Self-addictive leash cartridges chucks have two or three eccentric cams with a notch, with which they grip the workpiece at the start of cutting and bring it into rotation; as the cutting torque increases, the chuck torque also increases automatically. Therefore, they work reliably with any chip cross-section. Parts, as usual, are installed on fixed or floating centers. For the convenience of installing parts on the centers, structures with automatically opening cams are used, and to ensure uniform clamping by all cams, a floating cam system or a system with independent cams is used.

Kapek - and they were "auto" that in his social and political fantasy R.R. they act like workers, but they are able to perform actions planned by a specific program, and have some functional similarity with humans. Not to be confused with more or less ancient mechanical "robots" whose orders were strictly predetermined. interact with environment in which they are immersed, and then can initiate mechanisms feedback, that is, intelligent machines. Raffel was rather rudimentary, using simple relays.

Rice. 11.1- Driving chuck.

Cam driven chucks are widely used on multi-cutter lathes, where the transmission of large torques is required.

When using conventional cam chucks with eccentric cams, there are cases when the workpiece is twisted under the action of cutting forces at the beginning of processing, which leads to breakage of the cutter. To eliminate this drawback and increase the automaticity and reliability of the action, drive cartridges with weights, based on the use of centrifugal forces of inertia, have recently been introduced. The introduction of these chucks is facilitated by the speed of the spindles of modern lathes.

In the 40s, when the problem of manipulation arises radioactive substances, there have been other effective attempts, but to a certain extent. The "robot" was little more than the precise ticks that were kicked out of the human. It was the arrival of the transistor in the late 40s, and then in the early 60s, miniature electronics with the first integrated circuits gave a powerful boost to industrial robots. It is the “birthday of industrial automation” that becomes the master of production processes.

Tools and accessories for turning work

Later, at the same time, microprocessors became powerful and are now able to receive and store millions and millions of complex instructions and are able to process them without any human intervention, shocked the entire economic and industrial world. These new machines, as well as various functions in different time have the ability to learn and remember, that is, they can quickly and easily learn the sequence of operations they need to perform, remind them and then repeat them on indefinite term.

In fig. 11.1 shows a chuck with eccentric jaws. The chuck flange is bolted to the adapter flange or directly to the spindle flange as shown. The cartridge body is connected to the flange 14 by means of screws with spacers and guide pins. The body can move relative to the flange in the direction of its grooves, which ensures uniform clamping of the workpiece by the cams 2; the springs 11 return the housing to its original central position.

Cutting conditions for metal turning

There are robots for gluing, for cutting glass, for selecting parts, for printed circuits, handling ovens, heat treatment, metal stamping, plastic molding, unloading machine tools, spot welding, plasma cutting, palletizing and depalletizing, and in this latter sector, it is shocking to experience one of these giant robotic warehouses. Without a mini-human presence inside them, the robot received the order via telematics from the sales office, passes through the various sectors of the warehouse, picks up various items from the shelf, collects them and finally starts shipping to the delivery center with the invoice already paid, the delivery bubble and the invoice with the specified the quantities and costs of individual items and the final amount to be paid by the customer.

Eccentric cams 2 are freely mounted on the pins and have a notch on the profile. With the beginning of the spindle rotation, the cams, under the action of centrifugal force developed by the weights 1, clamp the workpiece and bring it into rotation; further clamping is carried out during the cutting process. When the machine stops, the cams under the action of the springs 11 are automatically opened by the pushers 20. By changing the jaws, the chuck can be used to clamp parts with diameters from 30 to 150 mm.

Of course, he also performs all the operations in your warehouse, calculating the result, keeping in mind the level of availability of a given product for several days, and when he lowers this level, he already lists all the goods that are used up and then sends them to various suppliers again. integration. But rope rope tools, albeit in different ways, are found in numerous Egyptian, Assyrian, Chaldean, Babylonian, and Greek iconographies.

Mass production different parts the object has already become a productive reality that preserves it. This last, unique of the four elements formulated by Ford, is the stage that develops and integrates the first three into an integrated design, coordinating its production potential synergistically. It consists in the fact that it sequentially connects all processing operations of parts with units through automatic processing systems. In other words, it is a "build chain". The system then spreads to almost all industrial sectors, even constituting a social anxiety for the depersonalization of human labor.

The workpieces are clamped by centrifugal force.

![]()

Centrifugal drive cartridges, depending on their diameter, can accommodate loads with a total weight of -3 to 6 kg. Then, for example, with G = 3 kg, R = 45 hp, n = 500, 1000, 2000 rpm, the centrifugal force pressing the cams against the workpiece will be Pc = 34, 138, 552 kg / s, respectively.

