Compressor equipment is usually used in conjunction with a device such as a moisture separator.

There are no high-tech elements in it, so a simple version with average characteristics can be made on your own.

Let's see how and from what you can make a dehumidifier for a compressor with your own hands.

Once they are dry, you can return them to use. Desiccant beads are not cheap, so this method will save you a lot of money. These beads will eventually deteriorate and eventually need replacing. These drying dehumidifiers work great if you are using intermittent tools like powder coated powder. The beads should last a long time. They are best used as a final filter in front of the instrument along with another front hand water removal device that captures the bulk of the water.

Natural air, as you know, always contains a certain amount of water vapor.

Natural air, as you know, always contains a certain amount of water vapor.

The solubility of steam increases with increasing air temperature, that is, the warmer it is, the more humid it can be.

This will give you the longest possible use of the bead. It is used by auto dealerships as a final filter before the spray gun. It also removes dirt particles down to 1 micron, removes oil and has a built-in air regulator. If you want to go this route and place a cooler between the pump and compressor, you will need to make your own copper lines going from the pump to the cooler and then from the cooler to the tank. Do not use rubber here as the air exiting the pump can exceed 300 degrees Fahrenheit.

A dehumidifier is a device that significantly reduces the moisture content of the air passed through it.

The efficiency of modern industrial designs can reach 90%.

Advantage and importance of application

Moisture in the air is almost always detrimental to both the equipment and the processes that are carried out with its help. First of all, the compressor itself suffers, inside which steam can partially turn into condensate, that is, already liquid water. Water is known to promote the corrosion process.

Your air lines themselves, and the way you shut them off, can be used to remove water from your compressor. long length metal pipe such as copper or ferrous iron will absorb a lot of heat from the air passing through it, allowing the water to fall out of the slurry.

This method is the cheapest of all the methods mentioned above, but it lasts until your ice melts. The idea is that you take a 50 feet air hose coming from your air compressor and roll it into a bucket of ice water. The hose then immediately falls into the water trap. The ice water will cool the hose, which will cool the air. After the air has cooled and the water vapor turns into water droplets, the water trap must trap the water. This method does work, but it obviously requires constant ice replenishment.

The same can be said about all kinds of open-ended pneumatic systems - for example, in trucks, in which the compressor periodically pumps air taken from the outside.

Water separator from the Geyser filter

If the compressor is used to paint a car, then in the presence of moisture in the air, the coating will be of lower quality (so-called craters are formed), and the body vehicle may corrode.

Making a dehumidifier with your own hands

An upgrade to this method uses a copper coil instead of an air stirrer. A rubber air hose is a very poor choice for heat transfer. By using a copper coil, you can transfer much more heat into ice water... To preserve ice for longer periods of time, you can use a cooler instead of a ladle. You will need to drill both the inlet and outlet in the refrigerator and then fill the gaps with some expanding foam to make a good seal.

Applying a moisture separator, it is possible to significantly dry the air entering the compressor, which means that all the listed phenomena are avoided.

The most common types of homemade dehumidifiers

Homemade moisture separators are made in the image and likeness of industrial ones. There are three types of such devices:

The cooler will stop the ice from melting for a longer period of time, or you can take it one step further and put a bucket of ice water in the mini fridge. Regardless of any of the above methods you choose to use to dry the air, you will need to drain the air compressor tank frequently. Do this every day that you use your air compressor... If you use the air compressor for a long time, drain it several times while you are using it.

This will allow the tank to be free of rust and is your first line of defense against removing moisture from your overhead lines... If water can form in the tank, over the years the tank will rust, making it weaker. Unfortunately, draining the reservoir is a pain because the valve is under your compressor. The automatic drain is electronically and timer controlled, so it periodically empties your tank for you. No more hassle when draining your tank. It is also known as a toilet paper filter.

Cyclones

This type of moisture separator has a cylindrical body in which a rotary motion is imparted to the air. In this case, the steam contained in it is thrown by centrifugal force to the walls, on which it settles in the form of condensate.

The dried air is removed through the outlet branch pipe, which is located at the maximum possible distance from the inlet.

How does a KamAZ water separator with a regulator work?

