Unlike conventional drive devices with a finger and a clamp (GOST 2571-53 and GOST 2572-53) self-gripping driver chucks chucks have two or three eccentric cams with a notch, with which they grip the workpiece at the start of cutting and bring it into rotation; as the cutting torque increases, the chuck torque also increases automatically. Therefore, they work reliably with any chip cross-section. Parts, as usual, are installed on fixed or floating centers. For the convenience of installing parts on the centers, structures with automatically opening cams are used, and to ensure uniform clamping by all cams, a floating cam system or a system with independent cams is used.

Cam driver chucks are widely used on multi-cutter lathes, where the transmission of large torques is required.

When using conventional cam chucks with eccentric cams, there are cases when the workpiece is twisted under the action of cutting forces at the beginning of processing, which leads to breakage of the cutter. To eliminate this drawback and increase the automaticity and reliability of the action, drive cartridges with weights, based on the use of centrifugal forces of inertia, have recently been introduced. The introduction of these chucks is facilitated by the speed of the spindles of modern lathes.

FIG. 22 shows a cartridge with eccentric cams designed by the Moscow Machine-Tool Plant. Ordzhonikidze. The chuck flange 1 is bolted to the adapter flange or directly to the spindle flange as shown in the figure. The body 3 of the cartridge is connected to the flange 1 by means of screws 5 with spacers 6 and leading pins 2. The body 3 can move relative to the flange 1 in the direction of its slots, which ensures uniform clamping of the workpiece by the cams 4; the springs 9 return the body to its original central position.

Eccentric cams 4 are freely mounted on pins 2 and have a notch on the profile. With the start of the spindle rotation, the cams, under the action of the centrifugal force developed by the weights 10, clamp the workpiece and bring it into rotation; further clamping is carried out during the cutting process. When the machine stops, the cams under the action of the springs 5 are automatically opened by the pushers 7; for unloading the pins 2, with their semi-cylindrical surface, they are pressed against the radial grooves in the body 3. By changing the jaws, the chuck can be used to clamp workpieces with diameters from 30 to 150 mm.

The magnitude of the centrifugal force is directly proportional to the square of the speed n rpm of rotation of the machine spindle and is determined by the formula

![]()

where Р „- centrifugal force in kgf;

and is the weight of the rotating weights in kg;

R is the distance from the center of gravity of the load to the spindle axis of the machine in m;

g - acceleration at free fall of the load in m / s2; g = 9.81 m / s2.

Centrifugal drive cartridges, depending on their diameter, can accommodate loads with a total weight of -3 to 6 kg. Then, for example, at G = 3 kg, R = 45 hp, n = 500, 1000, 2000 rpm, the centrifugal force pressing the cams to the workpiece will be Pc = 34, 138, 552 kgf, respectively.

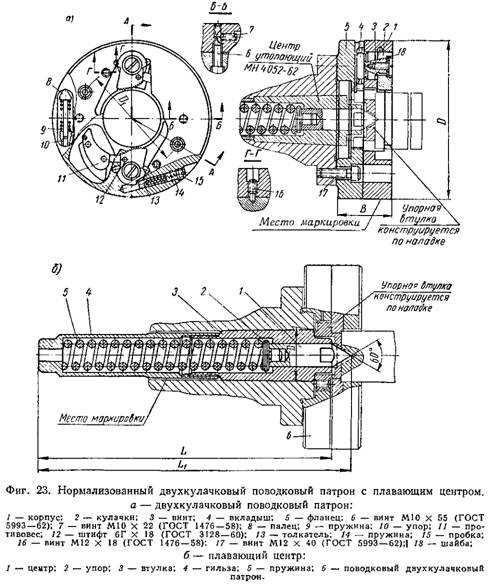

Two-jaw driver chucks normalized (MN 4051-62) and have a normalized floating (sinking) spring-loaded center (MN 4052-62).

FIG. 23 shows the constructions of the normalized two jaw chuck and its floating center.

