Hacksaw 8725 Designed for cutting round and shaped material from steel, cast iron and non-ferrous metals with a machine hacksaw blade for metal. Cutting is carried out in a plane perpendicular to the axis of the workpiece, as well as at angles up to 45°. The machine is used in conditions of individual and mass production. Climatic performance according to GOST 15150-69-UHL4, machine tool accuracy class H according to GOST 8-82E.

Scope of supply for hacksaw machine 8725

- Included in delivery

- Machine 8725 complete

- Hacksaw blade for metal 2800-0053 GOST 6645-86

- Syringe lever-plunger

- V-belt A-1400 - 2 pcs

- Manual

- Supplied for a fee

- Vice combined for cutting material at an angle of 45

- Batch cutter

- Cart

Location of controls

- Input switch.

- Control button "Start" of the machine drive

- Handle for fixing the saw frame in the upper position

- Flywheel for manual movement of the vise

- Hydraulic control handle

- Emphasis for automatic shutdown of the machine in the upper position of the saw frame.

- Control button "Stop" of the machine drive.

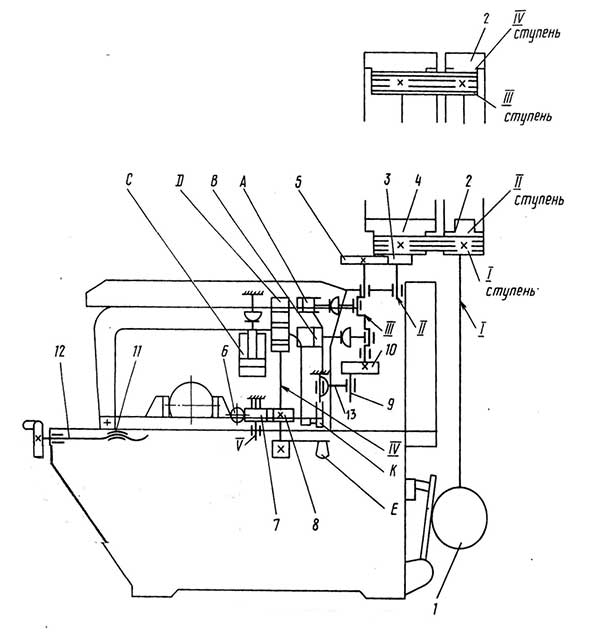

The movement from the electric motor 1 is transmitted by means of a V-belt transmission and two stepped pulleys to the drive shaft 11. The pulley 4, freely rotating on the shaft 11, is interlocked with the gear 3. Through the gear pair 3 and 5, the movement is transmitted to the shaft 111 at the other end of which the crank disk 10 is fixed finger 9. From the crank disk, through the connecting rod 13, the saw frame receives reciprocating motion. Its frequency of movement per minute is 120 (1st step) and 48 (11th step). To obtain the frequency of movement of the saw frame 62 (111 stage) and 94 (1V stage), it is necessary to reinstall the drive pulley 2 by turning 180. On the shaft 111, between the two supports, there are eccentric necks, from which the movement is transmitted by means of connecting rods by pistons A and B of the hydraulic pump. The pistons pump oil into the distribution valve D, from where it enters the working cylinder C. The piston of this cylinder is connected to the sleeve by means of hinged rods. Thus, the lifting and launching of the dusty frame, as well as the working feed during cutting, is carried out from a hydraulic drive.