People even used them in their cars daily instead of an oil filter. This means you use a quick disconnect fitting on each side and only use it when you need the cleanest air possible, such as powder coating. Compressing the roll causes the layers to separate slightly, allowing space to be placed between them. Air travels through the voids in the paper layers and any oil or dirt particles will be trapped. Apparently toilet paper works almost as well as filters to replace a motor fuse.

Moisture separator cyclone

There is a drain valve to drain the condensate.

Cyclone moisture separators have an important advantage: along the way, they remove dust from the air.

Adsorbers

Some substances absorb water vapor like a sponge. To dry the air, it is enough to pass it through a chamber filled with such a substance (it is called a sorbent).

By choosing toilet paper, they say the cheaper the better, which means a single layer material that looks like sand paper. Depending on your budget and your capabilities, you can choose which method or methods are best for you. All methods are effective and proven to be effective. Some of these options are expensive, but don't let that discourage you from powder coating. If you're just starting out and want to give it a try, insert the air hose into the ice bucket and start covering.

As you continue to work, you will improve your equipment and see the need for clean air. These items aren't just specific to powder coating, if you ever want to use a spray gun or plasma cutter, you need air that's just as clean and dry. Expert advice on how to repair a dehumidifier that is not working, performing poorly dehumidifying, or having other problems.

As it becomes saturated with moisture, the sorbent should be changed.

Coolers

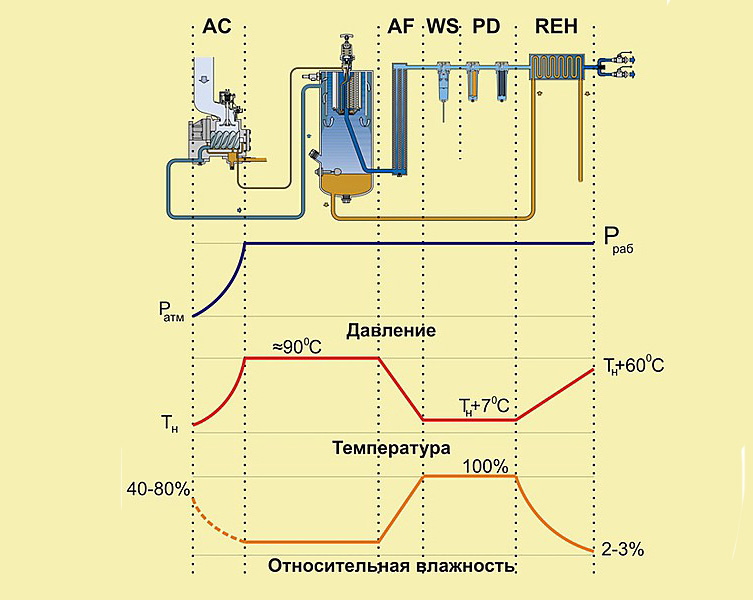

We have already said above that the "solubility" of vapor in air increases with an increase in the temperature of the latter. For example, at a temperature of 0 degrees, the air can contain up to 1 g of water vapor, while at + 20C - already about 20 g. Hence the simple conclusion: in order to dry the air, it must be cooled. In this case, a part of the steam will become excess and immediately turn into condensate.

If you see any ice blocking elements, allow the ice to melt and do not use the unit until the indoor temperature has exceeded 65 degrees Fahrenheit. Many people find that by unplugging the unit and waiting about 30 days per season, the problem is solved. You can do this with. Attach the leads to the terminals on the switch.

Press down on the lever or shift lever on the switch. You can easily test it with a voltmeter. Also, using a voltmeter meter, you can determine if the bypass switch is working or not. Turn the handle of the hygrostat as far as it will go in both directions. If the voltmeter meter registers zero ohms only through a part of the hygrostat range, then the hygrostat is operating.

A good example of this process can serve as such phenomena as the fallout of dew in the morning, constantly dripping from household air conditioner water, fogging of a cold mirror after taking a shower. And household dehumidifiers using this principle are not uncommon for a long time.

Dehumidifier not working well

If it registers zero across the entire range, it is broken and must be replaced. It is usually best to replace. If your dehumidifier seems incompetent, it can be downsized for space. Check the specifications of the device to make sure it can handle the size of the room. If you don't want to replace it with a larger one, try closing the doors and dehydrating the space in a section at a time. After unplugging the power cord, you can also.

