Perhaps the most sought-after device for your car is a tire inflation compressor. Also, many people use it to inflate boats, balls and other things. In general, the thing is not something that is needed, but simply necessary, especially on long journeys. BUT here's the problem, now there is just a huge amount on the market various types and types, ranging from the most simple and compact, ending with powerful and almost professional options. Which one is better and which one to choose, so as not to miscalculate and overpay, let's figure it out ...

Former compressors were only hand or foot, that is, they used the physical strength of a person. Now the people are spoiled and no longer want to “pump up” with arms and legs, because there are electrical models. BUT not everything, as they say, are the same, and often the price tag goes into the abnormal zone (5 - 6000 rubles), here you will think ten times before you buy. Today I will give you some tips on how to sort out this chaos and still choose a normal compressor.

Hand-foot options

I'll start with them because they were really the first. There are only two types:

- Manual option . Very simple and easy to repair. In the hollow cylinder, a piston moves, which pumps air into the tires. Now practically not used, it was popular in the 70s - 90s of the last century. However, even now one can meet

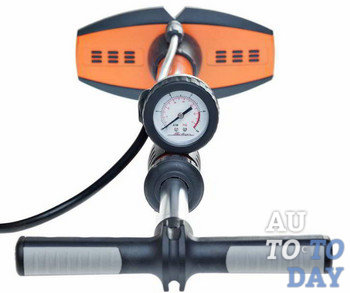

- . Probably everyone saw it, some even have it in stock (by the way, I have one). Here we just press the foot on a special “pedal”, air is pumped. A big plus is also its spaciousness, compactness, the presence of a pressure gauge.

Both pumps don't use energy (work on physical strength) and you can pump up the tires even on a dead battery or you don't need to start the engine. They are also CHEAP, which is also an added bonus.

I'll say this - manual version left just because he was big, and it was not always convenient to carry it in the trunk. But the foot-operated version is still on sale, and it can be a VERY good alternative to the newfangled electric compressors.

Electric compressors - start

To begin with, I want to say that there is a very large “run-up”, both characteristics and performances (we will definitely talk about this below). There are cheap Chinese devices, there are more efficient ones, and there are professional ones.

And you know what - I watched a bunch of videos on the Internet on this topic. And not one plainly tells - how to choose! There is stupid - "how much it can pump", "what body", "what pressure it holds." BUT is it possible that a person “unsavvy” in the question will come, and will really ask all this? OF COURSE NOT! He will choose with his heart, ruble and sometimes logic. So I will build my story based on this.

Diaphragm Compressor

Often these are the cheapest devices. As a rule, they are inexpensive, you can easily find up to 1000 rubles. They are compact and can be removed anywhere (I saw a video on the Internet that some types even fit in the glove compartment).

The principle of operation is based on the vibration of the membrane (which is made of high-strength material), with the help of a special drive, it goes up and down, thus pressurizing. The drive is based on plastic parts and an electric motor (the design is far from standard). The case is made of plastic (the only metal part is the motor).

The cons of the membrane compressor are more than the pros. YES, and often they are made by our "Chinese comrades" whose quality frankly pumps up:

- Not as productive, typically 3 to 10 liters per minute

- It can work with pressure up to 3-4ATM, it does not digest more pressure.

- If the membrane breaks, then it will not really work. And often it is very difficult and expensive to replace it, the cost comes to the price of a new unit.

- Low knot strength. Break down quickly

- Usually there is nothing really in the sets, not even bags

- Cannot be used for extended periods

Personally, I have had several of these. I bought the first one myself (out of inexperience), not even inflating tires often, it worked for me for about six months, then failed. I took it apart - the membrane broke. The second - the third, they gave me and won at the gas station. The one that won broke down after three weeks (there wasn’t even a company on it, only a brand of gas station and that’s all), which they gave also worked for about six months (maybe more and died).

What I noticed is that they do not work well in the cold, and it was after such “pumps” that they failed. As I think, the membrane does not tolerate frost well.

I DO NOT RECOMMEND YOU TO TAKE A MEMBRANE TYPE! Still, their reliability is at a low level, despite the low price.

How to recognize them - ask the seller (the most easy way), or look at the case, they are often made in plastic (flat case), less often in a plastic vertical case. They cost from 500 to 1000, less often about 1500 rubles (although I saw such ones for 400 in one large supermarket).

This option is the best. However, here again there is a big gap. There are small and compact options, medium, and there are the largest and most productive. As a result, prices vary widely.

