Homemade, the quill will also be unique in its kind. No, the quill will be the most common, just not made according to the factory sizes, which, by the way, I have never seen, but according to the ones I calculated.

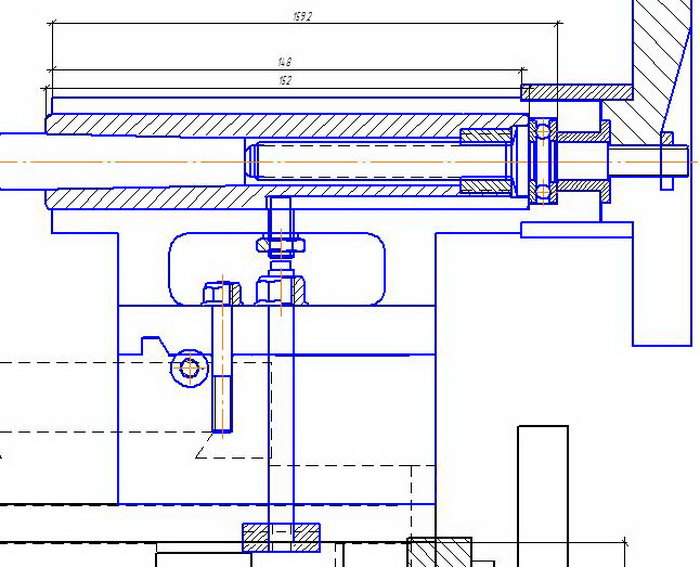

The departure of the quill from the body of the headstock should be about 50-70 mm, its diameter should ensure the installation of a tool with KM No. 2. Based on this condition, I will make a quill from a calibrated circle f30 and 130 mm long. Therefore, in the body of the headstock, you need to make a stepped through hole, in the wide place of which the quill will actually be placed, in the narrow one the tail of the screw will pass, and the support collar of this screw will rest against the step through the bearing.

Moreover, the quill should be as coaxial as possible with the axis of the machine spindle, and also have a minimum backlash in conjunction with the body, i.e. sliding landing.

