All knives will someday require the restoration of the cutting edge of the blade - sharpening, which has the following steps:

- Sharpening - correction of the edge of the blade with highly abrasive materials.

- Editing - the final polishing of the bevels and the edge of the knife with a ceramic pencil, GOI pastes or a leather belt.

- Regrinding - complete restoration of the required sharpening angle.

The last procedure can be performed only with special tools, on which you can adjust the degree of the sharpening angle.

The current market offers machine tools for professional knife sharpening, as well as for domestic purposes.

Sharpening angle

When sharpening a knife, it is important to maintain the correct inclination of the blade in relation to the bar.

Then you can not spoil the original angle of the cutting edge cutlery created at the factory.

| Knife type | Sharpening angle |

| Table (for meat, fish, butter) | 50-60 |

| Hunting, cutting ax | 45 |

| Folding, kitchen cleaver, hatchet | 40 |

| Professional for vegetables | 35 |

| boning (meat, fish) | 30 |

| Chef's professional | 25 |

| Gastronomic | 20 |

| Camping - ordinary knife | 15 |

| Fruit | 10 |

| Thinning | 5 |

Types of grindstones

Thanks to the presence in modern world high-quality sharpening correctly and efficiently, not only men, but also women can sharpen knives.

Most cheap option– lingering corundum knife sharpeners.

Their effect is very limited, because the turning disks are only set at 20 degrees, and the corundum is able to roughly notch the edge of the blade.

From the table above, it can be seen that different types knives, the degree of broach is different.

You can sharpen the knife at the required angle yourself using a simple mechanism that you can actually do yourself using a clerical binder.

With this tool you can sharpen both knives and stainless steel.

In such a mechanism, it will be possible to freely adjust the angle of the capture depth.

The consumer can buy mechanical machines in which the sharpening angle changes, of the following types:

- Long knife sharpener with degree adjustment and 2 abrasives.

- With zirconium discs.

- With fixed bars, the corners are fixed.

- With the ability to arbitrarily set the angles of fixation of the bars for sharpening.

- With a knife lock and a sharpening surface that slides, the angle is set arbitrarily.

To simplify the process of sharpening knives, electrical devices are also manufactured.

To use them, there is no need to apply force, and also in time, the sharpening process is faster. The only “but” is the price, since such machines are more expensive than mechanical ones.

Electric sharpening models with adjustable sharpening angle have a set degree of sharpening and 2 abrasive surfaces as standard.

We make grinding devices with our own hands

A knife sharpener that anyone can make

If someone does not like (no possibility) to bother much with manufacturing complex structures, you can use the tips on creating the simplest mechanism that can sharpen a knife.

Watch the video:

Sharpener Apex

To make an Apex sharpener, watch the following video:

Sharpener of a new sample

A more advanced version of the new sharpener, on which the main plate is replaced by three support plates, which makes it possible to sharpen any blade at any angle with better quality, is presented in this video:

Strogoff's whetstone

A sharpener for knives with a degree adjustment from improvised materials was developed by the craftsman Strogoff.

His drawings suggest creating a convenient mechanism for sharpening household cutting tools from a piece of aluminum profile.

In addition to the profile, to create the unit, you will need neodymium magnets (diameter 7 mm) and metal scissors. With this tool, you can sharpen the blade from 1 to 42 degrees.

Master people will appreciate.

The story of self-sharpening knives made of a wonderful supermaterial has naturally sunk into oblivion. It could not be otherwise - the nature of friction, the laws of solid state physics, the fundamentals of materials science and metal science have not yet been canceled. Even space titanium and Ceramic knives after a while they become dull and require sharpening. Well, steel and Damascus blades do require, if not daily, then monthly editing.

General information on the knife sharpening process

Stages

The process of sharpening knives consists of several stages and does not always require full observance of the entire cycle. At proper care for knives and a careful attitude towards them, it will be enough to perform only the so-called editing. Total there are 4 stages or method of sharpening cutting surfaces:

materials

- artificial abrasives- are diamond powders of different fractions; grains of different sizes from electrocorundum or silicon carbide. The quality of whetstones or cutters coated with these abrasives is greatly influenced by the material used to bind the fractions. They are used at the stages of regrinding, sharpening and rough finishing. Not recommended for continuous refinishing.

