The weight of the pipe is seamless. Table. 4.58 /5 (91.67%) voted 24

The weight of the pipe is seamless. Table.

Seamless steel pipe It is made by several methods, namely: rolling, drawing, forging and pressing. This type of pipe has a one-piece construction and does not have butt joints along its entire length. There are two types seamless pipes:hot-rolled (hot-formed) GOST 8732-78, are made from billets or ingots under high temperature, using one of the four methods (listed above) and cold-rolled (cold-formed) GOST 8734-78, their manufacturing method differs from hot-rolled by lower temperatures. With cold-rolled production, the finished product has a higher quality and material accuracy.

The use of this pipe can be different from mechanical engineering to utilities. Most often, a seamless type of pipe, due to its strength characteristics, is used where high reliability and durability are required (gas, oil pipelines). This type of pipe is economically beneficial, as it has an affordable price on the world market.

Seamless pipes they produce measured, random and multiple measures of length, their length can range from 4 to 12 meters, in some cases these sizes are neglected.

Depending on the wall thickness, seamless pipes are divided into thin-walled and thick-walled. They are expressed as outside diameter pipe to its wall thickness. If this coefficient lies in the range from 6 to 12.5, then such a pipe is considered thick-walled, and if from 12.5 to 40, then thin-walled.

It happens that this coefficient is less than 6, such a pipe is called "especially thick-walled".

The weight of the pipe is seamless. Table.

For calculation weight of 1 linear meter of seamless pipe you can use

If you need to find out the weight of a running meter of a pipe, fittings or other rolled products, then the most convenient and simple solution is our metal calculator.

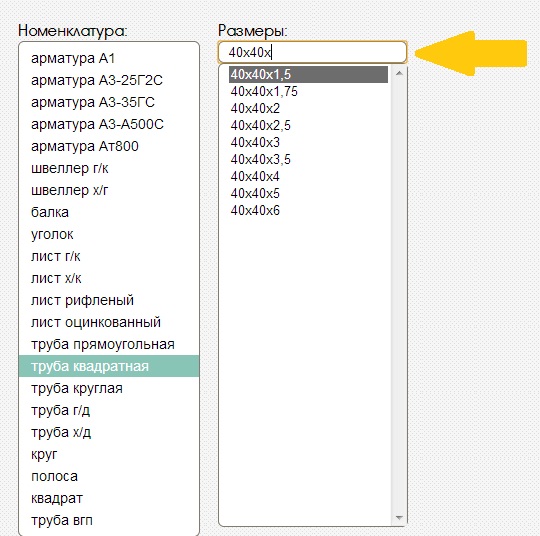

First you choose the nomenclature for which you want to calculate meters to tons.

Next, you choose the size of the product.

For the convenience of using the calculator, we have developed an interactive search bar that will facilitate the selection of product sizes.

If it is round steel, then the list contains diameters (rebar 10.12, etc., circle).

If you want to know the weight of the pipe, then pay attention to the wall thickness.

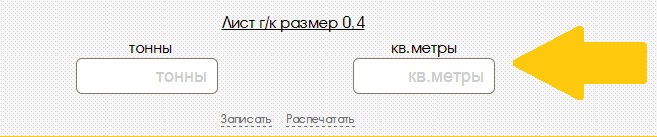

To find out the weight of the sheet, you need to select the thickness, and then the calculation of the mass will take place per square meters.

Then data in meters or tons is entered in one of the fields

If you enter values in the "meters" field ("square meters" to find out the weight of the sheet), then you will find out the total mass of the entire length (for example, the weight of the reinforcement).

If you are interested in calculating the length by weight, then you need to enter data in the “tons” field.