Overflow or leakage of dryer

While you're at it, make sure the condenser is not clogged with dust or dirt. If the voltmeter meter reads 0 ohms through only part of the range of the hygroscopic kit, the hygrostat is operating. If it registers 0 across the entire range, it is broken and must be replaced. Many dehumidifiers have a float switch that prevents the unit from overflowing with water that has been pulled out of the air. Sometimes this switch does not work well and needs to be replaced. If your dehumidifier is overfilled, you can check the bypass switch with a voltmeter.

Cooler and water separator - diagram

Removing moisture from the air by cooling it is a rather energy-intensive process, so this type of moisture separator is less common than the first two. It should also be borne in mind that refrigeration dryers do not purify the air from mechanical impurities, as cyclones and adsorbers do.

Prefabricated dehumidifiers are usually combined. The cooling block or cyclone is the first stage in which a coarse cleaning is carried out, that is, most of the steam is removed. In a cyclone, air is swirled into a vortex by means of a rotating impeller with blades.

Is your desiccant freezing? If your dryer is freezing, it is important to fix the problem - running a dryer that is completely frozen can damage the compressor. The dehumidifier often freezes if the room temperature is colder than about 65 degrees Fahrenheit.

Advantages and importance of using the device

If your room temperature is not too cold, air flow to the unit may be limited or blocked, the unit may have a defective de-icer, the refrigerant gas in the unit may be too low, or the compressor may fail.

To drain the condensate, just press the button on the case, and in high-performance models this process is carried out automatically.

The adsorber acts as a second stage, which already carries out fine cleaning... Thanks to the combined solution, the sorbent has to be changed much less frequently.

In the characteristics of industrial moisture separators, in addition to the amount of steam removed (indicated as a percentage), the size of the dust particles retained by the device is also given.

To troubleshoot a dehumidifier that freezes

If the room temperature is below 40 degrees Fahrenheit, the dehumidifier will definitely freeze. A striking indicator of this is the evaporative coil, which freezes completely and evenly. If you suspect that the temperature in your room may be too cold, try placing a dehumidifier on a table to circulate slightly warm air.

What to consider when choosing?

You can also try directing a small fan or heater towards the device, if that solves the problem, consider raising the room temperature. Anything that interferes with the free movement of room air through the unit can cause the dehumidifier to freeze. If you cannot hear the fan blowing air through the coils when the unit is turned on and should be running, the dehumidifier will freeze. If your dryer has a filter, follow the manufacturer's instructions to clean them.

Most modern devices filter out particles with a size of more than 5 microns, but there are also those that only allow dust grains less than 0.1 microns in size (they are very expensive).

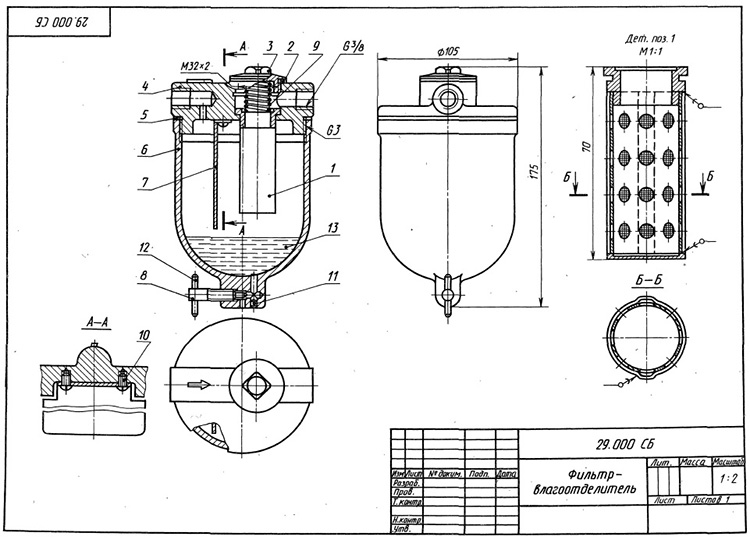

Device drawing

In the home-made version of the cyclone, for the sake of simplicity, we do without an impeller. Instead, air will be fed into the cylindrical body tangentially, due to which it will move in a vortex-like manner.