How they are arranged - in fact, this is the same “foot type”, only the drive comes from an electric motor. It pushes the piston inside, which walks in the cylinder, thereby building up pressure. The piston itself (and its drive) must be made of very quality metal usually made of alloy steel. BUT cheap manufacturers often neglect this.

ANOTHER IMPORTANT POINT is the body of the working cylinder - it must be metal! IT IS IMPORTANT! Personally, I have seen cheap options with a plastic case, this will not work for a long time

What parameters still need to be looked at:

- Performance . It is usually measured in "liters per hour". If you have a passenger car with a wheel diameter of 12-13-14-15-16 inches, 10 liters may well be enough. But if your wheels are large, say from 17 and above, and even wide, it is better to look for a more productive model that pumps from 20 and above (I personally have 50l). No, OF COURSE, the smallest compressor will pump up the big wheel, BUT it will get very hot (which can affect its resource), and it will take a VERY long time to pump up, so it’s worth overpaying 300-500 rubles and taking a more powerful one.

- Pressure. As I already wrote, membranes hold at best 3-4ATM (atmosphere). But the "piston" ones can hold 20 ATM each. But I will say this - for an ordinary layman you don’t need so much (even 10ATM will be for your eyes), because the pressure in the wheel is often about 2-3ATM.

- Power type. There are those that are connected to the cigarette lighter, and there are those that are connected to the battery through special clamps. Everything is simple here - those that are connected to the cigarette lighter are not so productive (but once again I emphasize often sufficient). that connect to battery terminals, have a large power (therefore, their connection to the cigarette lighter is not possible)

- To prevent it from burning out, many manufacturers install an overheat protection system. That is, if it works for a long time and reaches the maximum heating, it will simply stop and stop working.

- Frame. Here everyone chooses what they need, I personally need a compact compressor, that's why I took this one.

- Type of connection to the wheel. There is just a cap, that is, you simply put it on a nipple, and there are twisted ones (that is, threaded connection). Personally, I am for threading, because it sits more firmly on the nipple and does not hang out.

![]()

- Pressure gauge. Personally, I am more familiar with ATM (atmospheres) than, say, PSI, so it’s worth taking it with such a dial, or with a combined one.

- Some manufacturers make bags or cases for their pumps, this is a big plus, it will not collect dust. Also, some have various nozzles for inflating boats, balls and other things.

- Fuse. It is desirable that it be changed quickly and without problems; personally, my compressor has it in the cigarette lighter socket.

- Guarantee. This is a really important question. If the manufacturer is serious, he gives at least 3 years. And this is how I consider the necessary minimum, if it is given less, say only 1 year, then it is not worth watching.

About the manufacturer and brand

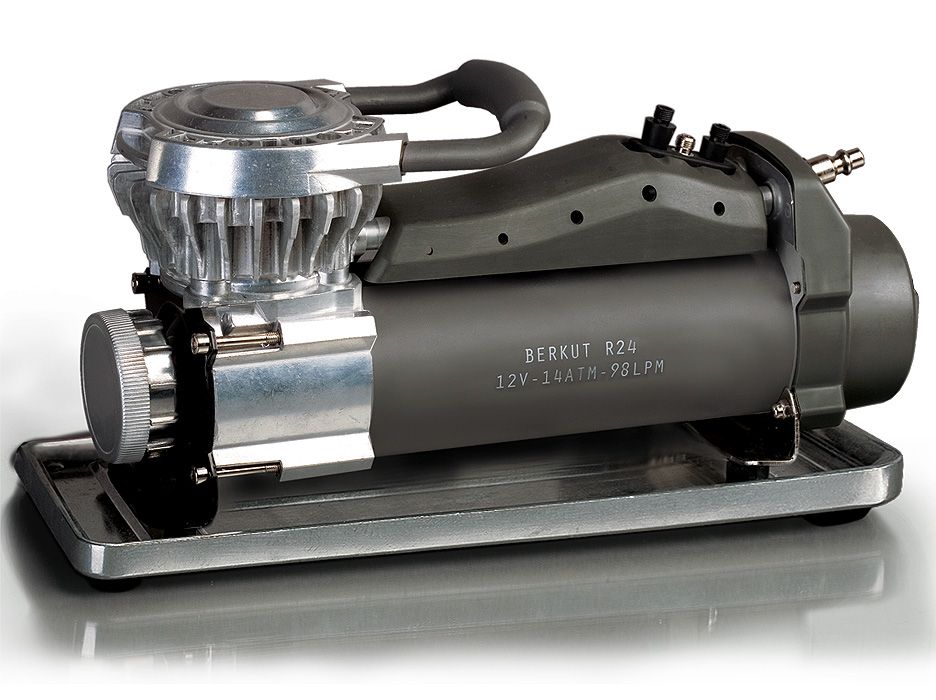

Separately, I wanted to talk about the brand. Personally, I have a DAEWOO compressor (my wife just gave it to me because of a good kit), now there are many more different companies, BERKUT, Aggressor, VIMPEL, etc., you can find about 30 - 50 different brands on the Internet (not counting "Wild China").

