Stairs- this is one of the main elements of the interior design of the room, therefore, when designing it, attention should be paid not only to reliability and functionality, but also to the appearance. Before taking on making a wooden staircase with your own hands, it is necessary to take into account a large number of factors on which not only its design, but also its dimensions will depend.

These factors include:

- available room area,

- height,

- maximum load for which the ladder is designed,

- ease of use for people living in the house.

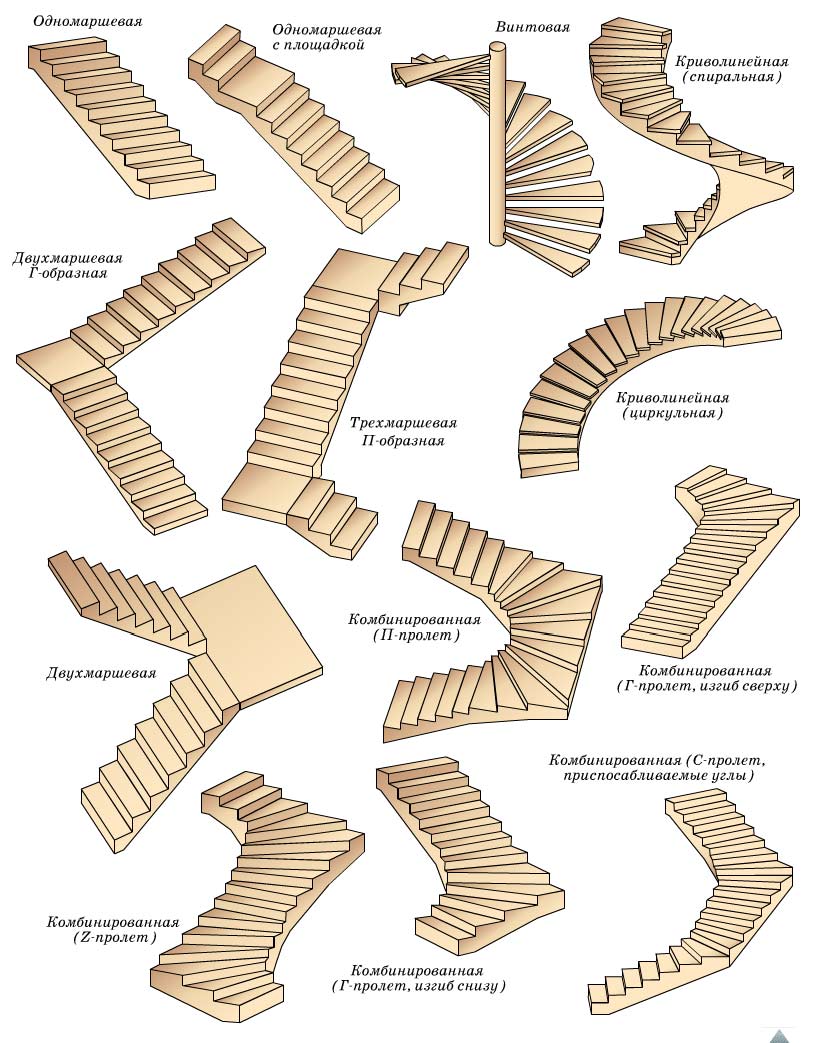

To date, there are a huge number of options for the execution of interfloor stairs, so choosing the right design is a rather difficult task.

Choosing which staircase to build

Stairs marching and spiral. The design of the mid-flight stairs is quite simple and is the best choice, if you plan to make it yourself, however, in order to provide an acceptable slope and height of the steps, a considerable area is required. This ladder is very easy to use and can withstand heavy loads. It can easily lift furniture and other large items to the second floor, in addition, it is safer, so it will be the best choice if children or the elderly live in the house.

The spiral staircase has a more complex device. It is used under conditions limited space when, due to lack of space, it is not possible to ensure a safe slope of an ordinary staircase. The main disadvantages include a not very convenient design, which makes it difficult to lift and does not allow you to carry large items. At the same time, a skillfully executed spiral staircase has sufficient strength and can be the main element of the interior.

Safety above all!

Before proceeding to making stairs with your own hands need to take care of its safety. Firstly, it must be strong and easily withstand a load several times greater than the weight of a person of average build. Secondly, the ladder should be comfortable and ergonomic. In this case, it is necessary to pay great attention to such factors as the height of the steps, the slope of the stairs, as well as the location and shape of the railing. The steps should have a non-slip coating, and the gaps between the balusters should be chosen so that the child cannot squeeze through them and fall.

Design features of stairs

Depending on the method of fastening the steps, marching stairs can be on bowstrings, stringers or bolts.

- Ladders on bowstrings have two side beams to which steps are attached. Such squirrels (strings) can be made of metal or wood. They can be attached to the wall or special supports, providing high strength of the entire structure.

- The steps of the stairs on the stringers are attached to the beams, which are located below and repeat the geometry of the entire structure. Such beams (kosoura) can be straight or curved. Straight stringers, as a rule, have a jagged shape, while the steps are superimposed on the teeth.