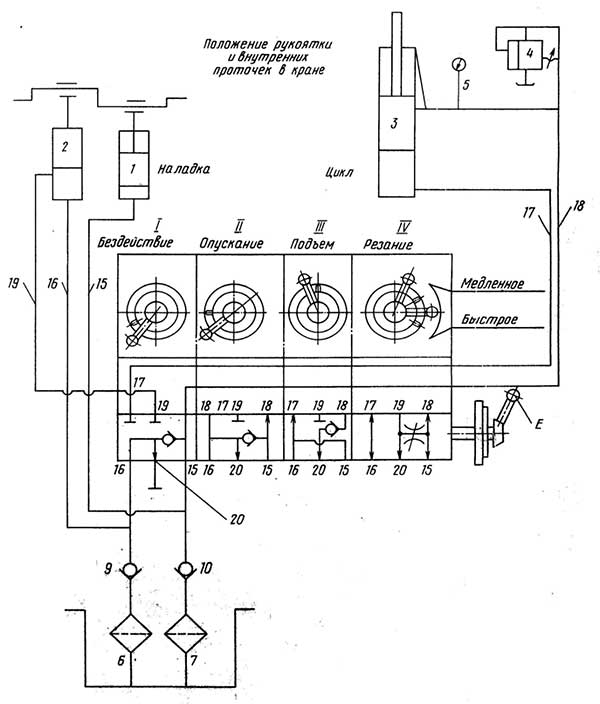

Hydraulic circuit diagram of machine 8725

The hydraulic drive of the hacksaw machine 8725 is controlled by the handle E, which can be fixed in the position: 1-"Inactive", 11-"Lower", 111-"Rise", 1V-"slow cutting" and "Fast". At the end of cutting the workpiece in the lowest position of the saw frame, the bar K fixed on the saw frame hits the rail 6 and moves it. The rail through the intermediate gear 7 transmits the movement to the gear 8, which is rigidly connected to the distribution valve shaft. In this case, the crane is installed in the lifting position of the saw frame. The saw frame rises until it presses the limit switch. In this case, the electrical circuit is opened, turning off the electric motor of the main movement.

All hydraulic equipment of the machine is mounted in the pump housing. Piston pumps 1 and 2 draw oil from the oil reservoir through filters 6 and 7, check valves 9 and 10., are located in the control valve body, and supply oil to the distribution valve through channels 15 and 16.

Regulation I - "Inaction"

When the valve is set to this position, the piston pumps operate at idle, the oil through the valve grooves is drained into the tank through channel 20. The machine arm remains stationary in any position. The saw frame with a hacksaw blade can only have a reciprocating movement along the sleeve.

Position II - "Lowering"

In this position, the piston pumps also work at idle, but the oil from the rodless cavity of the cylinder 3 through channel 17 and the valve grooves merge into the reservoir through channel 20. The sleeve and the saw frame smoothly go down.

When the machine is working in the working cycle, there are two positions: "Lifting" and "Cutting".

Position III - "rise"

When the valve handle is installed in this position, the oil pumped piston pumps through channels 15 and 16, through the grooves of the crane and to channel 17, it is fed into the lower cavity of the cylinder 3. The sleeve and the saw frame with the hacksaw blade are raised to the upper position. In the extreme position of the saw frame, the lower edge of the piston of cylinder 3 slightly opens a groove in the cylinder, through which excess oil is read through channel 18, valve grooves and channel 20.

Position IV - "Cutting"

In this position, two stages of work should be considered:

- supply of the cutting tool during the working stroke of the saw frame with a hacksaw blade;

- cutting, that is, lifting the cutting tool above the workpiece to be cut during the idling of the saw frame with a hacksaw blade.

The coordination of the reciprocating movement of the saw frame of the hacksaw machine 8725 and the initial movement of the sleeve ensures that the crank disk, driven by the saw frame, is mounted on a shaft with eccentric necks located at an angle of 125o to each other and transmitting the movement of pistons 1 and 2. feed is regulated by turning the handle of a variable cross-section valve connecting the cavities of piston 1 and the rod cavity of cylinder 3 with a drain through channel 20. Depending on the position of the handle, the amount of oil entering the rod cavity of cylinder 3 is regulated. Slow cutting is carried out with the throttle open, which corresponds to the upper position handles. Most of the oil drains through the throttle slot, and the rest enters through channel 18 into the rod end of cylinder 3. Fast cutting is carried out with the valve handle turned and the throttle closed. In this case, the throttle is completely closed and all the oil is pumped into the rod end of cylinder 3, creating maximum feed to the hacksaw blade. Excess oil is drained through the safety valve 4. The cutting tool rises above the workpiece during idling when the piston 2 moves down. Before closing the side hole in the piston cylinder 2, the pumped oil is drained through it through channels 19 and 20 into the reservoir. After the piston closes this hole, the oil flows through channels 16 and 17 into the rodless cavity of the cylinder 3 and raises the saw frame with a hacksaw blade. Adjustment of the amount of undercut is carried out by changing the length of the rod between the crankshaft and the piston due to threaded connection pivot bolt screwed into the bearing housing

Bed.

