The online store site offers manual and electric tile cutters for cutting porcelain tiles. On sale model trademarks DIAM, FUBAG, Husqvarna, KRISTAL and NUOVA BATTIPAV for construction teams, stone shops, domestic use.

Porcelain stoneware is a material of high strength and hardness. If the volume of work is large, it is necessary to cut thin strips, cut plates of considerable thickness, it is recommended to use equipment with an electric drive. Hand tool designed for small jobs.

In electric tile cutters for porcelain stoneware, the cutting part is a diamond disc. Models vary in power, length working area, the diameter of the disc and the mounting hole, as well as the location of the cutting block - lower or upper. The equipment is equipped with water supply systems to the working area and provides a smooth, accurate cut, including at an angle of up to 45 degrees.

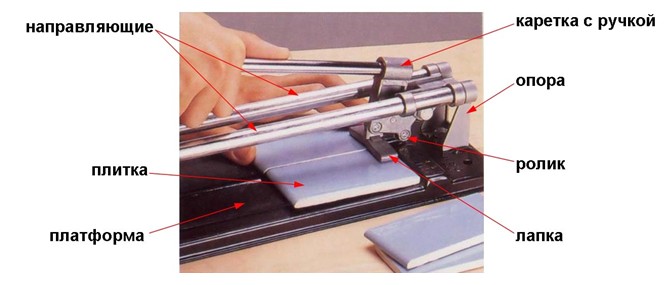

Manual tile cutters for porcelain stoneware work without noise and dust. The cutting part is a carriage with a roller made of superhard alloy, which moves along a monorail guide. In one pass, the equipment makes an incision of a given depth, along which the tile is subsequently broken.

The courier service of the store site delivers stone-working equipment in Moscow and the region. For orders over 10 thousand rubles, delivery within 10 km from the Moscow Ring Road is free. Goods are sent to buyers from the regions transport companies. You can also pick up the tool in person from our warehouse in Mytishchi.

Today, ceramic tile is a very common finishing material, as it has practicality, aesthetic appearance and durability. To lay it, you need to have certain skills and special tools, for example, a tile cutter. This is the simplest, and at the same time the most necessary fixture working with ceramic tiles. When choosing a tile cutter, a lot depends on the characteristics of the tile, so you first need to buy a tile, and then a tool for cutting it. So how do you choose the right tile cutter? In this article, we will try to figure it out.

Tile cutter - design, features

A tile cutter is a special tool that is used to cut all types of tiles - stone, tile, porcelain stoneware, etc. With this tool, you can make a high-quality cut of a tile, and you can get a cut line not only at a right angle, but also vary the angle up to 45 degrees.

The design of a modern tile cutter consists of a cutting element, a goniometer, a floating base and one guide. The main part in the tile cutter is the cutting wheel, which is mainly made of carbide steel.

A distinctive feature of all tile cutters is the ability to cut both ceramic facing and floor tiles.

Agree, it is difficult to cut porcelain stoneware with an ordinary grinder, and the cutting quality is not always very good. The tile cutter for porcelain stoneware is able to cut porcelain stoneware without any problems qualitatively and relatively quickly.

Five criteria for choosing a tile cutter

When choosing a tile cutter, regardless of which one constructive option was chosen, the tool must have 5 main criteria:

- Absence of marriage and other external defects. When choosing a tool, you need to visually inspect it, check the build quality and the condition of the materials. After that, you should start the machine, check the quality of the engine, work table, adjustment and if there are any additional vibrations.

- Engine power. When choosing a tile cutter, you should take into account the amount of work, the thickness and hardness of the material being processed and select the motor of the required power.

- Ability to cut material at an angle. Adjusting the angle must be quick and easy, and the angle must be accurately maintained without errors.

- Diamond disk. He is the "weapon" of the tile cutter. It is important to know the quality, purpose and type of disc that is present on the device.

- Availability of spare parts. Nothing lasts forever, therefore this criterion is relevant mainly to all tools, but for a tile cutter it is doubly relevant, since it is not so easy to find spare, necessary parts.

Which tile cutter to choose - manual or electric

Manual tile cutters - characteristics, advantages, what to look for when choosing it

The manual tile cutter is the easiest and most convenient to use. Its robust design allows for precise straight line cutting of tiles. It is used for tiles with a thickness of no more than 1.5 centimeters, and for cutting 8 mm wall tiles, a special tile cutter up to 40 centimeters long is used.