The main dimensions of the cartridges and centers are given in table. 3.

Seven sets of interchangeable eccentric jaws are provided for clamping parts with a diameter from 17 to 72 mm with a normal, and 8 sets of interchangeable jaws for diameters from 28 to 112 mm; parameters of eccentric cams and floating center (part 1) are normalized. Cam material - steel grade ШХ15 GOST 801-60; hardness - HRC 60-64. Center material - U8A steel in accordance with GOST 1435-54; cone hardness 60 ° HRC 55-60, the rest - HRC 45-50.

|

Table 3 Chucks driven two-jaw and sinking centers (dimensions in mm)

|

||||||||||||||||||||||||||||||||||||||||

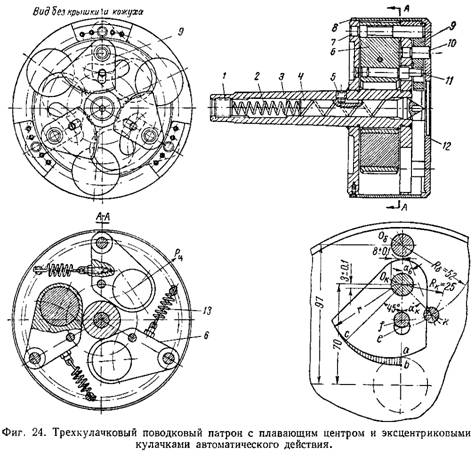

At the plant "Fraser" them. MI Kalinin designed and introduced into production a three-jaw centrifugal chuck.

The cartridge (Fig. 24) is a welded body "3, which contains a floating center 4 with a spring 2 and three weights or balancers 6U

installed on axles 7; the balancers are connected to the clamping jaws 9 by pins 11. The jaws are mounted on axles 10 pressed into the front wall of the chuck.

The axial movement of the center 4 is limited by the screw 5. The center has a tapered neck and in the working position mates with the tapered seat of the cartridge body, which eliminates its runout. The force of the spring 2 is adjusted with the screw 1.

To increase the weight of the balancers 6, holes with a diameter of 50 mm are provided, filled with lead; the weight of each balancer is approximately 2 kg. The balancers are under the action of springs 13 holding them in an inoperative position. The cartridge is closed by a casing 8 and a cover 12, which are fastened to its body with screws.

When working on the cams 9, in addition to the cutting forces, centrifugal forces from the balancers, transmitted by means of the pins 11. As a result, the cams are tightly pressed against the workpiece and do not allow it to rotate relative to the chuck.

In the design of the chuck, the distance from the center of gravity of each weight to the spindle axis is R = 0.05 mm. Then at G = 2 kg; n = 1000 rpm) min centrifugal force acting on each cam, according to the previous formula will be

The total strength of Rts. sum = 102-3 = 306 kgf.

The presence of such a force excludes the possibility of turning the workpiece at the beginning of cutting.

After machining the part and stopping the spindle, the balancers 6, under the action of the springs 13, return to their original position and, dragging the cams 9, automatically open them, freeing the workpiece.

The chuck provides uniform clamping of the workpiece without the use of a floating jaw system, since in the case of eccentricity of the workpiece, centrifugal forces clamp it at different points of the ca curve.

Three-jaw driver chucks of a similar design and eccentric cams to them are normalized (MN 4050-62). Clamping diameters from 12 to 85 mm.

TO Category:

Turning

Leader devices

Driving devices are used to transfer rotation from the spindle to the workpiece installed in the centers. The simplest of these is a lathe clamp. The bent shank of the collar enters the radial groove of the faceplate fixed on the machine spindle. Rotating with the spindle, the faceplate carries the clamp along with it, the workpiece installed in the centers. Clamps with straight shanks are also used; to work with them, drive faceplates are used, in which a finger or a bar play the role of a leash. Working with the collar poses a certain danger: there may be cases of the worker's clothing catching the collar shank. Therefore, for safety reasons, faceplates with protective covers (safe faceplates) are used. In order not to damage the surface of the workpiece being clamped, a split sleeve is put on it or rubber is placed under the clamping bolt.

