Ecology of consumption. Estate: Is it profitable to produce biofuel at home in small quantities on a private plot? If you have several metal barrels and other iron junk, as well as a lot of free time and you don’t know how to manage it - yes.

Suppose there was no natural gas in your village and there never will be. And even if there is, it costs money. Although it is an order of magnitude cheaper than costly heating with electricity and liquid fuel. The nearest pellet production workshop is a couple of hundred kilometers away, and transport is expensive. It’s becoming more and more difficult to buy firewood every year, and it’s also troublesome to burn with it. Against this background, the idea of obtaining free biogas in your own backyard from weeds, chicken droppings, manure from your favorite pig or the contents of the owner’s outhouse looks very tempting. All you have to do is make a bioreactor! On TV they talk about how thrifty German farmers keep themselves warm with “manure” resources and now they don’t need any “Gazprom”. This is where the saying “takes the film off feces” is true. The Internet is replete with articles and videos on the topic “biogas from biomass” and “do-it-yourself biogas plant.” But we know little about the practical application of the technology: everyone is talking about the production of biogas at home, but few people have seen concrete examples in the village, as well as the legendary Yo-Mobile on the road. Let's try to figure out why this is so and what are the prospects for progressive bioenergy technologies in rural areas.

What is biogas + a little history

Biogas is formed as a result of sequential three-stage decomposition (hydrolysis, acid and methane formation) of biomass by various types of bacteria. The useful combustible component is methane, and hydrogen may also be present.

The process of bacterial decomposition that produces flammable methane

To a greater or lesser extent, flammable gases are formed during the decomposition of any remains of animal and plant origin.

The approximate composition of biogas, the specific proportions of the components depend on the raw materials and technology used

People have long been trying to use this type of natural fuel; medieval chronicles contain references to the fact that residents of the low-lying regions of what is now Germany a millennium ago received biogas from rotting vegetation by immersing leather furs in swamp slurry. In the dark Middle Ages and even the enlightened centuries, the most talented meteorists, who, thanks to a specially selected diet, were able to release and ignite abundant methane flatus in time, aroused the constant delight of the public at cheerful fair performances. Industrial biogas plants began to be built with varying degrees of success in the mid-19th century. In the USSR in the 80s of the last century, a state program for the development of the industry was adopted, but not implemented, although a dozen production facilities were launched. Abroad, the technology for producing biogas is being improved and is being promoted relatively actively; the total number of operating installations is in the tens of thousands. In developed countries (EEC, USA, Canada, Australia) these are highly automated large complexes, in developing countries (China, India) - semi-handicraft biogas plants for homes and small farms.

Percentage of the number of biogas plants in the European Union. It is clearly visible that the technology is actively developing only in Germany, the reason is solid government subsidies and tax incentives

What uses does biogas have?

It is clear that it is used as fuel, since it burns. Heating of industrial and residential buildings, electricity generation, cooking. However, not everything is as simple as they show in the videos scattered on YouTube. Biogas must burn stably in heat-generating installations. To do this, its gas environment parameters must be brought to fairly stringent standards. The methane content must be at least 65% (optimum 90-95%), hydrogen must be absent, water vapor has been removed, carbon dioxide has been removed, the remaining components are inert to high temperatures.

It is impossible to use biogas of “animal dung” origin, not freed from foul-smelling impurities, in residential buildings.

The normalized pressure is 12.5 bar; if the value is less than 8-10 bar, the automation in modern models of heating equipment and kitchen equipment stops the gas supply. It is very important that the characteristics of the gas entering the heat generator are stable. If the pressure jumps beyond the normal limits, the valve will work and you will have to turn it back on manually. It’s bad if you use outdated gas appliances that are not equipped with a gas control system. At best, the boiler burner may fail. The worst case scenario is that the gas will go out, but its supply will not stop. And this is already fraught with tragedy. Let us summarize what has been said: the characteristics of biogas must be brought to the required parameters, and safety precautions must be strictly observed. Simplified technological chain for biogas production. An important stage is separation and gas separation

What raw materials are used to produce biogas

Plant and animal raw materials

- Plant raw materials are excellent for the production of biogas: from fresh grass you can get the maximum fuel yield - up to 250 m3 per ton of raw material, methane content up to 70%. Somewhat less, up to 220 m3 can be obtained from corn silage, up to 180 m3 from beet tops. Any green plants are suitable, algae and hay are good (100 m3 per ton), but it makes sense to use valuable feed for fuel only if there is an obvious excess of it. The yield of methane from the pulp formed during the production of juices, oils and biodiesel is low, but the material is also free. The lack of plant raw materials is a long production cycle, 1.5-2 months. It is possible to obtain biogas from cellulose and other slowly decomposing plant waste, but the efficiency is extremely low, little methane is produced, and the production cycle is very long. In conclusion, we say that plant raw materials must be finely chopped.

- Raw materials of animal origin: traditional horns and hooves, waste from dairies, slaughterhouses and processing plants are also suitable and also in crushed form. The richest “ore” is animal fats; the yield of high-quality biogas with a methane concentration of up to 87% reaches 1500 m3 per ton. However, animal raw materials are in short supply and, as a rule, other uses are found for them.

