During the operation of the car, rims suffer the most. There are plenty of potholes, potholes, speed bumps and other wheel traps on our roads. Falling into such a trap, not only rubber suffers, but also the wheel disk. If you can purchase the affected tire in a single copy, then the disk is unlikely. And the purchase of all four discs at once noticeably "hit the pocket". But you can paint and thereby "update" your set of aluminum rims in garage conditions With minimal cost and with your own hands. The cost of materials in this case will be only 10-20 percent of the cost of a new set of disks.

The rim is painted for various reasons - oxidized, peeled, scratched, or just don't like the color. You can bring the disc to a decent look without even removing the rubber. How to do this - consider step by step.

Step-by-step guide on how to paint wheels yourself in the garage

- Wash as much as possible (preferably at the sink) all the disks along with the rubber, because you will have to stick adhesive tape on the wheels.

- We inspect the wheels and decide whether it will be necessary to putty. If the wheels do not have severe chips, but the paint coating is simply damaged, puttying is not necessary (we save on buying putty).

- We go for materials. We will need:

- Aluminum putty (the smallest package), if you decide to putty.

— emery skin two types, dry sanding - 250th (two leaves) and wet - 800th (two leaves).

- 300 grams of primer for aluminum.

- 200 grams of car paint based on the 15th wheel size. We go to the offices for the selection of car paint, because. we don't need large volumes. We buy paint without selection (it's cheaper).

— Solvents. On the selection of paint, you will be poured the necessary solvents in small quantities.

- 300 grams of varnish + hardener.

- One covering film (which is for covering plants in the garden).

- Masking tape. - Preparation under the ground is the most time-consuming task in all work. With the 250th sandpaper we remove all the chips and transitions on the disks to the state - "I ran my hand and did not notice the roughness." Putty, if necessary, strong chips and also grind to zero.

- We divide the covering film into eight parts (twice four each) and, wrapping our wheels, cut a hole for the disc. We glue the film to the rubber with adhesive tape to the very edge of the disk.

- We dilute the primer and prime our wheels with a spray gun. You can always borrow a small compressor and sprayer from friends for a couple of days.

- After the soil has dried (usually the next day), remove the film and use the 800th sandpaper with water to go through the entire surface to the state of maximum smoothness. We wash the remnants of the erased soil with water, dry it and glue our wheels with a film like last time.

It is MANDATORY to change the film after priming before painting! The primer does not adhere well to the film and, when painting, can break away from the old film and get on the surface to be painted.

- We dilute the paint, degrease the surface and paint the wheels. Painting should be done in three layers. The first two coats can be applied "wet on wet" and the third coat is applied over the well-dried coats by wide spraying, so that the metallic paint particles lie evenly over the surface.

- While the paint dries, we dilute the varnish for 15-20 minutes. The varnish is diluted with a hardener and thoroughly mixed. The solvent is added immediately before painting, because. the varnish should be infused with a hardener for just 15-20 minutes.

- We apply varnish in 2-3 layers with drying for 10 minutes after each layer. Usually the discs are placed in a row, and while you are varnishing the last one, the first one has already dried up. Complete drying of varnish at +20 degrees takes an average of a day.

This is how you restore old rims in two days at minimal cost. Eyes are afraid, as they say, but hands do!

If you still decide not to bother with painting the wheels, but to purchase a new set, then the most popular today are GR wheels from the Asian company with world-famous GR Industries. Our own research center and two design bureaus allow us to create beautiful, ergonomic alloy wheels with ideal dynamic characteristics and an affordable price tag.

The wheels of any car are important detail, which is responsible not only for functionality, but also significantly affects the overall appearance. The appearance of the discs emphasizes the features of a particular model or can be a highlight, which is why varnishing this part is so popular with today's motorists.

Benefits of varnished alloy wheels

In addition to the spectacular appearance of varnished discs, which is due to the deep gloss, such a coating provides other advantages. Lacquer is an additional protection against various external influences. These are the impacts of stones, and the influence of moisture, salts and other chemicals that are found on the roads.

Thanks to the varnish coating, the wheels of the car retain their original appearance much longer. They do not fade in the sun, they do not get chips and scratches so actively. Therefore, it will be quite reasonable to apply several layers of transparent varnish when restoring the appearance of the discs. It will not cost so much, but it will significantly delay the next repair of the coating.

The choice of varnish for alloy wheels

Today's auto goods market offers a lot of varnish options that are suitable for rims. Their composition is designed for harsh conditions in which the coating of these elements is constantly located. It is worth noting that not only alloy wheels needs to be varnished. Steel car wheels will also last much longer with such a protective coating.

When choosing a varnish for discs, you should be guided by the rule of one manufacturer, that is, when buying materials, it is advisable to stick to one brand. This is especially true for base paint and varnish.

Ideally, it is better to buy a primer from the same manufacturer. This will ensure that all materials will not conflict with each other and provide reliable coverage.

Lacquer designed for alloy wheels of cars is produced by several manufacturers who have earned the trust of many users, and they are not difficult to find on the auto goods market:

- Mobihel Helios 2K;

- Vika Ak 1112;

- Motip;

- Pingo 00098-9;

- Hi Gear 7389.