- Stairs with a bolt connection of steps are highly durable, so this design does not require additional supports and can be held at two points. The steps are attached to each other with metal rods - bolts, which completely eliminates the creaking caused by the friction of two wooden surfaces.

How to make a staircase with your own hands. Choosing materials

For the manufacture of stairs, softwood is most often used, since it is affordable and easy to process. An oak staircase will be more durable, but the cost of such a design will increase several times, moreover, the processing of this type of wood is a rather laborious task and requires certain skills.

The main steps in the manufacture of stairs

Consider the basic principles of making stairs using the example of a wooden structure on stringers. Before starting the design, it is necessary to understand that any, even minor errors and inaccuracies in the calculations can lead to serious problems that will arise during installation, so each stage should be treated very carefully. Our future staircase will consist of three main elements: steps, handrails and stringers. On the initial stage design needs to be done necessary calculations designs.

Calculation of the width and height of steps

To calculate the size of steps, the formula 2A + B = 64cm is usually used, where A is the width and B is the height. Typical step heights range from 140 to 170mm. We measure the height of the future stairs and divide by the estimated value of the height of the steps.

Suppose it is 240cm, and the desired height of the steps is 17cm. We divide the resulting value by the height of the steps 240/16=15 and round the result to the nearest integer, therefore, our future staircase will consist of 15 steps. Now we determine the exact height of the steps, for this we divide the height of the entire staircase by the number of steps: 240/15 \u003d 16cm. We find the width by the formula, using the height value, we get 24cm. You can also use a table.

The protrusion (part of the step hanging over the riser) should be no more than 3-4 cm. How more height the riser, the narrower the step itself, but its width should not be less than the height. The most optimal step width should correspond to the forty-second shoe size (29-30cm.)

When calculating the stairs, it is also necessary to take into account the distance between the steps and the objects located above them (ceiling, beams, balconies, etc.). It should be at least 1.9-2 meters.

The horizontal size of the stairs is determined as follows: the width of the steps is multiplied by their number, while it should be taken into account that the floor surface serves as the first step, so in our case the calculation will look like this: 13x24=312cm.

If the height of the stairs is large enough, you can make a platform. Such platforms are recommended to be done in 7-8 steps. In the case when it is necessary to design a staircase with a certain number of steps, you can reduce their height in order to make a platform.

Manufacturing of stringers

As a material for the manufacture of stringers, you can use pine board 40mm wide. Make a pattern that exactly repeats the dimensions of the profile of the steps and mark the prepared boards. Then cut out the teeth with a hacksaw or electric jigsaw. In those places where the riser joins the step, it is necessary to cut off the corner. Having made one kosour, you can use it as a template for the rest. Since the strength, safety and durability of the stairs depend on the stringers, you should not save on their quantity, as well as on the quality of the material from which they are made. Boards should be free of knots and any signs of insect activity. Consider a way to attach stringers. To achieve the required strength, as a rule, 3-4 stringers are enough.

Installation of steps and railings making wooden stairs with your own hands

Steps can be attached both directly to the stringers, and with the help of additional wooden elements- filly. Measure and cut out the required number of steps and risers from wood, and do not forget to take into account the ledge. Steps are fastened with nails or self-tapping screws.

The design using triangular fillies is more reliable. The fillies are fastened using dowels, for which grooves are previously made. The most durable construction is obtained using complex-shaped fillies, while a special cutout is made on the stringers. The connection of the elements of the stairs is carried out with the help of glue and self-tapping screws.

After the steps are ready, you can screw the railing balusters to them. In order to protect the tree from the influence of destructive factors (dampness, mold of harmful insects), it is necessary to apply a paint and varnish coating on it.

Making a wooden staircase with your own hands, in principle, is not so difficult. All you need for this is quality wood, essential tool and a little patience. Before starting work, carefully consider all the nuances of the future design and check the preliminary calculations several times.

Hello everybody!

How to get to an object that is at an unattainable height for you? How to collect fruit from the very top of a tree or paint a house? Such questions, most likely, have visited you more than once, it was for these purposes that a special device was invented, which is called Step Ladder.

Stepladders are perhaps the most popular and necessary ladders, they are used in everyday life and in other areas of activity.

This article will describe a method for manufacturing a ladder, with detailed photo report.

For the manufacture of stairs we need:

Materials:

Two beams 60 * 40 mm;

- timber 50 * 35 mm;

- self-tapping screws;

- dye.

Tool:

Hacksaw for wood, or other available cutting tool;

- Sander;

- drill;

- hammer;

- axe;

- mounting.

Let's start with the fact that we take two vertical bowstrings with a beam section of 60 * 40 mm, we take its length at our discretion, in this case the length was 3.6 m.

In order to make the ladder strong and the upper edge of the steps was horizontal when tilted, we make special notches, mark in those places where we plan to install the steps, take the distance between the rungs 30 cm. We use a beam for steps with a section of 50 mm, according to these dimensions we make markings, we apply it on both sides of the bowstring. Next, we note the depth of the notch - 15-20 mm. We connect the received marks with each other with an oblique line, as shown in the photo.

