Serves for compression and movement of refrigerants in the refrigeration circuit of the air conditioner, a special type of compressor is used - a refrigeration compressor. Currently, there are two main fundamental types of compressors:

1. Reciprocating compressor:

The piston compressor operation is based on the rotation of the electric shaft drive. engine. This type of compressor can have a different number of pistons. In most cases, the number of pistons depends on the scope of application of a particular unit:

1-3 pistons are found in domestic reciprocating compressors;

up to 8 pistons can have large powerful industrial refrigeration compressors stationary placement.

The number of compressor pistons varies according to the stage, i.e. they can be single or multi-stage. A typical reciprocating compressor has two stages. In special cylinders of the first stage, the refrigerant is compressed and then passes under pressure into the cylinders of the second stage.

2. Screw or scroll compressor:

Screw (scroll) refrigeration compressors. Compression of the refrigerant in such compressors occurs in the space between the rotary rotors or in the gap between the rotor and the casing. Rotary screw (scroll) refrigeration compressors are very powerful and therefore outperform reciprocating compressors, although they have approximately the same physical dimensions.

Causes of compressor malfunction.

Oil analysis.

- A dark oil color and a burning smell indicates that the A / C compressor has overheated. Causes of overheating: refrigerant leak from the air conditioner or air conditioner heating when negative temperatures outside. In this case, the oil loses its lubricating properties and decomposes with the formation of resinous substances that cause the failure of the air conditioning compressor.

- The greenish tint of the oil indicates the presence of copper salts. The reason is the presence of moisture in the refrigeration circuit of the air conditioner. The acidity test of such an oil is usually also positive.

- A clear oil with a slight odor, similar in color to the sample, indicates that the conditioner does not need an immediate oil change.

Violation of the tightness of the refrigeration circuit.

It can be caused by various reasons and does not always lead to a breakdown. The location of the leak, the amount of freon that managed to leak out, the time interval between the occurrence and detection of the leak, the operating mode of the air conditioner and other factors are important. A leak is dangerous because the refrigerant-cooled compressor of the air conditioner overheats due to a decrease in the density of the refrigerant. The compressor discharge temperature rises, hot gas can damage the four-way valve. The compressor lubrication system breaks down, oil flows into the condenser.

Refrigerant leakage symptoms:

- Darkening of the compressor insulation.

- Periodic activation of the compressor thermal protection.

- Burnout of insulation on the discharge pipeline.

- The oil is dark in color with a burning smell.

If the leak is detected on time and the freon has not completely leaked out of the circuit, the air conditioner did not work for a long time without refrigerant, then the repair of the air conditioner in the workshop is not necessary.

Leakage caused by pipeline rupture is very small. More often leaks occur as a result of poor quality rolling joints. It is necessary to constantly monitor the operation of the air conditioner, then leaks can be detected in a timely manner. 5 minutes after turning on the air conditioner, depending on the selected mode, it should already produce cold or warm air, otherwise you must immediately turn off the air conditioner and call the master. If the pipes on the outdoor unit are covered with frost when the air conditioner is operating, it means that refrigerant is leaking.

Moisture in the refrigeration circuit.

Moisture usually enters the refrigeration circuit if the installation is not carried out in accordance with the rules. Evacuation of the refrigeration circuit during installation need to to remove air and water vapor from the installed line. Flushing the installed line with refrigerant, which is sometimes performed instead of evacuating, does not remove moisture, but only turns it into ice on the walls of the copper pipes. The ice subsequently melts and forms moisture inside the refrigeration circuit.

The danger is that moisture in the system often does not manifest itself in any way until the air conditioner compressor fails. The fact is that all processes in an air conditioner operating for cooling (in summer) occur at positive temperatures, and water manifests itself only when it freezes, causing a malfunction of the capillary tube or thermostatic valve. However, by indirect signs, it is possible to determine the presence of moisture in the air conditioner.

One indication of moisture in the circuit is a greenish tint to the oil and a positive acidity test. If these signs are found, urgent action is required to save the compressor from failure. In the earlier stages, moisture manifests itself when the air conditioner is operating in heating mode at low outdoor temperatures or when refrigerant leaks. In these cases, the moisture turns to ice and clogs the capillary tube or expansion valve. As a result, the suction pressure of the air conditioner drops, the compressor temperature rises and the thermal protection is activated. This cycle repeats until the compressor burns out. Removing moisture from the freon circuit can also only be carried out in a workshop.

The cost of replacing a compressor makes up a large part of the cost of the entire air conditioner, so its condition must be carefully monitored. Replacing a failed air conditioner compressor is associated with neglect of the air conditioner operating rules and untimely maintenance of the system.