- Ceramics - modern look materials for hand bars, musat and mechanical milling cutters sharpened: 1) corundum or aluminum oxide - designed for finishing knives made of all types of steel; 2) zirconium dioxide is a complex, expensive coating for knives and sharpeners for fine dressing and finishing.

- Japanese Waterstone- predominantly artificially ceramic, but natural ones are also rare. Before sharpening, the stones are soaked for 15 minutes in cold water, sometimes with a small addition of soapy water, and after work - dried. Apply at all stages of sharpening, depending on the size of the fraction. Stones require constant alignment of the plane of their surface.

- Novaculitis- "Arkansas", "Turkish", "Belgian" stones; yours. These are natural shales and chalcedony interspersed with grains of quartz and garnet. Artificial substitutes can also be found on the market. They work only in combination with special oil lubrication. Due to the natural variety of grain sizes and varying degrees of rock hardness, they are suitable for all stages of knife sharpening.

Ways

To sharpen cutting tools at almost all stages of work (except for regrinding), you can use two methods of sharpening: using special mechanical devices and manually.

To sharpen cutting tools at almost all stages of work (except for regrinding), you can use two methods of sharpening: using special mechanical devices and manually.

For manual sharpening, straightening and finishing of blades use bars, disks, musats, pencils and pastes. To facilitate this process, you can purchase or make your own special stands, fixers and clamps.

Deep regrinding requires professional sharpening machines. But in the modern market of grinding devices, mechanical sharpeners of the widest range of impact and domestic use are presented.

Sharpening angles

In the process of sharpening knives, it is important to constantly keep the right angle blade to the bar (milling cutter) and thereby maintain the original factory angle of the cutting edge.

Sharpening mechanisms with adjustable sharpening angle

The profession of a grinder and sharpening knives has always been a male priority. Modern sharpeners allow women, without the participation of men, to keep knives in "full combat readiness."

The profession of a grinder and sharpening knives has always been a male priority. Modern sharpeners allow women, without the participation of men, to keep knives in "full combat readiness."

Habitual cheap corundum broaching knives can not always help, since the grinding wheels are set in them at a standard angle - usually 20 degrees, and the corundum can rough cut the cutting edge. An exception may be simple ceramic broaching sharpeners, but they are also of little use due to the strictly set degree of sharpening.

From the presented table it can be seen that not all tools are sharpened at an angle of 20 degrees. You can, of course, try to find hand-held knives "each with its own degree of broach." However, here the consumer is in for a catch, not even in the total cost of such purchases, but in the "littering" of the kitchen space and the high probability of spoiling the knives by sharpening them on the knife with the wrong angle.

You can manually sharpen tools at the right angle using a primitive homemade device from a stationery binder by adjusting the angle of the gripping depth.

For the convenience of the consumer modern manufacturers began to produce fixtures and machines with variable adjustment of the degree of sharpening of the following varieties:

Mechanical sharpener

Mechanical, broaching sharpener with adjustable angle and two abrasive surfaces for sharpening (1) and finishing (2).

Mechanical, broaching sharpener with adjustable angle and two abrasive surfaces for sharpening (1) and finishing (2).

Mechanical sharpener with zirconium disks for Asian and serrated knives.

Mechanical sharpener with fixed bars for finishing or sharpening under different, but fixed angles.

Fixture with arbitrarily set angles for fixing sharpening bars.

Device with knife fixation and sliding sharpening surface at an arbitrarily set angle.

Household electric grinders

Machine with adjustable sharpening angle and two abrasive surfaces.

In conclusion, we recall that any mechanical devices facilitate, but do not replace manual labor for sharpening knives.

Date: 04/29/2014

I already shared my experience in one of the articles,. Manual sharpening is considered preferable, since after it the cutting edge is less subject to wear. But in the fifth decade, the hands become not as dexterous as before, and even the simple tying of shoelaces wants to be entrusted to someone else.

Here you involuntarily think about auxiliary devices that can at least slightly level the staggering of the limbs and the downed eye sight. Manual, perhaps the best option This will save you money and get rid of some junk.