Then, using a sharp ax and a hammer, we remove a piece of wood at an angle, but before that, with a hacksaw, you need to make a recess along the marked line, this is so that the beam does not split in an unnecessary place for us.

We use the ax as a planer, leveling the notch angle.

In a similar way, we make notches on both bowstrings.

Next, using a grinder, we process the surface of the beam.

We need to carefully align the notches we made.

Now paint with paint inner part notches. Set them aside until completely dry.

Next, we take a bar with a section of 50 * 35 mm for steps, it needs to be slightly modified. We take a planer and use it to remove the chamfer. We do the same operation on each bar.

Then you need to make one of the sides of the bars base, for this we take an angular ruler and use a pencil to mark.

When everything is ready, with the help of a cutting tool we saw off all the uneven edges, after that we process the surface with a grinder, smooth the ends.

Now you can proceed to the manufacture of the upper and lower rungs of the stairs. In order to distinguish the top and bottom of the stairs, it must be made with a slight narrowing. The top should be shorter than the bottom. We take the width of the stairs 65 cm from the bottom and 55 from the top. Other sizes can be taken at your discretion. Using a tape measure, mark the length.

With the help of a square, we mark the place where the future step will be cut.

We start cutting.

When the steps are ready, we process the ends with a grinder.

Next, at the edges of the beam we find the center, for this you need to step back from each of the edges by half the thickness of the bowstring (20 mm).

Then, on the marked centers, we make holes for the screws. The self-tapping screw should pass freely into this hole.

We make a countersink using a larger diameter drill for this.

Now install the top and bottom rails by placing and aligning them in the notch. We make the ends of the steps flush with the side parts of the bowstrings. After that, through the existing holes in the steps, we make a mark of the place where it will be necessary to drill a hole. They are needed so that the screws do not split the wood when twisting. The holes were made with a drill 0.2-0.3 less than the thickness of the self-tapping screws.

Now you can fix the step in its place, but before that you should paint the pressure side of the crossbar.

When the stairs are given required dimensions, add the missing steps, for this we lay out the prepared bars in the notches, exposing the base ends flush with the side parts of the bowstrings.

We note the length we need with reverse side bowstrings, draw lines using an angle ruler, then cut off the excess parts, the ends of the steps need to be sanded. We install the steps in the same way as the first two. There should be 11 steps in total.

Now let's move on to painting the product. In order for the paint not to clog the slots of the self-tapping head, they need to be unscrewed a little. We do painting. When everything is ready, screw the screws back.

If, after applying the paint, you notice that the wood has begun to show through in places, then it is worth applying another layer. When the paint is completely dry, this ladder is ready for use.

The article is over, thank you all for your attention.

Modern cottages and private houses suggest the presence of 2 or more floors, and the topmost of them can be both residential and non-residential. Either way, you need a ladder.

Independently make a reliable interfloor or attic stairs from concrete or metal structures is quite difficult, which cannot be said about wood.

Even a novice master can assemble it.

From this article you will learn what types of wooden stairs are, what are their differences, what material is used to make spans. In addition, each of you will be able to make a wooden staircase to the second floor yourself - in the article we will give approximate calculations and photos.

Types and types of structures

There are several species wooden staircase designs

- Marching stairs. Easy to manufacture and convenient to use, but require a large area of the room. The staircase of the march structure can be placed along the wall or mounted in the middle of the room;

- . Usually located in a limited space. Since the capacity of the structure is very small, it is better to move through it one at a time. A spiral staircase (if you build it yourself) will cost much less than other structures, and will last about the same;

- Combined stairs. Can be used in the construction of a private house, if the layout allows. Most often, mid-flight stairs with a screw element are made.

Construction types wooden stairs distinguish the following:

- stairs on the bolts- steps are attached to huge hinged bolts (balusters);

- stairs on bowstrings– a flight of stairs is mounted to a beam with special cutouts on inside butt;

- stairs on kosoura. Kosour - an inclined beam, on top of which steps are attached.

What kind of wood can be used to make stairs

Material selection for depends on the preferences of the owner of the house or apartment, the characteristics of the tree and the cost of it. Various breeds have their advantages and disadvantages:

- Maple. The ladder from this breed will turn out to be the strongest and most durable. Color - light brown. The disadvantage of maple stairs is the high price.

- Larch. The color of the structure is golden yellow or dark yellow with brown streaks. Fine tolerates external influences. The larch staircase will turn out to be strong and solid.

- Oak. The peculiarity of oak stairs is that the older they are, the darker the shade.

- Spruce. The most popular material due to its low cost. Spruce wood has a uniform structure and a light shade.

- Pine. Due to the low density of the wood, it is very easy to process. An additional advantage of pine is low cost material. The disadvantage of a pine staircase is a short service life. A pine ladder is best installed in the country house where it will be used. seasonally.

Pros and cons of wooden stairs

Wooden stairs have their advantages and disadvantages. Let's get acquainted with them in more detail.

Positive sides:

- Low cost of building materials;

- environmental friendliness of wood;

- ease of processing;

- the possibility of mounting with your own hands;

- light weight;

- aesthetic appearance.

Negative sides of wood:

- Low strength compared to concrete or metal stairs;

- wood is a natural material and it tends to deteriorate and change. Therefore, after some time, preventive work may be needed;

- fire hazard of the material.