Which to choose? I won’t advise you on one, yet there are many worthy and really good even domestic brands. Most importantly, DO NOT TAKE "UNDERGROUND CHINA", take manufacturers who are "well-known", who have a good warranty, high-quality assembly (you will understand when you pick it up) and warranty support in your city (so as not to go to a neighboring city).

For an average driver, you need a piston, with a good kit (at least a bag), a metal case and a twisting nozzle on the nipple, it holds a pressure of 5-10ATM, a capacity of 20-30 liters, a 3-year warranty, and a really normal brand. PRICE up to 3000, but not less than 1500 rubles. In my opinion, almost any of the list in stores will work for a really long time.

Now the video version, watch.

This is the end, I think it was useful, subscribe to our channel and website, there will be many more various videos and articles. SINCERELY YOUR AUTOBLOGGER.

Gaining more and more popularity car compressor for inflating tires, and this is understandable, because it is much more convenient to control the condition of the wheels than with its predecessor - a foot or hand pump. We will try to figure out how to properly use such a unit.

Varieties of compressors for cars

It already follows from the name that their main function is pumping, however, almost all models of such compressors are equipped with additional nozzles that allow you to easily inflate a rubber boat, mattress, ball, and other rubber inflatable products. In addition, quite often they also come with a pressure gauge, so now you can independently check what pressure is in a particular tire.

For owners of air mattresses and boats, a function that allows you to pump out air is also useful. A flashlight with a red light filter will help in an emergency. The compressors are powered by the cigarette lighter and become indispensable assistants on the road, if you need to travel long distances. However, as practice shows, the power from the cigarette lighter is very unreliable, for some reason the compressor burns out, so experienced motorists prefer to be powered by a battery.

There are two main types of automotive compressors: piston and diaphragm.. But they all consist of an electric motor, a cylinder, and a pressure gauge. In diaphragm type compressors, the main working element is a rubber membrane located between the cover and the cylinder. The compression of air, which can be called the basis of all its work, occurs through a series of reciprocating movements by the membrane. What about piston-type compressors, because in them air is compressed due to the movement of the piston.

The general principle of use is to connect the compressor to the power supply, wind the hose onto the nipple, check the pressure on the pressure gauge and turn on pumping air to the desired pressure.

![]()

Diaphragm Compressor for Wheels

Due to their shortcomings, membrane compressors are not widely used among motorists. Their main disadvantage is poor cold tolerance. At low temperatures, the membrane becomes more rigid, brittle, and during operation it can even collapse from the applied loads. Also, due to the cold, the power wire can also deteriorate, its sheath cracks, and the copper wires close, which leads to the failure of the cigarette lighter fuse.

In addition, they cannot provide maximum pressure, so do not rely on a quick pump. But at the same time, they all have dignity - an acceptable price, which is an order of magnitude lower than that of piston counterparts. If you still own a membrane compressor, then you should not overload it too much so that it does not burn out, therefore, if you need to pump up the tires of a truck, then let it rest somewhere every 15 minutes. It is perfect for bicycles, as well as cars that are operated in warm regions or just in the warm season, and do not require too high pressure.

Piston compressor for tire inflation

Piston compressors, due to their wear resistance and high degree of reliability, are more popular with motorists.. They also significantly outperform their membrane counterparts in terms of pumping speed. And the possibility of operation at any time of the year plays a significant role. It is clear that such reciprocating compressors are considered more reliable, in which all parts are metal. In addition, such models are considered the most resistant, where the metal connecting rod is installed directly on the shaft, and the piston ring is Teflon.

Despite their positive characteristics, piston compressors also cannot work for a long time without rest, as strong friction is created in the piston-cylinder pair. When choosing them, you need to pay attention to the carrying capacity and the metal from which they are made. The most durable are steel, but compressors made of soft metals such as aluminum fail much faster. Such units are perfect for owners of both cars and trucks.

Every car owner is literally obliged to have a car pump at his disposal. It can come in handy at any time, so it's better to keep it in the trunk, and not in the garage.

Many do not try to find a really good unit, but simply choose the first device they come across for inflating car tires.

By finding the best auto pump, you guarantee yourself efficient and trouble-free operation. All automobile pumps are divided into several categories and are produced by different companies, which somewhat complicates the process of finding the optimal device.

