At the exhibition "Metalworking-2017" held in Moscow, the premiere of the "Rapier SGS-01" machine took place. Thanks to its appearance, the production of barrels for small arms can rise by new level

The eighteenth international exhibition "Metalworking-2017" has opened in Moscow, at the Expocentre on Krasnaya Presnya. She will work from 15 to 19 May. One of the real sensations of the exhibition is the demonstration of the machine deep drilling, the likes of which we have never released.

In total, on an area of 39.5 thousand square meters 1000 companies from 30 countries demonstrate their achievements. Despite the sanctions, machine tools are offered to Russian enterprises by such countries as Austria, Great Britain, Germany, the USA, France, Switzerland, Sweden and Japan.

Minister of Industry and Trade Denis Manturov noted: "The exhibition is a key event in the field of material processing technology and makes a significant contribution to the implementation of relevant government programs and investment projects. It presents the best examples technological equipment meeting all the requirements of international standards".

It is gratifying that, along with the world's leading machine tool companies, Russian companies are also represented. True, I must say that they mainly produce licensed machines adapted to our conditions.

But the USSR was one of the world leaders in the field of machine tool building, no matter how strange it may seem to someone today. Back in 1991, our country ranked second in the world in terms of consumption of machine tools and third in terms of their production - after the USA and Japan. At the same time, the "soviet" machines were not much inferior in quality to foreign models. And for the production of machine tools with numerical program management we even took the lead. And a real rout Russian machine tool industry in the 1990s was hardly accidental.

In the early 2000s, attempts were made to revive this branch of engineering. Billions of rubles were allocated. They were simply stolen. The investigation was led by the FSB. Some of the culprits were found and jailed. But the machine tool industry has not really revived in our country. Today, all the most modern Russian factories, including defense ones, are equipped either with imported machines or manufactured in our country under license.

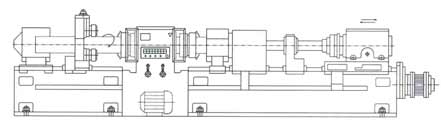

That is why it is possible to call the premiere demonstration of the machine "Rapier SGS-01" sensational. SGS-01 is a single-spindle deep drilling machine. Single-spindle, in turn, indicates that one workpiece can be processed at a time. However, as the developers assure, if necessary, it can be made with two or even three-spindle.

But perhaps the most surprising thing is that it was designed and assembled not by machine tool specialists, but by the creators of small arms.

The initiator was the head of the Central Design and Research Bureau of Sports and Hunting Weapons (TsKIB SOO), located in Tula, Alexei Sorokin. This bureau, of course, deals with both sports and hunting weapons, but its main direction is combat.

Here is what Alexey Sorokin told the correspondent " Russian newspaper about why we need a deep drilling machine and how it was created.

The machine is my private project, without false modesty, but also without pathos, says the director of TsKIB SOO. - On the one hand, its creation is not connected with the main activity - the management of a defense enterprise. On the other hand, I see all the problems of machine tool building and I understand perfectly well that good weapons can only be produced on good machines.

In particular, in order to manufacture the barrel of an assault rifle, machine gun or hunting rifle, equipment is needed that allows for the so-called deep drilling. It is not produced in Russia, and imported is very expensive, and it is problematic to purchase it today. Western manufacturers are reluctant to sell machine tools to defense enterprises.

Deep drilling is characterized by the ratio of the diameter of the drilled hole to the depth of drilling. If this ratio is 1 to 10, then it is already deep, for example, a hole with a diameter of 7.62 mm to a depth of 76 mm is deep. But in gun barrels, the ratio can be 1 to 100 or even more, and this requires special technology.

Neither in the USSR, nor in Russia, CNC deep drilling machines for small calibers have ever been produced. So we were first. And we tried to set maximum requirements during its design, which would ensure its effective use in a wide variety of technological operations.