Flammable gas from excrement

- Manure is cheap and is available in abundance on many farms, but the yield and quality of biogas is significantly lower than from other types. Cow pats and horse apples can be used in their pure form, fermentation begins immediately, biogas yield is 60 m2 per ton of raw material with a low methane content (up to 60%). The production cycle is short, 10-15 days. Pig manure and chicken droppings are toxic - so that beneficial bacteria can develop, it is mixed with plant waste and silage. A big problem is represented by detergent compositions and surfactants, which are used when cleaning livestock buildings. Together with antibiotics, which enter manure in large quantities, they inhibit the bacterial environment and inhibit the formation of methane. It is completely impossible not to use disinfectants, and agricultural enterprises that have invested in the production of gas from manure are forced to seek a compromise between hygiene and control over animal disease, on the one hand, and maintaining the productivity of bioreactors, on the other.

- Human excrement, completely free, is also suitable. But using ordinary sewage is unprofitable, the concentration of feces is too low and the concentration of disinfectants and surfactants is high. Technologists claim that they could be used only if “products” only flow from the toilet into the sewer system, provided that the bowl is flushed with only one liter of water (standard 4/8 l). And without detergents, of course.

Additional requirements for raw materials

A serious problem faced by farms that have installed modern equipment for producing biogas is that the raw material should not contain solid inclusions; a stone, nut, piece of wire or board that accidentally gets into the mass will clog the pipeline and disable an expensive fecal pump or mixer. It must be said that the given data on the maximum gas yield from the raw material correspond to ideal laboratory conditions. To get closer to these figures in real production, a number of conditions must be met: maintain the required temperature, periodically stir finely ground raw materials, add additives that activate fermentation, etc. In a makeshift installation, assembled according to the recommendations of articles on “producing biogas with your own hands,” it is barely possible to achieve 20% of the maximum level, while high-tech installations allow you to achieve values of 60-95%.

Quite objective data on the maximum biogas yield for various types of raw materials

Biogas plant design

Is it profitable to produce biogas?

We have already mentioned that in developed countries large industrial installations are built, while in developing countries they mainly build small ones for small farms. Let's explain why this is so:

Does it make sense to produce biofuels at home?

Is it profitable to produce biofuel at home in small quantities on a private plot? If you have several metal barrels and other iron junk, as well as a lot of free time and you don’t know how to manage it - yes. But the savings, alas, are meager. And investing in high-tech equipment with small volumes of raw materials and methane production does not make sense under any circumstances.

Another video from the domestic Kulibin

SUBSCRIBE to OUR YouTube channel Ekonet.ru, which allows you to watch online, download free videos from YouTube about human health and rejuvenation..

Please LIKE and share with your FRIENDS!

https://www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Without mixing the raw materials and activating the fermentation process, the methane yield will be no more than 20% of the possible one. This means that, in the best case, with 100 kg (hopper loading) of selected grass you can get 5 m3 of gas without taking into account compression. And it will be good if the methane content exceeds 50% and it is not a fact that it will burn in the heat generator. According to the author, raw materials are loaded daily, that is, his production cycle is one day. In fact, the required time is 60 days. The amount of biogas obtained by the inventor, contained in a 50-liter cylinder, which he managed to fill, in frosty weather for a heating boiler with a capacity of 15 kW (a residential building of about 150 m2) is enough for 2 minutes.

Those who are interested in the possibility of producing biogas are advised to carefully study the problem, especially from a financial point of view, and contact specialists with experience in such work with technical questions. Practical information obtained from those farms where bioenergy technologies have already been used for some time will be very valuable. published

With global energy prices rising, many rural residents are thinking about alternative methods to replace them. Some inventors have installed wind generators to provide electricity to their homes. But what about gas? After all, the lion's share of heating costs goes to pay for the gas consumed. People began to think about how to get gas themselves. For this purpose, a bioreactor was created that runs on agricultural waste. For a simple rural resident this is a very expensive installation. But some inventors claim that almost every owner of his own yard can make a bioreactor with his own hands.

The principle of operation of the bioreactor

The bioreactor operates on organic waste, so for its continuous operation it requires a constant presence of manure and other agricultural waste. The biogas produced by the installation is a biologically clean fuel, and its performance is similar to natural gas.

The job of a bioreactor is to process organic waste into gas and fertilizer. To do this, they are loaded into a bioreactor tank, where anaerobic bacteria process the biomass. To achieve proper fermentation, air must not enter the tank. Processing time depends on the volume of loaded waste. The released gas consists of 60% methane and 35% carbon dioxide. Other impurities account for 5%. The resulting gas is purified and is then ready for use in household appliances.

Note! The recycled material is removed from the tank and used as fertilizer in agriculture, and new waste is loaded in its place.

Design of a simple bioreactor

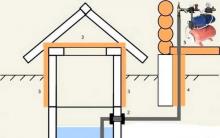

The simplest device that you can build with your own hands consists of a reactor for processing, a loading tank, an entrance hatch, a hatch for collecting waste waste, a water seal, and a gas exhaust pipe. For a better idea, there is a diagram of a bioreactor in a simple design.

The bioreactor is made of reinforced concrete or a metal container and installed in a selected area of the yard. The most important thing is that the installation is completely sealed. The size of the tank depends on the constant amount of waste available for processing, which is loaded at 2/3 of its size. For reference: from 1 ton of waste during processing, 100 m 3 of gas is obtained. Based on these calculations, it is not advisable to install a small container. After all, the amount of gas obtained depends on the amount of waste loaded for processing. One of the main devices on the tank is the waste collection hatch, which must be sealed.

