- Circular hand saw selection options

- Availability electronic system protection

- Base plate features

- Recommendations for choosing a hand saw

A circular hand saw is one of the tools that is often used during repairs, construction, fencing and other work at home and in the countryside. With its compact size, this tool is useful in a variety of situations, and its functionality is perfectly combined with the price. Just buying the model you like will not be entirely correct.

For a home, you need to pay attention to certain parameters. These are data such as power, operating conditions, the presence of some functions that will make using the tool safe and convenient.

Manufacturers today offer variety of options, among which there are ordinary household saws. For more intensive work, it is best to purchase professional equipment, the functionality of which is much wider.

Circular hand saw selection options

All circular hand saws can be classified according to the power of their engine. A significant level of power will ensure stability in work: productivity will become higher. To choose the equipment, you must first decide on what kind of work it will be used for. Today the division is as follows:

- Household saws that are used for simple work on suburban area, in the House. Their engine power is up to 800 watts.

- Versatile models that can be used for most jobs. They can be used for complex work and frequent use in construction. Engine power is 800-1200 watts. Their cost is higher, but it is easier to use this equipment, and the quality of work is much higher.

- Professional equipment has a motor power of 1200 watts. For domestic purposes, it is rarely used, usually it is used by professional craftsmen. The weight of such equipment is large, it is difficult to work with it.

Back to index

The presence of an electronic security system

Any disk a circular saw, which is produced today, is equipped with electronics. Important here is the presence of a protective electronic system. It is these systems that ensure the safety of the use of equipment, extend the service life, and ensure the quality of the cut. You should not save on such a function, since the absence of injuries depends on it.

To use a circular saw at home, you should choose a tool that gives a cut depth of up to 55 mm.

The mechanical part of the tool will be perfectly protected from shock, stress, accidental damage and failure. An overload protection system must be provided to protect the motor from accidental damage. In this case, the saw will work smoothly under almost any operating conditions.

Quite often, a situation arises when a hand-held circular saw jams during operation. This is an unpleasant phenomenon, as it can lead to negative situations. For example, the motor can easily fail: a kickback is possible, and this will already lead to injuries. That is why, in order to prevent such situations, it is necessary to choose models with protection.

This is a reverse slip function that allows you to cope with the situation when the motor is stuck. The clutch releases the motor shaft, it starts to rotate further. The windings do not burn out, and the motor will remain in working condition. Such a system is important, since even accidental jamming can lead to engine damage, and these are significant repair costs.

Back to index

Base plate features

When choosing a circular saw, you should pay attention to the frequency of rotation of the disk: the higher it is, the denser the material can be cut.

For a circular saw blade, the presence of a base plate is also important, on which control mechanisms, regulators, and fasteners are located. The plate is usually made from a stamped metal plate or cast. Cast plates are used for professional models.

Stamped plates are intended for household saws, but their quality remains high. With the help of a high-quality base plate, you can easily change the angle of inclination. Usually, fixed values \u200b\u200bof 30, 45, 55 ° are used. With the help of such a plate, it is possible to guarantee the accuracy, reliability of the cut, and the fixation of the workpiece.

Some models can be equipped with a special mechanism for stationary work, resulting in a semblance of a convenient machine. But usually it is used for heavy and massive units, for professional equipment. For household equipment, this function is rarely used.

Consideration should also be given to whether it is possible straight cutting: for this, the kit is supplemented with special equipment.

For example, it can be a special stop to ensure that the edge of the material is parallel. Some types of straight line cutting equipment need to be purchased separately.

Ergonomics is important when using any equipment. This parameter allows you to understand how easy the tool is to use, whether your hands will get tired. A circular saw is designed to make the job faster and easier, but the cutting process itself is quite laborious in itself, so the choice must be made with high demands.

Important for the normal operation of a circular saw is smooth start, which significantly extends the life of the tool and does not allow sudden jumps in work.

The ergonomics of the equipment plays a crucial role, it is necessary that the tool be as comfortable and easy to use as possible. Attention should be paid to the handle and its position. For each, such a position and shape will be individual, therefore, when choosing a model, you should pick up the tool, literally “try on” it. If the work is simple and comfortable, then the model is great, but if there are doubts or it is not convenient to hold the saw, then it is best to immediately abandon it.

