Calculation of the optimal log cut using Excel. It is important for every sawmill to minimize the raw material waste of production as much as possible. The profitability of the production of construction logs significantly depends on this.

An example of calculating the cut construction logs in Excel

The program for calculating the saw cut of a log will be useful for small entrepreneurs who are ready to create their own business for the production of rounded logs and the construction of wooden

A certain number of logs, each 10 meters long, are fed into the cut. The sawmill signed a contract for the supply of raw materials from wood in the following quantities:

- 100 logs of 5 meters;

- 200 logs of 4 meters;

- 300 logs of 3 meters.

What would be the optimal number of logs to be sawn to fulfill the contract terms? In other words, how to cut boards with a minimum amount of production waste?

Solving the problem of cutting logs

To create a solution model, it is necessary to determine all possible options cut logs 10 meters long each into 3-, 4- and 5-meter sections, taking into account the length of the waste. The result of such calculations is the identification of 6 cutting options:

- 2 beams of 5m each (0m of waste).

- 2 beams 5m + 4m (1m waste).

- 2 beams 5m + 3m (2m waste).

- 3 beams 3m + 3m + 4m (0m waste).

- 2 beams of 4m each (2m of waste).

- 3 beams of 3m each (1m of waste).

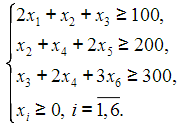

According to the condition of the problem, X i are sawn using the i method. Then the scheme will be correct:

F = X 1 + X 2 + X 3 + X 4 + X 5 + X 6 => min

You can create a system like this:

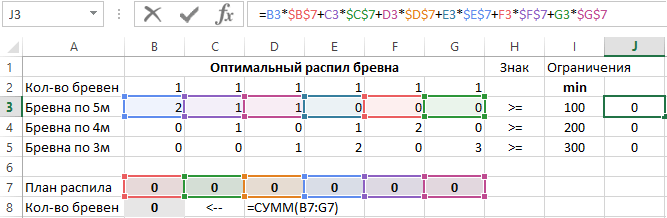

The next step is to prepare a Microsoft Excel spreadsheet that will contain the initial conditions of the problem.

To calculate the left side of the constraint and the objective function, the corresponding formulas are introduced. Fill cells J3:J5 with these formulas:

And in cell B8, enter the formula: =SUM(B7:G7).

Next, the form of the modules "Search for a solution" and "Parameters for search for a solution" is filled in. To do this, go to cell B8 and use the tool on the tab "DATA" - "Analysis" - "Search for a solution". If you do not have this tool on this tab, then read the instructions.

All photos from the article

In this article we will talk about how cutting logs is performed on a band sawmill. In addition, we will consider what are the criteria for selecting one or another method of wood processing and how this affects the characteristics of finished lumber.

Methods for cutting logs to obtain various lumber have been developed and improved for a long time, since this is the only way to get from a single tree trunk edged board, timber and other categories of similar products.

For a long time to this day, wood processing methods have evolved, and in addition, new, more productive equipment has appeared that allows you to get the necessary lumber quickly and with a minimum amount of production waste.

Features of wood processing

The instruction for processing raw materials and obtaining sawn products consists of a number of technological operations, including longitudinal cutting of logs, sawn timber trimming and cutting to width, sorting by standard sizes, sorting by workmanship quality, drying and storage.

Each of these stages is important in terms of quality finished products. But, it is cutting that is the most time-consuming and responsible stage, during which the main characteristics of finished lumber are formed.

Drawing up a plan for cutting logs into lumber (the choice of a suitable processing method) depends on the type of wood, on the standard sizes of raw materials, on the degree of humidity, on density and hardness, and on many other factors. Of course, the method of processing raw materials is largely determined based on the level of technical equipment of the enterprise.

Consider what equipment is used for industrial sawing of wood and what methods are relevant for each category of this equipment.

Equipment for cutting and features of its application

The following categories of equipment are used for longitudinal cutting of logs:

- Single band saws or circular (circular) saws are a traditional solution that has been used for a long time.

- The group of frame saws is a more advanced solution that allows you to significantly increase the productivity of raw material processing without compromising the quality of the finished product.

Let us consider in more detail the features of the use of the listed categories of equipment.

- Individual sawing is a method in which single saws are used. In this case, only one cut can be obtained in one pass of the saw. Therefore, the entire tree trunk can be cut in several passes.

Important: The advantage of individual sawing is the independence of each subsequent cut from the previous one.

That is, sawing can be carried out in different planes.

As a result, it becomes possible to use certain properties more rationally. different parts logs.

At the same time, this method is inefficient, and therefore not suitable for use in large woodworking enterprises.

