiveness.

Advantages and disadvantages

From positive sides this method of sharpening can be noted:

- High speed. To sharpen a very dull knife, 5-6 movements are enough, which is especially beneficial if the housewife has a lot of work or in the house a large number of different knives.

- Good quality sharpening. An ideal water stone has two surfaces - one is coarse-grained, and the second consists of grains of small diameter. By combining them, you can get a sharpening of almost perfect sharpness.

- Because of big size and the stone will not slip off the mass, but for greater certainty, it is better to fix it with something, for example, there are special boards with nails that you can make yourself.

The disadvantages of this method are the following:

- The stone wears out pretty quickly. With frequent use, it must be changed every six months.

- You need to constantly wet it, after working with it, splashes remain around.

- The slightest unevenness of the surface makes the whole stone unusable, since it is no longer possible to sharpen a knife on it.

- Due to the large size of the stone, it is inconvenient to hold in the hand; Smooth surface eg table.

Now consider how to properly sharpen knives on a bar.

Work algorithm

First, they must be properly soaked. It is necessary to soak for 15-20 minutes, only then the stone will be ready, but it not only makes no sense to work dry, but it is also impossible, because then both the knife and the stone itself will become unusable.

After you wet it, you need to fix it well. If there is no special board, press it against the wall, or put something heavy next to it, but the better you fix it, the sharper your blade will be.

Further, if you have a double-sided stone, then you should start from the side with larger grains. You need to put the blade at the beginning of the stone and smoothly draw it to the end at a slight angle with the cutting edge forward, as if you are cutting off a thin layer of oil, only you need to sharpen not one part of the blade, but completely process it in one pass, that is, you need to combine two movements - along the stone forward and from the handle to the tip. You have to change sides every time. Do, for example, 5 movements back and forth, in total you will get 10 movements, and try to cut something.

During operation, a suspension will form, it does not need to be removed, but it can be moistened, for example, by spraying it with your fingers. This method of sharpening is quite dirty, so it is better to use it not at home, but in the garage or in the garden. However, one might wonder if there is a garage, wouldn't it be better to put a sander there? No, the fact is that only the original shape of the blade is machined on emery, but if you regularly sharpen it on emery, it will undoubtedly deteriorate.

Musat is such a tool for dressing knives (note - not sharpening, but editing, that is, it is assumed that the blade is already sharpened and needs to be slightly corrected after use), which looks like a soldering iron - its sharpening part looks like a thin cylinder attached to the handle, and all together resembles a knife, only with a sharpener instead of a blade.

Advantages and disadvantages

Musat originally served as a portable tool for sharpening, and therefore it is deprived of the advantages that a normal grindstone has for the sake of mobility. Of course, you can use musat at home, but what's the point if you can sharpen your tool with a normal grindstone? Needless to say, it is most often used by the military, various extreme sportsmen - walkers, and also any hunting arsenal cannot do without musat.

Musat has the following advantages:

- Small dimensions and weight. You can take it with you in a hiking backpack and it will not take up much space, so in the field it is preferable to use a musat than sharpen it on a machine tool.

- The ability to sharpen a knife with one hand.

- The handle makes it comfortable to hold.

Flaws:

- Low productivity, it takes longer to sharpen than on a bar

- It is difficult to regulate the sharpening force, due to the fact that the process takes place on weight.

- Wears out quickly.

- Low efficiency. The blade is not as sharp as when working with a stone, but in order to sharpen a hunting or military knife, it will do just fine.

Consider how to sharpen knives with musat

Press the end of the musat against something hard, for example, against a tree or against a table, and begin to smoothly draw the edge of the knife along the grinding part. In order for you not to accidentally cut yourself, special guards are provided on the musat, which makes it even more like a knife. The sharpening mechanism is the same as in working with a bar. In principle, if you have sharpened your tool recently, but decide to adjust the blade after, say, butchering a boar carcass, 5-6 times will be enough. If you have not sharpened a knife for a long time, it is pointless to use musat, it is better to use a water stone.

grinding machine

Like musat, it is intended to maintain the blade in working condition. It consists of two rollers, between which, while sharpening, the blade passes. What is especially remarkable is that it is not even necessary here. detailed instructions how to sharpen a knife properly, because all you have to do is swipe it back and forth a few times and the blade is ready. It is more convenient to use Musat, however, it is extremely non-mobile, which is why you can only work on the machine at home.