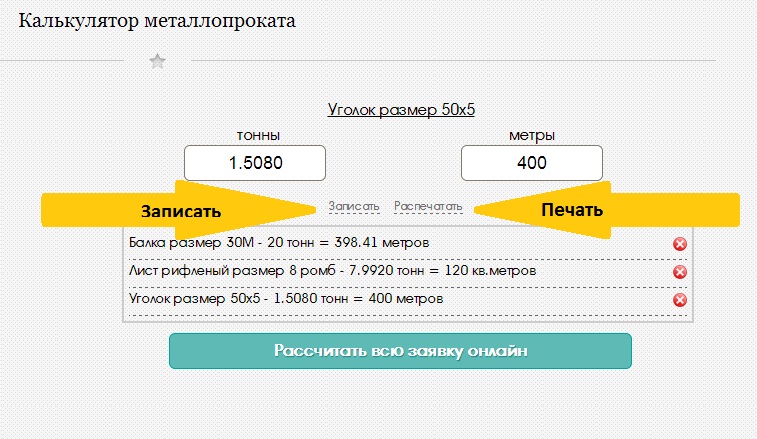

You can record and print your results

Our calculator allows you to record the received calculations in a special field so that you can easily see your latest calculations. To do this, you need to click on the "Record" button, and the result of your calculations will appear in a special field.

Also, after you have calculated all the necessary data, you can click on the "Print" button and get a printout of the results in a convenient form.

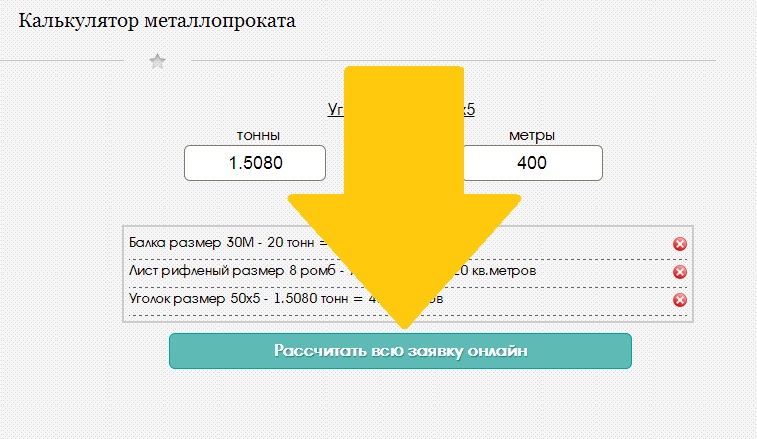

You can compare prices for selected items from all suppliers.

To do this, you need to write down your calculations. Please note that in the field with the recorded results there are positions that are of interest to you. Next, click "Calculate the entire application online", and the system will take you to a page where the results of processing suppliers' prices will be shown.

When we calculate the amount required material for building or creating communications, we use a standard measurement system and a unit - a meter. But in one case it is necessary to calculate the square meter, in the other - linear. How not to make a mistake and make the right measurements for buying, for example, pipes?

To begin with, it is worth deciding on the concept of a running meter. Everything is simple here, a running meter of a pipe is its length. Moreover, without a diameter or indication of other parameters. The length of the pipe can be completely different depending on the material and manufacturer, and in repair or installation work a certain measured element is required.

How to correctly calculate the required amount of pipe

When a pipe is bought in the construction department, it is cut according to the specified parameters, so in this case the expression about the sevenfold measurement will be most welcome. How to measure the required number of linear meters, for example, polypropylene pipes for a replacement in a standard bathroom? Understanding the calculation technology, you can later use it when buying other similar products.

First you need to measure the total length of the pipe. Here you will need a more flexible measuring tape or a tin tape measure made of thin material. It is necessary to measure not only straight elements, but also curved ones. If it is difficult to measure everything at once or the design involves many bends and plexuses, you can do it in parts, and in the end add all the resulting numbers.

"More is better, yes better." This also applies to purchases. building materials. Especially polymer pipes. If necessary, the excess part can always be cut off with a pipe cutter or special scissors, but the initially taken small size will have to be sharpened and combined using the necessary connecting elements.

So, when it comes to linear meters, it is better to add 10% of the total length at once. Moreover, taking into account the cost of pipes, this will not amount to huge expenses, but it can save you from re-visiting the store and protracted installation.

The area of pipes is calculated with additional parameters. Namely, the area will be equal to the number Pi times two and the radius with the length of this pipe. Therefore, even to calculate the area, it is necessary to know the length of the pipe that can be measured.