Note! Spent waste must be constantly unloaded. To ensure that the hatch does not become deformed due to frequent opening, and there is no gas leakage, it is necessary to provide for its reliable design.

Particular attention should be paid to the construction of the reservoir. The walls and bottom must have a solid concrete base. During pouring, reinforcement must be performed. After the solution has hardened, the surface is treated with waterproofing agents. The top of the tank is made of refractory brick laid on a metal frame.

Biomass heating

The constant operation of the reactor depends on the activity of bacteria that cause fermentation of biomass. In a cold mass they are in dormant mode. Once it is heated to the required temperature, the bacteria will resume their work. The optimal fermentation temperature is +38 º C. In warm regions, the outside air temperature is sufficient for the reactor to operate without heating. And for cold regions you will have to install a heating system. A heating coil installed under the container can solve this problem. It is connected to the heating system and taps (or a thermostat) regulate the circulation of hot water to maintain the desired temperature.

Note! Also, as an option, you can install a coil with electric heating elements. They are connected to an automation system that regulates the heating temperature. To do this, you can use conventional automation from hot water boilers.

Mixer for bioreactor

During operation of the reactor, for better bacterial activity, the raw material must be stirred periodically. This role can be performed by a device in the form of a mixer. Its blades are located inside the container, and the shaft goes outside. The mixer is driven by an electric motor. At the point where the shaft exits there should be seals that maintain the tightness of the chamber.

Note! In some cases, the sealed electric motor is installed directly in the container.

Receiving gas

The gas produced during the reaction is released through a gas outlet pipe connected to the top cover. It is supplied through a pipe to a water seal, which will prevent air from entering the gas. Gas purified in a water seal is sent to a gas tank for further transportation to the consumer. To improve the system, you can install two gas tanks. In this system, condensate will settle in the first container, and gas under pressure is pumped into the second container. To control the gas pressure, it is necessary to install a pressure gauge and a release valve. Exceeding gas pressure will open the valve and bleed the excess out.

The technology is not new. It began to develop back in the 18th century, when Jan Helmont, a chemist, discovered that manure emits gases that are flammable.

His research was continued by Alessandro Volta and Humphrey Davy, who found methane in the gas mixture. At the end of the 19th century in England, biogas from manure was used in street lamps. In the mid-20th century, bacteria were discovered that produce methane and its precursors.

The fact is that three groups of microorganisms alternately work in manure, feeding on the waste products of previous bacteria. The first to start working are acetogenic bacteria, which dissolve carbohydrates, proteins and fats in the slurry.

After processing the nutrient supply by anaerobic microorganisms, methane, water and carbon dioxide are formed. Due to the presence of water, biogas at this stage is not able to burn - it needs purification, so it is passed through treatment facilities.

What is biomethane

The gas obtained as a result of the decomposition of manure biomass is an analogue of natural gas. It is almost 2 times lighter than air, so it always rises. This explains the artificial production technology: free space is left at the top so that the substance can be released and accumulate, from where it is then pumped out for use for one’s own needs.

Methane greatly influences the greenhouse effect - much more than carbon dioxide - 21 times. Therefore, manure processing technology is not only an economical, but also an environmentally friendly way to dispose of animal waste.

Biomethane is used for the following needs:

- cooking;

- in internal combustion engines of automobiles;

- for heating a private house.

Biogas produces a large amount of heat. 1 cubic meter is equivalent to burning 1.5 kg of coal.

How is biomethane produced?

It can be obtained not only from manure, but also algae, plant matter, fat and other animal waste, and residues from the processing of raw materials from fish shops. Depending on the quality of the source material and its energy capacity, the final yield of the gas mixture depends.

The minimum amount of gas obtained is 50 cubic meters per ton of cattle manure. Maximum - 1,300 cubic meters after processing animal fat. The methane content is up to 90%.

One type of biological gas is landfill gas. It is formed during the decomposition of garbage in suburban landfills. The West already has equipment that processes waste from the population and turns it into fuel. As a type of business, it has unlimited resources.

Its raw material base includes:

- food industry;

- livestock farming;

- poultry farming;

- fisheries and processing plants;

- dairies;

- production of alcoholic and low-alcohol drinks.

Any industry is forced to dispose of its waste - it is expensive and unprofitable. At home, with the help of a small homemade installation, you can solve several problems at once: free heating of the house, fertilizing the land with high-quality nutrients left over from manure processing, freeing up space and eliminating odors.

Biofuel production technology

All bacteria that take part in the formation of biogas are anaerobic, that is, they do not need oxygen to function. To do this, completely sealed fermentation containers are constructed, the outlet pipes of which also do not allow air from the outside to pass through.

After pouring the raw liquid into the tank and raising the temperature to the required value, the bacteria begin to work. Methane begins to be released, which rises from the surface of the slurry. It is sent to special pillows or tanks, after which it is filtered and ends up in gas cylinders.

The liquid waste from bacteria accumulates at the bottom, from where it is periodically pumped out and also sent for storage. After this, a new portion of manure is pumped into the tank.

Temperature regime of bacteria functioning

To process manure into biogas, it is necessary to create suitable conditions for bacteria to work. some of them are activated at temperatures above 30 degrees - mesophilic. At the same time, the process is slower and the first product can be obtained after 2 weeks.