The employee is seen as a simple performer, motivated to work not by his content, but solely by his variable remuneration through production awards and awards. The “worker” no longer requires knowledge of the profession, since the operations that are entrusted to him are elementary and do not require intellectual potential. Wiener is the father of cybernetics, he plans the first systems that can independently program after the three fundamental areas of human knowledge, at 50, comes to such considerations about living organisms better than any humanistic philosopher, intelligent economists and technocrats of the industrial revolution.

The accuracy of the technological operation is characterized by the value of the installation error and depends on the values of the positioning errors b, fixing h and the position of the workpiece in the device pr. In the general case, the installation error

Position error of the workpiece in the fixture

where p is the error arising from errors in the manufacture of the device, p = 15 microns; s - error arising when installing the device on the machine, s = 10 microns; and - the error arising from the wear of the mounting parts, the amount of wear is approximately determined by the empirical relationship:

In his Introduction to Cybernetics, Wiener explores the consequences of organizing a conveyor line that transforms, but also alienates the world of work, showing that it is not scientifically "reasonable" those considerations that, using the concepts and schemes of cybernetics, tend to evaluate human behavior only on the basis of efficiency and productivity. If you want to draw conclusions about a person, you must study him and accept him as a complex lump and. Some - even politically - after they endorsed a mechanistic system, convinced that they received complete consent and murder, fell out of favor, see collapse in the blink of an eye - often with violent uprisings - the consent of subordinate people in this "slavery" is modern.

where N is the number of contacts of blanks with supports in 1 year, N = 50,000; a and - empirical coefficient and exponent = 0.7, = 0.5:

The value of AND is of great importance, therefore, we divide AND by four, and in technical requirements we write down to the equipment: change the supports after two months of operation (6 times a year). Thus, we take and = 26 μm.

pr === 31.63 microns.

When this happens, it happens because people do not become ants, and "people are responsible, but nothing else" except for "men" with all the contradictions. And there is no need for these contradictions, they are exactly what distinguishes us from the cute to Maeterlinck in the Life of the Termites. And this phase after Taylor's industrial revolution is the era of the cyber revolution. the capitalist party is immediately resolved by the "delocalization" of production and the "globalization" of the market. From the very beginning, there was no evidence of the existence of many, even Planck, who suspected that these were only mathematical products devoid of physical meaning.

The error in locating and fixing the workpiece is 0, therefore, the installation error is equal to the device error

Leader devices

TO Category:

Turning

Leader devices

To transfer rotation from the spindle to the workpiece installed in the centers, use levers... The simplest of these is a lathe clamp. The bent shank of the collar enters the radial groove of the faceplate fixed on the machine spindle. Rotating with the spindle, the faceplate carries the clamp along with it, the workpiece installed in the centers. Clamps with straight shanks are also used; to work with them, drive faceplates are used, in which a finger or a bar play the role of a leash. Working with the collar poses a certain danger: there may be cases of the worker's clothing catching the collar shank. Therefore, for safety reasons, faceplates with protective covers (safe faceplates) are used. In order not to damage the surface of the workpiece being clamped, a split sleeve is put on it or rubber is placed under the clamping bolt.

Instead, “theory of many” as it is called today, it is important to divide physics into “classical physics” before “900” and “modern physics” after graph theory. In fact, Einstein later showed that not only the radiation ol was absorbed by finite quantities, but the radiation itself consisted of elementary granules of energy: "how much light" or "photons".

Planck gave him the right recognition by awarding him the Nobel Prize in Physics at the Mentra. Einstein starts talking about himself. Many thought that these two particles are associated only with electric currents Bequerel during this year began to guess that they were indeed "electrons" bound to atoms. He said "every atom", while Beckel and others Only their radioactive elements were taken into account in their experience, but before the end of the year there was another surprise.

To reduce the time for installing and removing the clamp, fast-acting and self-tightening clamps are used. The main part of the self-clamping drive clamp is the ring, which is put on the workpiece installed in the centers. When the spindle is turned on, the plang; aib acts on the leash, which, turning on the axis, captures the workpiece with a corrugated working surface. When cutting, this clamp grips the workpiece more reliably, the larger the chip section.

Gear and pin driver chucks

Studying the two radiations of Bequerel and Rutford, a young French physicist, thirty-year-old Paul Ulrich Viard, discovered that there is "other radiation that was not affected by magnets." The property was very similar to X-rays, but was extremely insightful, coinciding with the emission of alpha and beta rays; Thus, the wavelength was even shorter, they were called Villiard's gamma rays, electrons or positrons. In the first case, they are emitted from nuclei, in which a neutron is converted into a proton, in the second case, from nuclei in which it undergoes the reverse transformation.