Conclusion

Linear meter pipes are conventional unit measuring the length of the material, it is easy to calculate it using a conventional measuring tape. Different pipes have different lengths.

If during the construction process it is required to erect a metal structure, then a correct strength calculation is necessary. This is a prerequisite for the durability of the erected object.

Is it important to calculate the mass of pipes or not?

To know at what distance to put metal supports that do not allow sagging of the line. When calculating the mass of the pipeline, the following parameters are taken into account: the mass of the pipe; the weight of the liquid being transported.

When you have to build metal for a building, you have to do the calculations. Calculating the weight of metal is a responsible task. People, equipment, other contents of the premises and the steel frame press on the foundation of the structure with supports. The last element for the mass of the building is the main one. For the construction of floors, a pipe with a two-tee beam or channel is used. These metal parts are of high strength.

Calculation of metal structures

Project documentation necessarily includes the calculation of metal structures for strength. It is represented by drawings, assembly diagrams and other related documents. To make the structure durable, professional specialists determine the configuration and characteristics of metal structures. Properly calculate the mass steel frame only engineers can. They take into account factors that can affect the value of a building. Employees of the company where you contact will select materials from the right size and a technology for connecting nodes that is suitable for the project: using bolts or welding.

The calculation of the strength of metal structures is indispensable for determining the reliability of the structure in the future. Metal structures are divided into the following types:

- agricultural;

- industrial;

- construction;

- lungs;

- heavy.

To calculate the correct strength, interface, product dimensions, load and cross section are required. Calculation of pipelines for strength is carried out by professionals using special programs. The use of online "helpers" allows you to get accurate results.

If we consider static loads simultaneously with dynamic ones, then the first ones are considered constant. They have another name "gravitational": their action is directed vertically. As for the dynamic ones, their character is changeable. Strength increases and decreases. The place to apply the load varies. This includes hail, rain, snow, wind, temperature fluctuations.

Thanks to specifications the maximum possible value of the force acting on the construction object is determined. Next, the force is multiplied by the safety factor. However, the use of such a formula is limited only in the case when there are no vibration loads.

For calculations, the method of limit states is used. Load bearing capacity metal structures - this is the first limit of states. Structures resist external influences. They may change.

When planning an object, a construction company evaluates individual elements for strength. In this case, an increase in corrosion is added. This value is the safety factor. It allows you to accurately determine what the effect of rust on metal parts will be. To make complex corrosion protection effective, the features of steel and the operating conditions of the construction site are taken into account:

- temperature regime;

- humidity level;

- pressure;

- the presence of an aggressive environment.

The calculation of metal structures must be entrusted to professionals: only in this case it is possible to adjust the strength and increase the service life of the object.

Calculation of the mass of a round pipe

How to calculate the number of pipes when purchasing?

Today on the Internet it is easy to find special online programs that remove the question from the agenda: “How to calculate?” If the project is drawn up correctly, then the purchase of materials should be carried out taking into account the calculated values. For example, for building metal structure or a pipeline, the owner of the future facility will have to purchase pipes - 1,200 meters. The value of the wall thickness of the products should be 4 millimeters, and the outer diameter should be 100 mm. Here the buyer faces a problem. The wholesale lot is sold exclusively by tonnage. The question arises: "How to calculate the mass?"

It is required to convert from tons to meters; this will help you quickly make a free online pipe calculator.

On the website of the manufacturer, consumers of products make various calculations, depending on the project being implemented:

- Determine the weight for a profile, electric-welded steel pipe with different form– round, square or rectangular;

- Calculate the weight of a pipe made not of steel, but of other metals;

- Enter the pipe length in m.

At the same time, the density of the material remains unchanged at 7.850 kg/m3. But this value is only suitable exclusively for steel. The calculation of the weight of the metal by size is made after entering the required material and grade, pressing the button with the image of the desired rolled product, entering the dimensions of the sides in mm. In addition to weight, length is calculated.