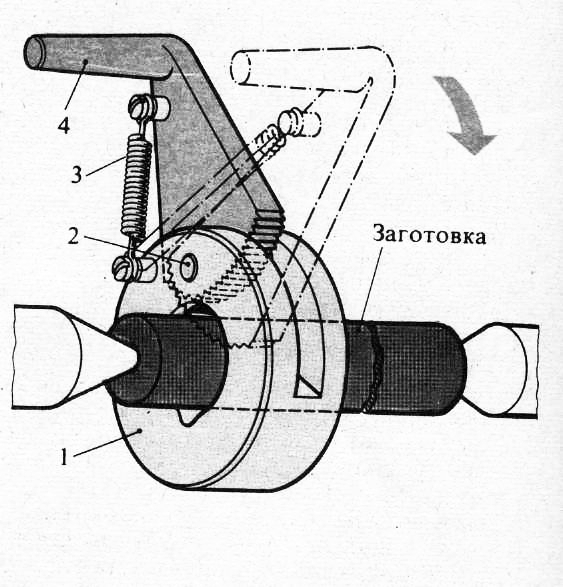

To reduce the time for installing and removing the clamp, fast-acting and self-tightening clamps are used. The main part of the self-clamping drive clamp is the ring, which is put on the workpiece installed in the centers. When the spindle is turned on, the plang; aib acts on the leash, which, turning on the axis, captures the workpiece with a corrugated working surface. When cutting, this clamp grips the workpiece more reliably, the larger the chip section.

1. CARBIDE CENTERS: a - with a deposited layer of hard alloy, b - with a soldered tip

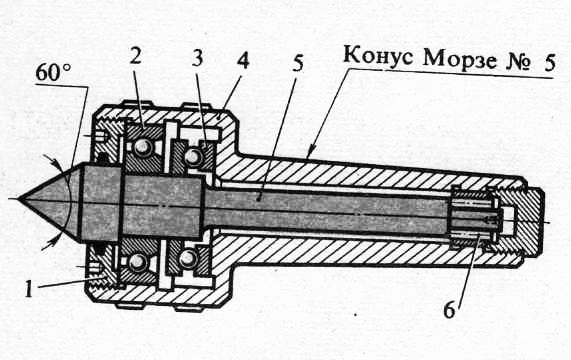

2. ROTATING CENTER FOR LIGHT RADIAL LOADS (UP TO 200 KG): 1 - cover. 2 - radial bearing. 3 - thrust bearing. 4 - body with a shank. S - center. 6 - needle bearing

3. APPLICATION OF THE COUPLER (a), DESIGNATION SCHEME (b): 1 - faceplate, 2 - front center. 3 - clamp. 4 - rear center, 5 - quill

4. SAFE PLANKS: a - with a leash pin, b - with a leash plate) “3- leash (finger or

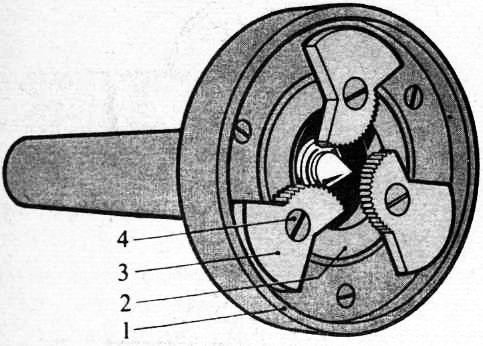

5. SELF-CLAMPING GUIDING CHUCK 1-rings, 2-axis. 3 -spring. 4 - leash

6. SELF-CLAMPING SLIDE CHUCK: 1 - faceplate, 2 - "floating ring", 3 - cam, 4 - cam axis

7. GUIDE BAR: 1 - mandrel body with a tapered shank. 2 - drive washer with end teeth. 3 - floating center. 4 -spring. 5 - spring adjusting screw

The transmission of torque from the spindle to the workpiece is often carried out with a special self-clamping drive chuck (faceplate) with eccentric cams. The design of such a chuck of the innovator-turner V.K.Seminsky is shown in Fig. 36. The presence of a "floating ring", on which the axes of the cams are located, makes it possible to fix workpieces with an uneven outer surface (for example, forgings).