Kinds

Before choosing a pump, you need to figure out what they are and what their features are. Drivers have to choose among three main types of car pumps:

- manual;

- foot;

- compressor.

Based on the type of drive, then the classification implies 2 categories:

- mechanical;

- electrical.

They are also divided into:

- membrane;

- piston.

To make a choice and buy the most suitable car pump, you need to get to know them in more detail.

Both options have their strengths and weaknesses. But it is obvious that between the membrane and piston type, preference should be given to the latter.

Ideally, the car owner should have a main compressor and a spare mechanical type of pump. This will allow, under different circumstances, to be able to pump up the tires to the desired parameters.

We also recommend separately purchasing a high-quality pressure gauge, and not electronic, but analog. On compressors with built-in pressure gauges, there is often an error caused by build quality or irregularities in operation. Because compressors vibrate, heat up and wear out, built-in pressure gauges can give incorrect readings over time.

If you are interested in foot pumps for a car and which ones are better to purchase in addition to an electric pump, then focus on the following models:

- GT Auto SD 1031. Taiwanese production and a price of 700 rubles allows you to get a fairly reliable foot unit for a car.

- Airline PA 300. Fully equipped, has a number of nozzles, a one-piece stamped pump frame and a welded pedal. Support teeth provide the pump with stability on different surfaces. The manufacturer gives a guarantee for 1 year and sells his creation for 550 - 600 rubles.

- ALCA 201000. The most compact and lightest foot unit in the ranking. It is equipped with a special arrow on the pressure gauge, setting which at the desired value, you can reach the required indicators without any problems. The plastic pressure gauge gives out up to 7 atm and has an error of up to 0.1 atm. It costs about 500 rubles and fully justifies the low cost.

- Salut 2M. The design in the form of an inverted cylinder is interesting and convenient in practice. The frame and pedal are assembled from 3 elements. In the kit there is only a poor quality cap cartridge and a pressure gauge. But the price of 540 rubles does not allow for increased demands.

- Avtomash. Rating leader among foot pumps. The device is made on a durable aluminum frame with a plastic cylinder. The support and pedal are notched, which simplifies the tire inflation process. Although the autopump has been produced for a long time, it costs about 800 rubles. Reliable, simple and trouble-free.

The best compressors

Since mechanical devices are not particularly in demand and are used in exceptional cases when it is not possible to use a compressor, manufacturers focus on electrical devices.

- Katun;

- Monsoon;

- Jock;

- Mustang;

- Sturm;

- ring;

- Black Decker;

- elegant;

- Heyner;

Consider the representatives of these brands, which have gained the greatest popularity this year and are considered the best choice for car owners.

MC8850

A novelty from the company Sturm, which recently entered the market, but managed to gain good popularity. The connection to the power supply is carried out using the terminals on the battery, which for some is not the most convenient option.

The cost of the device is about 1500 rubles. With a capacity of 50 l/min, power up to 0.16 kW and a reliable composite construction, the model can be considered as a compact and functional automobile compressor.

If you don't want to spend a lot of money, but want a durable device, the MC8850 is worth a look. There are a number of other worthy tire inflators in the Sturm range.

ASI 500

Interesting externally and in terms of its functionality, an electric compressor made by Black Decker. A multifunctional car device that combines two devices at once.

One lets pump up car tires, and the second serves for domestic purposes (mattresses, balls, inflatable accessories, etc.).

The device is equipped with a built-in flashlight and an auto-stop system. You can also use the compressor to bleed excess air, which somewhat facilitates the process.

The device functions through the cigarette lighter and with the help of terminals connected to the car battery.

Katun 320

A good and affordable option for an autocompressor, which has gained wide popularity among owners of cars, small trucks and.

The design provides for a built-in pressure gauge and a flashlight. The mains voltage is 12 V for operation.

One of best solutions among pumps in terms of price and quality ratio. It serves for a long time, does not cause complaints in terms of breakdowns. But during long-term operation it overheats, therefore it is better to take breaks if you plan to pump up more than 4 wheels.

Monsoon ME

In the domestic market, it is considered the most popular compressor among our manufacturers. Adapted to work with cars up to 5 tons. The pumps are produced by a plant in the Kaluga region, which has a positive effect on the price.

An indication sensor paired with a pressure gauge allows you to automatically turn off the operation of the device when the optimum pressure is reached in the tires. The declared service life is 10 years.

Now the price of Monsoon ME varies from 2 to 3.5 thousand rubles.

K90

One of the best representatives domestic market and the best option among the entire range of the Kachok brand.