- Group sawing- it technological process, during which a group of frame saws is used.

advantage this method is that the log is cut completely in one pass. This saves time and, as a result, reduces the cost of production. But you need to remember that group sawing is performed in one plane.

To date, the following categories of equipment for group sawing are most widely used:

- narrow-clear vertical frames, machines with circular saws, milling saws (diameter of processed raw materials from 14 to 22 cm).

- medium-light vertical frames (diameter from 24 to 48 cm)

- wide-clear vertical frames, double and quadruple band saw units (diameter of processed raw materials over 50 cm).

SawsOptimization is designed for sawmill technologists and planners and is a tool for optimizing sawmilling and maximizing yield. The program has convenient and flexible settings and an intuitive interface, which greatly facilitates the development of the program and further work with her.

The initial data for the program are:

log dimensions

· Required dimensions of lumber and their cost.

· Characteristics of sawmill equipment.

The basic functionality of the program is the calculation of optimal deliveries based on these data. The program gives deliveries that can be implemented on this equipment and provide maximum yield or maximum cost of products, allows you to calculate the amount of ash content of the boards, the volume and cost of the finished product.

By registering on our website, you can download a demo version of the program in the "Documentation and support" section.

What's new in version 3.0

The SawsOptimization program of the previous version 2.3 is well known to many sawmillers and has gained wide popularity in Russia. Users of SawsOptimization2.3 will find in new version programs the following improvements:

· advanced options for customizing sawing profiles and equipment settings, including: additional settings for saws, profiling machines, saws and cutters, additional equipment profiles (Carousel, Linck, SAB, sawing in 3 passes), dependence of the width of the saws on the thickness of the cut.

· Special sawing modes: coreless board, sawing with a fixed thickness of the outer side boards, sawing material with a false core.

· Improved optimization engine gives better results in some cases.

· advanced options for operations with stubs: manual creation and editing, saving-reading, application of an arbitrary stub to a log of arbitrary sizes, selection of the optimal diameter for a stub.

· Automatic calculation saw sizes depending on the final humidity according to GOST 6782-1.75

In addition to the basic version, there is version 3.0 Professional, designed to optimize the sawmilling cycle from log sorting in large enterprises and, in addition to the above, has the following additional functionality:

· Planner functionality: group optimization for logs of different diameters, general specification of output for the entire log volume, planning and optimization to obtain the desired output by section.

Optimization for curvature

· optimization of sorting of logs by deliveries to obtain the maximum yield of products.

integration with OptiGrade log sorting optimization software

Brief description of the program features Saws Optimization Professional:

- Batch optimization for all diameters, with the calculation of the optimal sets for each diameter, the total yield of sawn timber and the yield by section.

- Possibility of optimization to achieve the required cross-sectional yield.

Example: it is required to optimally obtain an output of section 32x150 of at least 10%. We achieve this, while the overall yield drops from 52.24% to 51.83%.

- Automatic optimization of sort group boundaries, as well as the ability to change the boundaries manually and see how changing the boundaries affects the output.

Example: changing the boundaries of the variety groups increased the yield to 52.66%

- The ability to choose an alternative set for any variety group and see how a change in set will affect the overall yield.

- Accounting for the availability of a cutting optimization system for an edge trimmer. Different variants the width of the side boards in one set.

Distribution of raw materials by diameters: the ability to either specify in pieces the remaining raw materials in the warehouse by diameters, or use a statistical distribution according to the sorting of logs. Consideration of all dimensional factors (diameter, runoff) when calculating the total output.

- Detailed configuration of equipment profiles, the ability to specify different profiles for different diameters.

When sawing wood, it is important to immediately calculate what the consumption will be, as this will affect the cost of lumber. The output of finished products may be different. It all depends on the quality of the wood used, whether measures are taken to optimize cutting. There are special measures to increase the efficiency of work, make the output better, and the quality of sawing is higher. Before cutting, you must first calculate everything. It's not as difficult as it might seem, but the expense roundwood will be optimal, beneficial for obtaining excellent results.

How to increase cutting efficiency

In order for the lumber yield to be significant, it is necessary to use special measures to increase the efficiency of the process:

- The calculation should be carried out only when using special programs, manually it will have low efficiency, the rejection rate will turn out to be large.

- The round timber must first be sorted so that the processing is carried out correctly.

- For cutting, high quality equipment must be used. Otherwise, the amount of waste will be large, and the quality of the resulting lumber will become low.

- It is best to cut wide lumber first, it takes longer to process narrow lumber.

- Logs are not recommended to take long.

- Before work, you must configure the equipment.