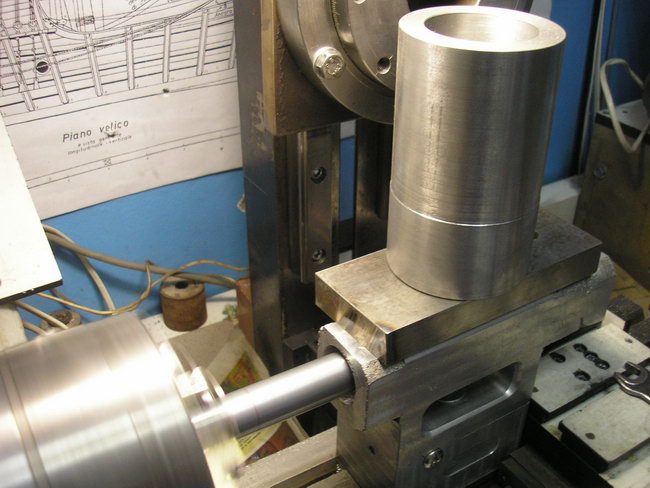

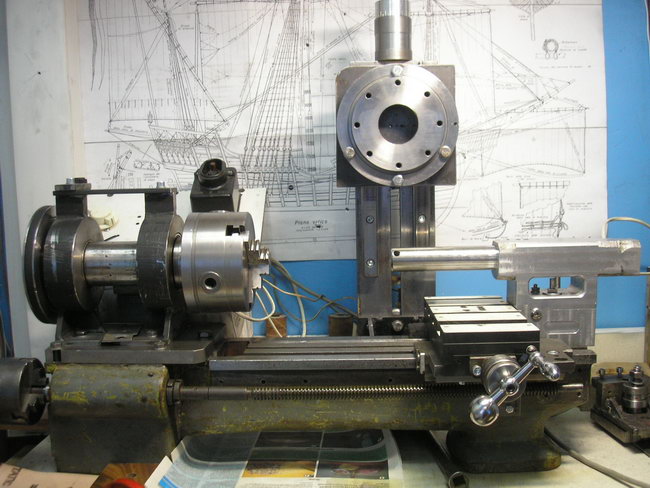

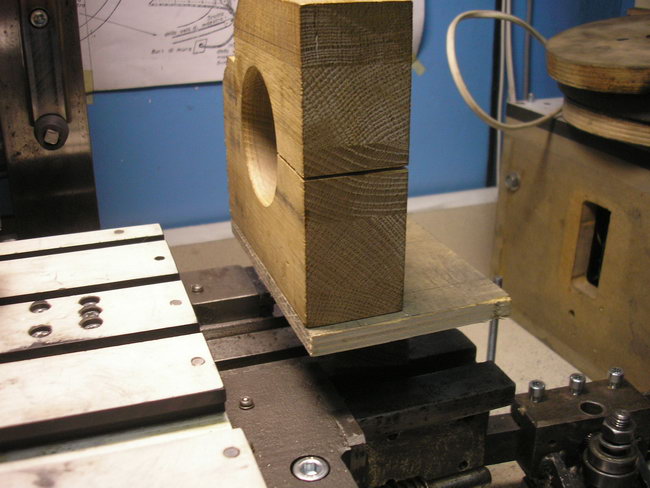

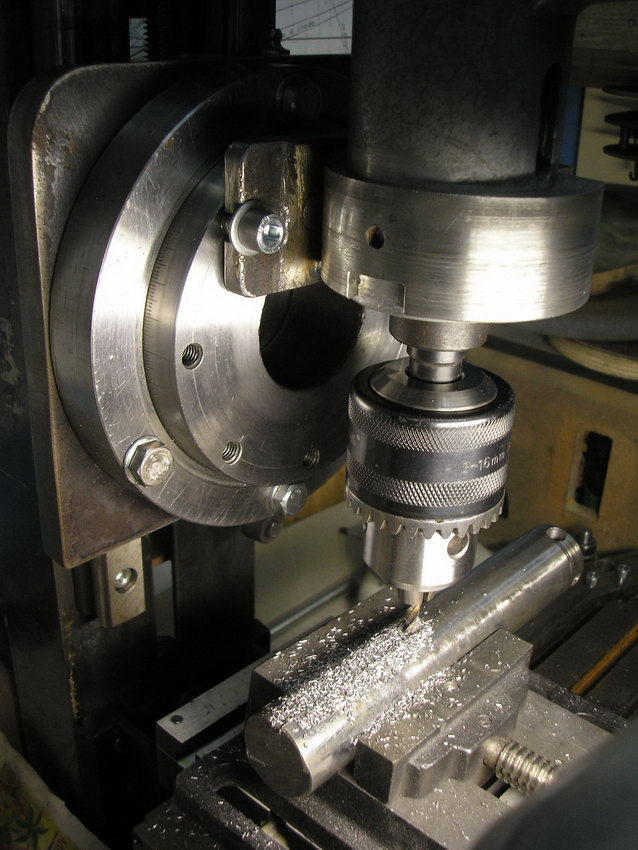

To solve this problem, I decided to make a hole directly on the machine frame, installing the necessary tool in the spindle (chuck), and attach the quill to the caliper and, in a tightened state, move it to the guides reciprocating.