The K90 model is characterized by increased reliability and adaptability to all types of passenger cars. Able to overpower a small truck and minibus.

Mustang M

The device is manufactured in strict accordance with safety and quality standards. For operation, a current of at least 14.5 A is required. Therefore, the compressor does not work from the cigarette lighter. The connection is made using crocodile terminals directly to the battery.

It takes 2 minutes to inflate a 14-inch wheel, which is a good indicator. But long time it is not worth operating the unit without interruptions, as it can overheat and fail.

Force Plus 100043

Elegant company product based on a rotary piston scheme. It is enclosed in a metal case to effectively remove heat. 4 rubber support feet provide stability on any surface.

Equipped with an automatic shutdown function, complete with nozzles for pumping other items and has a long cord for connecting to a power source. The hose is reliable and reinforced, which provides it with a long service life.

Some of the disadvantages include the use of an analog pressure gauge in the kit. But it's not so scary. Plus, they often work more accurately than electronic counterparts.

Digimatic Pro 236

Voin product compressor VP-610

A product of Voin, which is a piston autocompressor with an excellent performance of 70 l / min and a pressure of 10 atm.

The benefits include high performance performance, protection against dust and moisture, solid stability and rich equipment.

But it does not have additional functions, that is, it can only pump car tires. It is completed with an analog pressure gauge and works only from the accumulator. There is no way to connect the pump through the cigarette lighter.

This is rather a device for garage use, since its weight is not the smallest. It may seem too large for the trunks of some cars.

RAC 640

A model of an automobile compressor from the Ring company. It is a 2 in 1 device, combining two pumps for different tasks. Switching modes is carried out by a special button.

High power and rich functionality make RAC 640 one of the leaders in the rating. It has an auto-shutoff function, a backlit digital pressure gauge, an overpressure relief valve and a bright LED light.

With all their obvious benefits and the ability to connect through the cigarette lighter, some complain about the large size of the compressor.

Decide for yourself what type and model of compressor to buy for your car. But we do not recommend saving. Better spend more money and take a pump that can serve for a long time and reliably.

Subscribe, leave comments and invite your friends to join us!

Inconspicuous, but at the same time, simply an indispensable tool for every motorist is a pump (or compressor) for inflating car tires. Relatively low cost and indispensability in critical situations automatically make it the best "friend" of the driver. On the one hand, it is not always necessary to fully inflate the wheels, but on the other hand, it is still better to pump them up periodically. Therefore, the pump for the car must constantly ride in the trunk. But how to choose the right option? We will talk about this now.

Types of devices for inflating tires and their principle of operation

The modern market can offer buyers enough a large number of most variety of options for pumping wheels vehicle, but all such devices can be divided into two main groups - mechanical and electrical.

mechanical pump

Basic hallmark a mechanical pump for a car is the need to use the physical strength of the driver to inflate the wheels. However, when buying such an "assistant", you can choose one of two possible types- foot or manual.

The foot version has simple design and is presented in the form of scissors, with a piston and a cylinder (cylinder) installed in the middle. A rubber tube is removed from the cylinder, through which, when you press the pedal with your foot, air moves into the wheel. An important role in the operation of the foot pump is played by the manometer, which allows you to control the pressure inside the tires. The general arrangement of a foot pump with a pressure gauge and the principle of its operation practically do not differ from standard options.

The hand pump has a "T"-shape and is complemented by a vertical cylinder and handles, brine on both sides. If we disassemble the device of a hand pump in more detail, then it should be noted that its body (often cylindrical in shape) contains a piston, and special sealing gaskets made of rubber or other similar material are used to ensure the desired level of tightness. In turn, the piston is connected to a rod, at the end of which there is a handle (usually "T"-shaped, but for pumps with lower productivity, it is more cylindrical). Which car pump to choose: manual or foot? Everything is very individual here, although in most cases, car owners choose exactly last option(working with your foot is much easier).

The hand pump has a "T"-shape and is complemented by a vertical cylinder and handles, brine on both sides. If we disassemble the device of a hand pump in more detail, then it should be noted that its body (often cylindrical in shape) contains a piston, and special sealing gaskets made of rubber or other similar material are used to ensure the desired level of tightness. In turn, the piston is connected to a rod, at the end of which there is a handle (usually "T"-shaped, but for pumps with lower productivity, it is more cylindrical). Which car pump to choose: manual or foot? Everything is very individual here, although in most cases, car owners choose exactly last option(working with your foot is much easier).

Interesting! The appearance of the pump is associated with ancient times, and the first piston pump (water type) was used to extinguish a fire. It was invented by the ancient Greek mechanic Ctesibius in the 1st century BC.