1. CARBIDE CENTERS: a - with a deposited layer of hard alloy, b - with a soldered tip

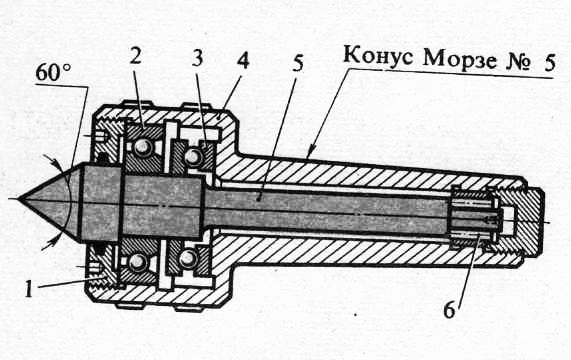

2. ROTATING CENTER FOR LIGHT RADIAL LOADS (UP TO 200 KG): 1 - cover. 2 - radial bearing. 3 - thrust bearing. 4 - body with a shank. S - center. 6 - needle bearing

Something similar happened many years ago when Edison, with the intention of reducing the incandescent fire on his light bulb, implanted a metal rod next to him. Surprisingly, the electricity has exceeded the gap that separated them and is transferred to the metal plate. Scientists say this was his only purely scientific discovery. Edison did not know what this phenomenon was, he even ran for a patent, but did not find a way to exploit it. He also carefully described it, and was also called the "Edison effect", but was ignored.

Seventeen years later, Richardson began working again with the Edison Effect; his discovery allowed for giant strides in emerging valve technology and then electronics, and later, when this became a reality, Richardson received the right recognition: he was awarded the Nobel Prize in physics in Fleming for this bowl called "valve". And since it contains two electrodes, it is also called a "diode".

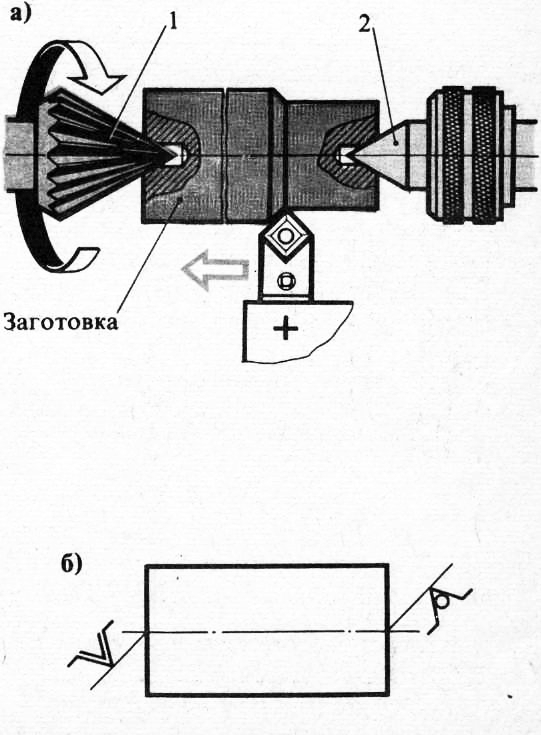

3. APPLICATION OF THE COUPLER (a), DESIGNATION SCHEME (b): 1 - faceplate, 2 - front center. 3 - clamp. 4 - rear center, 5 - quill

4. SAFE PLANKS: a - with a leash pin, b - with a leash plate) “3- leash (finger or

For forty years this "law" has always been in the drawers of some library, but during this year it returned to the fore. He wanted to grow them in his garden, and for over ten years he could understand, without knowing anything about "Mendel's law", which crosses some species, some improve, others worsen their characteristics. At the same time, in the same years, two other botanists, one German and another Austrian, not knowing each other, had the same experience and the same discovery. The year they decided to publish these results, the three found that the very same things had published them in a more detailed, more rigorous, and precise way, the Abbot Mendel forty years earlier. The "three" met and were honest: all their work presented them as mere confirmation of the abbot's work, and now the science of genetics is beginning to be studied.