In fig. 7 shows a driver mandrel, which carries the workpiece with teeth located on the working end of the driver washer. The workpiece is pressed against the teeth by the center of the tailstock.

A serrated drive center - "ruff" can serve as a leash for rollers of small diameters. For processing tubular workpieces, they also use "ruffs" that have teeth on the working surface - corrugations. Small diameter rollers (up to 20 mm) can be fixed in reverse centers. End cones and chamfers are pre-machined on the workpiece, and the front and rear centers have corresponding holes with landing cones. The workpiece is driven into rotation by friction between the front return center and the workpiece. The reverse center fastening method is used for finishing only. Installation of blanks in the centers (with putting on a clamp) lasts 0.25-0.6 minutes (depending on the weight of the part). Installation in centers with a self-clamping drive chuck (faceplate) or mandrel, as well as installation in friction clamps, reduces the time for clamping and removing the part by almost half. Experienced turners process small diameter rollers, fixing them in reverse centers of the "glass" type (with a bevelling position).

8. FIXING THE WORKPIECE WITH THE HELP OF THE HANDLING CENTER - "Ruff" (a), DESIGNATION SCHEME (b): 1.2 - centers

Rolled blanks are fixed in three-jaw chuck with center support installed in the tailstock quill.

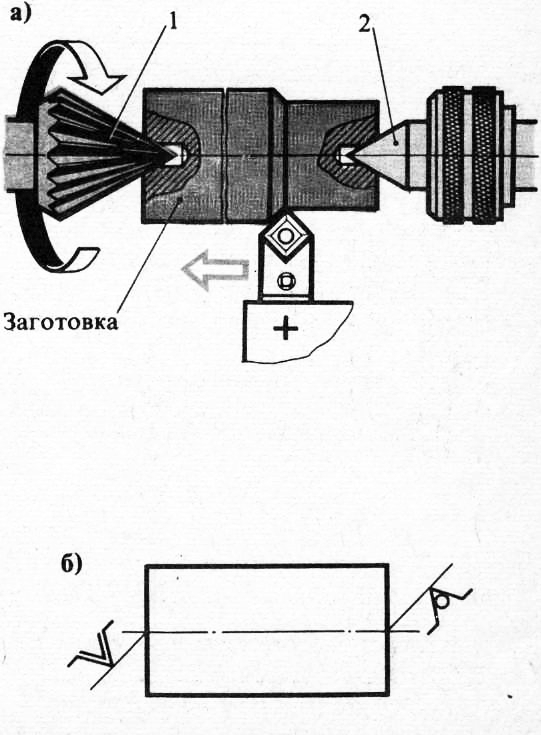

Processing in centers... Many parts on lathes are machined in centers. The simplicity and uniformity of the installation method for a large range of parts, as well as the high accuracy of the installation of workpieces both at the preliminary and final stages of processing, contribute to its widespread use. To transfer torque to the workpiece, a clamp is used, driven by the pin of the driver chuck. After processing all the steps of the right end of the workpiece, it is repositioned and machined from the other end.

There are three main disadvantages to this scheme:

1) the need to secure a leash at the left end of the workpiece, which requires high costs manual labor skilled worker;

2) for complete processing of the shaft, the workpiece must be reinstalled, which also requires manual labor;

3) basing due to the error in the depth of centering on a rigid center leads to large errors in the position of the workpiece along the length, which makes it difficult to set up the machine for automated production linear dimensions shaft.

