Driving devices

TO Category:

turning business

Driving devices

To transfer rotation from the spindle to the workpiece installed in the centers, apply leash devices. The simplest of them is a turning collar. The bent shank of the clamp enters the radial groove of the faceplate fixed on the machine spindle. Rotating with the spindle, the faceplate carries along the clamp, and with it the workpiece installed in the centers. Clamps with straight shanks are also used; to work with them, faceplates are used, in which a finger or a bar acts as a leash. Working with a collar presents a certain danger: there may be cases where the worker's clothing is caught by the shank of the collar. Therefore, for safety reasons, faceplates with protective covers (safety faceplates) are used. In order not to damage the surface of the clamped workpiece, a split sleeve is put on it or rubber is placed under the clamping bolt.

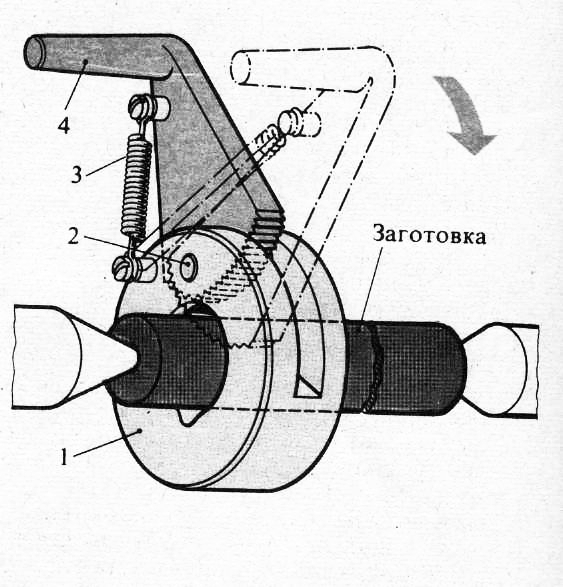

To reduce the time for installing and removing the clamp, quick-acting and self-clamping clamps are used. The main part of a self-clamping leash collar is a ring that is put on a workpiece installed in the centers. When the plang spindle is turned on, the aiba acts on the leash, which, turning on the axis, captures the workpiece with a corrugated working surface. When cutting, this collar clamps the workpiece more securely, the larger the chip cross section.

1. CARBIDE CENTERS: a - with a deposited layer of hard alloy, b - with a brazed tip

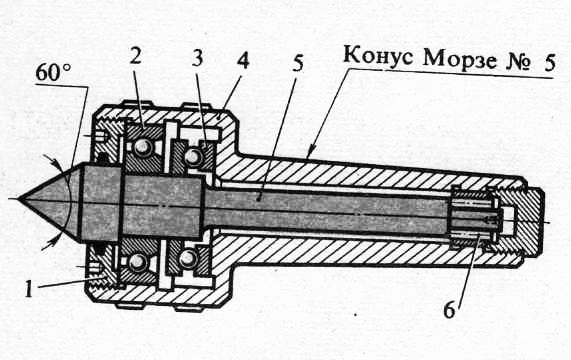

2. ROTATING CENTER FOR LIGHT RADIAL LOADS (UP TO 200 KG): 1 - cover. 2 - radial bearing. 3 - torsion bearing. 4 - body with a shank. S - center. 6 - needle bearing