Thermophilic bacteria work at temperatures from 50 to 70 degrees. The time required to obtain biogas from manure is reduced to 3 days. In this case, the waste is a fermented sludge that is used in the fields as fertilizer for agricultural crops. There are no pathogenic microorganisms, helminths and weeds in the sludge, as they die when exposed to high temperatures.

There is a special type of thermophilic bacteria that can survive in an environment heated to 90 degrees. They are added to raw materials to speed up the fermentation process.

A decrease in temperature leads to a decrease in the activity of thermophilic or mesophilic bacteria. In private households, mesophylls are more often used, since they do not require special heating of the liquid and gas production is cheaper. Subsequently, when the first batch of gas is received, it can be used to heat the reactor with thermophilic microorganisms.

Important! Methanogens do not tolerate sudden changes in temperature, so in winter they must be kept warm at all times.

How to prepare raw materials for pouring into the reactor

To produce biogas from manure, there is no need to specially introduce microorganisms into the liquid, because they are already found in animal excrement. You just need to maintain the temperature and add a new manure solution in time. It must be prepared correctly.

The humidity of the solution should be 90% (the consistency of liquid sour cream), Therefore, dry types of excrement are first filled with water - rabbit droppings, horse droppings, sheep droppings, goat droppings. Pig manure in its pure form does not need to be diluted, as it contains a lot of urine.

The next step is to break down the manure solids. The finer the fraction, the better the bacteria will process the mixture and the more gas will be released. For this purpose, the installations use a stirrer that is constantly running. It reduces the risk of a hard crust forming on the surface of the liquid.

Those types of manure that have the highest acidity are suitable for biogas production. They are also called cold - pork and cow. A decrease in acidity stops the activity of microorganisms, so it is necessary to monitor at the beginning how long it takes for them to completely process the volume of the tank. Then add the next dose.

Gas purification technology

When processing manure into biogas, the following is obtained:

- 70% methane;

- 30% carbon dioxide;

- 1% impurities of hydrogen sulfide and other volatile compounds.

In order for biogas to become suitable for use on the farm, it must be cleaned of impurities. To remove hydrogen sulfide, special filters are used. The fact is that volatile hydrogen sulfide compounds, dissolving in water, form acid. It contributes to the appearance of rust on the walls of pipes or tanks if they are made of metal.

- The resulting gas is compressed under a pressure of 9–11 atmospheres.

- It is fed into a reservoir of water, where impurities are dissolved in the liquid.

On an industrial scale, lime or activated carbon, as well as special filters, are used for cleaning.

How to reduce moisture content

There are several ways to get rid of water impurities in gas yourself. One of them is the principle of a moonshine still. The cold pipe directs the gas upward. The liquid condenses and flows down. To do this, the pipe is laid underground, where the temperature naturally decreases. As it rises, the temperature also rises, and the dried gas enters the storage facility.

The second option is a water seal. After exiting, the gas enters a container with water and is cleaned of impurities there. This method is called one-stage, when biogas is immediately cleaned from all volatile substances and moisture using water.

Water seal principle

Water seal principle

What installations are used to produce biogas?

If the installation is planned to be located near a farm, then the best option would be a collapsible structure that can be easily transported to another location. The main element of the installation is a bioreactor into which raw materials are poured and the fermentation process occurs. Large enterprises use tanks volume 50 cubic meters.

In private farms, underground reservoirs are built as a bioreactor. They are laid out of brick in a prepared hole and coated with cement. Concrete increases the safety of the structure and prevents air from entering. The volume depends on how much raw material is obtained from domestic animals per day.

Surface systems are also popular at home. If desired, the installation can be disassembled and moved to another location, unlike a stationary underground reactor. Plastic, metal or polyvinyl chloride barrels are used as tanks.

By type of control there are:

- automatic stations in which the filling and pumping out of waste raw materials is carried out without human intervention;

- mechanical, where the entire process is controlled manually.

Using a pump, you can facilitate the emptying of the tank into which the waste after fermentation falls. Some craftsmen use pumps to pump gas from cushions (for example, car inner tubes) into a treatment facility.

Scheme of a homemade installation for producing biogas from manure

Before constructing a biogas plant on your site, you need to become familiar with the potential hazards that could cause the reactor to explode. The main condition is the absence of oxygen.

Methane is an explosive gas and can ignite, but to do so it must be heated above 500 degrees. If biogas mixes with air, overpressure will arise, which will rupture the reactor. Concrete may crack and will not be suitable for further use.

Video: Biogas from bird droppings

To prevent the pressure from tearing off the lid, use a counterweight, a protective gasket between the lid and the tank. The container is not completely filled - there should be at least 10% volume for gas release. Better - 20%.

So, to make a bioreactor with all the accessories on your site, you need to:

- It is good to choose a place so that it is located away from housing (you never know).

- Calculate the estimated amount of manure that animals produce daily. How to count - read below.

- Decide where to lay the loading and unloading pipes, as well as a pipe for condensing moisture in the resulting gas.

- Decide on the location of the waste tank (fertilizer by default).

- Dig a pit based on calculations of the amount of raw materials.