You can calculate the mass of the pipe yourself. This requires knowledge of geometry. The multiplication operation is performed using an offline calculator. It is important to have an idea of how to find mass from volume. A special formula applies: Mass equals density times volume.

To a person who is far from construction works and does not know how to calculate the volume of a pipe, special online calculators will help. They allow you to calculate the volume of liquid inside the pipeline. For heating, you will need to additionally add volumes of batteries and a boiler. Such information is available in the passport. The results of the calculations are the total V, the surface area of the pipes and the volume per 1 linear meter. Using an online calculator is a handy way to figure out what a running meter is. Calculations will be useful in the future. When it is planned to paint the pipeline, it is better to know in advance how much paint is needed. To perform calculations, you will need to specify the diameter: internal and external, the length of the pipeline. The parameters are indicated in mm. The formula allows you to calculate the volume of the pipe: V \u003d ∏ * R1 * R1 * L. R1 means the inner radius, and L is the length of the product. The surface area is calculated using the following formula: P=2*∏*R2*L, where R2 is the outer radius.

Calculator-informer, if desired, is installed on the client's website. This version of the functionality is practically no different from the large version. The client program is smaller. Therefore, it does not require much space. The calculator is installed on the site panel on the left or right side. The customer allocates an independent page for the program on his Internet resource, if he needs it.

When the calculator-informer does not work, the problem is easy to deal with. Press F5 or the keyboard shortcut Ctrl+F5. You can also clear the browser cache of temporary files or enable support for Java Script.

Performing Pipe Weight Calculations Based on Shape

The formula for finding the weight helps to determine the cost of the project as a whole. For pipes various shapes You will need to perform various arithmetic operations. Mass formulas vary. There is no universal option applicable to all situations.

Calculate the mass of a round pipe

The calculation of mass for products with a circular cross section is done as follows:

- Calculate the circumference. To do this, multiply pi and outside diameter pipes;

- Determine the surface area of a linear meter of pipe. Multiply the circumference by the linear meter;

- Calculate the volume of liquid that is available in one linear meter. Multiply the area and wall thickness;

- Calculate the mass of one linear meter for the pipe. How to calculate running meter? You need the exact value of the density of the material from which the product is made. Multiply the density by the volume to get the mass per meter.

- Multiply the mass per meter by the length of the pipeline. We get the value in meters.

With the help of an online calculator, the results of actions on the monitor appear in a matter of seconds. You enter the required data and press the "Calculate" button. After a second, the result appears. Using the online calculator is not difficult for novice users.

Calculate the mass of a square pipe

Calculate the mass of several pipes in a bundle

A product with a square section makes its own adjustments to the calculation algorithms:

- Calculate the perimeter of the section for the pipe. Multiply the wall value of the product by 4;

- Calculate the area per meter. The length of the perimeter is multiplied by 1 m. The result is a number showing how many linear meters are in a square meter;

- Find out what is contained in one linear meter. Multiply the surface area of 1 linear meter and the value of the wall thickness of the product;

- Multiply the resulting volume by the steel density value, if the mass is determined steel pipe;

- Find the weight of the pipe. Multiply the mass of 1 linear meter and the footage.

We calculate the mass of a rectangular pipe

The difference with previous calculations is also present here:

- The perimeter of a section is the sum of the sides multiplied by 2;

- To get the surface area of a running meter, multiply the product's perimeter by one;

- The value of the volume of a substance is calculated using the following action - by multiplying the surface area and wall thickness;

- Calculate the mass of one running meter. Multiply the resulting volume by the density of the steel;

- Multiply the result of the calculation in kg by the length of the pipeline. The resulting number is the total weight of the product.

Using the geometric method is not as convenient as using an online calculator. This is a cumbersome method. Metallurgists use specialized formulas. They are used to calculate the mass of pipes with given dimensions. However, the results are different from the previous ones. When referring to GOSTs, differences with the results of the calculations become obvious. Conclusion: it is better to purchase pipes for construction, based on figures from generally recognized standards, which are the norm when it is important for the customer that there are enough materials. Focus on the minimum value from the calculations, when buying an additional pipe will not be a problem.