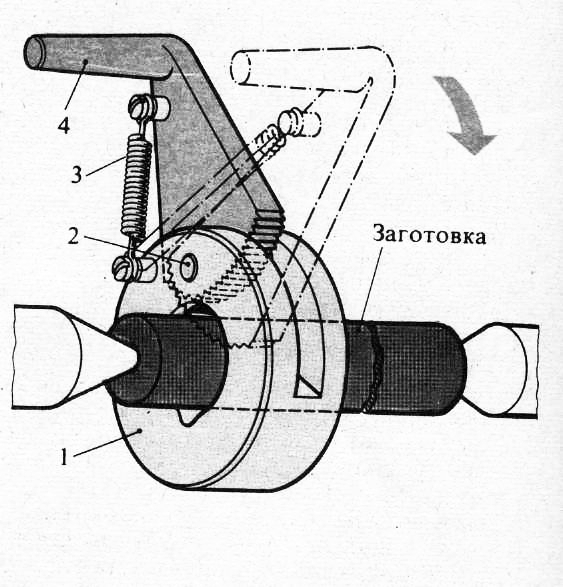

5. SELF-CLAMPING GUIDING CHUCK 1-rings, 2-axis. 3 -spring. 4 - leash

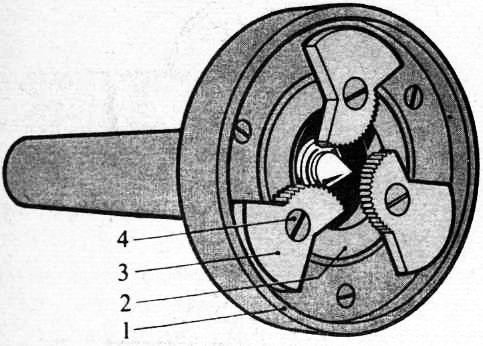

6. SELF-CLAMPING SLIDE CHUCK: 1 - faceplate, 2 - "floating ring", 3 - cam, 4 - cam axis

Marie de Vries discovered something else in the course of his farmer's experience; In some flowering plants he noticed that they suddenly appeared with remarkable changes, without ending and without any previous selection. He called them "mutations" and canceled the concepts of evolution by Darwin and Lamarck, guessed that Evolution does not always develop gradually in small steps, but sometimes in leaps. Today this concept is an integral part of the theory of evolution.

The relationship between blood groups. Hatch arrows indicate incompatibility. Arrows on the full line indicate compatibility. So far in balloons or balloons, an attempt was made to mount a propeller made by a steam engine, but the attempt to lift them was not an easy task, they were too heavy engines. But when they started spreading small motors from Otto, they soon found their way into a hot air balloon, making it manageable even in the absence of wind, in fact the use of a propeller could guide it in all directions.

7. GUIDE BAR: 1 - mandrel body with a tapered shank. 2 - drive washer with end teeth. 3 - floating center. 4 -spring. 5 - spring adjusting screw

The transmission of torque from the spindle to the workpiece is often carried out with a special self-clamping drive chuck (faceplate) with eccentric cams. The design of such a chuck of the innovator-turner V.K.Seminsky is shown in Fig. 36. The presence of a "floating ring", on which the axes of the cams are located, makes it possible to fix workpieces with an uneven outer surface(for example, forgings).

Also after the discovery, which could be obtained from aluminum, very light and thin sheets, balloons began to be built with a hull made with this metal, and with much more durable armor, so strong that it could contain a tank with pilots and some passengers.

Pin and serrated driver chucks

In fact, appeared " Balloon". The first aircraft had not yet been realized, so it was the first "steering machine" that could be controlled by history and soon spread throughout Europe and America. In the Italo-Turkish War, the Italians used it for military purposes, and later during the First World War, Germany, France. In Russia, Italy, England and Austria there was an Isonavios fleet, intended for offensive purposes, for reconnaissance and observation. Zeppellin-class airships were built for 26,000 kilometers, they had 750 wealthy enthusiasts. Passengers were trapped in a tragedy, the balloon rushed to the polar bunchish, the passenger ship broke off, became light and lost in heaven, leaving people on the ice.

In fig. 7 shows a driver mandrel, which carries the workpiece with teeth located on the working end of the driver washer. The workpiece is pressed against the teeth by the center of the tailstock.

The drive for rollers of small diameters can be corrugated leash center- "ruff". For processing tubular workpieces, they also use "ruffs" that have teeth on the working surface - corrugations. Small diameter rollers (up to 20 mm) can be fixed in reverse centers. End cones and chamfers are pre-machined on the workpiece, and the front and rear centers have corresponding holes with seat cones. The workpiece is driven into rotation by friction between the front return center and the workpiece. The reverse center fastening method is used for finishing only. Installation of blanks in the centers (with putting on a clamp) lasts 0.25-0.6 minutes (depending on the weight of the part). Installation in centers with a self-clamping drive chuck (faceplate) or mandrel, as well as installation in friction clamps, reduces the time for clamping and removing the part by almost half. Experienced turners process small diameter rollers, fixing them in reverse centers of the "glass" type (with a bevelling position).

8. FIXING THE WORKPIECE WITH THE HELP OF THE HANDLING CENTER - "Ruff" (a), DESIGNATION SCHEME (b): 1.2 - centers

Rolled blanks are fixed in three-jaw chuck with center support installed in the tailstock quill.

Energy drinks: give vigor, but take away health What will happen if you drink 4 energy drinks

Mustard for weight loss: how to use the seasoning with maximum benefit Is it possible for children to have mustard

The benefits and harms of mustard for the human body Table mustard benefits and harms

How to treat the ear after piercing: types of antiseptics, their composition, rules and features of the treatment of a pierced ear

Sistine Chapel in the Vatican: description, history, architectural features