Knife on knife

This method is the most "folk", since it is the simplest and most common, and, like all folk, is the most worst way of all existing ones, because besides the fact that it is impossible to sharpen a knife against another knife (you can only sharpen it, as in the case of musat), it is also very long and hard, and the blade is almost always sharpened somehow.

But still, how to sharpen knives against each other? The technique is simple, the only thing to be observed is to be careful not to get hurt, and not to make sudden movements so that the blades sharpen evenly.

If you still have questions about how to sharpen a kitchen knife, watch the video. Good luck!

We use a knife, especially a kitchen knife, every day, repeatedly, and for cutting various products. But do all of us know how to properly sharpen a knife so as not to do it all the time? We will deal with all the features and rules of such work in this article.

What you need to know about abrasive for sharpening

Type of grindstone

- Diamond coated. The highest quality sharpening with a minimum of required time. Minus - high cost.

- Ceramics. The price is lower, but more effort will be required.

- "A rock". In terms of its hardness, it is slightly superior to steel. Only suitable for sharpening metal blades. The effectiveness of sharpening the cutting edge on such an abrasive is highly questionable.

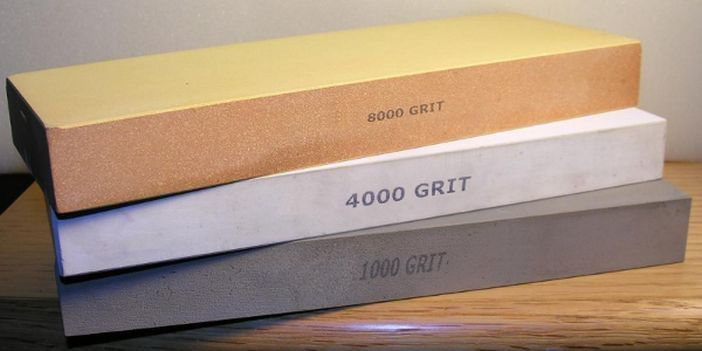

Grain

For high-quality sharpening, it is necessary to have at least two different abrasives - for “rough” processing of the cutting edge and its final finishing. In most cases, it will not work to sharpen a knife to the required sharpness with the same stone. Conventionally, grinding stones (circles) can be classified into 3 groups - with large, medium and small grains.

Terminology should be clarified:

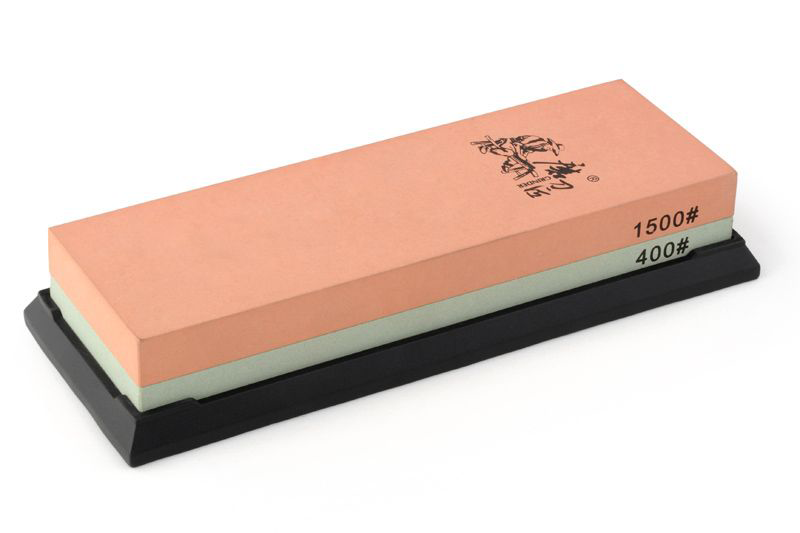

- A bar is a stone of medium or large fractions, which is mainly purchased for home sharpening blades and is considered universal (but not from professionals).

- Touchstone is a fine-grained abrasive used for final finishing of the cutting part of the blade. It is hard or soft. Visually differ in shade - solid donkeys are much darker.

The specifics of the use of abrasive

On sale meet different types stones (circles). Some samples require periodic wetting with water or oil. All these features are indicated on the packaging. When purchasing an abrasive, many of us believe that there is nothing special about the stone, and therefore reading the instructions is a waste of time. To avoid some problems with sharpening, be sure to read the manufacturer's recommendations.