Air conditioning compressor squeezes freon flowing through the pipes of the refrigeration circuit, and keeps him going... Gaseous freon is supplied to the compressor inlet from the evaporator at a low pressure of 3 - 5 atmospheres and a temperature of 10 - 20 ° C. The compressor compresses the freon to a pressure of 15 - 25 atmospheres, as a result of which the freon heats up to 70 - 90 ° C, after which it enters the condenser.

In split-system air conditioners (for example, in the most common wall-mounted air conditioners), the compressor is located in an external unit - on the street. This reduces the noise generated by the air conditioner in the room.

The main characteristics of the compressor - compression rate(compression) and refrigerant volume which he can pump. The compression ratio is the ratio of the maximum outlet vapor pressure of the refrigerant to the maximum inlet pressure.

What are the compressors?

Refrigeration machines use two types of compressors: (1) reciprocating pistons in the cylinders - piston; (2) with rotary movement of working parts - rotary, screw and spiral.Reciprocating compressors

Most often used in air conditioners hermetic reciprocating compressors in which the electric motor is located inside a sealed housing.- As the piston (3) moves up the compressor cylinder (4), the refrigerant is compressed. The piston is moved by an electric motor through the crankshaft (6) and the connecting rod (5).

- The steam pressure opens and closes the suction and discharge valves of the refrigeration compressor.

- Diagram "a" shows the refrigerant suction phase into the compressor. The piston begins to descend from the top point, while a vacuum is created in the compressor chamber and the inlet valve (12) opens. Low temperature and low pressure refrigerant vapor enters the working space compressor.

- Scheme "b" shows the phase of vapor compression and its exit from the compressor. The piston rises and compresses the steam. This opens the compressor outlet valve (1) and high pressure steam escapes from the compressor.

Rotary Rotary Compressors

Principle of operation rotary compressors rotation is based on suction and compression of gas when the plates rotate... Their advantage over reciprocating compressors is their low pressure ripple and reduced start-up current. There are two versions of rotary compressors:

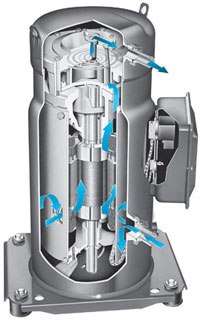

Scroll (SCROLL) compressors

Scroll compressors are used in small and medium-sized refrigeration machines. Such a compressor consists of two steel spirals... They are inserted into one another and expand from the center to the edge of the compressor cylinder. The inner spiral is fixed, while the outer one rotates around it.The spirals have a special profile (involute) that allows rolling without slipping. The movable compressor scroll is mounted on an eccentric and rolls over the inner surface of the other scroll. In this case, the point of tangency of the spirals gradually moves from the edge to the center. Refrigerant vapors in front of the touch line are compressed and pushed out into the center hole in the compressor cover. The points of contact are located on each turn of the inner spiral, so the vapors are compressed more smoothly, in smaller portions than in other types of compressors.

Refrigerant vapors enter through an inlet in the cylindrical part of the housing, cool the engine, then are compressed between the scrolls and exit through an outlet in the upper part of the compressor housing.

Screw Compressors

In chillers of high power (150 - 3500 kW), for example, chillers, screw compressors of two modifications are used: with a single or double screw.Single screw models have one or two satellite gears connected to the rotor laterally. Refrigerant vapors are compressed using rotors rotating in opposite directions. Their rotation is provided by a central rotor in the form of a screw. The refrigerant vapor enters through the compressor inlet, cools the engine, then enters the outer sector of the rotating gears of the rotors, is compressed and exits through the sliding valve into the outlet. The compressor screws must be sealed, therefore lubricating oil is used. Subsequently, the oil is separated from the refrigerant in a special compressor separator.

Twin screw models differ in the use of two rotors - main and drive. Screw compressors do not have inlet and outlet valves. Refrigerant is constantly drawn in from one side of the compressor and released from the other side.

Compressor malfunctions and their causes

Compressor cost accounts for most of the cost of the entire air conditioner, therefore, its condition must be carefully monitored. As a rule, replacement of a failed air conditioner compressor is associated with neglect of the rules for the installation and operation of the air conditioner. Often, insufficiently qualified or responsible employees of the service department do not carry out necessary work even if the insulation, air conditioner oil, or refrigerant leaks are darkened. If they are limited to installing a filter on the liquid line or fixing a leak and refueling an air conditioner, then the compressor will fail soon. We will tell you what to do in such cases when the air conditioner compressor can still be saved.Need compressor repair can be found out not only if the compressor is no longer working, but also according to the results of a routine inspection of the air conditioner. Examples:

In these cases, even if the A / C compressor continues to operate, a malfunction will soon occur unless urgent action is taken.