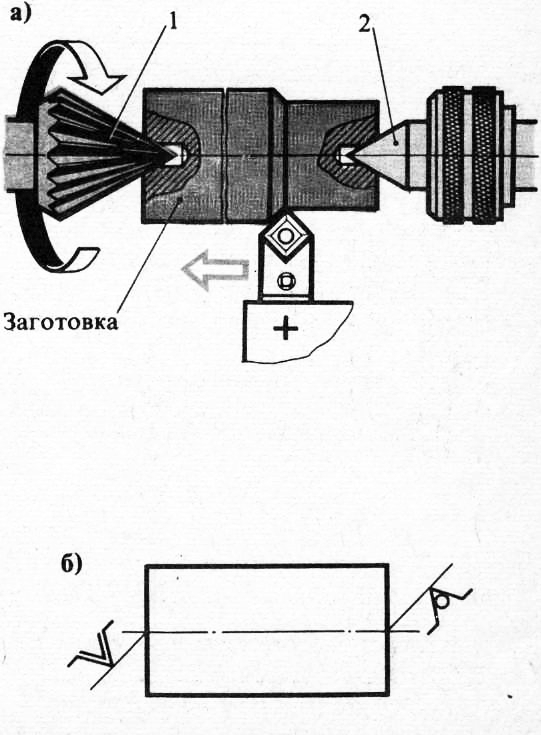

3. APPLICATION OF THE CLAMP (a), LEGEND SCHEME (b): 1 - faceplate, 2 - front center. 3 - clamp. 4 - rear center, 5 - quill

4. SAFE FACES: a - with a leash pin, b - with a leash plate) “ 3- leash (finger or

5. SELF-CLAMPING LEAD CHUCK 1-ring, 2-axle. 3 - spring. 4 - leash

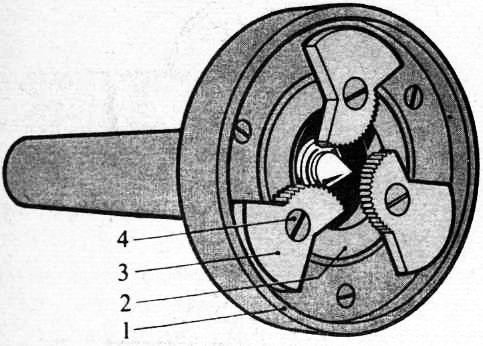

6. SELF-CLAMPING LEAD CHUCK: 1 - faceplate, 2 - "floating ring", 3 - cam, 4 - cam axis

7. LEADING MANDALE: 1 - mandrel body with a tapered shank. 2 - drive washer with end teeth. 3 - floating center. 4 - spring. 5 - spring adjusting screw

The transmission of torque from the spindle to the workpiece is often carried out by a special self-tightening chuck (faceplate) with eccentric cams. The design of such a cartridge by the innovator V.K. Seminsky is shown in fig. 36. The presence of a “floating ring”, on which the cam axes are located, allows you to fix workpieces with uneven outer surface(for example, forgings).

On fig. 7 shows a driving mandrel, which entrains the workpiece with teeth located on the working end of the driving washer. The workpiece is pressed against the teeth by the center of the tailstock.

The leader for rollers of small diameters can be a corrugated leash center- "ruff". For processing tubular blanks, "ruffs" are also used, which have teeth - corrugations on the working surface. Rollers of small diameter (up to 20 mm) can be fixed in reverse centers. End cones and chamfers are preliminarily machined on the workpiece, and the front and posterior centers have corresponding holes with landing cones. The workpiece is entrained in rotation due to the friction between the front reverse center and the workpiece. The method of fastening in reverse centers is used only for finishing. Installation of workpieces in the centers (with putting on a collar) lasts 0.25-0.6 minutes (depending on the mass of the part). Installation in centers with self-tightening chuck (faceplate) or mandrel, as well as installation in friction clamps, reduces the time for clamping and removing the part by almost half. Experienced turners process rollers of small diameter, fixing them in reverse centers of the “glass” type (based on a chamfer).

8. FIXING THE BLANK WITH THE HELP OF THE LEADING CENTER - "Ruff" (a), SIGNATION SCHEME (b): 1.2 - centers

Rolled blanks are fixed in three-jaw chuck with support center mounted in the tailstock quill.

Mixed Personality Disorder: Causes, Symptoms, Types and Treatments

GTA 4 control settings

FAQ on Smuggling in GTA Online

LSPDFR - welcome to the police

The huge map of Grand Theft Auto San Andreas and its secrets