- Helpful Tips

The knife is one of the most ancient tools, which has not lost its relevance for many centuries. A good knife has always been considered one of the most important attributes that a real man should own. In this regard, he must know how to sharpen a knife so that it is like a razor. Moreover, if earlier only warriors and hunters should have had such a skill, now every representative of the stronger sex should be able to do this.

Knife sharpening should be done every few months.

It is not a very difficult task, it is not necessary to entrust it to specialists. If you make some effort and follow the instructions clearly, then any knife will become razor sharp. A variety of tools can be used for sharpening:

- Electric sharpener.

- Bars, but you need to choose a few, the grain size should be different.

- Skin.

To sharpen knives, you can use a special sharpening tool.

An experienced person can sharpen a tool even in such conditions when none of the above is at hand, with which sharpening can be done. He can even use a stone that is harder than the knife itself. You can, of course, use special sharpening devices, which are offered on the modern market in in large numbers and whose price range is very different, which allows everyone to make a choice. However, such devices are not always at hand, so manual shaving sharpening at home does not lose its relevance.

How is such a process carried out?

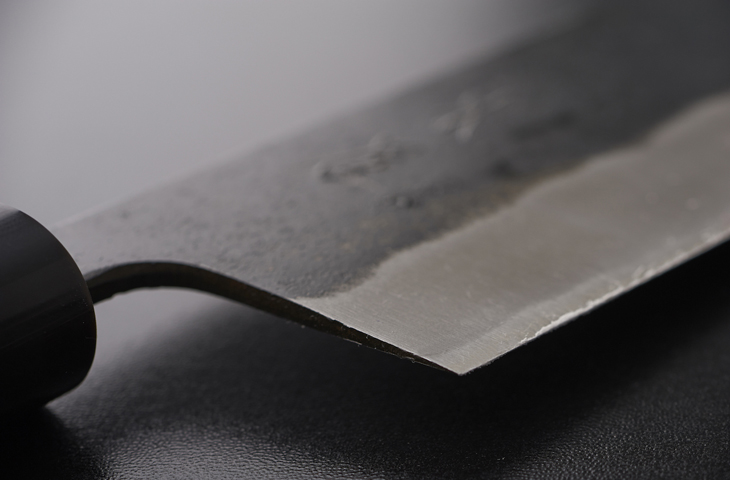

Before sharpening a knife, you need to properly inspect it.

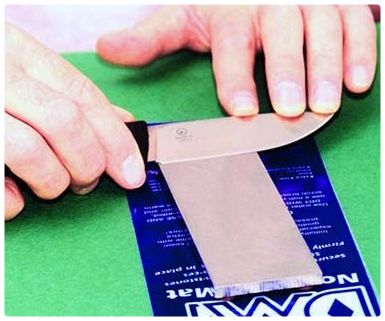

This must be done in order to be able to determine the state of its initial sharpness and the presence of notches on the blade. If the blade is in a completely unusable condition, then you need to use an electric sharpener, but it is recommended that professionals work with such a tool. If sharpening is carried out at home, then for this you can completely use a whetstone. This method is reliable and proven, but you should immediately be prepared for the fact that it takes a lot of time. In order to save time, it is recommended that you do not sharpen the entire knife in this way, but only the part that is dull. If there are teeth on one side, then the part of the tool where there are no teeth and the chamfer is removed should be sharpened. Razor sharpening can be done like this: the whetstone is placed on the base (it can be anything). It is necessary to use the base so that the countertop is not damaged during sharpening.

As a base, you can use a variety of things: a cutting board, an ordinary newspaper or a piece of linoleum. The knife is taken in the right hand by the handle, then the tool is placed with a cloth on the bar, you need to do this at a slight angle. As for the choice of angle, it is necessary to focus on the angle of the previous sharpening. For reliability, the bar should be held with the left hand, and right hand performs progressive movements. In this case, the knife blade should be pressed as tightly as possible to the bar. As for the range of motion, everything here depends on the length of the blade; the size of the blunt part of the knife blade can also be taken into account. Such an operation must be carried out on both sides of the knife blade. It is in this way that the main, as they say, rough sharpening of the knife is carried out, which helps to give the blade an acute angle.

Back to index

Fine-grained skin will help to complete the knife sharpening process.

After the knife has been sharpened to a fairly tolerable state, it is necessary to proceed to another stage of work, which is called “editing”. In order to carry out such a process with maximum efficiency, you need to use a tool that has more delicate qualities. In this regard, it is appropriate to use a fine-grained skin, a whetstone will also work. In order to effectively edit the knife, it should be quickly drawn along the bar, while both sides of the blade should be substituted alternately. And you can just run a bar several times on the blade on both sides, also very effective. The matter continues with the point being perpendicularly applied to the finger after the sharpening process. If the knife is indeed razor-sharpened, then the blade pulls on the skin somewhat when the tool is slid in a direction perpendicular to the blade.