There are other brands of varnish for discs, the main thing is that the material is of high quality, and the manufacturer's reputation is good. It is advisable to pre-acquire user recommendations about a particular company.

Tools and materials for varnishing discs

For such work at home, you will need the following tools and materials:

- drill or grinder with appropriate brush-type nozzles;

- sandpaper of different grain sizes;

- detergents and degreasers;

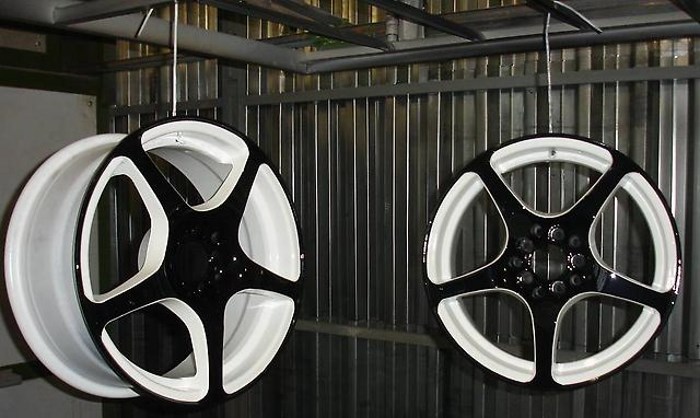

- homemade hooks for hanging discs;

- primer, base paint and varnish in cans.

For applying varnish, it is desirable to choose a room in which dust will not rise. Be sure to have normal lighting that does not form glare and dark areas in the work area. will be important temperature regime and room ventilation. All these factors can significantly affect the quality of work, so it is better not to neglect them.

Preparing wheels for varnishing

In addition to all of the above, the quality of work is significantly affected by proper preparation alloy wheels before paint and varnish are applied. Preparation includes dismantling the wheels, removing tires, stripping the old coating and eliminating defects. Before stripping, discs should be thoroughly rinsed with any available detergent. After that, the surface must be degreased. Minor scratches and chips are repaired with putty and carefully sanded with fine sandpaper.

Wheels ready for painting and varnishing are hung on hooks. Many work with wheels, placing them on the floor. If this method is chosen, then you need to make a substrate of film or paper to avoid raising dust. It should be noted that it is easier to make mistakes and make smudges on suspended disks, but it is more convenient to work this way.

Sequence of work

The restoration of alloy wheels should begin with the application of a primer. The instruction is preliminarily studied, which describes the sequence of work with the cylinder. Usually, the primer is applied to the surface in several even layers from a distance of 25 centimeters. Before applying each subsequent layer, the previous one is allowed to dry properly. At the priming stage, you can once again make sure that there are no small defects on the surface. If any have been identified, then they are eliminated by puttying or grinding.

After the primer has been applied in several layers, and the surface of the alloy wheels has an ideal flat surface, you can start spraying the base paint. At this stage, it is very important not to make mistakes, since later they will be visible under a layer of transparent varnish.

The base paint is applied in at least three layers. For the first time, the surface is pollinated from a long distance with a thin layer, the main task in this case is to break the gap of the primer. When the primer is no longer visible, the paint is given enough time to dry. This process can be speeded up a bit. To do this, you can use a building or household hair dryer. The main thing is not to overheat the paint. The second layer is applied in a thicker layer from a close distance, which is recommended by the manufacturer. If there are small smudges, they should be removed with a napkin, and the defective place should be repainted until a uniform layer is obtained.

The most important work is the application of the third layer, since the entire appearance of the restored wheels will depend on its quality. It is applied in a thick layer to achieve a deep gloss.

Leaks and other defects are immediately eliminated in the manner described above. After applying the base paint, the discs are dried until the coating is completely crystallized.

At the last stage, varnish is applied, this is also a crucial moment, since this material is transparent and it is not easy for an inexperienced eye to determine the thickness of the layer and avoid smudges. The varnish is also applied in two or three layers with drying. After drying, the discs can be polished and installed on a car.

Wheels are an important part of any car. They are responsible not only for the functionality of the car, but also greatly affect its appearance.

Benefits of varnished discs

After varnishing, the discs are given a deep gloss effect, but these are not all the advantages of such a treatment. The varnish is an additional protection against various external and mechanical influences - stone impacts, the influence of moisture, salts and other chemicals on the road. Thanks to the varnish coating, the wheels retain their appearance much longer. They don't get chipped and scratched as much. It will be logical to apply several layers of varnish when restoring discs.

The choice of varnish for discs

There is a huge variety and varnish options that are suitable for rims. It is worth varnishing not only cast, but also steel wheels. So they will last longer with such a protective coating.

Be sure to follow the rule of one manufacturer. When buying materials, stick to one brand. Varnish designed specifically for alloy wheels is produced by several manufacturers who have already earned the trust of users (Mobihel Helios 2K, Vika Ak 1112, Motip, Pingo 00098-9, Hi-Gear 7389).Of course, there are other brands for discs. The main thing is that the material is of high quality, the reputation of the manufacturer is good.