The bed has a box-shaped form, the main components of the machine are mounted on it (Fig. 2). The lower part of the frame is a reservoir for cooling liquid. An electric cooling pump is also installed here. At the same time with the frame, an oil reservoir for the hydraulic drive is cast.

Drive unit.

The drive of the hacksaw machine 8725 consists of the following main parts: racks; sleeves and saw frame. Rack, reinforced on the upper plane of the frame, with right side, serves as a support for the sleeve and the drive shaft. The lower part of the sleeve has dovetail guides along which the saw frame moves. By means of a rod and two hinges, the sleeve is connected to the piston rod of the working cylinder of the hydraulic drive, which controls its movement. When the sleeve is raised to the upper position, the stop presses the limit switch and the electric motor automatically turns off. The saw frame performs reciprocating motion from the crank disk, with which it is connected to the connecting rod. The hacksaw blade is installed with one hole on the pin of the fixed bar, and the others - on the pin of the movable bar and pressed with special bars. Before clamping the hacksaw blade, a bolt with a nut is inserted into the grooves of the movable bars to tension the hacksaw blade. The speed range of 17, 22.34 and 43 m/min provides for cutting workpieces depending on the structure of the material being cut.

Fencing.

All rotating elements of the machine drive are protected by a casing fixed on the frame.

Vice.

For cutting material of various profiles (square, rectangular, round), two strips pos. 6 (see Fig. 5), which allow cutting workpieces of 25 ... 250 mm. The right sponge 1 is fixed motionless on the machine frame. The blanks are clamped by moving the left jaw 2, turning the handwheel 5 through the nut 4 and screw 3.

Cooling.

To cool the hacksaw blade, the machine has a cooling system consisting of a coolant tank, an electric pump, a hose and a special nozzle, through which coolant is supplied to the cutting zone.

Operating Instructions for Hacksaw Machine 8725

- Machine 8725 is serviced by a worker of the third category. One worker operates three machines.

- When cutting workpieces up to 350 mm long, it is recommended to install technological containers manufactured by the customer plant. When cutting workpieces longer than 350 mm, it is necessary to install a receiving tray (supporting device) to prevent workpieces from falling to the floor in order to avoid injury.

- During the operation of the machine, it becomes necessary to regulate separate parts machine in order to recover from normal operation. If the main drive belts are loosened due to their stretching, loosen the bolt on the slotted bar, tighten the belts, then tighten the bolt again.

- Wear of the saw frame guides by tightening with round nuts. During idling, the size of the saw frame above the material being cut, the so-called “cutting”, is regulated by changing the distance between the crankshaft and the piston due to the threaded connection of the pivot bolt 1 and the bearing 2. To adjust, it is necessary to increase the distance between the piston and the crankshaft, and to reduce it, reduce it. After final adjustment on pivot bolt 1, tighten nut 3 again. The undercut value should be at least 1.5-2.5 mm.

- Depending on the type of material being cut (see Table 9) and the strength of the hacksaw blade, the pressure in the hydraulic system is regulated by a safety valve. The plug 1 is first unscrewed (see Fig. 9), then to increase the pressure in the system, it is necessary to tighten the screw 2, which compresses the spring 3 safety valve, and to reduce the pressure in the hydraulic system, it is necessary to loosen the spring 3, then re-screw the plug 1.

- The wear of the valve plug 1 and the valve bushing 2 (see Fig. 10) is completed by tightening the nut 3 to the desired seal.

- The elimination of noise in the gearing 3 (see Fig. 2.) is carried out by turning the eccentric axis of the shaft 11, after unscrewing the two nuts located inside the frame.