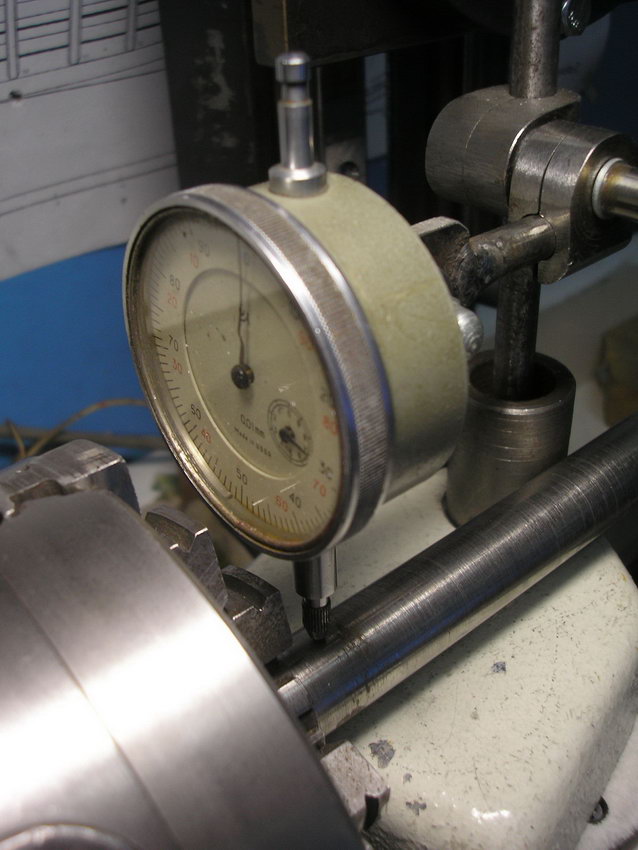

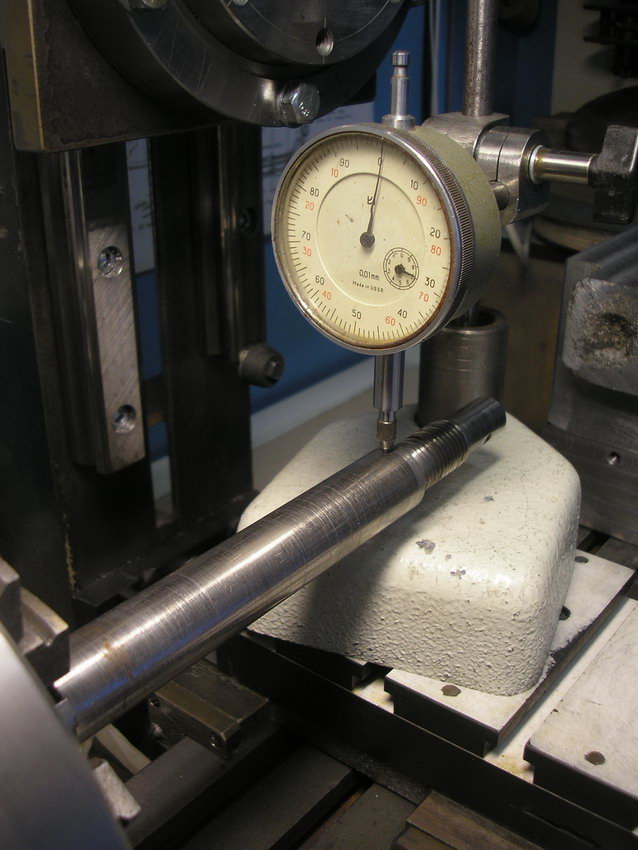

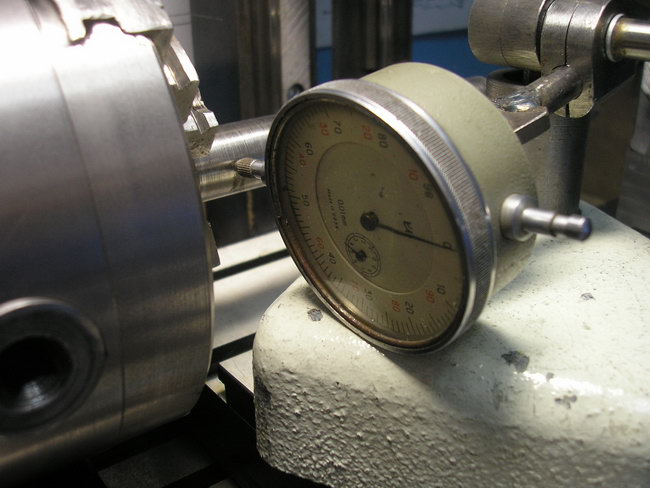

Once again I verified the installation of the headstock by measuring the alignment deviation with the bed guides in two mutually perpendicular planes:

And making sure that her position was correct, he proceeded.

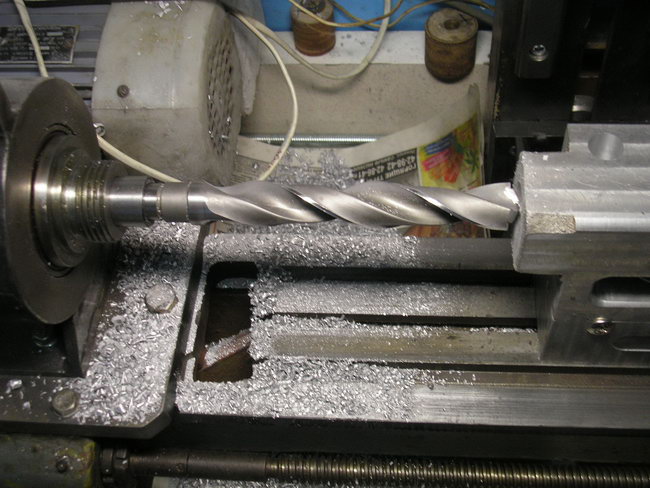

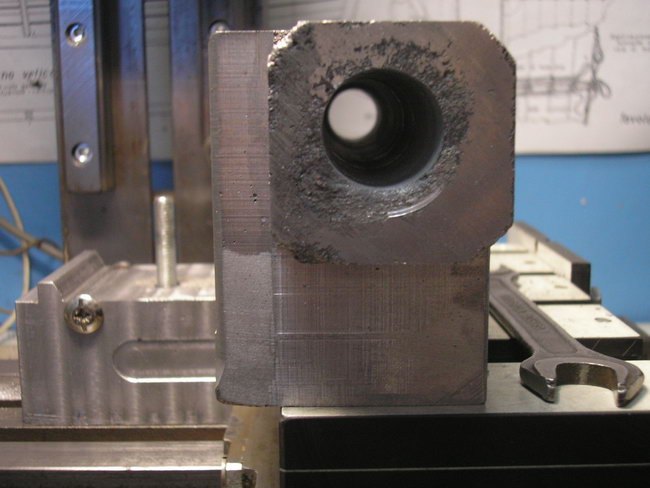

First of all, I drilled through the headstock with the longest drill in my arsenal, 17.5mm. Not a joke, but the length of the case is no less than 174 mm. Before drilling, he tightened the fixing nut of the headstock, and by loosening it a little, he achieved such a moment that the headstock, together with the support, began to move slowly, and turning the flywheel of the lead screw dragged this hitch to the drill and back.