Leader cartridges

The first drawback is eliminated by the use of drive cartridge designs that do not require the use of a clamp. In these chucks, the workpiece rests on the center, and the clamping jaws are used only to transmit torque, so they are made floating, that is, if one of the jaws rests on the surface of the workpiece and its movement stops, and the other jaws continue to move until the workpiece is clamped by all jaws with equal force.

To fasten the mandrel, the force transmitted from the tailstock quill to the front center is used, which moves to the left and pulls the ring with three lever cams attached to the axles. The rear ends of the cams, resting on the tapered ring, move apart, and the front ends fix the cylindrical part of the mandrel or workpiece.

The tapered back-up ring is fitted with sufficient radial clearance and is held in the middle position by springs. Therefore, if one of the cams abuts against the surface of the workpiece, then with further movement of the ring, the rear end of the cam presses on the support ring and displaces it in the radial direction, accelerating the movement of the cams from the opposite side.

In a self-clamping drive chuck, cutting forces are used to secure the workpiece. The workpiece is radially based on a spring-loaded center. When the workpiece is pressed against the back center, it shifts to the left, compressing the spring until the end face rests on the collet, which grips the front center.

Cams with a curved corrugated working surface are used to transmit torque. At the moment of turning on the spindle, the ring begins to rotate. Since the ring with the axes of the cams is still in place, the cams rotate on the axes until the working surface touches the surface of the workpiece. The ring is made floating to equalize the clamping forces of all cams when the surface of the workpiece beats.

At the beginning of machining, under the action of cutting forces tending to stop the workpiece, the cams additionally rotate around the axes in the direction of the arrow and the corrugated surface is even more pressed against the workpiece, jamming it. The shaft is detached after processing by rotating it by inertia in the direction of rotation when the spindle is decelerated.

In this design of the driver chuck, in addition to reducing the time for installing and removing the workpiece, the accuracy of its positioning in the axial direction is increased, since the left base end of all workpieces processed in the chuck occupies the same position regardless of the depth of the center hole.

Pin and serrated driver chucks

Promising processing of shafts using pin or toothed driver chucks, which transmit torque through the end, leaving it free for processing outer surface shaft. In this case, all stages of the shaft, including the one closest to the headstock, can be machined from one setup. The workpiece is installed in the front floating center and rear rotating center. It is pressed against the chuck pins with a tailstock quill with a hydraulic cylinder. The hydraulic cylinder creates and during processing maintains the necessary clamping force of the workpiece to the pins of the chuck.

Due to the ability to self-align, the pins are pressed against the end of the workpiece with the same force and participate in the transmission of torque, despite possible deviations from the perpendicularity of the end of the workpiece to the center axis. These chucks, which have a spring-loaded front center, support the workpiece well in the axial direction. These advantages of pin and gear chucks make it possible to efficiently process shafts not only on universal equipment, but especially on automated machines, including CNC and FPS machines.

Leader cartridges and clamps

| Parameter name | Meaning |

| Topic of the article: | Driver Chucks and Clamps |

| Category (thematic category) | Metals and Welding |

Centers

Tools and accessories for turning work

Cutting conditions for metal turning

The elements of the cutting mode when turning a workpiece are cutting speed, feed and depth of cut. Cutting speed is commonly referred to as the length of the path traversed by the cutting edge of the tool relative to the machined surface of the workpiece per unit of time. Cutting speed is measured in m / min and is indicated by the letter υ.

It is customary to call a feed the amount of movement of the cutting edge of the tool per one revolution of the workpiece (in the direction of feed) or per unit of time. The feed is measured in mm / rev or mm / min, denoted by the letter s and must be longitudinal (if the tool moves parallel to the workpiece rotation axis) and transverse (if the tool moves perpendicular to this axis). It is customary to call the depth of cut the value of the metal layer cut off in one cut of the cutter, measured along the perpendicular to the machined surface of the part. The depth of cut is measured in millimeters and is indicated by the letter t.