Manual lash cutters by design are:

- roller;

- mechanical;

- on bearings.

Roller tile cutter is quite simple in design, the cutting element is precisely a roller made of hard alloy.

Mechanical tile cutter has a rigid carriage, which allows you to cut the material with particular accuracy, including tiles of a fairly hard type.

Tile cutter on bearings designed for processing extra strong tiles up to 16 mm thick. This tool has a very soft running ability, as there are bushings on 2 bearings.

When choosing a manual tile cutter, you should pay attention to the strength of the frame, the length of the tool and the smoothness of the move.

The base of this tool must be rigid to avoid shock absorption during tile cutting. The stronger the handle of the tile cutter, the more powerfully you can press on the lever. It is better not to buy a tile cutter that is too small, but to purchase a universal model that is suitable for both floor and wall tiles.

The main part of the tile cutters are equipped with bearings for smooth sliding. There are, of course, models without bearings. In this case, during the selection, you need to make sure the quality of the sliding of the working fluid.

Advantages of manual tile cutters:

- Electricity independence. Compared to electric tile cutters, this is a significant savings. In addition, manual tile cutters can be used in all weather conditions, even with air humidity up to 90%.

- Small sizes. For their operation, it is not necessary to remove additional room or part of it, a small area of \u200b\u200bthe floor or table is enough.

- Ability to move from place to place. Because of his not heavy weight(0.2 - 9 kg) they are very comfortable and practical.

When carrying out large volumes of work, it is best to use an electric tile cutter. Unlike manual tile cutters, electric cuts tiles much more accurately, faster and with less waste. The tile may burst during cutting due to the rise in temperature, so electric tile cutters are equipped with water and air cooling systems.

The water-cooled tile cutter treats the tile with care, is able to make cuts accurately, evenly without splinters. The liquid, which is in the tank under the engine, must be supplied to the cutting zone forcibly and with supply adjustment.

During operation, it does not overheat and does not fail due to the constant supply of water during operation.

Advantages of electric tile cutters:

- The ability to cut at an angle of 45 degrees, which is important when laying wall corners.

- Precise, without rough edges, incision

- Minimum time spent on work - less than a minute of time is spent on one tile

- Easy, comfortable cutting of both porcelain stoneware and stone.

There are two types of electric water tile cutter:

- with the bottom position of the engine;

- with top engine.

The under-engine cutting tool is very compact, can work in small spaces and is able to cut tiles of almost all sizes. For more accurate and convenient cutting, tile cutters are used, in which the engine is located at the top.

At the time of selection electric tile cutter you should pay attention to the following parameters:

- Notch depth. It should vary between 3 - 4 cm.

- Notch length. It should be within 50 cm.

- Engine power. This indicator should be selected depending on the purpose of the tool and the type of tile.

- Cutter diameter. Mostly cutters with a diameter of 18-20 cm are used.

Cutting tiles with a tile cutter

Before starting work, it is necessary to wear special safety glasses and headphones to protect sensitive organs from fragments and excessive noise from the tile cutter.

Make sure the wheel is secure and does not move from side to side, as this can cause an uneven cut. You also need to check its degree of wear, if there is a need for replacement, then it is better to purchase a new wheel.

If a manual tile cutter is used, some oil should be applied to the guide frame of the tool before use.

To make a high-quality cut with a tile cutter, first you need to draw a cutting line with a marker on the tile. Then you need to lay the tile on the base of the tool, fixing it securely to avoid vibration. Then, in one quick movement, run the knife along the entire length of the finishing material. The cut is carried out on front side material. It is best to move the cutting material with two hands in order to make a uniform cut and avoid the formation of splinters.

During the touch of the tile and the tile cutter knife, the pressure force should be minimal. Do not press hard on the tile, as this may cause it to split. Further, it must be gradually increased, decreasing towards the end of the tile. If cutting is being done for the first time, then it is best to stock up on a few tiles in order to practice.

The tile cutter has sponges made of metal. They are used to separate two pieces of an already cut tile. With these sponges, you should gently press the tile on both sides, it should separate with a slight click.

If necessary, the cut edge of the tile can be trimmed sandpaper or grinding stone.