Oil analysis

- a dark color of the oil and a burning smell indicates that A / C compressor overheated... Causes of overheating: leakage of refrigerant from the air conditioner or the operation of the air conditioner for heating at negative temperatures outside. In this case, the oil loses its lubricating properties and decomposes with the formation of resinous substances that cause the failure of the air conditioning compressor.

- the greenish tint of the oil indicates the presence of copper salts. Reason - the presence of moisture in the refrigeration circuit of the air conditioner... The acidity test of such an oil is usually also positive.

- Clear oil with a slight odor, similar in color to the sample, indicates that the conditioner does not need an immediate oil change.

Violation of the tightness of the circuit

Violation of the tightness of the freon circuit can be caused by various reasons and does not always lead to breakdown. The location of the leak, the amount of refrigerant that managed to escape, the time interval between the occurrence and detection of the leak, the operating mode of the air conditioner and other factors are important. Refrigerant leakage is dangerous because air conditioning compressor cooled by refrigerant overheats due to a decrease in the density of the refrigerant. The compressor discharge temperature rises, hot gas can damage the four-way valve. The compressor lubrication system breaks down, oil flows into the condenser. Refrigerant leakage symptoms: - Darkening of the compressor insulation.

- Periodic activation of the compressor thermal protection.

- Burnout of insulation on the discharge pipeline.

- The oil is dark in color with a burning smell.

The percentage of sudden leaks caused by pipeline rupture is very small. Most often, leaks occur through small leaks on the rolling joints. It is necessary to constantly monitor the operation of the air conditioner, then leaks can be detected in a timely manner. 5 minutes after turning on the air conditioner, depending on the selected mode, it should already produce cold or warm air, otherwise you must immediately turn off the air conditioner and call a repairman. If the pipes on the outdoor unit are covered with frost when the air conditioner is operating, it means that refrigerant is leaking.

Moisture in the circuit

Moisture usually enters the freon circuit of an air conditioner if installation was performed in violation of the rules... Vacuuming the freon line during the installation process is necessary to remove air and water vapor from the mounted line. Flushing the installed line with refrigerant, which is sometimes performed instead of evacuating, does not remove moisture, but only turns it into ice on the walls of the copper pipes. The ice subsequently melts and forms moisture inside the refrigeration circuit.The danger is that moisture in the system often does not manifest itself in any way until the air conditioner compressor fails. The fact is that all processes in an air conditioner operating for cooling (in summer) occur at positive temperatures, and water manifests itself only when it freezes, causing a malfunction of the capillary tube or thermostatic valve. However, by indirect signs, it is possible to determine the presence of moisture in the air conditioner.

One of the signs of moisture in the freon circuit is a greenish tint of the oil and a positive acidity test. If these signs are found, urgent action is required to save the compressor from failure. In the earlier stages, moisture manifests itself when the air conditioner is operating in heating mode at low outdoor temperatures or when refrigerant leaks. In these cases, the moisture turns to ice and clogs the capillary tube or expansion valve. As a result, the suction pressure of the air conditioner drops, the compressor temperature rises and the thermal protection is activated. This cycle repeats until the compressor burns out. Removing moisture from the freon circuit can also only be carried out in a workshop.

A compressor for a split air conditioner is one of the most important working parts. And the most expensive one. Its price sometimes amounts to 75% of the cost of the entire device. What compressors are installed on best air conditioners split systems, read on.

Functions and types of split air conditioner compressor

A compressor is required to compress the refrigerant and increase its pressure and temperature.

It is the main element of any air conditioner or refrigerator. In a split air conditioner, the compressor is located in the outdoor unit. The average compressor life is 7 to 10 years.

According to the method of action and power, the following types of compressors of split-system air conditioners are distinguished:

- rotary;

- screw;

- spiral;

- piston,

- centrifugal.

In domestic and semi-industrial air conditioners split compressor systems are most often installed rotary hermetic. The capacity of such installations does not exceed 9 kilowatts.

Centrifugal and screw compressor are used in very powerful and efficient installations. They can be disassembled and repaired, unlike the rest, which only need to be replaced.

Reciprocating compressors

Inexpensive split-system air conditioners, as a rule, are equipped with reciprocating compressors. The low cost also speaks of the low reliability of such systems. Knowing this, the manufacturer gives a guarantee for his brainchild for only 12 months.

The system is outdated and cannot withstand the power of modern units, however, purchasing the cheapest split air conditioners, you can run into such a structure. The unreliability and low efficiency is due to the intense friction to which the internal parts of the device are subjected. All parts wear out much faster. Already in the second year of operation, the owners will notice that the piston split air conditioner cools the air much weaker.