After that, I already drilled to a depth of 145 drills: 19; 21 and 22mm

It was possible, of course, to drill immediately with a larger drill, but because spindle speeds are still unchanged for me (about 900), then I had to use stepped drilling, i.e. increasingly.

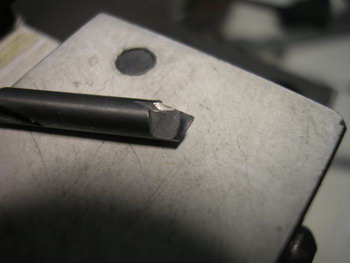

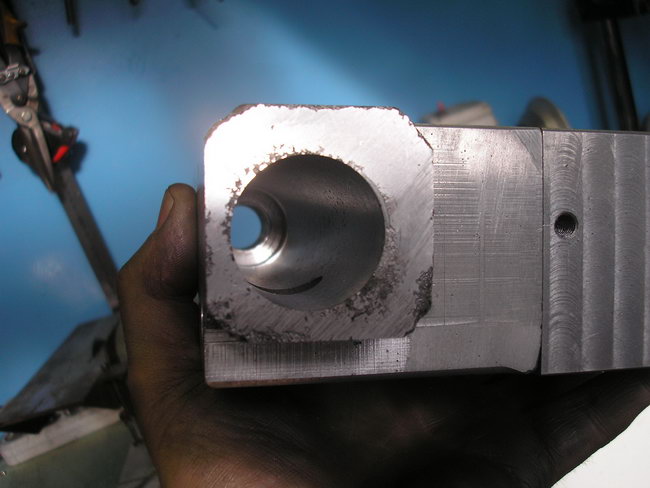

For further boring, I made a boring bar from the existing round timber f22mm. At one end, I drilled a hole f4mm at an angle, for installing a carbide centering cutter, perpendicular to which I installed the clamping screw.

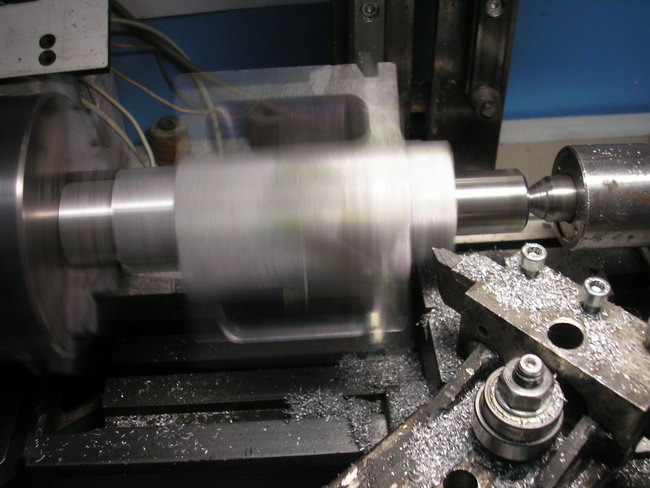

And setting the cutter 1-1.5 mm per pass, he bored the hole up to f29.4. Then, having thoroughly cleaned the machine and the base of the ZB, lubricated and prepared for the finishing pass. The cutter finished on the smallest diamond. The task was somewhat facilitated due to the fact that the hole for the quill itself was only 132mm. in depth.

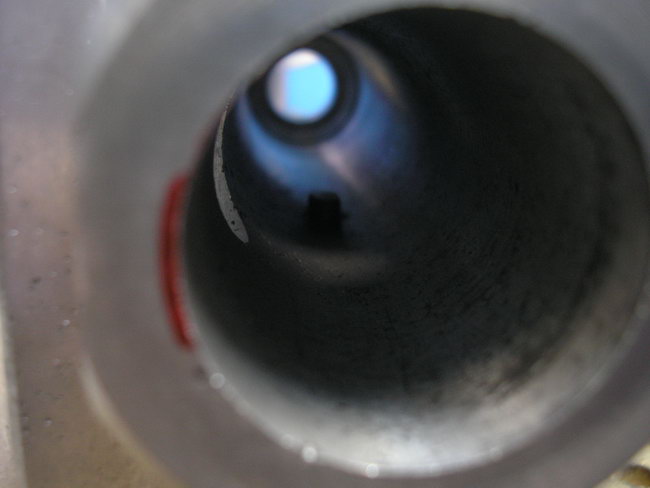

The first time I went about 0.4 and ran into a problem with measuring the hole.