The output of finished lumber may be different. It must be remembered that at the first stage boards are obtained, then they are sorted. As a result, the percentage decreases even more, for example, for hardwoods it can be only 10-20%.

How to optimize cutting

In order to increase the output of lumber, the sawing process must be optimized. This applies primarily to those blanks that have a significant curvature. To cut a curved roundwood, you need to perform a series of actions:

- First, only suitable wood is selected for work. If the remaining logs have rot, sprouts, cracks at the ends, then it is necessary to trim some sections.

- If a rotten core is found during operation, then you can carefully remove it, and then cut the rest. This will avoid large losses, get boards with a length of 1 m with the required quality.

- It is recommended to use logs with a larger diameter so that the yield percentage is higher. The coefficient can be 1.48-2.1, but it all depends on the diameter, quality of round timber, sorting, and equipment. For frame shops, this coefficient will be 1.48-1.6, and for lines with milling equipment- 1.6 for large forest. With a round timber diameter of 12 cm or more, the coefficient may exceed 2.1.

Waste volume after sawing

In order for the finished board to come out with a large percentage, it is necessary to prepare everything correctly, work should be carried out only in accordance with the technology. The round wood of coniferous and deciduous breeds gives various output. In the latter case, the volume is smaller, even if special additional equipment is used. Needles for sawing are considered more convenient, since the trunk is straight, and the log has a larger diameter. Coniferous forest is not so prone to decay, so there is less marriage. For hardwoods, 2 cutting technologies are usually used:

- using a band sawmill at Z75, Z63;

- into collapse, when a half-beam is cut out in the core of the material, passed through a multi-blade machine.

The volume of a band sawmill is 40-50%. When using the technology in the collapse, the yield is different, it can be increased up to 70%, but the costs of such work are higher. If roundwood is sawn, the length of which is 3 m, then you can see that the percentage of rejects is quite large, and the remaining material requires processing. This applies to the bulk with boards 22x105 (110, 115) x3000 mm. There are many options for such a marriage. For example, it may be a wormhole, which is no longer suitable for most jobs.

After sorting, the volume of hardwood material that is grade 0-2 will be only 20-30% of the amount that is obtained after sawing. This means that from the total mass of harvested roundwood, the output of a normal board will be only 10-20%. The rest of the materials are mainly used for firewood. Coniferous round timber will have a different yield, but attention should be paid to what average values of the obtained volume are observed.

lumber output

In order for the lumber yield to be optimal, numerous conditions must be taken into account. For a correct calculation, you can consider the example of the output of roundwood. The data was obtained on the real experience of specialists and on the performance of sawmills. This makes it possible to compare percentages and calculate optimal averages.

In conifers, the following output is possible:

- For unedged board and other unedged materials during sawing, the yield will be 70%. This is the amount of material obtained during processing, the amount of waste will be 30%.

- For edged material, when using sawmills at 63, 65, 75, there will be a lower yield of lumber, in the region of 45%. At band sawmills the yield is usually up to 55-60% of the finished material. If you apply the means to improve efficiency, then you can reach 70%, although this requires a lot of experience.

- 70-75% lumber can be obtained from a sawmill, although with efficiency improvement methods it may well be 80-75%. But experience is required.

According to GOST 8486-86, for grade 0-3, the percentage of yield, excluding sorting, is approximately 70%.

Another 30% can be left for rejection of the finished material. Rejected material is not thrown away, it is used for the manufacture of other types of lumber, which allow the presence of a certain marriage.

Hardwood roundwood has a different yield percentage:

- For unedged material - 60%.

- For edged wood - up to 35-40%, since the curvature of the original hardwood forest is usually large.

The output can be increased, for this additional equipment is used. It can be a special multi-saw machine, an edge trimming machine, a slab machine. In this case, it will turn out to increase the yield of lumber by about 20%. The given percentage is given on the basis of data on the production of grade 0-4 boards. When sorting grades 0-1, the percentage of lumber production is 10%. To get a cube of finished hardwood edged material, it is necessary to cut 10 cubes of the original roundwood for sawing.

The output of lumber from roundwood can be different. It all depends on the original wood species used by the sawmill. Special Measures to increase efficiency allow you to get a larger percentage than is possible, but for this you should have some work experience.

Chicken in kefir - recipes for marinated, stewed and baked poultry for every taste!

Simple Chicken Recipe in English (Fried) Recipes in English with translation

Chicken hearts with potatoes: cooking recipes How to cook delicious chicken hearts with potatoes

Recipes for dough and fillings for jellied pies with mushrooms

Stuffed eggplant with chicken and mushrooms baked in the oven with cheese crust Cooking eggplant stuffed with chicken