In most cases, a vacuum cleaner is used for this; foam filters can be cleaned with a tap spray. If the coils inside the device are dirty, they cannot work efficiently. Detach the dryer and open it by removing the screws that secure the outer cover. Note if the coils are completely frozen or only partially frozen. If only some sections of the coils are iced up, the problem is most likely caused by low refrigerant or a bad compressor. Allow all of the ice to melt and excess moisture evaporate from the coils.

However, it must be taken into account that such a moisture separator, which does not have a forced swirler, will work effectively only when installed after the compressor. That is, he cannot protect the supercharger itself.

Then, using the brush tool on the vacuum cleaner, remove any accumulated dust, being careful not to damage the coils. Drain the device and let it dry completely before plugging and plugging it back in. After turning on the dehumidifier, turn it on to make sure it freezes again. Make a decision. If it still doesn't work, it is likely to be low in refrigerant. Now you need to make a decision to either take it to an appliance repair shop, or drop it and buy a new one. Then assess whether it is worth doing.

If you decide to buy a new one, refer to our free dehumidifier buying guide. Is your desiccant evaporating poorly? If your desiccant smells or smells musty, or like sulfur or mildew, this expert advice can help you fix and fix the problem.

Filter drier - drawing

An important aspect is the distance from the inlet to the outlet - it must be sufficient for the steam to move under the action of centrifugal force to the wall.

Making a dehumidifier with your own hands

Now let's take a closer look at how to make a dehumidifier for a compressor with your own hands:

Cyclone

The cyclone body is a pipe welded on both sides. It should be noted that air will be supplied inside under high pressure, so the walls of the case must be thick enough. You can also take a gas cylinder or a fire extinguisher as a blank - they are just designed for high pressure.

Case dimensions:

- diameter: 100 - 110 mm;

- height: 600 - 700 mm.

Example of a finished device

Before starting work, the workpiece for the body must be processed from the inside. sandpaper- it is needed for painting.

Manufacturing procedure:

- From below, at a distance of at least 120 mm from the bottom plug (the pipe will be installed vertically), a fitting must be welded into the housing wall through which air will be supplied. It is most correct to weld the fitting tangentially, but if such a solution seems too difficult for you, just weld it on the side.

- Center of the end cap covering the upper end, you need to weld the outlet pipe. Some craftsmen weld it on the side, on the side opposite to the inlet pipe. With this design, the moisture separator is also quite effective, since the air has time to dry out during its travel along the body, but it would be more correct to place the outlet in the center of the upper plug (recall that the steam is thrown by centrifugal force just to the walls).

- To the center of the bottom plug you need to weld in the condensate drain pipe. If it is decided to use a cylinder as a blank for the body, it must be turned over - then the standard fitting will play the role of the drain hole.

When all welding works will be executed, inside the moisture separator you need to fill in the paint and varnish composition, which, in addition to the paint itself, already includes a primer and an anti-corrosion additive.

It is called "3 in 1 enamel primer". After rolling the composition inside the device, it is drained, after which the moisture separator is dried.

Adsorber

Silica gel possesses good sorption properties, granules of which are made by drying supersaturated solutions of silicic acid salts. This sorbent is quite affordable and is sold both in pure form and as a cat litter.

Different types of silica gel can differ in pore size, working surface area and the amount of water that they are able to absorb (indicated as a percentage of the sorbent mass).

Dehumidifier absorber

The amount of silica gel is selected taking into account the capacity of the installation: for every 800 - 850 l / min, 1 kg of sorbent is required. For permanent work, you will have to purchase a double volume: while the fresh portion is working, the already saturated portion will be dried in the oven.

It makes sense to look for such a type of silica gel, which, when saturated with moisture, changes color - it is most convenient to work with it.

A water filter or a car oil filter can be used as a container. Excess holes in the oil filter can be plugged with bolts set on the sealant.

If the interior is divided into three zones by two O-rings, moisture will be absorbed gradually.

Dehumidifier-cooler

It can be turned into a freezer of an ordinary refrigerator.However, it should be borne in mind that this option is rather difficult to manufacture, since it is necessary to ensure the tightness of the chamber, as well as to cut a branch pipe into it to discharge condensate (it is important not to damage the evaporator surrounding the chamber).