Components

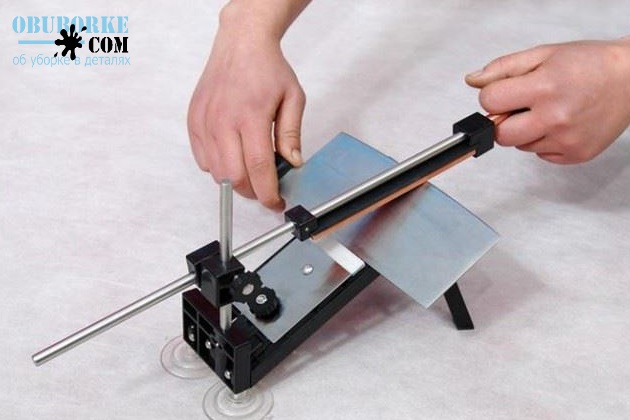

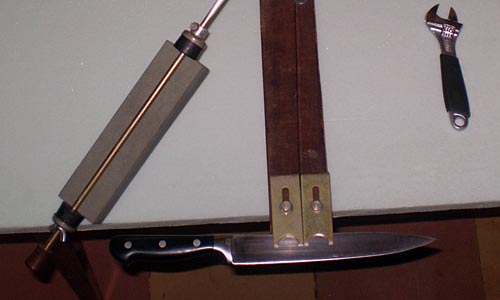

After watching a few videos on YouTube, it becomes clear that the configuration of a homemade sharpener and its details can be different. Most often, the Apex Edge Pro knife sharpener (USA) is taken as a sample. Main components: a) a rod with a handle and a device for clamping a stone (blank with sandpaper); b) a base with a mount for knives, a clamp, a stand and a knot that regulates the sharpening angle.

How to make a sharpener

As a base, I used a piece of textolite plate measuring 400x60x25 mm, although it was possible to limit myself to an ordinary board. Then I drilled one hole in it for the stand (a stud with an M8 thread 300 mm long), two holes for the M6 clamping bolts for the knife fixation device, three holes for the M4 bolts for fastening homemade clamp. In the holes, in addition to the one under the rack, I cut the thread.

The fastening of the knife blade can be made from any suitable size plates with holes rigid enough not to bend when the bolts are tightened. In principle, the bolts themselves do not need to be tightened strongly, the blade is held securely in such a tack.

I inserted the rack into the hole on the basis of a homemade sharpener and secured it with two nuts. I screwed two nuts with washers onto the rack, between them I placed a sleeve from a children's designer with a side threaded hole, into which he screwed and fixed with a nut a guide ring made of a long bolt.

![]()

The clamp was bent out of a thick strong plate, having previously drilled three holes in it for fastening to the base and one hole for the M6 clamping bolt, in which I cut the thread.

The rod of my sharpener is a metal rod 620 mm long with an M8 thread cut along the edges, on which movable and fixed stops (holders) made of dense rubber, a wing nut and a handle are installed.

The fixed stop of the rod is fixed with a sleeve with a bolt from a children's constructor. Inserted between holders grindstone(form with sandpaper) and tightened with a lamb. Useful advice: if you can’t get a smooth rod, buy a regular hairpin, and put a silicone tube (hose) of the appropriate diameter on the thread on one side.

You will also need triangular corner templates made of cardboard. You will have to tinker with them, because for each knife they will be different. It must be understood that the angle of sharpening the cutting edge is not the angle of the stone in relation to the axis of the blade. For example, if the angle of inclination of the stone to the axis of the blade is 20°, then the angle of sharpening the blade will be already 40°.

The homemade sharpener works as follows: it is installed on the rod grindstone, the base is fixed on the table with a clamp, the knife blade is fixed in the tack with bolts and plates, the free end of the rod is inserted into the guide ring on the stand. The desired template is placed on the blade of the knife, and a stone is applied on top. The angle of inclination of the stone is adjusted by lifting (lowering) the assembly with the guide ring along the rack, which is then tightened with the top nut.

To sharpen the blade, the movements of the bar must be smooth, away from you, with the stone shifting away from the heel of the blade to the tip. Sharpening angles of the cutting edges of knives: for soft products - 15-20°, kitchen - 20-25°, universal (for outdoor recreation) - 25-30°, for complex work- 30-45 °, for chopping tools - over 45 °.

Beef diet dishes: cooking features

Work with a manual wood router

Do-it-yourself coal melting furnace

DIY rowing machine

Stone and brick cutting machine