If the question arises, how to sharpen a knife to the state of a razor on an electric machine, it is necessary to carry out such a process in special gloves. This is done for security purposes, and this is especially true for those who work with electric machine for the first time. In order for the knife to really be sharpened like a razor (which is especially important if, for example, we are talking about a tool that is designed for wood carving), then after the sharpening is completed, you need to go through it with a sandpaper several more times, and you need to use different skins, each time decreasing its number until it is brought to zero.

At the end, the tool can be edited on a belt that is made of leather. It must first be nailed to a bar, which is made of wood. To achieve a greater effect, a grinding paste is applied to the leather belt. When sharpening a knife with a block, you can moisten the blade from time to time with water or vegetable oil. Thus, the process runs with greater convenience and greater efficiency. Everything, now with such a tool you can cut meat and other products, carve wood and even use it as a razor.

It is believed that every man should know how to sharpen a knife to razor sharpness. But for all the seeming simplicity of the operation, not everyone owns this art. And it's not about the ability to hold the blade at the right angle, but knowledge in the strictest confidence is passed down from generation to generation. In order to properly sharpen a knife, you need to know something about the knife itself, and about grinding tool, and about the materials from which our knife is made. Below we will tell our readers about all this. Well, and, of course, we will reveal the secrets of the skill of sharpening.

To safely use a knife, it must be properly sharpened.

A few words about knives

For a good owner, all knives in the house should always be sharp, like a razor. It has been so for a long time. Therefore, many men try to follow the tradition, regularly spending a lot of time trying to achieve unprecedented sharpness from a bread knife.

A sharp knife speeds up the process of working in the kitchen.

But sharpening should be considered not only as a tribute to some abstract traditions. Any cook will confirm that a sharp knife speeds up the cooking process several times. In addition, it is easy to work with him, the hand does not get tired of chopping meat or vegetables.

And a razor-sharp knife makes working in the kitchen safe. Yes exactly! A dull blade can move to the side, after which the hand slips. And, at best, everything will cost a fright. At worst, you can seriously injure yourself or catch one of those present nearby. After all, even a knife that does not have a razor sharpness remains sharp, especially its tip.

Before you start sharpening knives, you should find out the hardness of the steel from which the blade of each of them is made. The fact is that the angle at which sharpening will be carried out depends on the hardness of the steel. This parameter is measured in special units, and hardness can only be determined in laboratory conditions using special equipment. The standard value for most knives is 45-60 Rockwell Hardness Units (HRC). Both soft and hard steel will have to be sharpened all the time, because the first will constantly wear out, and the second will crumble.

Why is the knife dull?

The question is serious. If the steel has the right hardness, then why does the knife become dull and not retain its sharpness, like a razor?

The effort when cutting products is a sign of knife sharpening.

There are several reasons. First: no matter how hard the material is, in the process of use it is subject to external influences. Under the influence of the friction force, microscopic metal particles are detached from the main body, the sharp edge is gradually destroyed. In addition, it is not possible to constantly hold the knife in the so-called "ideal position", when the cutting edge of the knife is in contact with the surface at an optimal angle. The resulting loads have a destructive effect on the metal. As a result, razor sharpness is lost.

But since this process can be called microscopic, it is not possible to immediately understand whether the knife has lost its sharpness, like a razor. The first signal may be the increasing force that has to be applied to cut something with such a knife. The loss of sharpness can also be determined by eye: blunt areas on the blade look like polished, they have a characteristic sheen.

So it's time to sharpen the blade like a razor. To make the process as efficient as possible, you should choose the right tool.

Choosing a sharpening tool

In order to bring the blade to the required sharpness, you should choose the right material for sharpening it. It could be:

- whetstone;

- musat;

- electric grinding machine;

- abrasive machine;

- grinding machine;

- mechanical sharpener;

- electric sharpener.

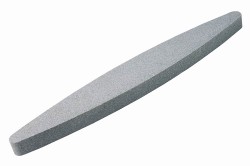

To sharpen knives, you can use a special bar.