For example, this is a wide range of possibilities for the rotation of the workpiece, counter-rotation of the drill, control of temperatures, forces, and so on. In the production of the machine, we have achieved a unique geometry. The accuracy of the coincidence of all elements along the drilling axis is less than a micron, and the error of the bed is 4.7 meters less than a hundredth of a mm, such an accuracy of the machine will give hole accuracy, high purity and minimal center-to-center drift. We can drill blanks from any of the strongest steel up to 1300 mm long. The maximum caliber is 30 mm.

Our development, by the way, has the widest possible applications. After all, deep drilling is used not only in weapons production. This includes medical equipment, energy, and the tool industry (production of channels in molds), and transport engineering, and even the manufacture of special tools for forestry - there are also technologies that require deep drilling of small diameter holes.

For a complete technological cycle of manufacturing gun barrels a line of nine different machines is needed. We clearly imagine what these machines should be and, most importantly, how they should be made. If we find understanding, then I am sure that the production of machine gun barrels, machine guns, sniper and hunting weapons in our country will rise to a qualitatively new level. That is why participation in the Metalworking-2017 exhibition is very important for us.

We were able to implement a real import-substituting project. Most the best machines deep drilling is produced in Germany. But they are very expensive, and in terms of their characteristics they are in no way superior to our machine, which we show at this exhibition.

Necessary business. I watched on ORSIS how the barrels were turned. The coin on the edge on the moving bed does not move. But there are imported, and here is ours!

HONG JI machines for performing deep drilling operations have proven themselves among Russian users as extremely reliable equipment. The company produces a wide range of equipment tailored to perform highly specialized tasks with maximum efficiency.

| Parameter | Model | ST-1200 | ST-1500 | ST-2000 |

|---|---|---|---|---|

| PLC / CNC type | Mitsubishi/Fanuc | Mitsubishi/Fanuc | Mitsubishi/Fanuc | |

| Desktop | Dimensions, mm | 1000x1200 | 1300x1800 | 1600x2600 |

| Max. part weight, kg | 5000 | 10000 | 15000 | |

| drilling range | Number of spindles | 1 | 1 | 1 |

| Drilling diameter, mm | 3…25 (5…40) | 3…25 (5…40) | 3…25 (5…40) | |

| Max. Drilling depth (Z-axis), mm | 1200 | 1500 | 2000 | |

| Movements | Transverse movement of the table (X axis), mm | 1000 | 1600 | 2200 |

| Vertical movement of the spindle (Y axis), mm | 1200 | 1000 | 800 | |

| Spindle power | kW | 5,5 | 5,5 | 5,5 |

| Speed | Working feeds, mm/min | 10…150 | 10…150 | 10…150 |

| Drilling spindle rotation speed, rpm | 6000 | 6000 | 6000 | |

| High pressure pump | Max. Pressure, bar (MPa) | 100 (10) | 100 (10) | 100 (10) |

| Consumption, l/min | 30…60 | 30…60 | 30…60 | |

| Coolant tank volume, l | 1000 | 1200 | 1200 | |

| Common parameters | Machine weight, kg | 10000 | 16000 | 18000 |

| Machine dimensions, mm | 5300x2800x2800 | 6300x5200x300 | 7100x6000x3000 |

CNC metal deep drilling machines HONGJI(Taiwan) are designed to process deep holes in large-sized, heavy, complex in design and precise products such as an internal combustion engine body or parts of the aviation industry. The machines have 4 controlled axes and allow deep drilling, threading and milling operations.

The tool is a deep hole drill that can be changed quickly and easily, which allows you to increase work productivity. The 4-stage coolant cleaning system keeps the oil clean and prolongs its life.

According to a special specification, deep drilling machines with a drilling depth of up to 3000 mm and a table load capacity of up to 20 tons can be manufactured.