Basic rules for sharpening a knife

- The cutting edge of the knife is processed sequentially, starting with a coarser abrasive. Which one to start with (large or medium) depends on the degree of wear and tear and is determined independently. But the final grinding - only on a fine-grained stone. If required, then you will also need a piece of leather, moreover, natural, and not its substitute. As an option - any ceramic product.

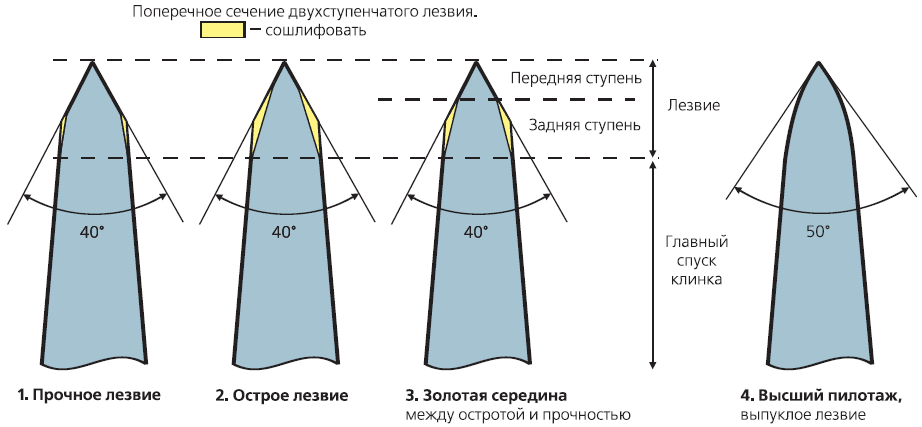

- Sharpening angle. Basically - 20º, unless otherwise specified by the manufacturer.

- When the angle is increased, the blade is removed more metal. Therefore, when processing on a large stone, it is somewhat reduced, and when sharpening on an abrasive of medium and fine fractions, it is kept within the specified limit - 20 (± 1)º.

- Knives with a thick blade, designed for rough work (for example, chopping bones), are sharpened at a large angle - up to 35 - 40º.

- The fact that the base on which the bar is located must be strong, even and at a height sufficient for the convenience of work is understandable. But to prevent the abrasive from shifting during sharpening, something should be placed under it (for example, a piece of soft cloth, thick paper).

- The knife is always held with two hands - the tip of the blade and the handle. In order to prevent the blade from “overshooting”, it is systematically wetted in water. Especially true when processing it on e / emery.

Sharpening technique

- The blade should fit snugly against the abrasive over its entire area. With proper sharpening, it is located perpendicular to its longitudinal axis (if it is a bar).

- All progressive movements - with pressure and away from you. In this case, the cutting edge should “look” at the master. On the "return" it should not come into contact with the stone.

- Since the length of the blade is many times greater than the width of the bar, it should be gradually shifted relative to the latter.

- After a complete "driving" on one side, the position of the knife changes to the opposite. Now part of the edge is turned on the back side using the same method.

The finishing of the blade on the bar is done a little differently. Everything is the same, only now the point should “look” from the master. The movements are smoother, more precise, and the pressure on the abrasive is as tight as possible.

On a note!

All of the above rules for sharpening the blade fully apply to the sharpening process using an electric sharpener. Naturally, after pre-treatment on a coarse wheel, it must be replaced with a sample with a fine grain.

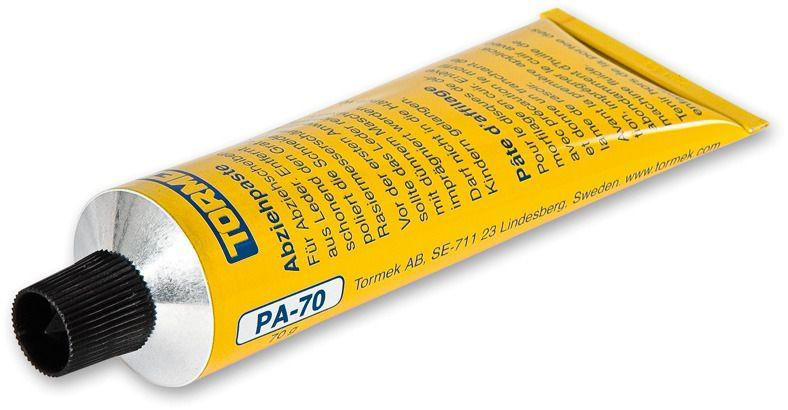

In some cases, it is necessary to bring the blade to razor sharpness. This is done on a piece of leather, pre-coated with a thin layer of technical petroleum jelly. As an option, make a mixture of it and crushed GOI stone (or its paste).