As a measuring plug, I found a bearing with an external diameter of 30mm, and since it was no longer possible to be mean for measurements, gradually pushing the cutter out to make test strokes at a length of about 6 mm. As soon as my plug entered the hole, I made a full pass, loading the headstock on top with whatever came to hand in order to press the headstock to the bed as much as possible and minimize vibrations. The caliper was very tight, the feed was done as little as possible so that the surface turned out to be as even and clean as possible, and the process took about 20 minutes, or maybe more. And my God! I managed!

The process took about six hours, but it was worth it!

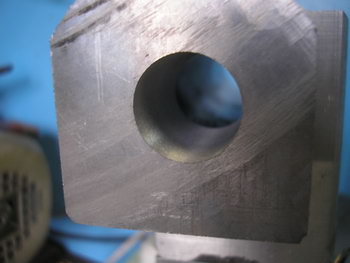

The quill enters the body freely, but without noticeable play. At the same time, the purity of processing is surprisingly very high and no longer requires any fine-tuning.

Today I finished with the tailstock body, giving it a more aesthetic appearance.

Wasted the right side with a longer boring bar with a thin end.

removed the minimum layer, to cleanliness. Subsequently, I will press the bronze bushing here.

Made the details of the jamming device:

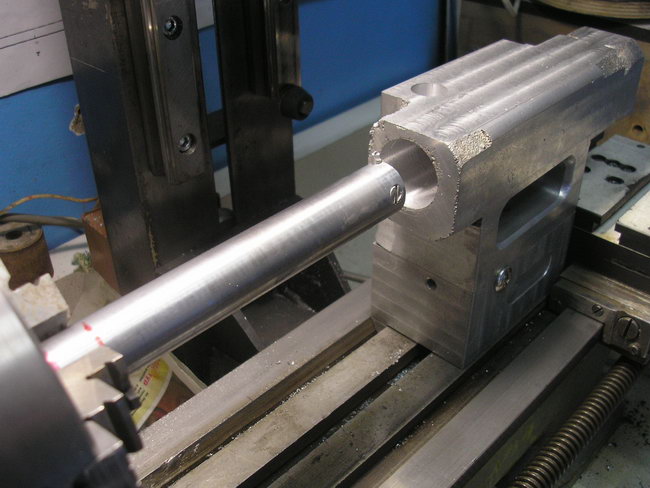

I inserted the quill blank and tightened the wedges.

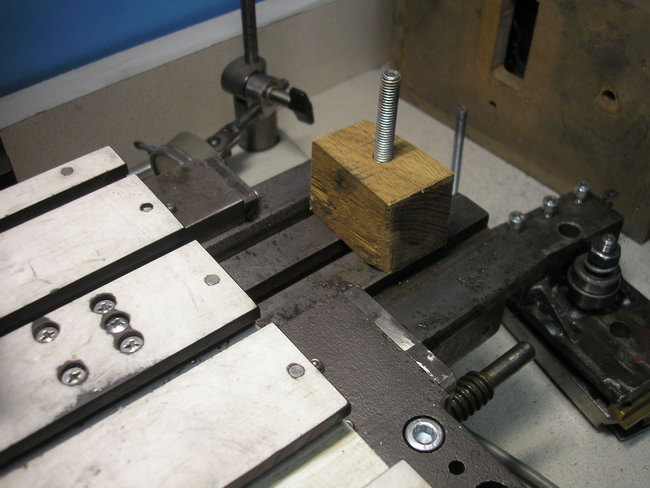

I made another temporary fixture to set the center of rotation to machine the body.

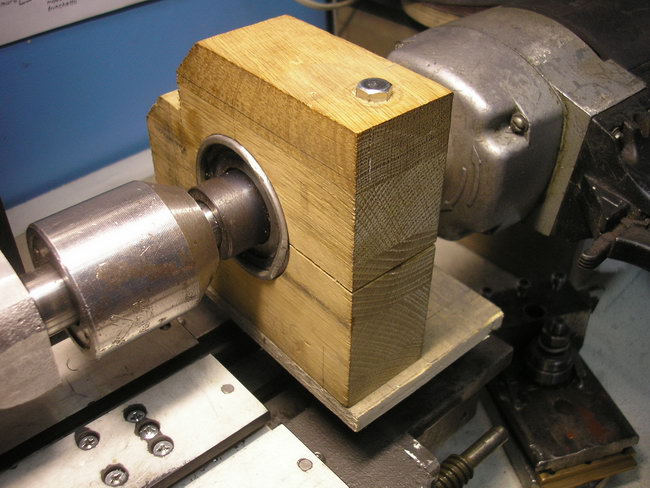

Pinol fixed in the cartridge, centered the right side.