Such a moisture separator will not be able to withstand significant pressure, but it is not necessary to install it after the compressor - it also works effectively when installed before the supercharger.

Even at the design stage heating system must be thought out. There is a traditional strapping scheme.

Even at the design stage heating system must be thought out. There is a traditional strapping scheme.

How to insulate brick house outside and what - an overview of materials and types of insulation is presented.

In conclusion, we can say the following: home-made moisture separators, of course, are inferior to industrial ones, but they should not be underestimated either.

The Network describes cases when using inexpensive Chinese moisture separators it was not possible to achieve an acceptable quality of painting, and after attaching a homemade moisture separator from a pipe to the compressor, this problem was solved.

Video on the topic

The compressor of the pneumatic system of trucks not only pumps air, but is also a source of moisture and oil that is hazardous to the system. Air dehumidification and oil separation is carried out by a special unit - a moisture-oil separator, the structure and principle of operation of which will be discussed in this article.

General arrangement of the braking system of trucks

In modern trucks of domestic and foreign production a pneumatic braking system is used, which simultaneously acts as a source of compressed air for a number of other systems and mechanisms. The use of the pneumatic system is due to its high reliability, efficiency and versatility, and in the future it is unlikely to give way to systems operating on other principles.

The pneumatic system of all trucks is approximately the same, it includes a compressor, pipelines, a receiver (or receivers), several valves and actuators. Also, the system includes several devices that ensure its normal operation in any conditions, as well as the protection of its constituent units from a number of negative factors. One of these devices is one that compensates for some of the features of the compressor and ensures that moisture and oil are removed from the system, the presence of which can seriously harm the operation of valves and other units.

Purpose and place of the moisture-oil separator in the pneumatic system

The basis of the pneumatic braking system is the compressor, which supplies air at a pressure sufficient for the operation of all mechanisms. However, the compressor has one peculiarity: during its operation, oil, which is used to lubricate the piston and other parts, gets into the air. It is impossible to prevent microscopic oil droplets from entering the air, since the compressor simply cannot work without lubrication.

Another problem is the air itself, which is taken from the atmosphere by the compressor. Atmospheric air always contains moisture, and the degree of moisture can be very significant - getting into the system, this moisture condenses, droplets settle on the surfaces of pipelines, valves and mechanisms, which leads to corrosion and other negative consequences.

Therefore, a device must be provided in the pneumatic system to ensure that the injected air is purified from droplets of oil and moisture. This problem is solved by a moisture-oil separator, which is installed immediately after the compressor. Passing through this unit, the air is dried and cleaned of oil, and only after that it enters the receivers and further to the actuators.

It should be noted that after passing through the moisture-oil separator, the air still contains a small amount of oil and moisture, therefore it poses some threat to the system. Additional cleaning is carried out using receivers: when leaving the pipeline into the receiver, the air expands, its temperature drops, moisture condenses and settles on the walls of the tank, taking with it microscopic droplets of oil. Over time, oil and condensate accumulate at the bottom of the receiver, which is periodically removed using a specially provided valve.

Pneumatic systems of all trucks operate according to this principle, and they use a limited number of types and models of moisture and oil separators, which have fundamentally the same device.

Types and device of moisture-oil separators

All devices used today for separating moisture and oil from compressed air have the same principle of operation, therefore they are designed according to the same principles, and differ only in the presence or absence of additional parts.

Currently, there are two main types of moisture and oil separators in use:

With built-in air pressure regulator (RDV);

... Without pressure regulator.

Moisture-oil separators with and without WFD have a different mechanism for cleaning condensate and oil. In addition, devices with built-in WFD make a separate regulator unnecessary, therefore, they provide a higher reliability of the entire pneumatic system.

How to understand: will the kitten be fluffy?

What light alcohol can pregnant women drink: consequences of consumption

Why do legs swell in the ankles and ankles of feet in pregnant women: causes and methods of treatment

The wedding of Prince Harry and Meghan Markle: scandalous and secret details of the marriage (photo) Future marriage of Prince Harry year NTV

How to close white plums for the winter