In some cases, it is necessary to bring the blade to razor sharpness. This is done on a piece of leather, pre-coated with a thin layer of technical petroleum jelly. As an option, make a mixture of it and crushed GOI stone (or its paste).

It is best to check the readiness of the knife on a sheet of thin paper. If its razor sharpness is needed, then it is tested on a piece of soft cloth.

- If you don't have a whetstone on hand, you can sharpen a blade that isn't too dull with sandpaper. In addition to it, you will need a solid object with an even (flat) edge. For example, a piece wooden lath. He's being wrapped sandpaper, and such makeshift fixture completely replaces the bar.

- If the steel of the blade is rather soft, then it is advisable to lightly spray the stone from any manufacturer with machine oil. This will prevent the filling of its pores with the smallest fractions of the metal.

- It is not advisable to purchase bars less than 150 mm. The longer the abrasive, the more convenient it is to work with it.

- Ceramic knives should be sharpened according to the manufacturer's instructions. It is better to ignore any recommendations and tips of "experts", since if the blade is handled incorrectly, it can be ruined. Given the cost of such a product, the advice is far from idle.

Each master has his own method of processing the blade. On the Internet you can find other (somewhat different from the above) recommendations. This does not mean that some of them are correct and others are not. You need to understand that all of them are only general. It is impossible to take into account the specific features of the stones, the steel grades of the blades, their linear parameters and the skills of the one who sharpens. Only practice will show how effectively you can sharpen a specific knife on the abrasive at hand.

Among the many ways to sharpen knives, natural or artificial stones. The composition of artificial whetstones includes elements such as silicon, ceramics, aluminum oxide. natural stones not as durable as artificial ones. Having a fine-grained structure, they are not suitable for severely blunt instruments. Artificial ones have a coarse-grained structure on the one hand and a fine-grained structure on the other, which makes these devices universal. Natural bars are made of either silicon or quartz.

How to sharpen knives

The first thing to do is lubricate the whetstone. To do this, it is necessary to apply oil or other substances to the knives and leave for about 15 minutes, then remove the excess lubricating compound and, with smooth movements, alternately on both sides of the knife blade. First you need to process the knives on the rough side of the grindstone, then on the finer one.

To properly sharpen knives, you need to position the sharpener to the blade at an angle of 20 degrees. If the knife is a hunting knife, sharpness is needed not of medium, but of a strong degree. To increase the resistance to blunting, these knives are sharpened at an angle of 35 degrees. Chef's and other spicy kitchen knives, as a rule, sharpen at a small angle - 10-25 degrees. That is, the smaller the sharpening angle, the sharper the knife.

Why does a knife need to be sharpened in two steps?

For sharpening, abrasive stones, corundum and ceramic whetstones and diamond whetstones are used. Rough processing knife is necessary to obtain cutting edges and edges of the knife. Of course, for a beginner grinder, manual sharpening is a laborious process. But it is this kind of work that gives the best effect.

After rough sharpening, it is necessary to proceed to processing the blade with a fine-grained part of the bar. It is possible, after fine-grained sharpening, to complete the processing with a piece of genuine leather or a special belt.

Today on the market you can buy electric sharpening or mini sharpening universal machine. When using an electric grinder with a capacity of 1500 rpm, it is better to use ordinary circles of the EBK 40 brand. Only professionals can work with high-speed devices, since experience and quick response are very important here.

Since there are no universal knives, the choice of sharpening angle depends on functional purpose knife.

The most traditional way to sharpen knives with your own hands is with a whetstone.

This article will help any beginner learn how to sharpen knives bar manually (with video without SMS and registration) and understand why do it at all. Professionals, of course, are aware of this topic, but for them, there may be helpful information. Or it will be an occasion to update your knowledge in order to "keep in good shape."

Different grits of grindstones have their own purpose

A good kitchen knife radically changes the idea of \u200b\u200bthe usual cutting and butchering

Fixture for manual sharpening knives at home - musat

If you have to put in more and more effort to cut, then this is an occasion to think about sharpening your knife. Because using a blunt weapon is dangerous. It can slip off at any moment, and believe that the sharpness of the blade will be enough to inflict a serious wound on you or a person standing next to you.