- Select a container that will serve as a reservoir for manure and install it in the pit. If a concrete reactor is planned, then the bottom of the pit is filled with concrete, the walls are lined with bricks and plastered with concrete mortar. After this, you need to give it time to dry.

- The connections between the reactor and the pipes are also sealed at the stage of laying the tank.

- Equip a hatch for inspection of the reactor. A sealed gasket is placed between it.

If the climate is cold, then before concreting or installing a plastic tank, consider ways to heat it. These can be heating devices or tape used in “warm floor” technology.

At the end of the work, check the reactor for leaks.

Gas quantity calculation

From one ton of manure you can get approximately 100 cubic meters of gas. Question: How much litter do pets produce per day?

- chicken – 165 g per day;

- cow – 35 kg;

- goat – 1 kg;

- horse – 15 kg;

- sheep – 1 kg;

- pig – 5 kg.

Multiply these figures by the number of heads and you get the daily dose of excrement to be processed.

More gas comes from cows and pigs. If you add energetically powerful plants such as corn, beet tops, and millet to the mixture, the amount of biogas will increase. Marsh plants and algae have great potential.

The highest is for waste from meat processing plants. If there are such farms nearby, then we can cooperate and install one reactor for everyone. The payback period for a bioreactor is 1–2 years.

Biomass waste after gas production

After processing manure in a reactor, the by-product is biosludge. During anaerobic processing of waste, bacteria dissolve about 30% of organic matter. The rest is released unchanged.

The liquid substance is also a by-product of methane fermentation and is also used in agriculture for root feeding.

Carbon dioxide is a waste fraction that biogas producers strive to remove. But if you dissolve it in water, then this liquid can also be beneficial.

Full utilization of biogas plant products

In order to completely utilize the products obtained after processing manure, it is necessary to maintain a greenhouse. Firstly, organic fertilizer can be used for year-round cultivation of vegetables, the yield of which will be stable.

Secondly, carbon dioxide is used as fertilizing - root or foliar, and its output is about 30%. Plants absorb carbon dioxide from the air and at the same time grow better and gain green mass. If you consult with specialists in this field, they will help you install equipment that converts carbon dioxide from liquid form into a volatile substance.

Video: Biogas in 2 days

The fact is that to maintain a livestock farm, the energy resources obtained can be a lot, especially in the summer, when heating the barn or pigsty is not needed.

Therefore, it is recommended to engage in another profitable activity - an environmentally friendly greenhouse. Remaining products can be stored in refrigerated rooms - using the same energy. Refrigeration or any other equipment can run on electricity generated by a gas battery.

Use as fertilizer

In addition to producing gas, the bioreactor is useful because the waste is used as a valuable fertilizer, which retains almost all nitrogen and phosphates. When manure is added to the soil, 30–40% of nitrogen is irretrievably lost.

To reduce the loss of nitrogen substances, fresh excrement is added to the soil, but then the released methane damages the root system of plants. After processing the manure, the methane is used for its own needs, and all nutrients are preserved.

After fermentation, potassium and phosphorus pass into a chelated form, which is absorbed by plants by 90%. If you look at it in general, then 1 ton of fermented manure can replace 70 - 80 tons of ordinary animal excrement.

Anaerobic processing preserves all the nitrogen present in manure, converting it into ammonium form, which increases the yield of any crop by 20%.

This substance is not dangerous for the root system and can be applied 2 weeks before planting crops in open ground, so that the organic matter has time to be processed by soil aerobic microorganisms.

Before use, the biofertilizer is diluted with water. in a ratio of 1:60. Both dry and liquid fractions are suitable for this, which after fermentation also goes into the waste raw material tank.

Per hectare you need from 700 to 1,000 kg/l of undiluted fertilizer. Considering that from one cubic meter of reactor area up to 40 kg of fertilizers are obtained per day, in a month you can provide not only your own plot, but also your neighbor’s, by selling organic matter.

What nutrients can be obtained after manure processing?

The main value of fermented manure as a fertilizer is the presence of humic acids, which, like a shell, retain potassium and phosphorus ions. Oxidizing in air during long-term storage, microelements lose their beneficial qualities, but during anaerobic processing, on the contrary, they gain.

Humates have a positive effect on the physical and chemical composition of the soil. As a result of adding organic matter, even the heaviest soils become more permeable to moisture. In addition, organic matter provides food for soil bacteria. They further process the residues that have not been eaten by anaerobes and release humic acids. As a result of this process, plants receive nutrients that are completely absorbed.

In addition to the main ones - nitrogen, potassium and phosphorus - the biofertilizer contains microelements. But their quantity depends on the source material - plant or animal origin.

Sludge storage methods

It is best to store fermented manure dry. This makes it more convenient to pack and transport. The dry substance loses less useful properties and can be stored closed. Although such fertilizer does not deteriorate at all over the course of a year, it must then be sealed in a bag or container.

Liquid forms must be stored in closed containers with a tight-fitting lid to prevent nitrogen from escaping.

The main problem of biofertilizer producers is marketing in winter, when plants are dormant. On the world market, the cost of fertilizers of this quality fluctuates around $130 per ton. If you set up a line for packaging concentrates, you can pay for your reactor within two years.