Standard equipment:

- FANUC CNC

- paper filter

- Magnetic separator

- Screw conveyor chip

- High pressure pump

- Pump automatic feeding lubricants

- External coolant tank

- Portable control panel

- Telescopic rail protection along X, Y, Z, W axes

- Interface RJ45, RS232

- Transformer 380/220V

- Adjustable machine feet

- Tool kit for machine maintenance

Additional options:

- Oil cooler

- Drill sharpening machine

- Rubber inserts for drill

- Drill Guide Bushings

- Full enclosed machine guard

- Centrifuge for coolant cleaning system

- Manual turntable

- Milling and tapping function

- Deep hole drills

Machine tools Precihole

Company Precihole

defense industry andautomotive industry, nmedical implants, uh energy, p recycling of materials, shswabs and molds, theavy engineering, paerospace industry.

BVN series deep hole drilling machines from the company Precihole have a robust construction that can withstand the high metal cutting forces that accompany drilling. These machines can drill holes up to 400 mm in diameter and up to 20 m deep.

Micro deep drilling machine from the company Precihole designed for drilling small parts where high hole accuracy is required. Using the most modern developments such as high speed electrospindles, tool monitoring systems, coolant pumps, tool magazines large capacity and reverse rotation of parts provide exceptional hole straightness, strict adherence to tolerances and surface quality requirements. Being a high-precision and high-performance equipment, this category of machine tools is widely used in the medical and aerospace industries.

GVN series deep hole drilling machines from the company Precihole meet all the basic requirements for this type of equipment: high accuracy, high performance, compact design, affordable price and reliability. These machines can be used for a wide range of workpieces and deep hole drilling from 2mm to 40mm in diameter.

Machines for trimming and finishing burnishing with rollers of the SBN series from the company Precihole Designed for high performance machining. Trimming and finishing burnishing with rollers is performed approximately 30-40 times faster than honing. These machines are ideal for the production of hydraulic cylinders of all lengths and diameters.

XYBVN series deep hole drilling machine Precihole have a robust construction that can withstand the high metal cutting forces that accompany drilling. With these machines it is possible to drill holes up to 50 mm in diameter and up to 500 mm deep.

XYGVN series deep hole drilling machine Precihole designed for processing parts in the form of a prism and drilling holes along the diameter of the pitch circle. As high performance precision equipment, these machines are ideal for many industries.

Machine tools Precihole have been produced for thirty years. These technologies provide high speed and accuracy of metal removal for obtaining deep straight holes while maintaining tolerances and requirements for surface quality. These machines are designed for 24/7 operation. manufacturing enterprises within 7 days a week.

Company Precihole is ISO 9000 certified and cares about the quality of its products, its customers and its staff. The company offers competitive prices for its products and strong commitment to its services.

Deep hole drilling and hole finishing technologies are used in a wide range of industries, including, among others:

defense industry andautomotive industry, noil and gas industry, mmedical implants, uh energy, p recycling of materials, shswabs and molds, theavy engineering, pproduction of hydraulic cylinders, andaerospace industry.

Benefits of Precihole

- over 25 years of deep drilling experience

- field-proven experience with deep hole drilling and hole finishing equipment

- technical competence in developing solutions for complex equipment

- unified business processes that provide the best value for money in the industry

- worldwide supply of equipment and technical support for all types of products and services

Main characteristics

Deep drilling with BTA technology

Micro Deep Drilling Machines

Single Axis Deep Drilling Machines

Multi-axis deep drilling machines

Roller trimming and smoothing machines

Machines for the production of tube sheets

3-axis deep hole drilling machines

Deep drilling machines

Deep drilling is generally characterized by a hole length to hole diameter (L/D) ratio of at least 10:1.

Precihole - deep drilling and hole finishing technologies

Machine tools Precihole have been produced for thirty years. These technologies provide high speed and accuracy of metal removal for obtaining deep straight holes while maintaining tolerances and requirements for surface quality. These machines are designed to work around the clock in manufacturing plants for 7 days a week.

Company Precihole is ISO 9000 certified and cares about the quality of its products, its customers and its staff. The company offers competitive prices for its products and strong commitment to its services.