With a longer bolt, I fixed the counterweight on the wedged cracker.

Then he turned the case over and processed the left side ...

Removed the center and trimmed the right.

I finally finalized the headstock scheme, deciding to lengthen the quill as much as possible:

The pinole turned out to be 20 mm. longer, so I had to bore the body again, devoting almost half a day to this.

Then, having installed a large drill with a 5 mm cutter on the column, he made a groove to a depth of 4.

I made a key to prevent the quill from turning, drilled the body, cut the M8 thread, screwed in the key and countergail.

Picked up and installed a spring between the wedges

I milled the slide of the tie rod and checked the fixation on the bed ...

Now the working reach of the quill will be 80mm.

In fact, the working reach of the quill was only 70mm. The overhang is determined by the length of the threaded part of the screw, which is calculated so that when pushed into the quill body at the last two or three revolutions, the screw pushes the tool out. But if, for example, a center of rotation is installed in the quill, then it can be released outward up to 110 mm and it will be securely fixed with wedges.

Page 1

The tailstock quill is moved by a hydraulic cylinder controlled by a handle located on the hydraulic tank. Inside the body of the headstock there are two hydraulic cylinders that serve to secure the quill; when the center of the tailstock rests against the product, oil enters these cylinders and they clamp the quill.

The tailstock quill moves from a hydraulic cylinder attached to the headstock body. The quill is fixed automatically after the center of the tailstock enters the center socket of the part. It is carried out with the help of two hydraulic cylinders, pulling together two pairs of crackers, pressing the pintle to the headstock body. The tailstock spindle rotates in rolling bearings which are lubricated with grease. The knockout of the center is carried out with the help of a special wedge through the oblong holes in the body of the headstock and the quill.

The tailstock quill is moved by a hydraulic cylinder.

The tailstock quill is retracted. At the end of the stroke of the piston 17, air through the hole in the pneumatic cylinder 16 will enter the cylinder 19, which feeds the blanks to the center line. At the same time, air is supplied to the valve 14 to turn off the self-propelled gun.

The quill of the tailstock is connected by a system of rods to the gate of the bunker, which ensures the opening of the bunker at the beginning of each cycle.

The tailstock quill is lubricated through oilers 13 and 14 with Turbine-22 oil. The quill is lubricated at least once per shift. The roller guide keys of the lead screw are packed with TsIATIM-203 grease at the factory and do not need lubrication during operation. Lubrication of the gears of the feed mechanism is carried out by leaks from the hydraulic motor.

The quill of the tailstock, which has an adjusting movement depending on the length of the tap being processed, has movement only along the axis.

The tailstock quill is pressed by a spring, the force of which depends on the distance rear center from the workpiece. The position of the rear center is adjusted by moving the headstock along the bed rails.

The tailstock quill is pre-pulled out by 80 - 100 mm and secured.

For ease of maintenance of the machine, it is advisable to move the tailstock quill by means of a handwheel located on the front side of the machine.

The tailstock quill has the largest longitudinal movement of 40 mm, and the headstock spindle - 5 mm. In the collet, the quills strengthen the cutting tool, and in the collet of the headstock, the workpiece. Handwheel 2 serves to clamp the collet with a cutting tool and feed the quill. Handwheel 3 serves to clamp the collet with the workpiece. When the cutting tool presses on the workpiece, the headstock spindle moves to the left side, and the left pulley 4, on which a straight belt is put on, turns on the spindle rotation to the right side at a speed of 820 rpm. After threading, the translational movement of the cutting tool is delayed. The headstock spindle moves to the right side, and the right pulley 5, on which the cross belt is put on, tells the spindle to rotate left at a speed of 1300 rpm. The tap is unscrewed from the workpiece.

The tailstock quill stroke is 150 mm, which allows you to install short and long parts without changing the tailstock.

Retraction of the tailstock quill is carried out only when the grinding headstock is retracted.

Instructions for work

"Disassembly and assembly of the tailstock lathe".

I. Rules for safe work.

You can only use a serviceable tool of the appropriate size. The use of gaskets if the key is larger than required, as well as building up the handle of the keys with tubes or other objects, is prohibited, as this may lead to slipping of the tool.

intelligence and injury.

It is not allowed to start work without familiarizing yourself with the tailstock device according to the drawing.

Before starting work, you should prepare a place to place the parts. Small parts are put in a box. The tailstock quill must be carefully protected from dirt and dust.

You can only use a hammer with the permission of the teacher. In no case is it allowed to use a chisel to unscrew bolts and nuts.

For the correct assembly of the tailstock, it is necessary to understand its structure and the interaction of individual parts, and also to know the disassembly sequence well in order to be able to assemble in the reverse order.