Materials for the manufacture of stairs

For stairs to the second floor You will need:

For stairs to the second floor You will need:

- Bars for steps;

- beams for risers (foot supports);

- boards;

- beams wide 30 - 40 mm;

- beam for kosour - 50*240mm;

- screws, self-tapping screws;

- wood glue;

- building level, square, tape measure;

- handrails and, but they are best purchased at a hardware store.

Ladder design calculations

If you decide to make a wooden staircase do it yourself, think over the nuances of the design: determine its dimensions, calculate the number of steps and supports. It is important to first imagine what function the staircase will perform: connect the floors or lead up to the attic. (Information about self-insulation attic can be read).

Draw scheme it's easy too. Most often, a straight marching staircase is made. It connects the first floor with the second, and reaches a height of several meters. For convenience, the angle of inclination of the structure should be equal to the value in 30-40 degrees.

Note! Wooden houses shrink significantly in the first two years after construction, so the angle of inclination may change.

So, for your convenience, we will provide basic calculations staircase elements (for example, a wooden one) standard designs:

- Base length - 3.5-4 m;

- flight of stairs - 2.5 m;

- step width - 30 cm;

- step height - 15-20 cm.

Necessary calculations

- We define ladder height. Average value from ceiling to floor - 250 cm. To this value, you need to add the thickness of the interfloor overlap. Its mean value 35 cm. We get:

250+35=285 cm

- We define ladder height. Average value from ceiling to floor - 250 cm. To this value, you need to add the thickness of the interfloor overlap. Its mean value 35 cm. We get:

- calculate number of steps: Divide the height of the stairs by the height of the step. The last value (i.e. the height of the steps) is better to take the average - 17 cm. We get:

285cm/17cm=16.76

- calculate number of steps: Divide the height of the stairs by the height of the step. The last value (i.e. the height of the steps) is better to take the average - 17 cm. We get:

The value is rounded up. Total we get 17 steps.

- define step width. It is believed that the allowable width of the tread (flat facing part of the step) can be in the range from 22-40 cm. In Russian practice, to calculate the width of the step and rise (risers), the formula is used: a + b = 47 cm, where a- riser height b- step width. We get:

47-16.67=30.3cm

- define step width. It is believed that the allowable width of the tread (flat facing part of the step) can be in the range from 22-40 cm. In Russian practice, to calculate the width of the step and rise (risers), the formula is used: a + b = 47 cm, where a- riser height b- step width. We get:

The value is rounded up to 30 cm. - this is the width of the step.

- the width of the flight of stairs must be a multiple of the width of the step. In our case, this value can be equal to 60 cm, 90 cm, 120 cm. etc.

- calculate ladder length. The length of the stairs is equal to the product of the number of steps and their width. We get:

17*30= 480cm

- calculate stringer length. We make calculations according to the Pythagorean theorem: the sum of the squares of the legs is equal to the square of the hypotenuse. That is A²+B²=C². In this formula:

A- kosour height,

V- the length of the flight of stairs,

WITH- the length of the kosour. We get:

230400 + 81225 = 311625

The root of this number is 558.23 cm. can be rounded up to 560 cm.

Advice! If it is difficult to make geometric calculations, then you can draw a staircase on paper in an appropriate scale and measure the angle and length of the base.

Ladder assembly

Before proceeding with the assembly of the stairs to the second floor, you need to decide on place of installation of stringers(bearing structure of the flight of stairs). Installation stairs (in our case, a marching structure) includes several stages:

- Installation of stringers. We fix the lower part of the kosour with a support beam. From above we cut the kosour into the beam of the ceiling.

- grinding stairs, protective coating.

- varnishing and painting. To do this, use a roller or brush. paint over ladder needed in 2-3 layers, each subsequent layer must be applied after some time, so that the previous layer has time to dry.

The cost of the finished staircase

Those who decide to buy ready a wooden ladder or make it order, should be aware that the cost will depend on the complexity of the design and the type of wood.

Those who decide to buy ready a wooden ladder or make it order, should be aware that the cost will depend on the complexity of the design and the type of wood.

For example, the most common design of a mid-flight staircase with a turn to 90 degrees from pine will cost 60-80000 rub., from birch - 100,000 rubles.,from oak - 150,000 rubles.

You can order a wooden staircase in a specialized store or on company websites. Manufacturing stairs on average 5-10 working days.

To make a wooden staircase yourself or order from specialists - it's up to you. Self-assembly not a quick process, but it has its advantages. First of all, this saving cash and visual Quality control building materials.

How to make a wooden staircase with your own hands tells this video.

You can turn to professionals for help, but keep in mind that they may not pay attention to minor defects during construction, which can later lead to serious damage and subsequent repairs. Stairs to the second floor, made by yourself, will give you several advantages:

- the result will meet expectations;

- help save money and nerves;

- a staircase made by yourself will become your pride.

If you are limited in cash for the purchase of materials, you can buy cheaper analogues: instead of wood, use chipboard, which can be varnished or painted.