Deep hole drilling and hole finishing technologies are used in a wide range of industries, including, among others:

defense industry andautomotive industry, noil and gas industry, mmedical implants, uh energy, p recycling of materials, shswabs and molds, theavy engineering, pproduction of hydraulic cylinders, andaerospace industry.

Benefits of Precihole

- over 25 years of deep drilling experience

- field-proven experience with deep hole drilling and hole finishing equipment

- technical competence in developing solutions for complex equipment

- unified business processes that provide the best value for money in the industry

- worldwide supply of equipment and technical support for all types of products and services

The CNC deep drilling and boring machine is Zhenhua's own development. internal surfaces hydraulic cylinder. At the moment there are 6 machines of various standard sizes available: 1 machine with a total length of 12m; 1 machine with a total length of 9m; 3 machines with a total length of 6m; 1 machine with a total length of 12m. With high build quality and efficiency, our equipment has won the trust of many national hydraulic cylinder companies, including Zoomlion, Sany and Sunward. Moreover, machines with a total length of 9m and 12m are widely used for the production of telescopic hydraulic cylinders for cranes such as Zoomlion, Sany and Sunward.

Our production allows deep drilling with fifty types of drilling heads. Many years of experience in the practical use and modernization of equipment has allowed us to achieve the best machining results, as well as to become an expert in the selection of boring and cutting heads and setting up equipment for the production of products using specific materials. In order to further improve the efficiency of the equipment, we are waiting for any wishes and suggestions from you.

Performance and scope

The TZH series is designed for drilling, milling and rolling of hydraulic cylinder liners made from standard steel or cold drawn tubing. The use of modern European technology and Zhenhua drilling and rolling tools can achieve the following results: the accuracy of the hole diameter of the workpiece is IT8, the surface roughness is Ra0.1-0.4 microns. The detailed specifications of the TZH CNC deep drilling and boring machine series are as below.

The use of this type of equipment allows you to reduce up to 80-90% of the processing time for each product, in comparison with traditional boring-milling and honing machines. For example, to obtain a cylinder liner with inside diameter 180mm and 4m long, takes an average of 5 to 6 minutes. While it takes up to 300 minutes for a honing machine to get a part with the same parameters. In addition, the TZH series of machines allows you to produce products with a tolerance and roughness level that is not inferior to European brands.

The machine is characterized by a strong and rigid structure, the movement of the working mechanisms of the machine is carried out by parallel guides, allowing to achieve high positioning accuracy and smooth running. Precision stiffener has increased strength, which is achieved by thermal aging. High power motor and Siemens CNC control systems provide high performance and easy operation. The machines are equipped with high-precision drills, the working tolerance of which is 12mm.

Specifications CNC deep drilling and boring machine TZH series| Model | TZH 125×6000 | TZH 250×3000 | TZH 250×6000 | TZH 250×9000 | TZH 360×12000 | ||

| Cylinder liner parameters | Outer diameter, mm | Æ73-140 | Æ73-300 | Æ145-426 | |||

| Inner diameter, mm | Æ63-125 | Æ6-250 | Æ125-350 | ||||

| Length, mm | 1700-6000 | 600-3000 | 1700-6000 | 1700-9000 | 2000-12000 | ||

| Speed of rotation of the main axis, rpm | 100-800 | 100-600 | |||||

| Maximum piston stroke, mm | 6350 | 3350 | 69350 | 9350 | 12350 | ||

| Feed rate, rpm | 0-2.4 | ||||||

| Main engine power, kW | 22 | 39 | 51 | 60 | |||

| power, kWt | 70 | 106 | 118 | 140 | |||

| Operating voltage, MPa | 10 | ||||||

| CNC system | Siemens 802 | ||||||

| Overall dimensions, m (L×W×H) | 21×4×2 | 15×4.5×2 | 21×4.5×2 | 27×4.5×2 | 34×5×2.2 | ||

| Weight, tone | 35 | 32 | 41 | 50 | 62 | ||

Deep drilling machines. Buy from stock. Machines to order

To ensure high quality and productivity in deep hole machining, a modern, high-performance and reliable special machine is required. Based on a variety of practical tasks have been developed special machines various standard sizes and in various designs.