8725, 8725 hacksaw Mechanical hacksaw 8725 8725 machine. HACKSAW CUT-OFF MACHINE - MECHANICAL HACKSAW 8725, Driven hacksaw mod. 8725 weight hacksaw cutting machine 8725 CUTTING MACHINE 8725 year of manufacture 1986. how to make hydraulics on a saw mashkamadel 8725, a passport for a mechanical hacksaw 8725 hacksaw 8721 which blade for saw 8725. hacksaw 8725, hacksaw saw 8725 buy a hacksaw saw 8725 hacksaw cutting 8725 passport. [email protected], hacksaw machine 8725 second-hand mechanical hacksaw 8725 price second-hand mechanical hacksaw 8725. 827m hacksaw, hacksaw 8725 documentation hacksaw 8725 passport hacksaw 8725. Bi-metal blade for cutting machine 500-38-1.8 alide, -mash.ru cutting hacksaw 8V72, hacksaw cutting 8725 Krasnodar. Machine 8725 used & price, saw 8725 passport hacksaw machine 8A725 for cutting workpieces price price of machine 8725. Cut-off mechanical hacksaw 8B72 price, mill 8725 passport hacksaw cut-off machine 8725 used hacksaw cut-off machine 8725 repair manual. hacksaw machine 8725 doc, machine 8725 price hacksaw machine 8725 passport of the hacksaw-cutting machine 8725. used mechanical saw 8725, plunger pumps for mechanical hacksaws 8725 hacksaw machine 8725 hacksaw machine TO-18-10 price 2013. hacksaw 8725 user manual, Automatic hacksaw 8A725 price mechanical hacksaw 8725 hacksaw cutting machine 8725 passport download. hacksaw-machine hacksaw 8725 SM passport, hacksaw-machine 8725 passport buy used washing machine in kiev whirlpool awe 8725 documentation cutting saw 8725. hacksaw 8725, hacksaw-cutting machine 8725 price who wants to buy hacksaw machine model 8725 repair hacksaw machine 8725 instruction. hydraulic pump of the hacksaw 8725, who will buy the hacksaw machine model 8725 mechanical saw 8725 passport 8725 hydraulic drive. cut-off machine 8725 to buy, mechanical hacksaw 8725 passport Hacksaw-cutting. hacksaw 8725, hacksaw 8725 cooling pump hacksaw cut-off model 8725 price used automatic hacksaw 8725. saw 8725, hacksaw 8725 repair hacksaw SM 1 8725 used sale price passport HACKSAW MECHANICAL 8725. hacksaw-cutting 8725 passport , HACKSAW 8725 weight production instruction manual for mechanical cut-off saw model 8725 hacksaw 8725 consists of. hacksaw cutting machine 8725 consists of, hacksaw cutting machine 8725 design mechanical saw 8725 cutting machine 8725. blades for hacksaw 8725, download passport for hacksaw cutting machine 8725 installation of a hacksaw in the machine 8725 used mechanical hacksaw 8725 manual. mechanical saw 8725 repair instructions, hacksaw-cutting machine 8A725 hacksaw cutting machine 8725 ENGINE passport for hacksaw machine. Model 8A726. mechanical saw USSR 8725 instruction manual, Hacksaw mod. 8724 prices hacksaw 8725 passport documentation hacksaw 8725 free download pdf. hacksaw 7825, hacksaw 8725 operating instructions Hacksaw cutting machine 8725 passport Hacksaw cutting machine model 8725 AM. hacksaw cutting machine 8725, hacksaw cutting machine 8725 passport SM-1 (8725) (Russia) cutting machine 8725. hacksaw cutting machine 8725 price, Passport for a mechanical saw 8725 Operating instructions for a mechanical saw 8725 mechanical hacksaw 8725 technical characteristics. mechanical saw 872, mechanical hacksaw diagram 8725 download passport Hacksaw cutting machine 8725 passport for automatic sawing machine 8725. Hacksaw machine 8725 used price, operating principle of hacksaw 8725 hacksaw 8725 passport download mechanical hacksaw 8725, passport. cutting hacksaw 8725 M, blade for hacksaw cutting 8725 mechanical saw model 8725 hacksaw 8725 bu. 8D725 hacksaw cut-off machine, saw blades 8725 hacksaw 8a725 principle of operation, mechanical saw 8725 passport technical certificate on a mechanical hacksaw 8725 cutting hacksaw 8A725. mechanical saw 8725 sell, passport for mechanical saw 8725 download hacksaw model CM1 passport Hacksaw mechanical model 8725 Price. Hacksaw 8725, passport for hacksaw machine 8725 Mechanical hacksaw 8725 price Hacksaw type 8A725. machine 8a725 technical characteristics, hacksaw cutting 8725 buy Mechanical saw 8725 blade hacksaw mod.8725. machine 8725 passport download, 8725 passport download free of charge instruction manual 8725 hacksaw 8725 new. hacksaw cutting machine 8725 price, electric saw for metal, model 8725 device blade for hacksaw machine mod. 8725 Repair manual for hacksaw machine 8725. 8A726 technical characteristics, instructions for a hacksaw 8725 download instructions for a hacksaw 8725 download a passport for a hacksaw 8725. sawing machine (cutting off) 8725, sawing machine (cutting off) 8725 buy a used sawing machine model 8725 general view and what the pendulum saw machine consists of 8725 + passport. passport for machine tools mechanical saw 8725, mechanized hacksaw 8A-725 hacksaw cutting machine 8725 rub. price Hacksaw type 8725, used. Passport Cutting machine. For cutting any profile, 1690x700x900. Power 2200 W. Type, brand: 8725, passport of the cutting hacksaw 8725 operating manual CM-1 (8725) operating instructions for the machine CM-1 (8725). buy mechanical saw 8725, hacksaw 8725 passport hacksaw cutting machine 8725 mechanical saw 8725 bu in St. Petersburg. oil for cutting hacksaw 8725,