In the pursuit of economy, quality can be overlooked. Although a cheap wooden staircase can also last quite a long time, it will start to creak very soon. In order not to encounter this trouble, the stairs must be assembled using silicone sealant, which cannot be done without first painting the parts.

In this article, we will talk about how to make a staircase to the second floor with our own hands from wood and metal, and also show photo and video instructions.

For the manufacture of an interfloor staircase, concrete with a tile or marble lining, metal (a welding machine is required), as well as wood can be used. Last option the most practical and convenient. The wooden structure is lightweight, easy to install and beautiful in appearance.

In the presence of a room with a ceiling height of 2.8 m, preference should be given to direct structures, or with a 25% turn of the stairs. The flight of stairs is made with a length of 80 cm. This option allows you to use the space under the stairs for storage. It is impossible not to note the minus: on the upper and lower floors, the free space will be significantly reduced.

To save precious square meters a spiral version of the staircase is ideal, but it is also not without drawbacks:

- too steep climb;

- small width stairs.

To install a spiral staircase, you will need 3 m² of free space and a lot of work.

Another variant of the ladder device is possible, in which it is located along the wall surface. In this case, it is worth considering two marches and a turn. Thus, you will make it as compact and comfortable as possible for movement.

- Calculation of the dimensions of the stairs. Measure the distance between the floors of the first and second floors together with the ceiling. Thus, you determine the height of the structure. The step should have a height of 18-20 cm. Further dividing the height of the stairs by the height of the steps, you will get the total number of steps.

- Projection of dimensions on the floor surface. To design a structure, it is necessary to determine the width of the steps (about 30 cm), after which their number must be multiplied by their width. As a result, you will get the projection size.

- Production of staircase elements. To make a kosour, you will need a 14 × 16 beam, steps - 4 cm boards, risers - 2.5 cm boards. You will determine the length of the steps yourself, remember that the larger it is, the better.

- Pre-sampling. If during the preliminary fitting of the parts everything came up, process each element with a grinder and assemble the structure. To fix the parts of the stairs to each other, coat all the places where they come into contact with each other with glue (PVA or carpentry) and additionally fix it with screws.

- Stain and lacquer finish. First, apply a stain on the surface, and after waiting for it to dry, cover with several layers of varnish.

As design solution you can consider the mortise steps that are inserted into the grooves cut in the stringer:

- Make markings on the stringer at the places where the steps are installed. Using a hacksaw and a chisel, cut out the grooves.

- In the center of the groove, make several holes with a size of 9 mm.

- Screw the turbo coupling into the holes made.

- Install the step into the groove and tighten the bolts.

When buying planed wood, the following requirements must be considered:

- there should be no dark spots on the surface;

- the presence of cracks, chips, roughness and other defects is unacceptable.

Knots (diameter up to 1 cm) can only be present if steps or risers are made from the material. Also pay attention to humidity, the large mass of the board suggests that you should refuse to purchase.

When making a structure without experience, you may encounter certain difficulties, but your desire and desire will help you achieve the desired result.

Now we invite you to familiarize yourself with the technology of manufacturing stairs made of wood. First of all, it is necessary to make drawings with individual structural details. To do this, take a well-dried wood and transfer the appropriate dimensions to it. In doing so, several factors should be taken into account:

- The strength and reliability of the stairs will depend entirely on the correct cutting of the stringers. Therefore, their production must be approached responsibly. Moreover, for the kosour, it is necessary to choose a solid board that does not have large knots in in large numbers. The thickness of the board can be 45–50 mm.

- The board for risers can have a thickness of 15-20 mm more than allotted for them on the stringer, and the thickness of the riser is also taken into account. The treads themselves must have perfect flat surface with neatly rounded edges. The thickness of the board can be in the range of 30–35 mm.

- If you want to make a closed staircase with risers, then their manufacture must also be extremely accurate. Its thickness should not be large, 15-20 mm is enough. In this case, the main load will go to the stringers. The risers themselves play the role of support.

- As for balusters and handrails, it is recommended that they be purchased ready-made with stationary mounts.

If you have small children at home, then for safety reasons, install 2 balusters on each step. In all other cases, you can install one at a time.

When all the blanks of the structure are ready, you can proceed to the most important stage of work - the installation of the stairs. All subsequent work looks like this:

- Stringers are mounted at the selected location. To do this, fix the support beam on the floor, it is on it that the kosour will be attached. At the top, the fastening is carried out in a cut groove in the beam. In some cases, a metal support is used for fastening. In this case, an anchor bolt is used for fastening. During the installation of the kosour, be sure to check everything by level or plumb.

- Before laying the tread sheet, the risers must be screwed on.

- After that, treads are fixed on the stringers and on top of the risers with self-tapping screws in the direction from bottom to top.

- After that, the installation of balusters is carried out.

So, on top of the stairs and below you mount support drains. They will serve as the border of the handrails and also support the railing.

In addition, the support posts serve as a decoration. Therefore, they are often made using wood cutting.

Balusters, in turn, may have different shape, dimensions and methods of fastening. Some, for example, are simply screwed on with self-tapping screws, others are mounted in pre-drilled holes. But in any case, the attachment point must be closed with a decorative plug. Further work is as follows:

- On top of the installed balusters, fasten the railing to the extreme support posts. Additionally, 1 or 2 additional support posts can be installed in the middle.