A car tire pump is certainly a good thing, but there is something that you might like a lot more. Of course, now I mean electric compressor for inflating wheels. It does not require any physical effort, and its work is based on the interaction of a small piston pump and an electric motor, which can be powered by both the cigarette lighter and battery terminals, but a car compressor from the cigarette lighter is considered a better option.

Moreover, many car compressors can offer their owner not only the function of inflating wheels, but also other features: a digital pressure gauge with the Autostop function, white workplace illumination, red emergency warning lights and even a separate pump for inflating boats. Thanks to this whole set, it is compressors that hold the lead in terms of sales.

Moreover, many car compressors can offer their owner not only the function of inflating wheels, but also other features: a digital pressure gauge with the Autostop function, white workplace illumination, red emergency warning lights and even a separate pump for inflating boats. Thanks to this whole set, it is compressors that hold the lead in terms of sales.

These products can be divided into types based on their design features. In this way, allocate membrane, piston and rotary products. Currently, diaphragm compressors are practically not used anymore, the reason for which was low level their reliability, while piston counterparts, on the contrary, have taken root better. They consist of an electric motor and a cylinder with a piston, and almost all compressor models are equipped with a built-in pressure gauge. As for the latter, as in the case of mechanical pumps, it is needed to control the air pressure in the tires.

The high level of reliability of the reciprocating compressor is explained by the fact that the piston rod is driven directly from the motor shaft. However, if there are intermediate drive elements (in most cases they are made of plastic), then this will only reduce the coefficient useful action compressor and shorten its life.

Rotary devices, in terms of performance, somewhat outperform their counterparts. Such "pumps" are characterized by ease of operation and reliability, but even despite this, they are not very common, the reason for which is too high a price.

Rotary devices, in terms of performance, somewhat outperform their counterparts. Such "pumps" are characterized by ease of operation and reliability, but even despite this, they are not very common, the reason for which is too high a price.

Important! Rotary piston compressors are capable of supplying a large amount of air, but at the same time, their pressure will be quite low.

Advantages and disadvantages of a foot pump

Each version of the described products has its own advantages and disadvantages. So, for example, a foot pump, like a similar hand-held product, requires the use of human physical strength. Such a need does not suit all drivers, especially car owners with limited physical abilities. Nevertheless, we can say that this is practically the only drawback of foot pumps, but there are many more pluses.

Among them are compactness (practically do not take up space in the luggage compartment), lightness (the absence of an engine contributes to the low weight of the structure), ease of use (no need to study the instructions for a long time) and an affordable price, which is especially noticeable in comparison with electric models. In addition, the advantage of a foot pump over a compressor also lies in the absence of dependence on power sources, as well as electronics, which can fail at the most inopportune moment. If you need additional lighting for the workplace, no one bothers to supplement the pump with a flashlight. Unlike the manual type, when using foot structures, the back does not get tired.

Among them are compactness (practically do not take up space in the luggage compartment), lightness (the absence of an engine contributes to the low weight of the structure), ease of use (no need to study the instructions for a long time) and an affordable price, which is especially noticeable in comparison with electric models. In addition, the advantage of a foot pump over a compressor also lies in the absence of dependence on power sources, as well as electronics, which can fail at the most inopportune moment. If you need additional lighting for the workplace, no one bothers to supplement the pump with a flashlight. Unlike the manual type, when using foot structures, the back does not get tired.

Did you know? In 2016, the Sorokin compressor became the champion in inflating wheels with the declared performance of 52 l / min, 6.9 bar, 14.5A.

Pros and cons of using an electric pump

The first and most important advantage of using compressors is the ease of use. The driver no longer needs to inflate the wheels for a long and painful time, applying physical force for this. Moreover, electrical products are more powerful (you can pump up the wheels up to 8 atmospheres) and the possibility of all-weather operation.

However, with regard to the disadvantages of using compressors, there is something to be said here. The piston and cylinder, which are included in the design of the piston electrical product, do not change, which is why the maintainability of the device is significantly reduced. Also, one should not forget about the possibility of overheating, which occurs under heavy loads (the compressor must cool down every 15 minutes of operation).

However, with regard to the disadvantages of using compressors, there is something to be said here. The piston and cylinder, which are included in the design of the piston electrical product, do not change, which is why the maintainability of the device is significantly reduced. Also, one should not forget about the possibility of overheating, which occurs under heavy loads (the compressor must cool down every 15 minutes of operation).

The advantages of the membrane type of compressors are their reliability and maintainability (unlike piston-type products, all components can be replaced). True, the power of membrane compressors cannot be compared with that of a piston type, moreover, such products will not be able to help in severe frost.