In production, tools are used that are made of special metals and alloys. They subjugate all other materials. This factor is due to the fact that for metal processing it is necessary that the cutting tool in the machine be harder and stronger than the metal of the workpiece to be processed. In order to be processed, namely cutting or sawing parts from any metal, even from aluminum, a hacksaw cutting machine is required. For these machines, the following cutting tools are used: abrasive discs, and hacksaw blades.

Purpose and principle of operation of the hacksaw cutting machine

Metal processing on a hacksaw cutting machine is carried out by the plane of a rotating saw or hacksaw blade. In this case, these devices perform reciprocating motion. Before the workpiece takes on the appropriate form, it goes through a series of procurement operations. One of these operations is the cutting of raw materials supplied for the manufacture of various products.

The hacksaw cutting machine is designed for splitting parts made of any metal, whether it is a product made of aluminum mass or a bar of steel alloys. With the help of this machine, pipes are cut and cut, which differ in diameter. After the cutting operation is performed, the pipes separated according to the established size are finished by. The main technical characteristics of the hacksaw cutting machine are: the power of the equipment, dimensions aggregate fixture, the dimensions of parts that can be processed, the dimensions of the cutting disc, the presence of CNC.

Hacksaw cutting machine, also called a mechanical hacksaw. With the help of such a device, it is possible to cut materials from any metals (of various sections). Also, a hacksaw cutting machine is used for cold cutting of metal. On this equipment, it is possible to cut the profile, both at straight and at sharp oblique angles. At acute angles, cutting is done in special combined clamping mechanisms, but such clamps are only included in the package of an improved hacksaw cutting machine. The machine can be equipped with auxiliary devices, for an additional charge.

The cutting tool of the hacksaw is hacksaw blade, which is produced by both foreign and our manufacturers. The scale of speeds and cutting feeds of the machine are adjusted stepwise, or steplessly, depending on the specific model of the unit, and also mainly on the hardness of the material being processed.

The device of the hacksaw cutting machine

A standard hacksaw cut-off machine consists of: a bed, a hydraulic drive, a main drive, a cooling system for the machine, a device for clamping the metal being cut, and electrical equipment. On the bed, which is mainly box-shaped, the main components of the machine are located. The tank for the coolant is the bottom of the frame of the hacksaw. Together with the frame of the hacksaw cutting machine, a tank for hydraulic drive oil was made. Lowering and lifting of the saw frame is carried out using a hydraulic drive.

The improvement of the hacksaw cutting machine includes the installation special mechanism supplying coolant, installation of a device for the production of batch cutting of materials, as well as a trolley for cutting very long workpieces. With a complete improvement, a CNC is also installed on the machine.

Designed for cutting profile and round material from non-ferrous metals, steel, cast iron. The cut is performed with a machine hacksaw blade for metal. Cutting angle - 90° to the axis of the workpiece, as well as an acute angle up to 45°C. The cutting hacksaw 8725 is used in serial and individual production.

Model Features

- Climatic version according to GOST 15150-69-UHL4.

- The vise is equipped with a special bracket for fixing workpieces.

- The saw frame is driven by a separate electric motor through a crank mechanism. The wire pulleys are made in two steps so that the number of double steps can be varied.

- Raising and lowering the saw frame, feeding the hacksaw blade during cutting, lifting the saw frame during the reverse stroke is carried out using a hydraulic drive. The return of the saw frame to the upper position after cutting is completed automatically.

- Coolant is supplied to the hacksaw blade during the cutting process.