The front handle of a circular saw can have a different shape:

- Straight line, perpendicular to the plane of the material being processed.

- Mushroom, which provides more freedom to work.

There are special models for left-handers to make the work as convenient as possible. Some jobs require the use of rubberized handles. Attention should be paid to the weight, balancing of the saw.

It is important that the visibility of the working field is excellent. The supply cable, if any, should not interfere during operation, its length must be sufficient. It is desirable, if a bag is available, a vacuum cleaner for collecting sawdust. This allows you to clean the work surface, make work easier.

A hand-held circular saw is an indispensable assistant for every owner country house and dachas. This is a high precision saw blade. It cuts several times faster than all the others electrical devices such an action. The cut from the saw is smooth, without chipping. Before we talk about how to choose a hand-held circular saw, let's take a quick look at the types of this tool.

From the article you will learn:

- 1 Types of hand-held circular saws

- 2 Additional features

- 3 Video on the topic: an overview of several circulars

Types of hand-held circular saws

Among the huge range of goods, you can get confused. To prevent you from being sold something that you do not need, before buying, you should familiarize yourself with some important points. When choosing a saw, consider the following factors:

Types of hand-held circular saws

produced infrequently, purchase better saw with a cutting depth of 55 mm, a power of 800 watts. If you need a tool for working on construction sites, then in this case you need to buy a device with indicators of 65 mm and above. Power must be at least 800 watts.

- If you need to saw a tree and you need to make a precise cut, then in this case you should choose a device with a disc that has a large number of teeth. So the tree will be sawn without a single notch and burr.

- If you need to cut a large amount of material, then you need a blade with a small number of teeth. In this case, the saw will help to complete the work quickly and efficiently.

- If you need to cut plastic, then a saw with speed control is suitable. For such work, it is desirable to set the disk rotation speed to 4 thousand rpm.

- If you need to work with metal, then you need a special disc - carbide with a large number of teeth.

Additional functions

When purchasing a saw, pay attention to the following parameters:

The presence of a soft start function.

There are many more secondary criteria when choosing a manual circular saw. This is the shape of the handle, the material from which it is made, ways to replace the disk, the presence of cooling and ventilation functions. Depending on the set of these factors, the functionality and power of the saw, the cost of the device depends.

- Saw for metal cutting

- What are the features of a plunge and cord saw?

- Criterias of choice

- What should be the power?

- Varieties of discs

- How to choose saw blades?

When choosing any tool, it is necessary to take into account various parameters. Among them are not only the price and capacity, but also the type of equipment, the planned type of work. Before you buy a circular saw, you need to carefully consider not only its design, but also some parameters that will determine the quality of future work. In addition to the equipment itself, discs are purchased separately. They differ in the material of manufacture, spraying, additives. Particular attention should be paid to the shape of the teeth of the disc, what is their number, diameter. Only having decided on all the parameters, you can buy a tool for work.

Manual circular saws are more compact and more convenient to use than stationary ones.

Saw for metal cutting

Circular saws are designed to work with a wide variety of materials, but separately it is necessary to single out the class that is used to work with metal. This equipment is also called multifunctional, as it allows you to cut any material, and not just metal parts. The basic package usually includes only carbide discs, however, for working with plastic, profiles and other, you need to choose other models of discs that differ in the shape of the teeth. Such saws are characterized by high performance, no sawdust emission, and an excellent level of safety.

Back to index

What are the features of a plunge and cord saw?

Circular submersible Circular Saw allows you to plunge into the workpiece without entering from the end.

The plunge-cut saw is a separate class of circular tools that can plunge cut anywhere on the part, not just from the edge. Such a model does not have a lower automatic casing, the disk itself is located directly above the platform, but it only lowers when the start is pressed.

Depth of cut is always adjustable special mechanism management. This equipment is used in order to repair the roof, to work with countertops, beams. It is simply indispensable for sampling grooves, gutters. There is a mode that protects against the formation of chips, which is especially important when accuracy and quality come first.

Need a circular saw: which one is best to choose? It is impossible to give an unequivocal answer, it is necessary to take into account not only indicators, but also the comfort of use. Today, a big plus is that many tools are produced with special batteries, that is, the equipment does not depend on the presence of an electric current source.

Chargers are compact, and the batteries themselves are capacious, they can work for a long time without requiring recharging.