Did you like the article? Share with your friends:

Hello, dear readers! I am the creator of the Fertilizers.NET project. I am glad to see each of you on its pages. I hope the information from the article was useful. Always open to communication - comments, suggestions, what else you want to see on the site, and even criticism, you can write to me on VKontakte, Instagram or Facebook (round icons below). Peace and happiness to everyone! 🙂

You may also be interested in reading:

The constant increase in the cost of traditional energy resources is pushing home craftsmen to create homemade equipment that allows them to produce biogas from waste with their own hands. With this approach to farming, it is possible not only to obtain cheap energy for heating the house and other needs, but also to establish the process of recycling organic waste and obtaining free fertilizers for subsequent application to the soil.

Excess produced biogas, like fertilizers, can be sold at market value to interested consumers, turning into money what is literally “lying under your feet.” Large farmers can afford to buy ready-made biogas production stations assembled in factories. The cost of such equipment is quite high. However, the return on its operation corresponds to the investment made. Less powerful installations that work on the same principle can be assembled on your own from available materials and parts.

What is biogas and how is it formed?

As a result of biomass processing, biogas is obtained

Biogas is classified as an environmentally friendly fuel. According to its characteristics, biogas is in many respects similar to natural gas produced on an industrial scale. The technology for producing biogas can be presented as follows:

- in a special container called a bioreactor, the process of processing biomass takes place with the participation of anaerobic bacteria under airless fermentation conditions for a certain period, the duration of which depends on the volume of loaded raw materials;

- as a result, a mixture of gases is released, consisting of 60% methane, 35% carbon dioxide, 5% other gaseous substances, among which there is a small amount of hydrogen sulfide;

- the resulting gas is constantly removed from the bioreactor and, after purification, is sent for its intended use;

- processed waste, which has become high-quality fertilizers, is periodically removed from the bioreactor and transported to the fields.

Visual diagram of the biofuel production process

In order to establish continuous production of biogas at home, you must own or have access to agricultural and livestock enterprises. It is economically profitable to produce biogas only if there is a source of free supply of manure and other organic waste from animal husbandry.

Gas heating remains the most reliable heating method. You can learn more about autonomous gasification in the following material:

Types of bioreactors

Installations for the production of biogas differ in the type of loading of raw materials, collection of the resulting gas, placement of the reactor relative to the surface of the earth, and material of manufacture. Concrete, brick and steel are the most suitable materials for constructing bioreactors.

Based on the type of loading, a distinction is made between bio-installations, into which a given portion of raw materials is loaded and goes through a processing cycle, and then completely unloaded. Gas production in these installations is unstable, but any type of raw material can be loaded into them. As a rule, they are vertical and take up little space.

A portion of organic waste is loaded into the system of the second type daily and an equal portion of ready-made fermented fertilizers is unloaded. The working mixture always remains in the reactor. The so-called continuous feeding plant consistently produces more biogas and is very popular among farmers. Basically, these reactors are located horizontally and are convenient if there is free space on the site.

The selected type of biogas collection determines the design features of the reactor.

- balloon systems consist of a rubber or plastic heat-resistant cylinder in which a reactor and a gas holder are combined. The advantages of this type of reactor are simplicity of design, loading and unloading of raw materials, ease of cleaning and transportation, and low cost. The disadvantages include a short service life, 2-5 years, and the possibility of damage as a result of external influences. Balloon reactors also include channel-type units, which are widely used in Europe for processing liquid waste and wastewater. This rubber top is effective at high ambient temperatures and there is no risk of damage to the cylinder. The fixed dome design has a completely enclosed reactor and a compensating tank for slurry discharge. Gas accumulates in the dome; when loading the next portion of raw materials, the processed mass is pushed into the compensation tank.

- Biosystems with a floating dome consist of a monolithic bioreactor located underground and a movable gas holder, which floats in a special water pocket or directly in the raw material and rises under the influence of gas pressure. The advantage of a floating dome is ease of operation and the ability to determine gas pressure by the height of the dome. This is an excellent solution for a large farm.

- When choosing an underground or above-surface installation location, you need to take into account the slope of the terrain, which makes it easier to load and unload raw materials, enhanced thermal insulation of underground structures, which protects the biomass from daily temperature fluctuations and makes the fermentation process more stable.

The design can be equipped with additional devices for heating and mixing raw materials.

Is it profitable to make a reactor and use biogas?

The construction of a biogas plant has the following goals:

- production of cheap energy;

- production of easily digestible fertilizers;

- savings on connecting to expensive sewerage;

- recycling of farm waste;

- possible profit from gas sales;

- reducing the intensity of unpleasant odors and improving the environmental situation in the area.

Profitability chart for biogas production and use

To assess the benefits of building a bioreactor, a prudent owner should consider the following aspects:

- the cost of a bio-plant is a long-term investment;

- homemade biogas equipment and installation of a reactor without the involvement of third-party specialists will cost much less, but its efficiency is also lower than that of an expensive factory one;

- To maintain stable gas pressure, the farmer must have access to livestock waste in sufficient quantity and for a long period of time. In the case of high prices for electricity and natural gas or the lack of possibility of gasification, the use of the installation becomes not only profitable, but also necessary;

- for large farms with their own raw material base, a profitable solution would be to include a bioreactor in the system of greenhouses and cattle farms;

- For small farms, efficiency can be increased by installing several small reactors and loading raw materials at different time intervals. This will avoid interruptions in gas supply due to a lack of feedstock.

How to build a bioreactor on your own

The decision to build has been made, now you need to design the installation and calculate the necessary materials, tools and equipment.