The following surfaces are distinguished on the workpiece:

processed (from which the chips are removed), processed (obtained after removing the chips) and cutting (which is transitional between the processed and processed surfaces and is formed by the cutting tool).

Lecture 3 (2 hours)

2. Driver chucks and clamps

3. Collet chucks. Diaphragm cartridges

4. Securing workpieces

Centers. Taking into account the dependence on the shape and size of the processed parts, centers of various types are used. The vertex angle of the center working part is usually 60 °. The conical surfaces of the working and tail parts of the center should not have nicks, as this leads to errors in the processing of workpieces. The diameter of the support part is less than the small diameter of the tail taper, which allows knocking the center out of the socket without damage conical surface tail section.

The center is used to accommodate workpieces with a diameter of up to 4 mm. For these blanks, instead of center holes, an outer cone is made with an apex angle of at least 60 °, which enters the inner cone of the center; in this regard, such a center is usually called the reverse center. If it is extremely important to cut the end of the workpiece, then use the rear cut center, which is installed only in the quill of the rear grandmother.

Center with spherical working part used in cases when it is required to process a workpiece, the axis of which does not coincide with the axis of rotation of the machine spindle.

A center with a grooved surface of the working part is used when processing workpieces with a large center hole without a driver chuck.

During machining, the front center rotates with the part and serves only as a support, while the rear center does not rotate and therefore (due to the loss of hardness from increased heating) wears out intensively. To prevent wear, the working part rear center made of hard alloy. When processing at high cutting speeds and loads, rear rotating centers are used. In the tail part of the center on the rolling bearings, an axle is mounted, at the end of which working part center, which ensures its rotation along with the workpiece being processed.

When processing in centers, the transfer of movement to the workpiece can be carried out by a drive chuck through a lead-pin and a clamp , which is attached to the part with a screw.

It is important to note that in order to reduce the auxiliary time during roughing in the centers of shafts with a diameter of 15-90 mm, self-clamping driver chucks are used. The workpiece is set in the centers of the machine and pressed against the tailstock quill. In this case, the center of the chuck, shifting, compresses the springs until the workpiece with its end presses the collet ,

which rigidly fixes the center.

Posted on ref.rf

When the spindle is started, the ring is rotated together with the chuck body, ĸᴏᴛᴏᴩᴏᴇ is fixed to the body with screws. The ring rotates the cams counterclockwise with its fingers relative to the axes until the toothed surface of the cams comes into contact with the surface of the workpiece. The clamping force of the workpiece with the jaws depends on the cutting force. For uniform load on the cams, the ring ,

in which the axes are fixed, can move in the radial direction and provide self-alignment of the cams on the surface of the workpiece. After the spindle stops, the part, rotating by inertia, rotates the cams clockwise with the disk relative to the axes and is freed from the fastening.

The transfer of rotation from the spindle to the workpiece to be processed, installed in the centers of the machine, is carried out using a clamp, which is put on the workpiece and fixed with a screw, while the shank of the clamp rests on the pin of the driver chuck.

The self-tightening clamp is more convenient in operation, in which the shank is fixed in the body movably on the axis . The lower part of the shank facing the workpiece is eccentric with respect to the axis and has a notch. To install the clamp on the workpiece, the shank is tilted towards the spring , which, after installing the clamp, pre-tightens the workpiece with a shank. In the process of machining, the pin-driver of the chuck makes the final tightening of the workpiece with the shank in proportion to the cutting force.

Leader chucks and clamps - concept and types. Classification and features of the category "Driving chucks and clamps" 2014, 2015.

Energy drinks: give vigor, but take away health What will happen if you drink 4 energy drinks

Mustard for weight loss: how to use the seasoning with maximum benefit Is it possible for children to have mustard

The benefits and harms of mustard for the human body Table mustard benefits and harms

How to treat the ear after piercing: types of antiseptics, their composition, rules and features of the treatment of a pierced ear

Sistine Chapel in the Vatican: description, history, architectural features