Tile cutter brand

The RUBI tile cutter is able to quickly and most importantly cut all types of tiles smoothly. tiles and porcelain stoneware.

Benefits of rubi tile cutter:

- There are one-piece, steel guides. They guarantee excellent cutting quality and a long service life.

- The most efficient and comfortable bushing systems are used. This eliminates the use of bearings that can wear out and break.

- The tile cutters are made of very durable aluminium, making this tool both lightweight and durable.

The Matrix tile cutter is used to cut tiles up to 1.4 cm thick and 30-60 cm long. This tile cutter has only 1 guide rail that wraps around the carrier carriage on both sides. It moves with the help of a ball bearing mechanism.

The matrix tile cutter has a special rail coating and alloy that provide a secure grip between the rail and the ball mechanism.

The KORVET tile cutter is used for cutting tiles both at a right, oblique angle, and for combined angles.

The tile cutter of this brand is of two types: an automatic saw and a tile cutter with a manual mechanism. The tile cutting machine can work in multifunctional mode, able to determine the diameter of the tile and the correctness of its fixing by CNC.

While working with a construction tool such as a tile cutter, you must follow some rules to eliminate the possibility of injury.

The fragments that form during operation can damage the eyes, so safety goggles should be used. Do not bring your hands too close to the cutting tool. If used electrical equipment, then you have to be extra careful.

Electric tile cutters do not tolerate high humidity. It is important not to overload the tile cutter by trying to cut very fast or very thick tiles. Through this, the engine can overheat or crack the tile.

Particular close attention should be paid to the electrical cable - it should not interfere underfoot, twist or bend.

Tile is by far one of the most common finishing materials. For proper placement, use whole line tools, one of which is a tile cutter, without which laying tiles is simply impossible. This article will discuss the main characteristics that a manual tile cutter has: price, design differences, as well as the rules for handling the tool.

Manual type tile cutters are used not only for cutting tiles, but also for working with other materials (for example, glass or stone). The choice of one or another type of such a device primarily depends on the purpose.

Nuances of preparation various types surfaces. How to grout seams on tiles. Criterias of choice tiled flooring for the floor.

Electric tile cutters for porcelain stoneware operate on the principle of a "wet" cut. In turn, a “dry” cut is not suitable for working with this wear-resistant material. Of course, you can use a mechanical hand tool, but this is accompanied by some difficulties. For example, such models cannot cut off a piece of this material if its width is less than 3 cm. Because of this, the edges of the tile material will have to be processed by grinding.

There are other problems of a manual device that arise when working with porcelain stoneware:

- problematic fault clearly along the cut line;

- inability to cut diagonally;

- inability to use when crossing obstacles.

Porcelain stoneware cutting is carried out using the "wet" method

Electric models do a much better job when working with porcelain stoneware. They not only exclude dusting of the room, but also contribute to more accurate cuts of this material.

Manual tile cutter: price and overview of popular models

To date, there are several of the most popular devices that are distinguished by high performance, convenience and reliability. Among them there are both manual mechanical and manual electronic models.

The best manual tile cutters that function through mechanics:

- STAYER 3310-48;

- ZUBR EXPERT 33195-60;

- RUBI STAR-60-N.

The most popular manual models that operate on electrical energy include:

- STANLEY STSP125-B9;

- STURM TC-9811.

Note! Mechanical manual devices are perfect for working with tiles under normal conditions (when repairing an apartment). Electronic, in turn, are less common and even rarely used by experienced professionals. However, in some situations, their use is the only possible option.

Tile cutter from each brand has its own advantages and disadvantages. Therefore, to select the right product, it is recommended to carefully study the characteristics of each tile cutting device. The prices of manual professional tile cutters are quite high, but such devices are much more reliable and have a long service life.

Features of STAYER manual tile cutter

Manual tile cutters STAYER 3310-48 are manufactured by a German company in China. The peculiarity of this model is that it is excellent for performing curly cut. The size of such a device is 42 cm, which limits its capabilities. However, tile cutters of this brand are distinguished by the best indicators of functionality and low cost. The cutting depth of the STAYER is 16 mm, which is more than enough for normal finishing work.

This model has an additional element that allows you to make round holes in the tile - a "ballerina". Hole diameter varies from 30 to 80 mm. Also, STAYER 3310-48 is equipped with guide elements, which are necessary to perform a diagonal cut.