If the refrigerant pressure is exceeded, the parts are subjected to even greater stress, risking breakage.

Thus, the entire resource of the equipment will not be used up and its service life will be somewhat extended.

Stuck compressor car air conditioner- one of the most unpleasant and expensive problems in auto repair. Why do air conditioner compressors break down, wedge, stop pumping? When is the repair needed?

The car air conditioner compressor is a powerful hermetic pump powered by the car engine. Compressors are of several types:

- Reciprocating, where pressure is generated by five or seven pistons arranged in a circle.

- Blade, where in an eccentrically located flywheel, the blades move under the action of centrifugal force.

- Spiral, where pressure is created by an aluminum "snail" rotating in another, the same snail.

Reciprocating compressors are most susceptible to seizure. The vane and spiral ones most often stop swinging and begin to emit a terrible roar during operation.

For what reasons can the air conditioner compressor jam? First of all, this is the lack of the required amount of oil in the system. Where can the oil from the car air conditioner go? It may go away with freon if it leaks, it may not be added when refueling after replacing any part of the air conditioner, some of the oil may "spit out" through emergency valve with overpressure. Long-term operation of the air conditioner with an insufficient amount of freon also leads to oil starvation and seizure. After all, the oil is carried through the air conditioner by freon. Little freon - little oil goes to the rubbing parts. So don't use a half-empty air conditioner. It should be noted that an excess of oil in the system, as well as its refilling with freon, is also, to put it mildly, not useful.

Overpressure in the system is the second reason for seized A / C compressors. The overpressure is caused, first of all, by insufficient cooling of the air conditioner radiator (condenser). Most often this happens due to an air conditioner radiator elementary clogged with dirt or from behind a wall of fluff and dirt accumulated on the engine cooling radiator. Fans are not able to blow through dirty radiators, the pressure from this can rise to emergency.

The fans themselves may be faulty, in this case the air conditioner will work normally only when driving on the highway, when the air conditioner radiator is blown by the incoming air flow. It is worth stopping - the pressure creeps up inexorably.

When should you consider repairing a car air conditioner compressor?

The first alarming symptom to look out for is the deterioration in cooling efficiency when the machine is stopped. We got stuck in a traffic jam - the air conditioner cools worse. Let's go - it's cold. The reason for this strange operation of the car air conditioner is dirt on the radiators. If you do nothing, by the end of the summer you will most likely be in for an unpleasant surprise in the form of a "wedge" compressor.

For some time, the compressor has enough safety margin and it works "for wear and tear." Gradually on interior surfaces bullies appear, and then the situation develops quickly and uncontrollably. At one point, you hear a terrible rumble or grinding sound from under the hood, smoke comes from somewhere. This may cause the belt to break or come off. On many modern cars, where a constant rotation compressor is installed, you may not hear or understand anything. The safety plates on the pulley will snap off with a quiet click, and the air conditioner will simply stop cooling.

How To Repair A Correct Air Conditioning Compressor?

What to do if the air conditioner compressor is stuck? Simply changing it, alas, is not enough. The fact is that when worn out, before jamming, the compressor of your air conditioner strenuously "planed" chips from its body and contaminated the oil circulating in the system with it. Whereas before the oil was clear and clean, now it is dirty gray or black. The whole system is polluted from the inside. All pipes and hoses, evaporator, receiver-dryer, expansion valve, air conditioner radiator ...

If you just take and install a new compressor (some do it, even at dealer services), then it will not live long. Depending on the degree of soiling - from a few minutes or hours to several months.

Before installing a new compressor, the entire system must be flushed from the inside. Change to a new receiver-drier. In almost half of the cases, it is necessary to change the radiator of the air conditioner, because it is often not possible to flush it qualitatively. Flushing the system is not an easy task. Automatic washing stations are ineffective in the event of heavy contamination. We disassemble the entire system and wash all its parts by hand using special chemicals and strong solvents. This is the only way to guarantee that the sad story will not repeat itself in the near future.

After washing and assembly, the air conditioner is evacuated and filled with clean fresh oil and freon. After that, the compressor shaft is rotated several times by hand to insure against hydraulic oil hammer. Now the air conditioner can be turned on and, having checked the pressures and the operation of the system as a whole, enjoy the cold.

Flushing the system in time takes from one working day on most cars, up to 2-3, in the case of executive class cars with double air conditioning.

How to understand: will the kitten be fluffy?

What light alcohol can pregnant women drink: consequences of consumption

Why do legs swell in the ankles and ankles of feet in pregnant women: causes and methods of treatment

The wedding of Prince Harry and Meghan Markle: scandalous and secret details of the marriage (photo) Future marriage of Prince Harry year NTV

How to close white plums for the winter