Many people think that the power of this equipment is lower, but this is a delusion. Today, circular saws with rechargeable batteries do not differ in their performance from network ones, but you can work with them even without electricity, and this is a significant plus. The weight of such equipment is greater, but the comfort of work completely negates this minus.

Back to index

Criterias of choice

The main criteria for choosing equipment are:

- saw power;

- speed;

- disk diameter;

- maximum cutting depth.

Disc diameter and type is one of the most important criteria choice. After all, the whole system must work not only reliably, but also without extraneous vibrations, beats, noises. The larger the disk, the better the work will be. The more massive and larger the equipment, the more difficult it will be to work with small parts. Therefore, before buying, you need to clearly determine for what work the saw is purchased.

It is important to pay attention to the depth of the cut. For example, a circular saw for wood may have a different depth of cut depending on what it is designed for - cutting MDF or chipboard, or working with thick beams. Depth parameters are always indicated in the product passport, they can be:

- Heavy class at 65-140 mm. These are professional saws, very massive, designed for long-term work with metals, wood, foam concrete.

- Middle class by 50-65 mm. These are the universal saws that are most common. They can be used to build a country house, to carry out repair work. If you do not plan to use the tool permanently, then it is necessary to give preference to just such models.

- Lightweight class at 40-50mm. These are small saws that are designed to perform occasional work. They are used for cutting sheet material, are unsuitable for more serious work. Their price is the lowest, but the quality is not very high, which is quite enough for home repairs.

Back to index

What should be the power?

Another criterion to pay attention to is power. It is best to take equipment with a small margin of power to ensure stable operation. Today, manufacturers produce circular saws of three classes:

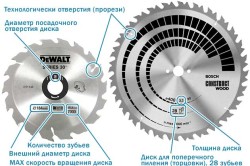

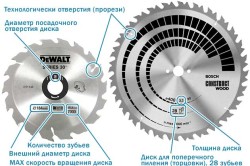

Information placed on the saw blade.

- up to 800 W (small household tools that can be used for home repairs);

- from 800 W to 1200 W (universal tool, often called semi-professional);

- from 1200 W (professional, very powerful saws).

When choosing which circular saw is better, you should not immediately grab the most powerful one, since often it will not be needed for home use, but its cost is quite high. It is important to immediately pay attention to the speed of rotation of the disk, since at high rates the cleanliness of the cut will be higher. High speeds mean an increase in temperature, i.e. the material being processed begins to melt, and this is not always acceptable. To choose better tools, which have a speed and stroke regulator, idle mode.

When choosing equipment, it is necessary to take into account the convenience of working with it. In this sense modern equipment differs significantly. Saws include electronics, which can significantly expand the functionality. Controllers read the speed, allow you to automatically change it when working with the material, which reduces time, improves the quality of the cut. There is also such a function as idle adjustment, which allows you to stabilize the operation of the tool, make it more clear and accurate.

It is best to take tools, the plates for which are cast from light alloys. They perfectly retain their shape, are lightweight, easy to use. But stamped plates are also characterized by certain advantages. They are resistant to loads, impacts, which is so important during construction work.

Back to index

Varieties of discs

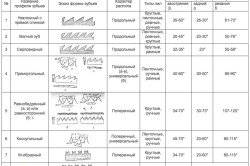

To select good and quality tools it is necessary to pay attention to which discs are suitable for a particular model. Today, manufacturers offer a large selection of such parts, but it must be approached very carefully. All discs are made of different materials, the number and type of teeth have a strong influence on how the cut will be, the cutting speed. It is worth paying attention to the marking, which will show what material the disc will be used for cutting.

There are no universal discs suitable for all types of work. But you need to start such a choice with which circular saw was purchased. The following parameters are taken into account:

- what is the maximum and minimum diameter for a saw it is admissible;

- size of the diameter of the landing pin;

- maximum rotation speed for the spindle;

- saw power, maximum allowable load on the equipment.

When choosing saw blade take into account:

- allowable number of disk revolutions;

- what work is planned. Today, there are a large number of a wide variety of discs on sale that are designed for specific purposes. This must be taken into account without fail;

- disk design;

- type, angle of teeth;

- disc material;

- web thickness.