Note! The low power rating of the membrane-type compressor is not critical, since the pressure in the tires of passenger vehicles rarely exceeds three atmospheres, which means that a more powerful device will be needed only if it is necessary to service large trucks, SUVs and special equipment.

A common problem with reciprocating and diaphragm compressors is cost and weight, especially if the model has additional features.

What parameters you need to pay attention to when choosing a pump for a car

Considering the fact that there are a fairly large number of options described products, find good pump for a car can be a daunting task. However, There are several key characteristics that should be considered in a choice situation. These include: the maximum possible pressure, air flow rate, continuous operation time and engine power.

Considering the fact that there are a fairly large number of options described products, find good pump for a car can be a daunting task. However, There are several key characteristics that should be considered in a choice situation. These include: the maximum possible pressure, air flow rate, continuous operation time and engine power.

As for the mechanical options (foot or hand pump), these indicators will be rather arbitrary, since the person himself acts as the engine, and the maximum air pressure is the pressure that, in principle, the compressor can reach. In most cases, car tires are pumped up to two atmospheres of pressure, and most compressors can easily handle this task.

However, if it is necessary to pump up more pressure, which is especially important for large trucks (they require from 4-5 to 8-9 atm), then you should pay attention to the most productive models. True, even high pressure does not guarantee a high margin of safety for such compressors, because ordinary “passenger” products with an allowable pressure of 7-10 atm will work to the limit, which will soon cause them to quickly break down.

Another important parameter is the inflation rate, which is measured in l / hv. A conventional compressor is quite enough to effectively inflate the wheels of a passenger vehicle in just 2-5 minutes, so faster compressors are needed only for those drivers who are constantly in a hurry somewhere or owners of large vehicles.

Here the rule easily works: “greater productivity = high level reliability”, and the point here is not only a margin of safety, but also the fact that such compressors can be equipped with a cooling system (even if it is a regular fan), which prevents overheating of the motor and piston pump inside the case.

If you decide that you need a mechanical pump, then you should give preference to the option with a pressure gauge. Also pay attention to the fact that all the designations on it are large and easy to read (all values \u200b\u200bshould be indicated both in familiar bars (ATM) and foreign PSI), which will allow you to set clear inflation parameters for the tire.

If you decide that you need a mechanical pump, then you should give preference to the option with a pressure gauge. Also pay attention to the fact that all the designations on it are large and easy to read (all values \u200b\u200bshould be indicated both in familiar bars (ATM) and foreign PSI), which will allow you to set clear inflation parameters for the tire.

The accuracy of the measuring device must also be on top. Often, mechanical pumps can be supplemented with special sensors that can monitor tire temperature and pressure. Such structures consist of a body, a support platform, a piston, a rod, a seal and a lever mechanism.

In conclusion, it should be noted that the most important parameters of pumps are the maximum pressure and performance(this is what the wheel inflation speed depends on), which means that the best option for cars with wheels from R13 to R16 is a compressor with a capacity of 30 to 40 liters per minute.

Subscribe to our feeds

header

The car compressor has replaced the hand and foot pump for tire inflation. The most pleasant advantage of this device is that it is fully automated and no physical effort is required to inflate the wheel. It is convenient when the compressor is always at hand, wherever you are. However, it happens that it fails and then repair may be required.

Why is a compressor a must-have for a driver today? After all, there are so many service stations and tire shops around where you can pump up tires and, if necessary, make other repairs. Everything is simple. The wheel can be lowered anywhere, for example, in a mountainous area or in a summer cottage, far outside the city - there is not always a specialized workshop nearby. And then, it is better not to lose control over the situation and fix the problem yourself, quickly, without unnecessary expenses and hassle.

Causes of compressor failure

The most common cause of a car compressor failure is a banal blown fuse. The fuse of the unit or the one located on the wire may burn out. Such a breakdown is not serious and is very quickly eliminated. Moreover, spare parts for repairs can be bought in almost every store.

Also, one of the options in which the compressor fails involves damage to the power wire. Determining this problem is very simple. It is enough to visually examine the wire and find the place of the tear or break. This problem can also be dealt with easily and quickly, for sure every man changed the plug on the iron wire.

There are more serious reasons for the inoperability of automotive compressors. For example, when a winding of an electric motor or a vibrating coil ignites, it is rarely possible to save a patient.

If you find that the compressor turns on, but does not give the desired action, that is, it does not pump air, look for a problem in the wear of the piston or the PTFE ring. In this case, it will be cheaper to purchase a new autocompressor than to repair and buy new spare parts.