- Accuracy class

Model 8725 Saw Blade Manufacturer Information

The Model 8725 Saw Blade is manufactured by PromStroyMash, Orenburg founded in 2002.

On the market construction equipment Russia there are several domestic developers and manufacturers of hacksaw cutting machines and many foreign firms from China, Turkey, Bulgaria, etc.

Hacksaw cutting machines manufactured by machine-tool enterprises of the USSR, Russia, Belarus:

- 8725 – PromStroyMash, Orenburg

- VSh-042, VSR-042- Wistan, Vitebsk

- CH1- Gomel plant of machine tools

- MP6-1697- Machine-tool plant them. Kirov, Minsk

- 8725 – Spektr, Polevskoy, Sverdlovsk region

- 8725 - Krasnodar Experimental Plant named after. Kalinina (SIAL)

- 8715, SM-1– Klinsk machine-tool plant – Klinsky plant automatic lines(KZAL)

- 8725A, 8725AM– StankoService, Aksai

- 872 – Troitsk Machine-Tool Plant, Troitsk

- 8725-22 - Barnaul Machine Tool Plant

- 8B72K, N-1- Kaunas Machine Tool Plant "Neris"

Hacksaw cutting machines. General information

A hacksaw cutting machine (hacksaw, mechanical hacksaw, hacksaw-cutting machine) is used in procurement workshops for cutting single and bundled workpieces with a hacksaw blade both in the transverse direction and at an angle.

Drive unit Most hacksaws are driven through a gearbox driven by an electric motor using a silent chain or V-belts. The change of frame speeds is made by movable gears or devices with gear being turned off. The reciprocating movement of the frame with the hacksaw blade fixed in it is usually obtained from the crank mechanism. To reduce idle time, some machines have a rocker drive, however, the axis of the frame deviates from the axis of the guides.

saw frame. Most hacksaws are made with tilted saw frames. The frame travel length is constant - 100 mm for small and 150 mm for large machines; in some designs, the stroke length is changed by changing the radius of the crank. The teeth of hacksaw blades are designed to work in only one direction - the working stroke occurs when the saw frame moves towards the axis of the crank disk. The frame movement is controlled from one handle.

Design of hacksaw blade holders allows you to create sufficient tension and the possibility of quick replacement. The width of the cut with conventional hacksaw blades is from 1 to 3.5 mm. When working with great effort, to increase the rigidity of hacksaw blades, stop bars are used that are adjacent to the narrow side of the blade opposite the teeth. The beds of hacksaws are made of cast iron, box-shaped, and for small saws - in the form of a table with four corner legs.

Hacksaw frame guides on the trunk are rectangular, round or dovetail-shaped and arranged so that the saw frame has a one-sided, two-sided or rear direction. One-sided and rear directions do not exclude the possibility of frame distortion. The most applicable guides are in the form of a dovetail.

Feed mechanism carries out the working feed and frame lifting during reverse idling. The working feed is set depending on the width of the cut by moving the load, hydraulic mechanism, friction gear, screw feed mechanisms or remains constant. The lifting of the hacksaw frame at the beginning of the reverse stroke is carried out by a hydraulic mechanism or by means of cam mechanisms. At the end of the cut, the machine automatically stops and the saw frame usually returns to its original position.

clamping vise mounted on the table of hacksaws and have jaws, the shape of which is selected depending on the cutting angle and profile of the workpiece. When mass cutting long bars, the machines are equipped with a device for automatic feeding blanks to a given length. Parts are usually clamped by hand; some machines have hydraulic material clamping.

trolleys used to support long bars.

Cooling is fed to the cut site from a centrifugal or gear pump, and in small hacksaws, sometimes from a tank placed on the frame.

8725 electromechanical hacksaw cutting machine. Purpose, scope

The 8725 hacksaw cutting machine is used for cutting pipes, channels, angles, round bars, square and strip steel with a machine hacksaw blade.

The hacksaw cutting machine is designed for cutting round and shaped material from steel, cast iron and non-ferrous metals with a machine hacksaw blade for metal by translational motion.

Cutting is carried out in a plane perpendicular to the axis of the workpiece, as well as at angles up to 45°. The machine is used in conditions of individual and mass production.

Climatic version according to GOST 15150-69-UHL4, accuracy class of the machine H according to GOST 8-82E.