The following designs can be used

Structural form 1 (lathe machine):

Locating a rotating product in the headstock chuck and roller rests. The stem with the installed tool is attached to the stem stock. Holemaking takes place with a non-rotating tool.

Structural form 2 (lathe machine):

Locating a rotating product in the headstock chuck and roller rests. Depending on the technological needs, processing can be performed with a rotating product with both a non-rotating and a rotating tool.

Structural form 3 (swivel machine):

Locating a rotating product in the headstock chucks and roller rests. The ends of hollow blanks are easily accessible for measurement, for changing tools; work using the "draw boring" method. Machining takes place with a non-rotating tool.

Structural form 4 (swivel machine):

Locating a rotating product in the headstock chucks and roller rests. Processing can be performed with a rotating product as a non-rotating and rotating tool.

Structural form 5 (machine body version):

Basing a non-rotating product in fixtures. Hole machining is done with a rotating tool.

Specifications

2825P 2830P 2840P 2850P

Height of centers above guides, mm............ 315............ 400............ 500..... ...... 630

Diameter of the installed product, mm:

in the headstock chuck ....................................................... 50-320....... 80-400...... 100-500..... 160-630

in the roller rest .............................................................. ...... 50-320....... 80-400...... 100-500..... 160-630

Processed hole diameter, mm:

drilling in solid material............................... 40-100....... 40-100.. ..... up to 125....... up to 125

for core drilling ............................................... up to 250. ...... up to 320....... up to 400....... up to 500

when boring .............................................................. ......... up to 250....... up to 320....... up to 400....... up to 500

when rolling .............................................................. ......... up to 250....... up to 320....... up to 400....... up to 500

Product headstock:

speed limits, rpm ............................... 40-500...... 40-500 ....... 16-250 ....... 16-250

electric motor power, kW .............................. 23/34 .......... 23 /34............55.............55

maximum torque, Nm ......................... 3000 .......... 3000 ........ .. 8000.......... 8000

Tool headstock:

speed limits, rpm....................... 100-630..... 100-630... ... 80-500....... 80-500

electric motor power, kW .............................. 30.......... .... 30.............. 55.............. 55

maximum torque, Nm ........................ 2000 .......... 2000 ........ .. 5000.......... 5000

Feed drive:

working feed, mm/min (steplessly) ............................. 5-3000....... 5-3000....... 5- 3000......5-3000

rapid traverse, mm/min .............................................. ... 5000.......... 5000.......... 5000.......... 5000

maximum feed force, N ........................................ 50000....... .50000........50000........50000

Performance pumping station coolant supply, l/min...... 300............ 500............ 640........... 1000

highest weight processed product, kg:

with one lunette ....................................................... .............. 3000.......... 3000.......... 5000.......... 6000

with two lunettes ............................................... ............ 4000.......... 4000.......... 6500.......... 7500

with three lunettes ............................................... ............ 5000.......... 5000.......... 8000.......... 9000

Depth of processing - any, according to your requirements.

CNC according to customer's choice

Machine operation video

| Machine name | Technical characteristics |

|

Buy deep drilling machine: |

||

| deep hole drilling machine | 2825P | + |

| deep hole drilling machine | 2830P | + |

| deep hole drilling machine | 2840P | + |

| deep hole drilling machine | 2850P | + |

| * deep drilling machine is produced according to the individual technical specifications and technological requirements for the workpiece. Manufacture comes from standard modules that have different structural forms, methods of processing parts (boring, drilling, drilling and boring) and various designs. | ||

The influence of the Internet on a person

Types of seizures Tonic-clonic seizures in children

Profession Internet project manager

best remedy for prostatitis

Symptoms and treatment of mastopathy of the mammary glands