On sale, there are often devices from this company that do not meet the declared quality. Therefore, when buying a STAYER 3310-48 model, you need to pay attention not to purchase a defective fixture.

The advantage of buying this model is obvious if you find out how much the STAYER 3310-48 tile cutter costs. The average price of such devices is approximately 1750 rubles, which is very profitable from a financial point of view.

Manual tile cutter ZUBR EXPERT

Tile cutters of this domestic manufacturer are highly popular, as they are the best value for money. In comparison with more famous brands that produce these products, the ZUBR EXPERT 33195-60 device costs an order of magnitude cheaper.

BISON EXPERT has a length of 60 cm, which allows it to be used for cutting long tiles. Also, its design takes into account the use of a built-in ruler, which eliminates the need for preliminary marking.

The cutting depth of such a device reaches 30 mm, which is very high rate. ZUBR EXPERT 33195-60 is equipped with a carriage on bearings and has a comfortable handle. And also thanks to such a mechanical tile cutter, it is possible to cut the tile material at an angle.

Of the shortcomings of this model, only one can be noted, namely: the presence of a backlash (gap) in the roller. Such a minus can affect the accuracy of the cut. The cost of the domestic device ZUBR EXPERT is approximately 3350 rubles.

RUBI STAR manual tile cutter: model features

RUBI tile cutters are manufactured by a well-known Spanish company, and are famous for their best quality. The RUBI STAR-60-N model is one of the best examples of this manufacturer. In most cases, these tile cutters are used by professional tilers.

Helpful information! The base of the RUBI manual tile cutter is distinguished by good strength characteristics and high rigidity. And well-fixed guide elements exclude the possibility of free movement of the cutter when cutting. Thanks to this, the cut almost always turns out to be perfectly even.

The RUBI STAR-60-N has a set of interchangeable bits for different types tiles. Their thickness varies from 6 to 10 mm. It is also worth mentioning that this model is equipped with special plastic wings for additional fixation of tiles.

Of the shortcomings, only one can be noted - a rather small depth of cut, which is a maximum of 12 mm. The average cost of a RUBI tile cutter is 7,500 rubles.

Electric manual tile cutter STANLEY

The device is manufactured by a US company. The main difference between the STANLEY STSP125-B9 tile cutter is its low weight. The engine of this unit is slightly more powerful than the competition, which is a small plus.

Separately, it should be said that the STANLEY STSP125-B9 electronic model has a large cutting depth (41 mm). Thanks to this, it becomes possible to work not only with conventional facing materials, but also with rather massive slabs.

STANLEY STSP125-B9 can be used in both dry and wet cutting conditions. The price of such professional electronic devices averages 3500 rubles.

Electronic manual tile cutter STURM

The STURM models are manufactured by a Chinese company and feature better functionality than the competition. Model STURM TC-9811 is a very compact device, which greatly increases its versatility and operational scope.

The main feature of the tool is that it is equipped with a system that cools the disk by means of water supply. Due to this, the possibility of overheating of the tile and its damage is excluded. The cut made by such a tile cutter is almost perfect.

Among other advantages of the TC-9811, it can be noted that its device allows you to make cuts at an angle of 45 °. And also it can be found and non-standard application (as a strobe apparatus). Additional equipment for this electronic tile cutter includes a second diamond blade and spare brushes. The average cost of the device is approximately 2600 rubles.

A device for cutting tiles can be purchased at a specialized store, a construction hypermarket, or ordered on the Internet. In the latter case, there is the possibility of buying defective products, so it is recommended to be careful and not order tile cutters from dubious sites.

How to choose a manual tile cutter? There is a range important factors Things to Consider When Choosing a Cutting Machine facing materials. Let's consider each of them in more detail.

Appearance. The visual component is important when choosing a tile cutter. Special attention must be paid to the base, which must be of high quality and durable. Its thickness should be sufficient for the convenience of working with the device.

Helpful information! When choosing a tile cutter, it is worth examining the lever and guide elements. For example, when cutting porcelain stoneware, great efforts are required, so the tile cutter in this case must have a long handle.

The length of the working area of the tile cutter. When choosing a tile cutter, it is necessary to take into account the length of the diagonal of the tile with which to work. It is desirable that the length of the working area is not less than the diagonal of the facing unit.