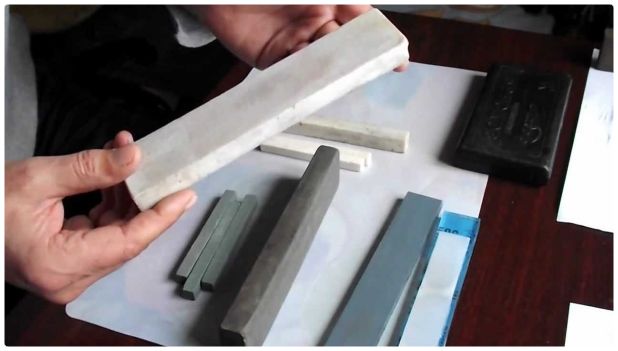

Let's look at each of them separately. whetstone - ancient instrument, designed to make a knife sharp as a razor. Experienced craftsmen know that in fact there are many bars, with different size grains (the smallest abrasive particle that makes up the bar itself), of different hardness and density. In order to sharpen the blade with high quality and then grind it, you need two bars. One with large grains, the other with small grains. You can determine this by special markings, but you can also see the difference between such bars by eye.

Musat, as well as a mechanical sharpener, is a kitchen accessory. With its help, knives are not sharpened, but rather corrected, removing micro-chips and returning the sharpness of razors for a while. This time is short, because the musat and the sharpener do not affect the steel at a sufficient level.

An electric sharpener saves us from applying physical effort to sharpen the blade, but it is also not able to return it to razor sharpness.

Special sharpening and grinding machines are able to quickly return to the knife its cutting properties, but the trouble is that it is expensive and dangerous to keep such equipment at home. The machine produces a lot of dust and noise, while taking a decent amount of electricity. But with its help, you can give any of the knives any sharpness for a short time and without much effort.

But experts advise not to take up work on grinding machines, if there is no experience at least as a toolmaker. You can hopelessly ruin the blade on a knife by overheating it or sharpening it at the wrong angle.

How to sharpen

An electric sharpener is very convenient for sharpening knives.

So, we come to the most important question: how to properly sharpen so that the blade reaches razor sharpness?

The main thing is to be patient. Steel processing takes time, the more we want to achieve, the more time it will take. In order for the knife to be operated like a razor, it will take at least 30 minutes of hard work.

Consider the classic way of sharpening with a whetstone. The abrasive should be placed on flat surface(table or workbench in the workshop) and place a rough cloth or fleecy material under it. This will facilitate the work process, since the bar will not fidget and you will not have to hold it with your hand all the time.

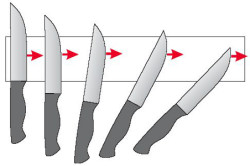

Knives are sharpened by making passes along the entire length of the abrasive. In this case, it is necessary to ensure that the cutting edge of the blade is constantly in a perpendicular position with respect to the longitudinal axis of the bar. In practice, it looks like this: the blade has a curved surface, so when moving, the knife should be turned so that each of its sections is at right angles to the axis of the abrasive material.

In the process, it is important to keep the metal at the same angle in relation to the sharpener.

It should be equal to 20-25 degrees, since this is the optimal value for the cutting edge. Knives intended for chopping meat should be sharpened at a large angle. By keeping the angle of metal processing constant, you can sharpen literally any steel to an incredible sharpness.

The blade should be carried along the entire length of the bar, and it is not at all necessary to apply great efforts. Excessively strong pressure will lead to the destruction of the material and the violation of the integrity of its surface. Because of this, the sharpening process may be delayed.

When a thin uneven edge appears on the knife, you can proceed to the next step and change the rough bar to a smaller one. Having achieved uniform sharpening, you should fix the result obtained by grinding.

knife grinding

This is the final step in the knife sharpening process, resulting in a razor-sharp edge. For work, a special grinding block with a very fine grain is used. It feels like a velvety surface to the touch, but don't be deceived: it can sharpen a blade as sharply as the finest razors in the world.

What is grinding for? It not only gives the cutting edge desired properties but also reinforces them. A polished metal surface is not as susceptible to destruction as a regular one. Thanks to this, the sharpness will remain for a long time.

In the process of grinding, you should follow the same principles as when sharpening. The movements must be uniform and measured, the blade must always be perpendicular to the axis of the bar, the angle of inclination of the metal to the abrasive must also be constant. And there is no need to exert excessive effort, because the metal will level out layer by layer. Razor sharpness will be the result.

It remains to add that you can learn all this, but it will take some practice. But thanks to the acquired skills, each owner will always be able to keep the knives in his house sharply sharpened.

"Are there dull knives in the house? Well, therefore, there is no man in it." Where this "sign" came from, now no one will say. However, is it about her? Sharpening your knife to perfect sharpness will save you both time and health.

If you have ever tried to wield a blunt knife, then you know, long, uncomfortable, heavy, and in addition also dangerous. Do not cut with such a knife, but saw. In this case, the knife, having broken, can injure the owner himself. However, it happens that even an unspoken reproach about the owner and blunt knives hurts much more.