- When using two, three or more support posts, instead of balusters between the posts, you can install several boards parallel to the slope of the stairs.

- At the next stage, you can start grinding with an emery or grinder. After that, a paint coating is applied.

The first layer acts as an antiseptic against rotting and the appearance of mold / fungus. The design should dry out, after which you can proceed to the main painting.

The stairs are covered with water-based varnish, hot wax or paint. You can also cover the wood with stain, which will slightly darken the structure. Everything depends on your desire.

Thus, the wooden staircase is ready for operation.

Ladder made of metal requires a lot of labor, plus not everyone has the skills to work with a welding machine. And yet, if you are ready to complete the work of such a plan, then you need to prepare such a set of tools:

- Welding machine and electrodes for DC Ø3.2 and 1.6 mm.

- Protective mask of the welder.

- Mittens.

- Bulgarian and cutting discs 125 × 1.6 mm.

- Grinding disc 125 mm.

- Drill and a set of drill bits for metal.

- Metal table.

- Clamp that can be adjusted in height from 0 to 800 mm.

- Vice.

- Pencil.

- Square.

- Roulette.

- Metal paint.

- White Spirit.

- Primer.

With all of this, plus suitable material you can start installation work. As for the selection of material, this can be done according to the completed drawing. We invite you to familiarize yourself with the principle of manufacturing a metal staircase on two stringers.

It is worth noting right away that the whole process consists of the following phased actions:

- Production of blanks.

- Filly making, i.e. step attachment points.

- Corner welding.

- Kosour installation.

- Welding steps and railings.

- Sanding and priming/painting.

All work should be done slowly, strictly adhering to all dimensions of the drawing. Otherwise, any small distortion will be problematic to fix, moreover, it will spoil the appearance of the finished structure. So, the work is carried out as follows:

- From the corners it is necessary to make fasteners for the steps (filly). In relation to each other, they should be mirrored.

- You can make fillies from a corner. To do this, cut out the samples and dock the corners together. The result should be L-shaped blanks with shelves down and inward. Depending on the number of steps, you make a pair of fillies. One of them will be on the left, the other on the right.

- Between each pair of corners, weld brackets for fastening the steps and crossbars. The crossbar is similarly made from a corner.

- To increase the strength, you can install small scarves from the bottom of the step towards the stringer.

- Now take a square profile pipe and make markings on it, or rather, on its edge. On it you can weld fillies to the kosour. Transfer exactly the same markup to another kosour. As a result, it will be possible to achieve the geometry of the entire structure.

If the metal staircase has a width of more than 1.2 m, then you will need to install an additional stringer.

Next, you need to mount the kosour. At the bottom, it is welded to the support platform, and at the top it is fixed to the floor slab or to the wall with anchors. In each case, the method of fastening may differ. Therefore, be guided by the features of your opening. During this process, it is important to stick to the level. Moreover, two stringers must be strictly on the same level. In conclusion, it remains to weld the steps to the fillies. As an option, you can install wooden steps on the filly. But for this you need to use mounting bolts.

The uppermost step should be installed as close as possible to the wall (if the stringers are anchored to the wall). Next, weld the fence. At the same time, install it on the side so as not to reduce the width of the steps.

When arranging the railing, you can use forging or purchase prepared elements. Here again, it all depends on your personal taste and vision of the final result.

When all welding work completed, it's time to grind all the welding joints. It is also necessary to eliminate all burrs and notches. Using a wire brush, sweep away all particles. After that, the surface of the stairs is primed and painted in the desired color.

If the steps are wooden, then their installation is carried out after the paint has dried.

Finally, you can decorate the stairs. For example, trim the steps from the bottom side with wood. Stainless steel railings are also available. Lay out steps ceramic tiles. Due to this, a seemingly careless and bulky design will acquire beautiful outlines and will be an excellent addition to the interior of the house.

Although this whole process may seem easy, working with metal is very tedious. Unlike working with wood, when it is easy to fix defects in case of shortcomings, it is much more problematic with metal. However, the life of the entire structure significantly exceeds its analogue from wood.

If we talk about attractiveness and a bright element of the interior, then competitors to the spiral staircase can hardly be found. With the right construction, it will last for many years. It can be made both from wood and from metal with forging elements. There are 4 main types of spiral staircases:

- Design with wedge-shaped steps, which with a narrow side rest on a supporting central column, and with a wide side on a wall or a fabricated frame. In this case, spiral bowstrings are constructed on stringers.

- A free-standing structure, remote from the walls with cantilevered steps on a monolithic pillar placed in the center.

- Design without a central support column. The steps are supported by curved bowstrings or stringers, which smoothly pass into the railing. This option is very beautiful and sophisticated. However, it is very difficult to manufacture.

- Design with a central support rod (asbestos-cement or steel pipeØ50 mm). This type of ladder is the most common.

As practice shows, the most convenient spiral staircases with a span of 0.8–0.9 m wide. As a result, the diameter of the entire staircase structure will reach up to 2 m, this is taking into account the central support post and railings. If we talk about the shape of the stairs, then it can be round, square, rectangular or oval.