Carriage travel along guide elements. During operation of the carriage, its movement must be smooth. In no case should it get stuck when moving or sway due to play. Bearings can be included in its design, which is a definite plus.

Cutting roller. The roller should not have play, and its movements should be smooth. In the event of failure, the replacement of this element should not be accompanied by difficulties.

How to choose a tile cutter depending on the purpose? If you need a device to work reusable, then you should think about purchasing a manual professional tile cutter. Buying such a device is not difficult, and it can last more than one year. For a one-time use, a less expensive model made in China is suitable. And for trimming 1-2 tiles, you can even take an amateur model in the form of a pencil or wire cutters.

There are many materials on the Internet that will help answer the question of which manual tile cutter is better to buy. Reviews on relevant websites will also help you decide on the choice of tool.

How to use a manual tile cutter

In order to answer the question of how to work with a manual tile cutter, it is necessary to study in detail the algorithm of actions. Consider the process of cutting tiles in stages:

- First of all, you need to determine the size of the trim. In this case, it is very important to take into account the gaps near the wall and the seams.

- Guided by previously determined measurements, you need to place ceramic tiles on the frame cutting device.

- Next, you need to fit and align the tiles along special lines.

- While holding the tile, it is necessary to draw a cutting element along the cut line.

- At the end, you need to lower the legs of the separator on the handle and press (with force) on the lever.

Knowing how to cut tiles with a manual tile cutter and performing all of the above steps in the right sequence, cutting the material will happen without difficulty. In this way, trimmings up to 1 cm wide can be made.

A tile cutter is a functional construction tool that can greatly simplify the work of laying ceramic tiles. For more effective work with the device, it is recommended to familiarize yourself with various instructions on the topic of how to work with manual tile cutters. Videos on this topic can also be easily found on the Internet.

How to cut tiles with a manual tile cutter: video

When you bought porcelain tiles, the question arises before you: which tile cutter for porcelain tiles to choose?

There are several types of ceramic tiles on the market, you can choose from matte, polished, waxed for sanitary areas or glazed.

Technical characteristics - high strength, low water absorption and stable, not prone to abrasion, pattern - made porcelain stoneware much more popular than its counterpart - tiles.

If there is practically no difference in the process of laying and cutting tiles and ceramic tiles, then cutting porcelain stoneware is significantly different.

Tile - a light and fragile material - it is quite possible to cut it with a glass cutter. Porcelain stoneware is a dense and durable material, so a special tool is used for it - a tile cutter.

To make it easier for you to decide which one to choose, we will consider the procedure for working with a manual tile cutter and electrical option, we will tell you how to cut porcelain stoneware with each of them.

The most important advantages of a manual tile cutter are low cost and the ability to cut in rooms where there is no or unstable power supply.

Most often it is used to prepare tiles for laying in small volumes, for example, in the sanitary rooms of a private house.

Externally, a manual tile cutter for cutting porcelain stoneware is similar to a conventional glass cutter - a rigid base, on it there are two guides, between which a holder with a fixed carbide wheel moves.

The work with a manual tile cutter is as follows - a line of the future cut is applied with a pencil, porcelain stoneware is fixed on the basis of the tile cutter so that the roller passes exactly along the drawn line, raise the handle of the device and start cutting by pressing the handle and moving the roller from one edge to the other.

To keep the edge of the cut tile smooth, try to cut in one motion. Edge roughness resulting from several cuts can be further corrected.

On porcelain stoneware, an incision is obtained along which a chip will occur. Raise the handle of the tile cutter, fix the paws in the middle of the cut and gently, with even force, press on the handle.

The fracture of porcelain stoneware will be made clearly according to the applied canvas. If all actions are carried out correctly and with the necessary effort, then the cut will be even.

If any flaws are found, the cut surface can be polished with a disc on a stone mounted on a grinder.

Before using the manual tile cutter for the first time and after long work you need to make sure that the holder moves smoothly along the guides, the handle rises and falls easily.

Before starting work, make sure that the roller is firmly fixed. Otherwise, tighten it by tightening the fixing bolts.

If the movement of the roller or the movement of the holder is difficult, then you can drop oil on them. A roller with significant wear must be replaced, otherwise the insufficiently deep canvas will not provide an accurate break.

Make some test cuts. If they turn out to be even, then you can start cutting porcelain stoneware.