Fig.1. Tailstock lathe: 1, 14 16, 18, 24 - screw; 2, 7, 19, 21 - nut; 3 - quill; 4 - body; 5 - handle; b - power screw; 7 - nut; 8-head; 9 - limb bushing; 10-spring; 11 - flywheel; 12 washer; 13 - key; 15 - handle; 17 - plate; 20 - key; 22 - diameter; 23 - bolt.

Tools spanners 12, 10 and 8 mm, 5 mm screwdriver.

Sequence of work.

1. Familiarize yourself with the tailstock device according to the drawing.

2. Unscrew the nut 21 from the bolt 23 and, lowering the diameter 22 together with the bolt 23 down, take them out and put them on the workbench.

3. Remove the headstock together with the bottom plate 17 and transfer it to the workbench.

4. Rotate the flywheel 11 until the quill 3 with the nut 7 come off the power screw 6, then remove the quill.

5. Unscrew screw 14, remove washer 12 and flywheel 11 with limb bushing 9, spring 10 and handle 15.

6. Remove the limb sleeve 9 from the flywheel 11 and remove the spring 10 from it.

7. Remove key 13.

8. Unscrew the screw 16 and remove the head 8, as well as the power screw 6.

9. Unscrew screw 1 and unscrew nut 2 from it.

10. Pull out handle 5 with croutons and remove croutons.

11. Unscrew the screw 18 for the transverse movement of the body 4 of the tailstock.

12. Unscrew the screw 24 that connects the headstock body to the plate 17.

13. Disconnect the body from the plate 17, remove the nut 19 and the key 20.

14. Wipe all parts with a rag.

15. Lubricate surfaces between which friction occurs with a thin layer of grease.

16. Collect the headstock and install it in place.

III. Tasks.

1. Determine the tailstock screw pitch.

2. Determine the largest possible displacement of the tailstock body relative to the plate.

IV. Questions to review.

1. How to prevent self-unscrewing of the quill?

2. What is the purpose of the spring, which is installed in the limb sleeve?

3. What is the purpose of the nut on the screw?

Instructions for work.

"Setting up the machine and processing the outer cylindrical surface".

I. Rules for safe work.

Before starting work:

1) fasten all buttons so that there are no hanging parts of clothing that can be caught by the rotating parts of the machine; remove hair under a headdress;

2) familiarize yourself with the placement of buttons and control knobs and the purpose of each of them;

3) check that all controls are off or in the neutral position.

During work it is forbidden:

1) lean on the machine;

2) switch the belt drive on the go;

3) switch gear box and feed box on the go;

4) leave the machine without supervision;

5) stop the chuck by hand after turning off the machine;

6) measure the part on the go.

Violation of these rules may result in an accident

Remember that the "Stop" button is colored red.

1. Install the chuck in the spindle, for which do the following: wipe the thread at the end of the spindle and in the chuck hole with a rag and lubricate it with oil; screw on the cartridge; protect the cartridge from self-unscrewing.

2. Install the turning tool by doing the following: wipe the center and hole in the tailstock quill with a rag, install the center in the tailstock; bring the tailstock to the caliper; using a set of pads, install the through cutter so that its top coincides with the top of the center (there should be no more than two pads, they should not be shorter than the part of the cutter that is fixed in the tool holder, the cutter overhang should not exceed 1.5 heights); fasten the cutter.

3. Check that the dimensions of the workpiece correspond to the dimensions specified in the drawing.

4. Fix the workpiece.

5. Set up the machine for the specified mode of operation.

Turn on the machine.

7. Bring the cutter in contact with the workpiece.

8. Move the cutter with the support to the right.

9. Set the cutter to the specified cutting depth; combine the zero division of the limb with the risk on the fixed screw hub; determine the value of the division of the dial, turn the cross feed screw in accordance with the specified depth of cut.

10. Machine a belt 5.7 mm long.

11. Stop the machine.

12. Check the dimensions of the workpiece with a caliper.

13. Roughly grind the workpiece using manual feed.

14. Set the cutter to the specified depth of cut for fine turning.

15. Turn the workpiece clean using the power feed.

16. Stop the machine.

17. Check the size of the workpiece with a caliper.

18. Remove the part and cutter.

19. Clean up the workplace.

III. Questions to review.

1. Why is the cutting length limited?

2. Why is it not allowed to fix the cutter with one bolt?

3. How to eliminate the possibility of self-unscrewing of the chuck?

The results of experimental verification of the optimal model of teaching students in grades VII-VIII in the process of working on screw-cutting lathe

The experimental base for qualification work to test the designed model of the process of teaching students in grades VII-VIII to work on a screw-cutting lathe is secondary school No. 5 in Oktyabrsky, Krasnoarmeisky district, Krasnodar Territory.