Important! Resistance to aggressive acidic and alkaline environments is the main requirement for bioreactor material.

If a metal tank is available, it can be used provided it has a protective coating against corrosion. When choosing a metal container, pay attention to the presence of welds and their strength.

A durable and convenient option is a polymer container. This material does not rot or rust. A barrel with thick hard walls or reinforced will withstand the load perfectly.

The cheapest way is to lay out a container made of brick or stone or concrete blocks. To increase strength, the walls are reinforced and covered inside and outside with a multi-layer waterproofing and gas-tight coating. The plaster must contain additives that provide the specified properties. The best shape to withstand all pressure loads is oval or cylindrical.

At the base of this container there is a hole through which waste raw materials will be removed. This hole must be tightly closed, because the system only works effectively in sealed conditions.

Calculation of necessary tools and materials

To lay out a brick container and install the entire system, you will need the following tools and materials:

- container for mixing cement mortar or concrete mixer;

- drill with mixer attachment;

- crushed stone and sand for constructing a drainage cushion;

- shovel, tape measure, trowel, spatula;

- brick, cement, water, fine sand, reinforcement, plasticizer and other necessary additives;

- welding machine and fasteners for installation of metal pipes and components;

- a water filter and a container with metal shavings for gas purification;

- tire cylinders or standard propane cylinders for gas storage.

The size of the concrete tank is determined from the amount of organic waste that appears daily in a private farmstead or farm. Full operation of the bioreactor is possible if it is filled to two-thirds of the available volume.

Let us determine the volume of the reactor for a small private farm: if there are 5 cows, 10 pigs and 40 chickens, then per day of their life activity a litter of 5 x 55 kg + 10 x 4.5 kg + 40 x 0.17 kg = 275 kg + is formed 45 kg + 6.8 kg = 326.8 kg. To bring chicken manure to the required humidity of 85%, you need to add 5 liters of water. Total weight = 331.8 kg. For processing in 20 days you need: 331.8 kg x 20 = 6636 kg - about 7 cubic meters only for the substrate. This is two thirds of the required volume. To get the result, you need 7x1.5 = 10.5 cubic meters. The resulting value is the required volume of the bioreactor.

Remember that it will not be possible to produce large amounts of biogas in small containers. The yield directly depends on the mass of organic waste processed in the reactor. So, to get 100 cubic meters of biogas, you need to process a ton of organic waste.

Preparing a site for a bioreactor

The organic mixture loaded into the reactor should not contain antiseptics, detergents, chemicals that are harmful to the life of bacteria and slow down the production of biogas.

Important! Biogas is flammable and explosive.

For proper operation of the bioreactor, the same rules must be followed as for any gas installations. If the equipment is sealed and biogas is discharged into the gas tank in a timely manner, then there will be no problems.

If the gas pressure exceeds the norm or poisons if the seal is broken, there is a risk of explosion, so it is recommended to install temperature and pressure sensors in the reactor. Inhaling biogas is also dangerous to human health.

How to ensure biomass activity

You can speed up the fermentation process of biomass by heating it. As a rule, this problem does not arise in the southern regions. The ambient temperature is sufficient for the natural activation of fermentation processes. In regions with harsh climatic conditions in winter, it is generally impossible to operate a biogas production plant without heating. After all, the fermentation process starts at a temperature exceeding 38 degrees Celsius.

There are several ways to organize heating of a biomass tank:

- connect the coil located under the reactor to the heating system;

- install electric heating elements at the base of the container;

- provide direct heating of the tank through the use of electric heating devices.

Bacteria that influence methane production are dormant in the raw materials themselves. Their activity increases at a certain temperature level. The installation of an automated heating system will ensure the normal course of the process. The automation will turn on the heating equipment when the next cold batch enters the bioreactor, and then turn it off when the biomass warms up to the specified temperature level.

Similar temperature control systems are installed in hot water boilers, so they can be purchased in stores specializing in the sale of gas equipment.

The diagram shows the entire cycle, starting from the loading of solid and liquid raw materials, and ending with the removal of biogas to consumers

It is important to note that you can activate biogas production at home by mixing biomass in a reactor. For this purpose, a device is made that is structurally similar to a household mixer. The device can be set in motion by a shaft that is output through a hole located in the lid or walls of the tank.

What special permits are required for the installation and use of biogas

In order to build and operate a bioreactor, as well as use the resulting gas, you need to take care of obtaining the necessary permits at the design stage. Coordination must be completed with the gas service, firefighters and Rostechnadzor. In general, the rules for installation and operation are similar to the rules for using conventional gas equipment. Construction must be carried out strictly in accordance with SNIPs, all pipelines must be yellow and have appropriate markings. Ready-made systems manufactured at the factory cost several times more, but have all the accompanying documents and meet all technical requirements. Manufacturers provide a warranty on equipment and provide maintenance and repair of their products.

A home-made installation for producing biogas can allow you to save on energy costs, which occupy a large share in determining the cost of agricultural products. Reducing production costs will affect the increase in profitability of a farm or private farmstead. Now that you know how to obtain biogas from existing waste, all that remains is to put the idea into practice. Many farmers have long learned to make money from manure.