If the traffic intensity in your house is small, then the total diameter of the stairs is enough to make up to 1.5 m. In this case, the treads will have a width of up to 0.6 m.

It is also necessary to consider the ergonomics of the spiral staircase. The principle of the size and height of the steps is the same as on ordinary straight stairs, we have already talked about such measurements above. But there are some features, namely a comfortable lifting height for a person. For example, we suggest you consider the option of a spiral staircase, 3 m high and 0.8 m march wide.

The calculations are presented below:

- The total diameter of the stairs with such dimensions is equal to twice the width of the march, and the thickness of the support post is 20 cm. As a result, we get the following - D = 0.8 × 2 + 0.20 = 1.8 m.

- The lifting radius is equal to half the width of the flight of stairs and support: Rn \u003d 0.4 + 0.1 \u003d 0.5 cm.

- Now dividing the length of the trajectory of movement by the depth of the tread, we can determine the number of steps in one turn: L = 2 π: 200 = 2 × 3.14 × 500: 200 = 17.2. As a result, there can be 17 steps in one turn of the flight of stairs.

- It is also necessary to calculate the ergonomic step height. This must be done from the point of view that a person in full growth can move freely. Take for example a height of 1.8 m, add operational 20 to this value and divide by the number of steps in one turn. As a result, it turns out like this: h \u003d 2000: 17 \u003d 120 mm.

If the spiral staircase has a height of 3 m, then to determine the number of steps, perform the following steps n \u003d 3000: 120 \u003d 25. The result is 25 steps, 12 cm high.

In order for the spiral staircase to be durable and easy to use, it is important to observe the following rules:

- On a spiral staircase, it is better not to install risers. This will increase the safety of the structure, and the foot will rest well on the step and not slip off the step in a narrow place.

- If the height of the passage is 2 m, then even tall man can move comfortably up the stairs.

- To install the support stand, choose a place that will support the weight of the entire structure and 2-3 people.

For steps, it is best to choose a durable wood, such as oak or beech. Although it is much easier to buy ready-made steps. For example, you buy a step rectangular shape, and cut out the necessary configuration from it. The thickness of the product can be 40mm or 30mm. If one step is divided diagonally, then the result will be two steps at once. The edges of the workpiece must be rounded and sanded with a grinder. Then you can cover them with varnish or paint. A special sleeve should be fixed on the step, which will hold it on the support post.

Anyone who decides to build a house with at least two floors will definitely face the problem of making stairs. You can, of course, buy a ready-made kit, but this is a rather expensive way to solve the problem. The services of professional masters are even more expensive. To get a really decent option, you will have to pay an amount commensurate with the cost of a part of the house. Therefore, most self-taught builders decide to build an interfloor structure on their own.

An inexperienced craftsman should not try to build a complex structure, the manufacture and installation of which is expensive and material-intensive. But a simpler option, for example, a straight wooden staircase without risers will be possible even for an amateur.

Of course, in order for the product to turn out to be of high quality, and the construction was not very expensive, you first need to figure out what types of stairs are and the basic principles of their assembly. And also to purchase materials and tools. And now everything is in order.

Choosing material and design

Wood is considered the easiest material to process. And if you follow the elementary rules, then the ladder will last a very long time.

What kind of wood to use

Beech. There is wood with light grayish or reddish-yellow hues. The tree has a weak structure, mediocre strength and is subject to external factors. For example, beech is sensitive to fluctuations in humidity and even expands at high values. Therefore, beech stairs should be placed inside well-heated rooms. The competitiveness of this variety is explained low price;

Spruce. The low cost makes spruce a very popular raw material. The texture of the wood is uniform, has a light color. Spruce is not affected by external factors;

Oak. Solid wood with beautiful pattern light yellow. It is believed that solid oak stairs are the strongest and most durable, which, of course, affects the cost: it is one of the highest in the segment;

Larch has a golden or dark yellow tint with light brown streaks. The material is remarkably durable. The breed is resistant to mechanical stress and aging: it is not afraid of rot or moisture. The cost is above average.

Ash It has a light shade and a characteristic fiber structure. Making stairs from this type of wood is a pleasure: ash is easily processed and bent, and strength exceeds oak. The influence of external factors is minimal;

Maple has increased strength, which is due to the absence of pores. Wood does not absorb moisture, which allows you to place products on the street. However, because of this, wood processing protective compounds causes a lot of difficulties. The output is durable, reliable and very expensive stairs made of solid wood.

Preparation of components

We make a list of everything you need. To assemble a wooden staircase, you will need the following parts and assemblies:

- steps; it is possible to choose them in the size that is needed specifically for your project, and thereby simplify further work, we take a step 1 meter wide;

- galvanized corner for fastening steps;

- self-tapping screws 40 mm;

- string for stairs; since we have one span, we need 2 pieces, keep in mind that this is the largest part of the structure, so it’s better to buy it in the nearest store;

- other components: balusters, handrails, pillars;

- materials for wood processing: varnish and stain.