Sawing is a sure sign that the knife is dull and needs to be sharpened. Test yourself by arranging good lighting and examining the blade along; if light gleaming stripes are noticeable on it, these are duller areas, and the conclusion is clear. There is also a test from professionals who always need only sharpening a knife to perfect sharpness. And they resort to it whenever the blade is unable to shave off the hair from the forearm or cut the leaf in the air.

Do not confuse sharpening knives with straightening them. That is, if they tell you that diamond knife sharpening is the best in the world, and they offer diamond-coated musat for this, do not succumb to provocation. Musat, like any metal or ceramic disc devices, is also a useful thing, but it only helps to straighten the knife, and after that you still have to work hard to sharpen it.

The ideal sharpening of a knife is done on sharpeners, or, importantly, they come in different degrees of graininess, and are used for different operations. With a coarse grit grindstone, the correct sharpening angle and the shape of the cutting edge are restored. Medium grit is only suitable for edge restoration. Finally, a fine grain finish is used to finish and dress the blade.

It is better to choose the length of the whetstone equal to twice the length of the blade of the knife you are going to work on. So that at the same time the blade does not break off the bar, a width of 5 cm will be enough. This is the best tutorial how to sharpen a knife to perfect sharpness.

It is better to choose the length of the whetstone equal to twice the length of the blade of the knife you are going to work on. So that at the same time the blade does not break off the bar, a width of 5 cm will be enough. This is the best tutorial how to sharpen a knife to perfect sharpness.

It can be done sitting or standing, it doesn't matter much. True, if you stand, select the appropriate one. Under the whetstone, place a sheet of rubber, position it accordingly. In general, make sure that all sharpening movements are performed correctly and from a position that is convenient for you.

The knife blade is placed flat on one end of the bar. The angle to its surface should be 23 degrees. Performing the movement, gradually move the point of contact between the blade and the sharpener towards the point. Calculate so that at the moment the end of the bar is reached, this point is exactly on the tip. In this case, the blade should remain on the surface of the grindstone.

The blade returns back with the same movement, as if scrolled backwards. This will help to avoid constantly setting the angle between the blade and the sharpener surface.

Don't expect quick results. Sharpening a knife to perfect sharpness is an action that is somewhat comparable to meditation. It can be reached in half an hour, and in an hour, and in three. Some masters spend at least 30 hours on the sharpening process! But the result...

Don't expect quick results. Sharpening a knife to perfect sharpness is an action that is somewhat comparable to meditation. It can be reached in half an hour, and in an hour, and in three. Some masters spend at least 30 hours on the sharpening process! But the result...

Remember how the cinematic Shurik in the short story "Partners", preparing to "cut through" the outside of Fedya wrapped in wallpaper, sharpened a knife and checked it by cutting his own hair on the fly? If you think that this is a joke, then you shouldn't. This is how a perfectly sharpened blade is tested.

When sharpening, you will put more pressure on the grindstone - speed up the process to a minimum and wear the bar to the maximum. Yes, and clog with steel particles torn from the blade.

Use another tried and tested sign when working: "Patience and work will grind everything." In our case, the knife blade will be sharpened in such a way that it will be expensive to both see and use it.

It is hard to imagine professional cooking without good and sharp knives. A set of knives is the main shrine of any chef and this fact is dictated by practice. However, even having collected a small collection of knives for different cases, you do not solve the problem of their sharpness. The subtlety of processing products depends on it, and it is better to maintain it on your own. If your kitchen still has a knife sharpener - urgently send it to the trash because of its complete uselessness and learn to sharpen the knife yourself - you can make sure that this is not difficult.

Grindstone

Today, it can be difficult to buy a good grindstone - they were once sold in any store, but are now quite rare. However, if you still found such a stone, take care of it, because this thing can be inherited. Grinding stones can be of varying degrees of coarseness. The hardest stones are designed for the most aggressive sharpening; for domestic use, a medium grit ceramic bar will suffice. For sharpening large kitchen knives Metal musats are often used, however, we recommend mastering knife sharpening primarily on stones.

factory sharpening

All knives are already factory sharpened and in most cases the user is only required to maintain the sharpness of the cutting edge. In order to do this correctly, you need to understand the angle of the cutting edge of the knife. You need to sharpen the knife trying to observe this angle. Sharpening at a different angle will take much longer and may damage the blade more quickly.

Correct Angle

The knife sharpening range should be within an angle of 10 to 30 degrees. The larger the angle, the faster the knife will need sharpening again. One of the most difficult moments in sharpening knives is maintaining the chosen angle. To achieve progress will help the correct mechanics of movements during sharpening.