But most often the problem is not acute and requires a little intervention, replacement of a spare part or component. Usually this is a leaky hose, a valve worn on the nipple of the wheel, a rubber ring-gasket, brushes, nozzles.

Features of autocompressors

Due to the fact that the car compressor comes with various nozzles, it can be used not only for inflating car tires, but also for balls, inflatable boats, bicycles, etc. That is, the compressor plus nozzles is a universal device that allows you to solve several problems at once.

In order to repair the compressor, it is important to know its device and features. So, each representative of automotive compressors is equipped with:

- Electric motor;

- pressure gauge;

- cylinder;

- piston;

- Other accessories (cables, brushes, gaskets, nipples, nozzles).

According to their device, diaphragm and piston compressors are distinguished.. The principle of operation of the membrane compressor is to compress the gas, due to the fact that the translational movements of the membrane reduce the volume of the chamber. The membrane, sandwiched between the cylinder and the cover, begins to oscillate and acts like a piston.

Piston compressors are equipped with a special piston, which, when connected to the crankshaft, sucks in air masses. They are much more popular among car enthusiasts.

To ensure the highest pressure, reciprocating compressors operate in a stepped mode. So, the compressed air mass is distilled from one cylinder to another, through a cooling tube. The volume of one cylinder is intentionally larger than the second, but the latter compresses the air, increasing the efficiency of the device.

Weaknesses of the diaphragm compressor

The weakest part of diaphragm compressors is the diaphragm. If foreign particles accumulate in the gas cavity of the block. Important aspects of working with such a compressor are:

- Maintain unit cleanliness.

- Exclusion of moisture and dirt ingress into the membrane unit.

- Timely replacement of spare parts (membrane, gas valve, pressure limiter).

Weaknesses of the piston compressor

The most common problems with reciprocating compressor, it:

- The compressor refuses to start;

- No air is released into the receiver, although the motor is running;

- Knocks out fuses;

- The air pressure drops sharply;

- Incorrect operation of the thermal protection machine;

- The humidity of the air pumped by the compressor is increased;

- The motor runs on high vibrations;

- The junction of the hose and nozzle is worn out and the air poisons.

What to do if the compressor does not start

If the device refuses to work, you need to perform certain diagnostic actions using an indicator screwdriver. We investigate whether there is a phase, and whether voltage is applied. If everything is in order with the phase, proceed to check the fuses, maybe they have melted. If this is the case, then just replace the fuse. It is important to remember that when making repairs, the installed spare parts must be equivalent.

After replacement, everything should work, however, it happens that the fuse blows again. This suggests a possible short circuit. Repair needed. Call the diagram. When the defective parts are installed, replace them with new, similar parts.

The failure of the compressor may be due to a failure in the settings of the pressure control switch. In order to diagnose this problem, do the following: bleed the air and start the compressor again. If you hear the sound of a running motor, reset the settings, the motor does not function, you need to replace it. Remember that with intensive work of thermal protection, it is necessary to cool the motor for at least 20 minutes, this will normalize the operation of the compressor.

Particular attention deserves the situation when, when the device is turned on, both the fuse and thermal protection fail. If the only problem is that the installed fuse is not designed for the operating power of the unit, then the repair comes down to a simple replacement of the spare part. But if the relay is out of order, do not try to climb there yourself. In order to get a qualified repair, go to the service.

In a situation where the piston is faulty, you need to disassemble the device. When making repairs, release the air, clean the valve from dirty formations, if the pressure continues to drop - the problem is in the valve, it needs to be replaced.

Where to get spare parts for compressor repair

With such an abundance of car dealerships and places for the sale of components, your head can just go round and round. Where to buy repair parts or new nozzles. In principle, there is no big difference in the places of sale of spare parts. It's a matter of convenience for everyone. Someone goes to a specialized store, someone goes to meal, and someone finds it convenient and profitable to order spare parts via the Internet. The taste and color as they say.

The main thing is not to run into a fake when making a purchase. Original spare parts are the key to their long service life. Ask for a certificate or warranty card when purchasing new compressor repair parts from the seller.

In general, compressor repair is not difficult and can be done without the appropriate experience or qualifications. Although it is better to prevent damage in advance, simply by caring for the equipment.

How to understand: will the kitten be fluffy?

What kind of light alcohol can be drunk for pregnant women: the consequences of drinking

Why do the legs swell in the ankles and ankles of the feet in pregnant women: causes and methods of treatment

The wedding of Prince Harry and Meghan Markle: scandalous and secret details of the marriage (photo) The future marriage of Prince Harry year NTV

How to close white plums for the winter