The constant increase in the cost of traditional energy resources is pushing home craftsmen to create homemade equipment that allows them to produce biogas from waste with their own hands. With this approach to farming, it is possible not only to obtain cheap energy for heating the house and other needs, but also to establish the process of recycling organic waste and obtaining free fertilizers for subsequent application to the soil.

Excess produced biogas, like fertilizers, can be sold at market value to interested consumers, turning into money what is literally “lying under your feet.” Large farmers can afford to buy ready-made biogas production stations assembled in factories. The cost of such equipment is quite high. However, the return on its operation corresponds to the investment made. Less powerful installations that work on the same principle can be assembled on your own from available materials and parts.

This video shows a small installation that allows you to produce biogas from manure. Livestock waste products (100 kg/day) are loaded into the bioreactor.

SUBSCRIBE to OUR YouTube channel, which allows you to watch online, download free videos from YouTube about human health and rejuvenation. Love for others and for yourself, as a feeling of high vibrations, is an important factor in healing -.

Please LIKE and share with your FRIENDS!

Subscribe -https://www.facebook.com//

What is biogas and how is it formed?

Biogas is classified as an environmentally friendly fuel. According to its characteristics, biogas is in many respects similar to natural gas produced on an industrial scale. The technology for producing biogas can be presented as follows:

- in a special container called a bioreactor, the process of processing biomass takes place with the participation of anaerobic bacteria under airless fermentation conditions for a certain period, the duration of which depends on the volume of loaded raw materials;

- as a result, a mixture of gases is released, consisting of 60% methane, 35% carbon dioxide, 5% other gaseous substances, among which there is a small amount of hydrogen sulfide; the resulting gas is constantly removed from the bioreactor and, after purification, is sent for its intended use;

- processed waste, which has become high-quality fertilizers, is periodically removed from the bioreactor and transported to the fields.

How to build a bioreactor on your own?

To begin with, I would like to indicate what kind of structure can be built:

Scheme of the simplest biogas plant, assembled on your own. Its design does not provide for heating and a mixing device. Legend: 1 - reactor (digester) for processing manure; 2 - hopper for loading raw materials; 3 - entrance hatch; 4 - water seal; 5 - pipe for unloading mining; 6 - pipe for biogas removal

To obtain free biofuel on the site, you must select a place to build a reinforced concrete tank that will serve as a bioreactor. At the base of this container there is a hole through which waste raw materials will be removed. This hole must be tightly closed, because the system only works effectively in sealed conditions.

The size of the concrete tank is determined from the amount of organic waste that appears daily in a private farmstead or farm. Full operation of the bioreactor is possible if it is filled to two-thirds of the available volume.

Organic waste is fed into a sealed bioreactor container buried in the ground, which contributes to the release of biogas during the fermentation process.

If there is a small amount of waste, the reinforced concrete tank can be replaced with a metal container, for example, a barrel. P

When choosing a metal container, pay attention to the presence of welds and their strength. Remember that it will not be possible to produce large amounts of biogas in small containers. The yield directly depends on the mass of organic waste processed in the reactor. So, to get 100 cubic meters of biogas, you need to process a ton of organic waste.

How to ensure biomass activity?

You can speed up the fermentation process of biomass by heating it. As a rule, this problem does not arise in the southern regions. The ambient temperature is sufficient for the natural activation of fermentation processes. In regions with harsh climatic conditions in winter, it is generally impossible to operate a biogas production plant without heating. After all, the fermentation process starts at a temperature exceeding 38 degrees Celsius.

There are several ways to organize heating of a biomass tank:

- connect the coil located under the reactor to the heating system;

- install electric heating elements at the base of the container;

- provide direct heating of the tank through the use of electric heating devices.

Similar temperature control systems are installed in hot water boilers, so they can be purchased in stores specializing in the sale of gas equipment.

Scheme of organizing biogas production at home. The diagram shows the entire cycle, starting from the loading of solid and liquid raw materials, and ending with the removal of biogas to consumers

It is important to note that you can activate biogas production at home by mixing biomass in a reactor. For this purpose, a device is made that is structurally similar to a household mixer. The device can be set in motion by a shaft that is output through a hole located in the lid or walls of the tank.

Correct gas removal from the bioreactor

The gas produced during the fermentation of organic matter is removed through a special hole provided in the design of the upper part of the lid, which tightly closes the tank. To eliminate the possibility of biogas mixing with air, it is necessary to ensure its removal through a water seal (hydraulic seal).

You can control the pressure of the gas mixture inside the bioreactor using the lid, which should rise when there is excess gas, that is, play the role of a release valve. You can use a regular weight as a counterweight. If the pressure is normal, then the exhaust gas will flow through the outlet pipe into the gas tank, being cleaned in water along the way.

A home-made installation for producing biogas can allow you to save on energy costs, which occupy a large share in determining the cost of agricultural products. Reducing production costs will affect the increase in profitability of a farm or private farmstead. Now that you know how to obtain biogas from existing waste, all that remains is to put the idea into practice. Many farmers have long learned to make money from manure.

P.S. And remember, just by changing your consumption, we are changing the world together! ©

Design of a corridor in an apartment, color scheme, choice of wall and floor coverings. Hallway with blue walls

Kitchen corners and sofas Kitchen sofa room with sleeping place

Desk for two children

TV stand in a modern style: photo, equipment, selection rules Stylish TV stands

Long TV stands are an excellent solution for the living room