There are a lot of models of manual tile cutters, most of them have similar functions.

Most often, a tile cut is used in a straight line, but in some models it is possible to cut at an angle or cut holes.

A manual tile cutter is perfect if you have a small amount of porcelain stoneware (for example, only in the bathroom). In this case, you can not overpay and not buy an electric one.

When it is planned to lay porcelain stoneware on the floor and walls of a private house or in office space, then the purchase of an electric tile cutter is justified.

Electric tile cutter

The electric tile cutter has a simple device - the cutting process in it is implemented by an electric drive.

Electric flat cutters can be divided into three groups - dry cutters, wet cutters and industrial tools for waterjet cutting porcelain stoneware.

The third group, due to its large weight, large dimensions and high price, is not used in private construction. The cut quality of such tile cutters is no different from the factory one.

In addition, they implement the functions of a software cut along any contour.

If you want to do without a tile cutter at all or, on the contrary, cut out figures on porcelain stoneware, then you can place an order at a company that provides industrial cutting services.

Which tool to choose? An electric tile cutter of the “dry cutter” type is an ordinary grinder, with a “diamond” coated disk installed on it. The disc is solid and has no slots.

When cutting with this type of electric tile cutter, it is important to move the line 1-2 mm to the greater side. Make a cut by directing the grinder towards you. Chips and irregularities with this cutting method are inevitable.

They are easy to grind with the same grinder, but with a grinding stone installed.

Try to cut the slab in one motion. Cut slowly, with equal pressure on the tool. This will ensure fewer chips.

Dry cutting has a number of significant disadvantages. The most important is the technological complexity of the process and high risks of self-injury.

Excessive pressure on the disk in the presence of a marriage in it can lead to a fracture of the disk at the time of cutting and scattering of fragments. It is important to observe safety precautions.

Since in the process of work it will scatter a large number of dust of different fractions, it is necessary to work in glasses with a protective coating that protects against splitting.

An important nuance of working with a dry cutter is to start and finish the cut at low speeds. A sharp increase in the number of revolutions can crack the porcelain stoneware.

In the process of cutting, press the slab firmly against the base of the tile cutter. This will help dampen the inevitable vibrations that result from the movement of the cutting device.

Affordable, this electric tile cutter has a significant technological drawback - the need for an additional work cycle for grinding cuts.

In home construction, this increases the finishing time, and in the case of a hired team, it leads to an increase in the cost of services.

An electric tile cutter, in which the function of minimizing cut chips is implemented, is called a wet cutter.

As well as a manual flat cutter, an electric one consists of a base, on which, in fact, the material is cut, and an electric drive, from which the cutting wheel is powered.

Porcelain stoneware is pressed against the base, and the guides fix the cutting wheel.

The device can be used for a long work cycle, in which the work surfaces would inevitably overheat.

To minimize excessive heating of parts and porcelain stoneware, the electric tile cutter is equipped with a water-cooling function.

In some models, water enters directly to the disk, while in others, the cutting itself occurs when the material and the cutting device are partially immersed in water.

The cuts obtained in this way are much more even and smooth and do not need additional polishing.

Such a device is suitable for cutting all types of tiles, but it is necessary to select your own wet cutting disc for each type.

More expensive models electric tile cutters can be equipped with additional devices for cutting at an angle.

They will find application if a design renovation is planned, and the lines of the porcelain stoneware masonry will not be parallel to the lines of the floor and ceiling.

When you have to choose an electric tile cutter, then pay attention not only to the feature set, but also to the manufacturer.

A tool that is significantly cheaper than its counterparts will almost certainly have some flaws.

There are no complex parts in an electric tile cutter, but there are technological requirements for rigidity.

The material of the parts responsible for the rigidity of the fastening of the cutting mechanism may not correspond to the loads and undergo stretching.

Therefore, before buying an electric tile cutter, take a look at whether it is possible to tighten the fixing bolts or replace the moving head.

If in doubt, then opt for a more expensive similar tool.

As you can see, there is nothing difficult in choosing a tile cutter and using it for porcelain stoneware. Now you can cut materials with both manual and electric devices.

Chocolate biscuit: the secrets of cooking in a slow cooker and oven

Chemical composition and nutritional value

Apple chips at home

Braised cabbage with white beans, recipe

How to reduce the ass, hips and stomach at home?