If you figured out how to find the mass, knowing the weight, then it will not be difficult for you to determine how much material you need. This will allow you to calculate future costs. If you know how many pipes will be needed for construction, it is easy to determine how much the project will cost.

The range of water and gas pipes is often needed for online calculation of the weight of pipes of water and gas pipeline systems during construction, laying communications, laying water pipes, gas pipelines. A full range of pipes is used in the installation of heating systems and the execution of pipeline parts, in external drinking water supply networks.

GOST 3262-62 for plumbing and gas pipes allows the production of pipe products without threads at the ends or with threads, while the length of black pipes without threads ranges from 4 to 12 m, and black and galvanized pipes with threads - from 4 to 8 m.

Steel water pipes GOST 3262-75 of increased manufacturing accuracy is used for parts of water and gas pipeline structures.

When welding pipelines, in the case when water and gas pipes are used, manual welding or a socket connection is used. Couplings are used for VGP pipes with normal wall thickness, welding is possible in all cases: light, conventional, reinforced VGP types.

The range of steel pipes for water and gas pipelines of ordinary accuracy allows the manufacture of steel according to GOST 380 and GOST 1050 without standardizing mechanical properties and chemical composition. The most popular range of pipes - black pipe rolling, is used for water supply, gas pipelines and heating systems. High-precision VGP pipes are made from steels according to GOST 1050. The range of galvanized pipes is used for parts of water and gas pipeline structures with high requirements for durability and corrosion resistance.

Round pipe is a type of metal-roll assortment, which is produced by electric welding. The technology for the production of rolled pipes consists in the fact that steel sheet blanks from strips (steel sheet in rolls) go through the process of unwinding and straightening on rolls, cut to the size of a given length and width, after which the edges of the strips are processed by chamfering. Next, the strips are butt-welded, the sheet blanks are fed into the accumulator for supplying material to the forming mill, where they are profiled into a round pipe of the required diameter. The wall thickness of the pipe (thin-walled, thick-walled) depends on the thickness of the sheet strip. At the next stage, a longitudinal seam is welded (either in a straight line or in a spiral) by melting the edges of the metal with high-frequency currents, closing them into an integral connection to obtain solid metal over the entire cross section of a round pipe. At the final stage technological process deburring the finished product and electrowelded pipe cooled, calibrated to meet the diameters of GOST within the tolerances and cut into the required size along the length.

Correspondence inches to the nominal diameter of the pipe DN

1 inch = 2.54 cm

Quarter of an inch - 8 mm; half an inch - 15 mm; three quarters of an inch - 20 mm; inch - 25 mm; an inch and a quarter - 32 mm; one and a half inches - 40 mm; two inches - 50 mm; two and a half inches - 65 mm; 4 inches - 100 mm.

This ratio between inches and millimeters greatly simplifies the selection of imported pipeline fittings for Ukrainian pipes, but it is important to understand here that such dimensions are also suitable for domestic bends, transitions, water taps, gas valves. Imported couplings, valves, bends, tees, spurs (and now imported stainless pipeline fittings are often used) have real inch dimensions, which are somewhat different from the connecting dimensions of VGP pipes.

Table of pipe diameters - How many kilograms (kg) in one meter (m) of pipe

|

Diameter mm - inch |

Outer |

Lungs | Ordinary | Reinforced | ||||||

| Wall thickness s, mm | Weight 1m, kg | Meters per ton | Wall thickness s, mm | Weight 1m, kg | Meters per ton | Wall thickness s, mm |

Weight, kg/m |

Meters per ton | ||

|

8 - 1\4 |

||||||||||

|

15 - 1\2 |

||||||||||

|

20 - 3\4 |

||||||||||

|

25 - 1 |

||||||||||

|

32 - 1 1\4 |

||||||||||

|

40 - 1 1\2 |

||||||||||

|

50 - 2 |

||||||||||

|

65 - 2 1\2 |

||||||||||

|

100 - 4 |

||||||||||

| 46,2 | ||||||||||

The weight of a running meter of a steel pipe in the table is the theoretical mass. Actual value may vary by 4-8%

To convert meters to kilograms of pipe, you need to multiply the weight of a running meter in the assortment table by the total length of the pipe.