Hand movements

To make your sharpening more effective, you should make arcuate movements when touching the blade and stone. Timing this movement and maintaining the angle is the key to success in sharpening a knife. Beginners are advised to put a coin under the back of the blade to maintain the necessary slope.

Water and oil

To achieve a more effective sharpening will help a drop of oil added to the grindstone. Special mineral oil is best suited for this, but olive oil is also quite suitable - its task is to lubricate the blade for better glide. However, many sharpen their knives using only water, occasionally wetting the stone.

Strive for imperfection

Many of those who try to sharpen a knife on their own try to bring the blade to the ideal razor sharpness. Such a blade will easily cut paper, but in the case of products it will quickly become dull and require editing. A rougher and chipped edge of the knife contributes to an additional effect on the fibers of the products, that is, such a knife also acquires the properties of a saw. Coarse sharpening is best for meat, vegetables and most other products, in the case of fish, a fine razor sharpening will be the winner.

In principle, such a formulation of the question is not entirely correct. If we are talking about the “razor sharpness” of a knife, then we should probably talk about the direct finishing of the blade. after sharpening at home. And this is the second stage of bringing the knife into working condition. Here its specificity is worth considering in more detail.

All knives have differences: in the shape of the blade, in its material (there are products, for example, made of ceramics), steel grade (), sharpening angle, and the like. But there are several general rules, adhering to which, you can really make the cutting part unusually sharp.

On a note!

This work is done only by hand. Use of various technical means in the form of a variety of "sharpeners", e / emery will not give the proper result. This is more suitable for the initial sharpening of a knife, when you just need a sharp tool, and not a razor.

What you need to sharpen a knife blade

- Bars with different grain sizes. The minimum is 2, although experienced craftsmen use at least 3 for high-quality sharpening.

- Leather. Moreover, natural, and not its substitute, and quite thick. For example, from an officer's harness or other belt.

- Paste GOI.

- Vaseline (technical).

Basic rules for sharpening a knife to razor sharpness

Sharpening on a bar

During the primary processing of the blade on an abrasive with large grains, the direction of translational movement back and forth. But if the final finishing of the cutting part is made, then the technique changes. The blade moves only forward, and with a sharp edge. During the "reverse stroke" it should not touch the abrasive.

During the primary processing of the blade on an abrasive with large grains, the direction of translational movement back and forth. But if the final finishing of the cutting part is made, then the technique changes. The blade moves only forward, and with a sharp edge. During the "reverse stroke" it should not touch the abrasive.

fine-tuning

Produced in sequence:

On a fine-grained bar

The position of the knife is chosen so that its sharp edge is always perpendicular to the motion vector. It is pointless to sharpen at an angle to the longitudinal axis of the bar, diagonally.

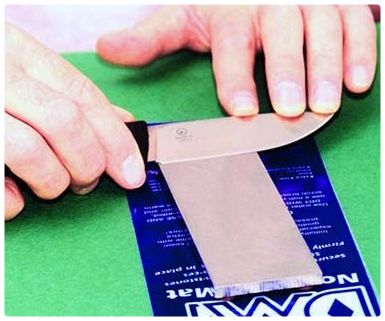

The picture shows the way we usually hold the blade. This is the wrong position.

The picture shows the way we usually hold the blade. This is the wrong position.

Option - to do fine-grained sandpaper or even damp bricks. There are tips that the blade should be moistened with water before processing. You can try, but not the fact that it will help, since the steel grade plays a role.

On the skin

In this case, the position of the blade changes. It is fed forward not with a cutting edge, but with a butt. Moreover, this is done no more than 3 times on one side, after which the position of the blade changes.

To give it the proper sharpness, the skin is pre-treated by GOI. If this remedy (which is common) is a solid substance, then a mixture is prepared on its basis. Powdered GOI is added to the vaseline and constant mixing is carried out. Then the skin is rubbed with this composition (or purchased paste).

Here, perhaps, are all the tricks that allow you to simply bring a sharpened blade into a state of “razor sharpness”. The difficulty is not in some special technology, but in the need to be extremely careful and maintain the sharpening angle unchanged. This is what prevents many from bringing the knife “to mind”.

The author does not claim that this technique is the only true one, since every good owner has his own "professional secrets". But the fact that the result of such sharpening will be excellent is guaranteed.

How to cook ham in the oven at home

Pain in the lower abdomen during pregnancy, reasons for what to do Can the lower abdomen hurt if pregnant

Protein for muscle gain

The best vitamins for men according to customer reviews

How to lose weight on a vegan diet?