A set for a wooden marching staircase will cost a relatively small amount, approximately 10 thousand rubles.

Anyone who has the appropriate tools and skills will save a lot by making all the necessary elements on their own. If there are no tools and there is not enough experience, then accessories for stairs can be purchased at any building market.

How to make calculations and drawing

First of all, it is necessary to make a calculation of the stairs - to determine the number of steps and their dimensions. It is equally important to correctly calculate the dimensions of the stairwell. If you want the product to be comfortable and safe, the calculations must be made in the most careful way.

Video: how to calculate a staircase made of wood

To make it easier for you to find all dimensions, use simple drawings. It is very important to have an idea of how the finished product will look like and how it will fit into the interior design. And only after careful design, proceed to construction.

Wooden stairs on bowstrings look very neat due to the fact that the ends of the steps do not look out, but are covered by a supporting element.

Making a wooden staircase with your own hands

The manufacturing technology is quite simple. The most important thing is to fit all the details well to each other so that there are no gaps. Thus, the design will turn out to be rigid and will not creak. The most time-consuming operation is cutting the bowstring. The better the cut is made, the smoother the flight of stairs will turn out.

Making a bowstring

To make a bowstring, you have to sweat a lot. The bowstring is quite massive: 60 by 300 mm in cross section, so it will be difficult to cut it manually. To make even cuts, use the guide bar, which must be pressed against the previously marked saw line, as shown in the photo. With a certain skill and patience, the cuts are quite even. To avoid skewing the steps, the bowstrings should be as uniform as possible. It is recommended that you first make one, and then mark and cut the second one along it. Each stair string is sanded and set in place.

To perform cuts, you should get a sharpened hacksaw with fine teeth, otherwise, there is a chance to hopelessly ruin the bowstring. The cuts that will face the floor can be made with a two-handed saw. Small chips must be carefully sanded. With apparent complexity, it is quite possible to make a bowstring on your own.

Step fixing

The assembly of the stairs begins with the marking of the steps. In accordance with the calculations and the drawing, we outline the places for installing the steps. Be sure to use a level to check the horizontal lines. To avoid mistakes, first mark the place where the steps are attached to one bowstring. Then install the stage and check the level. Only after that mark the step on the other bowstring. It is not worth fixing the steps right away, otherwise, in case of an error, the holes from the self-tapping screws may be in the most noticeable place.

Mark the places for the steps in the manner described above, starting from the bottom and going up to the very top of the flight of stairs. Check if the last step is at the same height as the others. If necessary, make adjustments to the markup. After making sure that the ladder is marked correctly, proceed to attaching the steps to the bowstring.

We mount the corners on the drawn lines with the help of self-tapping screws and install steps on them, which we also fix with self-tapping screws from below. Practice shows that for each metal corner for a step, at least 4 self-tapping screws are required. And in order for the staircase to never creak, it is better to increase their number. So we made a flight of stairs.

We install the railing

To properly install the railing, you need to take seriously the process of preparing the balusters. They must be sawn off at exactly the same angle, which is quite difficult to do manually, because there are already 12 of them. There is a high probability of error. Therefore, you should use special machine, which is capable of sawing a beam of small thickness at a given angle.

As an alternative, you can buy a set of ready-made stainless steel railings, the installation of which is extremely simple and comes down to assembling the prepared parts.

We fasten the pole to the floor with hardware. This is quite enough, but if you want, you can additionally screw it to the bowstring. A groove is first made in the column, into which the end of the bowstring is inserted.

The question often arises of how to correctly install the balusters on the bowstring and attach the wooden handrail. As a rule, dowels are used for this, which are coated with glue. It is also possible to cut steel rods with a diameter of 5 mm and a length of at least 8 cm from ordinary nails. The effect will be the same.

In the bowstring, balusters (on both sides) and in the handrail, it is necessary to drill recesses with a diameter slightly smaller than the diameter of the rods. Then the structure is mounted on pins and fixed with self-tapping screws.

The next stage of installation is the installation of handrails. Attach the lower end to a pole, the upper end to a wall or again to a pole. Remember that the main load falls on these places, so you need to fix it soundly.

We can say that the work ends here. It remains only to apply a protective coating. depends on several factors, such as the location of the product, its purpose, patency and other performance characteristics.

- In conclusion, it must be added that wooden stairs for the house, first of all, should be comfortable. The most comfortable is the height of the step up to 22 cm, the depth is not less than 25 cm, but not more than 40 cm. These dimensions must be selected so that the upper step coincides in level with the floor of the second floor;

- If a flight of stairs ends with a door, then a platform must be provided, the width of which is sufficient so that this door can be freely opened;

- Even for the sake of saving space, one should not make the flight of stairs too steep, because, first of all, the structures must be safe.

Chicken in kefir - recipes for marinated, stewed and baked poultry for every taste!

Simple Chicken Recipe in English (Fried) Recipes in English with translation

Chicken hearts with potatoes: cooking recipes How to cook delicious chicken hearts with potatoes

Recipes for dough and fillings for jellied pies with mushrooms

Stuffed eggplant with chicken and mushrooms baked in the oven with cheese crust Cooking eggplant stuffed with chicken