Preparing for sharpening. What needs to be done before then?

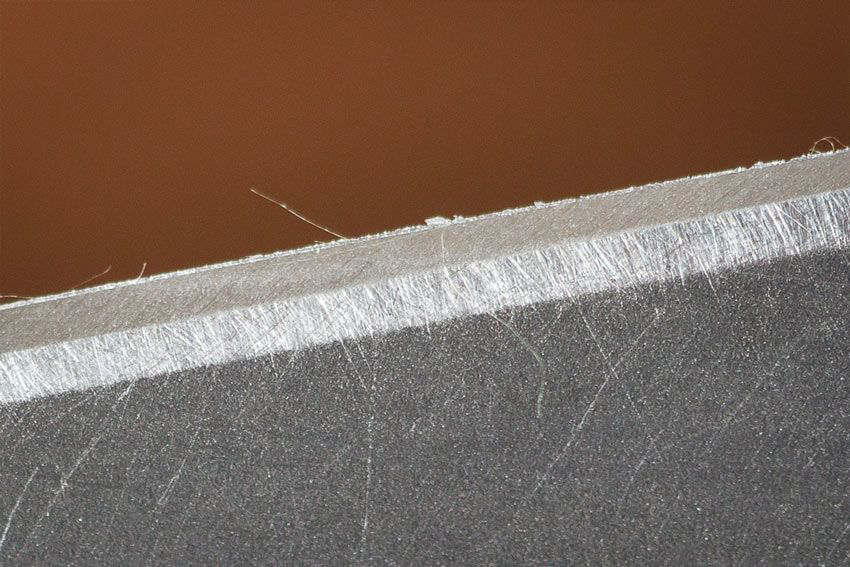

The blade of a knife, upon closer inspection, looks like a saw, and the more often the teeth are located in it and the smoother the transition between them, the easier it is to use the tool. A dull knife loses these teeth, they wear out, bend and crumble.

There are many ways to sharpen a knife using mechanical and electric sharpeners, as well as special machines with grinding wheels. But sharpeners do not give an ideal result, and easel sharpening requires considerable knowledge and skills. Therefore, we will consider how to properly sharpen knives with a bar, in step by step guide for independent work v at home. This method will give you two main advantages: considerable money savings and excellent results.

The first thing to do is to determine the degree of damage to the blade. It is very easy to do this. Place it at an angle to a beam of bright light. This method instantly reveals all the chips and bumps that you need to eliminate. They will look like dots or lines on the blade. If the boundary between the planes is uniform, sharply defined, without transitions, then the instrument is in excellent condition.

After that, the knife should be washed in water with the addition of soap. This is done to facilitate subsequent work. The knife will become easier to slide on the whetstone, and it will be easier for you to maintain the required angle between the planes of the blade and the blade.

Choosing the right bar

The main tool in the subsequent work will be a whetstone. To get the perfect result, you will need several stones of different grits. The minimum number is two, but if you need a razor sharpness of the blade, brought to perfection, then you can use up to five whetstones.

There are two types of bars. The first ones are artificial, used for primary metal processing, made of the following materials.

Synthetic gems(diamond, sapphire, etc.):

- borazone;

- silicon carbide;

- elbor;

- and others.

The second is natural. They are used for finishing knife sharpening:

- diamond;

- Garnet;

- corundum;

- Japanese water stones

It is clear that natural whetstones cost decent money, but if you want to get a really good result, you will have to fork out a little.

An important parameter is the choice of the size suitable for the work of the bar. At a minimum, it should be the same length as the knife with which you will have to work. And ideally - one and a half to two times more. At the same time, the width of the stone does not matter and is selected based on personal preferences. Although if you take a wider donkey, then even an inexperienced beginner will find it easier to work on it.

Before starting, it is necessary to soak the bar in water (artificial) or oil (natural). The liquid will nourish, close the pores in it, reduce subsequent pollution and make your work easier.

Correct sharpening angle

How to sharpen a kitchen knife with a bar? Keep it at the right angle. It is this parameter that will subsequently determine the length of the blade's service life and the frequency of its sharpening. The larger the angle you get, the higher the resistance of the metal to external influences, which means that you need to update its sharpness less often. An acute angle gives ease of cutting, but due to the thinness of the metal obtained in this place, it is erased faster.