Materials for varnishing discs

For such work at home, the following tools are required:

- Drill or grinder with appropriate brush-type attachments

- Sandpaper

- Detergents and degreasers

- Homemade hooks for hanging discs

- Primer, base paint and varnish in cans

For the procedure for applying varnish, it is desirable to choose a room in which dust will not rise. There must be good lighting. The room must be ventilated. It is better not to neglect these factors, as they can significantly affect the quality of work.

Preparing for varnishing

It is necessary to properly prepare the discs for applying varnish. Preparation includes dismantling the wheels, removing tires, stripping the old coating and eliminating defects. Before stripping, the discs should be thoroughly washed with any detergent available to you. After that, the surface must be degreased. Small scratches are repaired with putty and polished with sandpaper.

When the wheels are ready for painting, they are hung on hooks. Someone works with the wheels, just placing them on the floor. When choosing this method, you need to make a substrate of film or paper to avoid dust that may rise during operation. Do not forget that when working with suspended wheels, there is a possibility of smudges.

Sequence of work

Start by applying a primer. Read the instruction manual for the bottle first. Usually the primer is applied to the surface in several layers with a distance of 25 cm. Before applying each layer, the previous one is allowed to dry.

After the surface of the discs has an ideal shape, you can begin the process of applying paint. At this stage, it is important not to make mistakes. The base paint is applied in at least three layers. The first time the surface is pollinated from a great distance and in a thick layer. It is necessary to interrupt the clearance of the primer. After you have covered the primer, the paint is given time to dry. This process can be accelerated using a building or household hair dryer. But do not overheat the paint. The second layer is already applied from a closer distance. Small smudges should be removed with a napkin. The most important and responsible process is the application of the third layer. The appearance of the wheels will depend on it. It is applied in a thick layer to achieve a deep gloss.

After the wheel is dried until the coating is completely crystallized. At the very last stage, varnish is applied. This is also a very important moment. Since the material is transparent, it is much more difficult to determine the thickness of the layer. The varnish is applied in several layers with drying. After the discs are dry, they can be polished and installed on the car.

Many attentive and careful drivers manage to protect the rims of their cars from serious damage for several years. But with minor problems: scratches, chips, scuffs - quite often everyone, even the most accurate car owners, encounters.

The fact is that the standard enamel, which is applied to the disks by manufacturers, hardly lasts a year on our roads. It will help restore the original radiant appearance powder coated rims- one of the services of the company "AvtoRay".

Powder coating prices

DISC COLORING IN 8 HOURS WITHOUT EXTRA PAYMENTS

Advantages of powder coating wheels

- Beautiful decorative effect . The surface of disks painted by powder polymer attracts with the ideal smoothness and gloss. This good way update the appearance of the car without resorting to major repairs.

- Resistance to chemicals. Roads are mercilessly sprinkled and watered with special chemicals. They not only make the snow melt, but also corrode the enamel. Therefore, in winter, powder coating of wheel rims will serve not only decorative, but also protective purposes.

- High operational properties . Firstly, in terms of their shock-resistant characteristics, powder paints are many times superior to ordinary cheap materials. Secondly, high resistance to atmospheric influences, and hence to corrosion.

Stages of the painting process

- Diagnosis of violations of the disk geometry.

- Cleaning the disc with a sandblasting (SHOT Blasting) apparatus.

- Performance manual preparation surfaces for painting, including elimination of deformations

- and damage (scratches, chips, dents, renewal of missing parts). That is, powder coating of discs is not just a cosmetic repair, but also a restoration of the original state.

- Applying an anti-corrosion coating.

- Surface degreasing is carried out by chemical means(elimination of oil stains improves the adhesion of powder dye)

- Application of a primer layer of coloring matter.

- Reapplying paint in an electrostatic field.

- Application of anti-gravel varnish coating (paid separately).

- Heat treatment of discs in a polymerization oven.

Why should you use our services?

- For powder coating, we use materials from such a leading manufacturer as AKZO NOBEL, whose polymer paints are the world-class quality standard in terms of resistance to all kinds of chemical, physical and mechanical influences.

- of the AvtoRay company (in South Administrative District) powder coating of disks is carried out only by professionals. All work is carried out strictly in accordance with the technology, and the achieved effect is reliable and durable.

- We inexpensively paint wheel rims of any type of car: stamped and cast, compound and forged.

- AvtoRay gives a 3-year warranty on the work performed.

- Coloring of disks is carried out in 8 hours (examples of the work performed can be seen in the photo in the "Gallery" section).

- Regular customers receive discounts and pleasant bonuses.

In addition to powder, our company also produces acrylic painting car rims. It is suitable for cosmetic repairs and the elimination of partial damage to the surface.

Mixed Personality Disorder: Causes, Symptoms, Types and Treatments

GTA 4 control settings

FAQ on Smuggling in GTA Online

LSPDFR - welcome to the police

The huge map of Grand Theft Auto San Andreas and its secrets