Standard designation of pipe diameter in the assortment (see table):

- The inner diameter is the main dimensional characteristic of pipes and fittings (fittings) to them.

- The outer diameter of the pipes (in the table - dn). Steel pipe rolling is classified precisely according to the outer diameter: small pipe sizes - 5-102 mm; medium sizes - 102 - 406 mm; large sizes 426 mm and more.

- The nominal diameter of the pipe (in the table - Dy, Du) is the nominal size inner diameter in millimeters or its rounded value in inches.

- Nominal diameter (in the table Dn, Dn)

- Wall thickness, mm (in table S).

Maximum deviations in the mass of pipes in the table of diameters and weight data should not exceed + 8%

How much does 1m of steel pipe weigh? Weight calculation

If there is no table of pipes, then the calculation of the mass of 1 linear meter can be performed using the calculation formula on a conventional calculator and find out how many kg are in a meter of pipe:Calculation of the weight of stainless steel pipe: m = Pi*(d - s)*s*R/1000

The formula for calculating the weight of the "black" pipe: m = (d - s)*s/40.55

where:

m- theoretical mass of one linear meter of pipe (specific gravity) in kg,

Pi= 3.14 (constant value in our calculation),

d- outer diameter in mm,

s- wall thickness in mm,

R- specific gravity of steel in g / cu. cm.

Weight 1 m VGP pipes in the assortment is calculated with a specific weight of steel equal to 7.85 g/cm3. Galvanized steel pipe is 3% heavier than non-galvanized steel. To automate the process of calculating pipes, you can use online calculator pipes (round, VGP, seamless, electric-welded), presented in the section of the website "Metal range". In this pipe metal calculator, you can select the material from which the pipe is made, for a more accurate calculation of the weight.

Steel pipes, depending on their parameters and cross-sectional dimensions: diameter and wall thickness, have different sphere Applications:

• installation of heating systems, laying of water communications, gas pipelines, installation of sewerage, water disposal and gas supply;

• manufacturing and construction of fences and fences, protection electrical cables from damage;

• transportation of substances under pressure over long distances: oil, chemicals and gas;

• production of wells, casing strings in mining;

• manufacturing and installation of simple and complex metal structures of buildings and structures;

• distribution of tap water, technical water supply in irrigation systems;

• production of furniture frames;

• exploration and development of oil and gas fields, etc.

Conventional designation of pipes according to GOST 3262-75

Examples of symbols:

Ordinary steel pipe, non-galvanized, of the usual manufacturing accuracy, random length, with a nominal bore of 20 mm, a wall thickness of 2.8 mm, without thread and without a coupling: water pipe 20x2.8 GOST 3262-75.

Designation example: M-20x2.8 pipe GOST 3262-75 - with a coupling.

Symbol: R-20x2.8-4000 pipe GOST 3262-75 - measured length, threaded.

Steel water and gas pipes for knurling are marked: in symbol the letter H is indicated, the letter D is indicated in the marking of the VGP with a long thread.

For steel pipe products of increased manufacturing accuracy, the letter P is indicated after the size of the nominal bore in the symbol.

Water and gas pipes pass 100% non-destructive eddy current testing, they are supplied with a hydrotest guarantee.

Technical requirements of GOST

In accordance with the requirements of the standard, depending on the type, the pipes must withstand the hydraulic pressure of the following value:

Ordinary and light - are subjected to an internal hydrostatic pressure of 2.4 MPa (25 kgf / cm2);

Reinforced - the action of hydrostatic pressure of 3.1 MPa (32 kgf / cm2).

Pipe steel grades

Pipes are made from steels according to DSTU 2561 (GOST 380), parts of water and gas pipeline structures are made from steels corresponding to GOST 1050.

Chocolate biscuit: the secrets of cooking in a slow cooker and oven

Chemical composition and nutritional value

Apple chips at home

Braised cabbage with white beans, recipe

How to reduce the ass, hips and stomach at home?