- Nuances and features of choice

- Engine power

- Rotation frequency

- Cutting depth

- Additional features and capabilities

- Circular saw blades

Regardless of whether a hand-held circular saw or a stationary one, the principle of its operation remains the same: the electric motor rotates the disk, with which an even cut is made in different materials.

A hand-held circular saw can handle wood, plastic, and laminate.

A hand-held circular saw differs from a stationary one not only in its size, but also in the way it transfers rotation from the engine to the disk.

If in stationary models there is a belt for this, then in hand saws the disk is mounted directly on the shaft. This reduces the size of the tool but makes it less powerful.

Regardless of which circular saw, manual or stationary, any model has a support platform. This platform allows you to adjust the angle and depth of the cut. Thus, the functionality of the saw is significantly increased.

If you need a hand saw, how to choose one that suits your needs. The disadvantage of a cordless saw is its lower power, but it has high mobility.

Nuances and features of choice

In order to choose any power tool correctly, you need to know its main characteristics and only then make a choice. The hand-held circular saw is no exception in this matter.

Back to index

Engine power

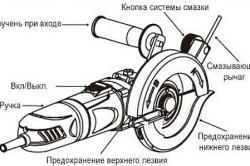

Circular saw device: 1 - base; 2 - branch pipe for removing sawdust; 3 - switch; 4 - protective cover; 5 - protective cover, movable; 6 - scale of the angle of inclination of the body.

This parameter affects the disk of what diameter can be installed on the specified model. The more power, the larger disc can be used. The maximum depth of cut will depend on the size of the disc. Engine power also affects the ability to work with dense material. If it is small, then when passing through a knot, the disk may jam.

A powerful saw will last longer without breaking because it doesn't work at full power all the time. Despite these advantages, a hand saw, which has a powerful electric motor, has one significant drawback - big weight. If a saw with a 2 kW motor weighs 7 kg, then a model with a 4 kW motor weighs only 4 kg.

Back to index

Rotation frequency

An important characteristic is the frequency of rotation. The higher it is, the easier it is to cut dense material and the better the cut is. This is especially true when sawing chipboard or plywood. To cut without chipping, you need to choose a high-speed saw. Power and RPM are not proportional, so a low power saw can have high RPM, and conversely a powerful saw can have a low RPM. It is very convenient when it is possible to adjust the rotational speed of the disk, since for various materials and wood species, it should be different.

Back to index

Cutting depth

This value directly depends on the power of the installed engine: the higher it is, the larger diameter disk can be installed. When choosing this option, you must take into account the tasks for which you will use a hand-held circular saw:

- for domestic purposes, a cutting depth of 40-45 mm will suffice;

- for semi-professional use - 50-55 mm;

- for professionals - up to 60-70 mm.

If we talk about the possibility of adjusting the inclination of the cut, it is worth noting that almost all models have this function. This feature is usually used only by professionals, but can be very useful in everyday life.

Back to index

Additional features and capabilities

![]()

Protective coatings improve disc cleaning and protect against corrosion.

Depending on the model of the saw, it may have a number of additional and useful functions. Significantly increases the safety of using the tool, the presence of an accidental start lock. In order to turn on the saw, you will need to press two buttons at the same time. Although such an operation makes starting more difficult, it increases safety when using the saw, making it less traumatic. The handles and body of the saw must be strong and reliable so that it does not slip in your hands.

The presence of the function of immersion in the material allows you to start making a cut from any place, and not strictly from the beginning of the material.

In order for the tool to work for a long time and without sharp blows, the soft start function will help. To ensure the cleanliness of the workplace, the sawdust collection function will be useful. It is implemented, as in other power tools, by connecting a household vacuum cleaner to a circular saw.

The presence of a laser pointer helps to make a long cut without a guide bar. It is suitable for household saw application. If you need to make a high-precision cut, then you cannot do without a guide bar. Hand saw can also be used in a stationary position. There is a special frame for this, it allows you to fix the tool in the desired position.

Chicken in kefir - recipes for marinated, stewed and baked poultry for every taste!

Simple Chicken Recipe in English (Fried) Recipes in English with translation

Chicken hearts with potatoes: cooking recipes How to cook delicious chicken hearts with potatoes

Recipes for dough and fillings for jellied pies with mushrooms

Stuffed eggplant with chicken and mushrooms baked in the oven with cheese crust Cooking eggplant stuffed with chicken