Features of the design of the hacksaw 8725:

Metal cutting is carried out perpendicular to the axis of the workpiece, fixed with a special bracket on the vice, or at angles up to 45 degrees, for which the workpiece is fixed in a special combined vice.

With the help of the upper clamp on the vise in the machine 8725, batch cutting of workpieces is possible.

The range of cutting speeds is regulated stepwise, depending on the structure of the material being cut.

The supply of coolant (coolant) occurs automatically.

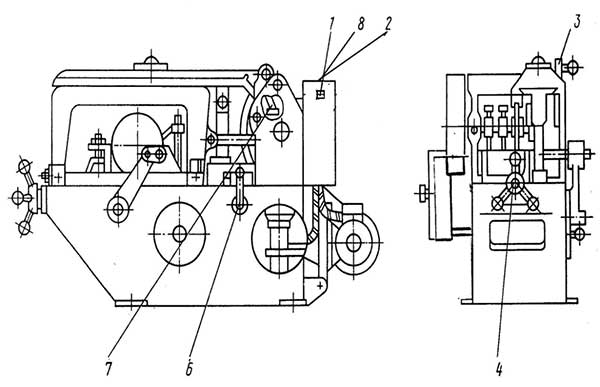

General view of a mechanical hacksaw 8725

Specifications of a mechanical hacksaw 8725

| Parameter name | 8725 | |

|---|---|---|

| Main parameters of the machine | ||

| The largest cross-sectional dimensions of a round billet (cutting angle 90°), mm | 250 | |

| The largest cross-sectional dimensions of a round billet (cutting angle 45°), mm | 140 | |

| The largest cross-sectional dimensions of a square billet (cutting angle 90°), mm | 250 x 250 | |

| The largest cross-sectional dimensions of a rectangular billet (cutting angle 45°), mm | 140 x 250 | |

| The maximum length of the cut workpiece on the stop, mm | 350 | |

| Distance from the base of the machine to the supporting surface of the workpiece, mm | 550 | |

| Dimensions of the used hacksaw blade (LxWxThick.), mm | 450x40x2; Ø 8 | |

| Center-to-center distance of the hacksaw blade, mm | 500/ 450/ 400 | |

| Maximum cutting width, mm | 3,5 | |

| Number of double strokes of the saw frame per minute | 45, 56, 71, 112, 140, 128 | |

| Saw frame travel length, mm | 180 | |

| Angle of rotation of a vice, hail | 45 | |

| Productivity when cutting steel 45 GOST 1050-74 Ø 100mm, not less than cm 2 / min | 30 | |

| Specific weight, kg/kW | 250/20 | |

| Specific power, kW / cm 2 / min | 0,066/0,0839 | |

| Workpiece clamping mechanism | manually | |

| The period of preservation of accuracy standards until the first average repair during two-shift operation, thousand hours | 16 | |

| Installed time between failures, h | 1000 | |

| Electrical equipment of the machine | ||

| Main drive electric motor, kW | 2,2 | |

| Cooling pump motor, kW | 0,12 | |

| Dimension and weight of press scissors | ||

| Dimension of press scissors (length x width x height), mm | 1690 x 700 x 900 | |

| Mass of press scissors, kg | 700 |

Designed for cutting profile and round material from non-ferrous metals, steel, cast iron. The cut is performed with a machine hacksaw blade for metal. Cutting angle - 90° to the axis of the workpiece, as well as an acute angle up to 45°C. The cutting hacksaw 8725 is used in serial and individual production.

Model Features

- Climatic version according to GOST 15150-69-UHL4.

- The vise is equipped with a special bracket for fixing workpieces.

- The saw frame is driven by a separate electric motor through a crank mechanism. The wire pulleys are made in two steps so that the number of double steps can be varied.

- Raising and lowering the saw frame, feeding the hacksaw blade during cutting, lifting the saw frame during the reverse stroke is carried out using a hydraulic drive. The return of the saw frame to the upper position after cutting is completed automatically.

- Coolant is supplied to the hacksaw blade during the cutting process.

- The accuracy class of the cutting machine for metal is H according to GOST 8-82E.

How to cook ham in the oven at home

Pain in the lower abdomen during pregnancy, reasons for what to do Can the lower abdomen hurt if pregnant

Protein for muscle gain

The best vitamins for men according to customer reviews

How to lose weight on a vegan diet?