The determining factor will be the purpose of the knife:

- japanese cooking blades sharpened at an angle of 10-20 degrees;

- fillet knives and professional chefs require an angle of 25 degrees;

- household knives - 30 degrees;

- hunting blades are processed at an inclination of 35-40 degrees.

You will need not only to determine the angle of inclination, but also to maintain it during the entire work.

Advice! To find and maintain the required number of degrees, it is good to use a sheet of paper folded several times. It is a fast, cheap and accurate meter.

In addition to the angle of the blade, you will also need to observe the angle between the whetstone and the cutting edge of the knife. It should be 90 degrees. That is, you should always hold the tool with the blade perpendicular to the stone. For you, this means the following: at the beginning of the movement, the knife is located across, parallel to the chest, and at the end you go out at an angle of approximately 45 degrees (depending on the shape of the knife) in relation to you.

Getting Started

How to sharpen knives with a bar by hand, having an angle of inclination of the blade and a grindstone directly? You need to start with coarse-grained stones. They are used for rough work and will remove all noticeable bumps and chips in the blade, after which you gradually move on to a finer abrasive. The smaller it is, the better the result you will get. You can complete the sharpening with an abrasive paste, and not with a bar.

Double-sided whetstone with different grits

Advice! Be sure to set the bar on the work surface so that it does not move during the work, otherwise you risk “breaking” the movement, which can ruin the final result. It will be a good option. It will provide the required adhesion to the surface.

First you need to position the knife across the donkey sharpening away from you. In this case, the edge of the blade is above the edge of the grindstone. Next, you begin to smoothly lead the knife, gradually deflecting it to the side, so that the end of the movement coincides with the edge of the blade. In this case, it is not recommended that the knife break off the edge of the bar, as you can scratch the side of the blade. When the movement reaches the bend of the blade, the handle must be slightly raised, starting to “wrap” towards the handle. This will keep the desired angle.

Features of the knife sharpening process

In this section, we will tell you how to sharpen knives with a block in order to get a durable and sharp tool. The main indicator of the success of your actions will be the appearance of the so-called "burr" on the blade. It looks like a lighter stripe on steel, covered with metal dust. The “burrs” are always directed in one direction, which is ensured by the uniform movement of the sharpened blade.

Since sharpening is carried out on both sides, they must be alternated. Turn the knife over after each swipe. In another version, one side is first sharpened, after exactly the same number of movements, the second. But this method is somewhat worse, as it gives not quite uniform sharpening.

When the "burrs" have formed along the entire length, you can move on to a stone with a finer grit and repeat all the steps described above. With a decrease in the size of the abrasive, the size of the resulting “burrs” also decreases, because the layer of metal removed from the blade becomes smaller and smaller.

On each bar, it is desirable to make from thirty to fifty movements (depending on the hardness of the steel and the degree of wear). Remember that the main parameter is your patience and smoothness of movements. Strength does not matter here, and if you put too much pressure on the blade, it will not sharpen faster, but will simply be damaged.

It is recommended to rinse the knife with water between transitions, washing off the formed metal dust.

How to sharpen knives with a bar: bring to razor sharpness

If you want a blade that cuts through multiple folded rope equally easily, or produces the thinnest slices of a soft tomato, then you need to perfect your knife. An abrasive paste will help you with this. You can buy it at any hardware or specialty store.

For the final stage of work, you will need a strip of thick leather. If there is no such thing at home, then a belt without engraving will perfectly replace it. The work surface must be flat and free of bumps.

A small piece of leather can help sharpen your main kitchen utensil.

Apply abrasive paste to the skin so that it completely covers the part on which you will be finishing the knife. After that, again smoothly, slowly run the blade along the belt, turning it over alternately to sharpen the steel on both sides.

Do not be afraid that you will not see visible manifestations of your activity, as when working with grindstones, because the paste removes particles so microscopic that they are not visible to the naked eye. The result of labor will only be a change in the color of the abrasive applied to

These are standard checks.

Many people wonder: is it necessary at all - to spend so much time and effort just to get sharp steel? The answer is simple - it is necessary. Even if you only have ordinary kitchen knives. Properly sharpened, they will give you an indescribable feeling of ease of cutting, increase the safety of work and, in the end, will save money, because the longer the sharpening lasts, the longer the tool will last.

Mixed Personality Disorder: Causes, Symptoms, Types and Treatments

GTA 4 control settings

FAQ on Smuggling in GTA Online

LSPDFR - welcome to the police

The huge map of Grand Theft Auto San Andreas and its secrets