Doctor of pedagogical sciences, professor Shchekoldin A.G., doctor of pedagogical sciences, professor Zarechnaya L.P., candidate of technical sciences, associate professor Zinoviev A.I., Ph.D. n., Associate Professor Radchenko N.V., Ph.D. Ph.D., Associate Professor Makhnenko A.Ya., Candidate of Pediatric Sciences, Associate Professor Zarechny A.V., Senior Lecturer Ilyinykh A.P., Director of Secondary School No. 5 - Nelly Pavlovna Maksimenko, Deputy Directors for Educational and Educational Work, teacher technology - Mishchenko Andrey Eduardovich, student of the Faculty of Technology and Entrepreneurship Lukyanchenko D.A., students of VIII "A" class - 12 boys. A total of 29 people took part in the experiment.

Experimental work was carried out in the process of passing pedagogical practices. The experimental work consisted of ascertaining and forming experiments.

The design of lathes provides for the use of certain equipment. Only if you have the necessary equipment, you can make a part with the right parameters accuracy. In this case, you need to purchase special equipment or make a home-made version. It is worth noting that not everything for precise turning can be created with your own hands.

Turning Live Centers

Fixing workpieces

Turning on a lathe occurs by fixing it in jaw chuck, which transmits rotation and at the same time holds it in place. Such a device is effective when turning cylindrical bodies. In this case, the cutter is fed perpendicularly, which allows you to machine the metal to the desired diameter.

When considering a metal lathe, keep in mind that many homemade and industrial versions have a structure in the back to support the workpiece and perform other tasks. homemade look lathe for metal also has a version of the headstock, which requires special equipment.

Thus, when fixing on two opposite sides on the lathe, the tailstock and the front headstock, the workpiece will be in a predetermined position during the occurrence of even a strong load.

When considering the tailstock, the following features should be noted:

- The device in question is intended only for mounting special equipment. The types of equipment used on the lathe determine the purpose of the tailstock: it can serve both for fixing a cylindrical body and for processing.

- In order for the workpiece not to change its position at the time of strong feed or at high revolutions, the center is used, which determines the purpose of the tailstock.

- You can make a center with your own hands or purchase it in a specialized store. At self-manufacturing it must be borne in mind that the workpiece must be solid solid metal with an increased strength index. This is due to the method of fastening: the quill presses the part against the spindle along the end and throughout the entire time the tip is in contact with it, there is little friction.

- The position of the quill of the lathe is adjustable only in the longitudinal direction. Given this feature, it is worth remembering that the center position must coincide with the axis of rotation of the spindle. Otherwise, the rotations will occur with a beating.

The device under consideration can also be used for drilling end holes and for solving other technological problems.

Mounting on two ends

Fixation on two ends occurs in the following cases:

- An industrial type metal lathe has an adjustable number of revolutions. The high speed of rotation, which is transmitted to the part, leads to the "wobble" of the part. With precise processing, according to GOST, this phenomenon leads to a rather large error.

- The large length and weight of the workpiece also determines the need for a tailstock. Under its own weight, the cylindrical body can be deformed and the metal cutter will “beat” during the feed of the cutter.

- Depending on the turning mode and spindle speed, excessive cross feed may occur. When processing a part in such a situation, it is quite difficult to make it with high accuracy.

In such cases, fixation should be carried out on both ends.

Types of turning centers

Carry out a fix necessary tool in quills you can do it yourself. It will take a few minutes to complete this work, and you can do it yourself. According to GOST, the following types can be distinguished:

- persistent. GOST determines that the tip and shank have almost the same diameter. The device of this design determines that the tip is made of hardened steel or hard alloy in accordance with GOST 13214-79.

- the fungal version is somewhat different from the previous one. according to GOST 8742-75, the fungal tip has a larger diameter with a truncated working cone. according to GOST 8742-75, there are two types of tip that the fungal center has: with a centered roller or with a nozzle for it. the mushroom tip allows the use of the considered device for fastening bodies of revolution with hollow end holes during processing.

When turning during high centrifugal force, the most favorable conditions can be made by using a center in the design of which there is a bearing. Such equipment can be different: the fungal or thrust center also has a bearing.

The cone angle can be 60 or 90 degrees. The angle is selected depending on the cutting mode.

There are more complex types of equipment for installation in quills, which may have, for example, a device for measuring downforce. It is impossible to make some variants of centers for a lathe with your own hands. Spindle retraction does not affect the ability to use the quill.

Download GOST 8742-75 "Rotating turning centers"

Mixed Personality Disorder: Causes, Symptoms, Types and Treatments

GTA 4 control settings

FAQ on Smuggling in GTA Online

LSPDFR - welcome to the police

The huge map of Grand Theft Auto San Andreas and its secrets