One of the most demanded metals in industries is copper. It is most widely used in electrical and electronics. Most often it is used in the manufacture of windings for electric motors and transformers. The main reason for using this particular material is that copper has the lowest electrical resistivity currently available. Until it appears new material with a lower value of this indicator, it is safe to say that there will be no replacement for copper.

General characteristics of copper

Speaking about copper, it must be said that even at the dawn of the electrical era, it began to be used in the production of electrical engineering. It has been used largely for the reason unique properties possessed by this alloy. By itself, it represents a material that differs high properties in terms of plasticity and having good malleability.

Along with the thermal conductivity of copper, one of its most important advantages is its high electrical conductivity. It is due to this property that copper and widely used in power plants in which it acts as a universal conductor. The most valuable material is electrolytic copper, which has a high degree of purity - 99.95%. Thanks to this material, it becomes possible to produce cables.

Advantages of using electrolytic copper

The use of electrolytic copper allows you to achieve the following:

The use of electrolytic copper allows you to achieve the following:

- Provide high electrical conductivity;

- Achieve excellent laying ability;

- Provide a high degree of plasticity.

Applications

Cable products made from electrolytic copper are widely used in various industries. It is most often used in the following areas:

Cable products made from electrolytic copper are widely used in various industries. It is most often used in the following areas:

- electrical industry;

- electrical appliances;

- automotive industry;

- production of computer equipment.

What is the resistivity?

To understand what copper is and its characteristics, it is necessary to understand the main parameter of this metal - resistivity. It should be known and used when performing calculations.

To understand what copper is and its characteristics, it is necessary to understand the main parameter of this metal - resistivity. It should be known and used when performing calculations.

Under resistivity it is customary to understand a physical quantity, which is characterized as the ability of a metal to conduct electricity.

It is also necessary to know this value in order to correctly calculate the electrical resistance conductor. When calculating, they also focus on its geometric dimensions. When making calculations, use the following formula:

This formula is well known to many. Using it, you can easily calculate the resistance copper cable, focusing only on the characteristics of the electrical network. It allows you to calculate the power that is inefficiently spent on heating the cable core. Besides, a similar formula allows you to perform resistance calculations any cable. It does not matter what material was used to make the cable - copper, aluminum or some other alloy.

A parameter such as electrical resistivity is measured in Ohm*mm2/m. This indicator for copper wiring laid in the apartment is 0.0175 Ohm * mm2 / m. If you try to look for an alternative to copper - a material that could be used instead, then silver is the only suitable, which one resistivity is 0.016 Ohm*mm2/m. However, when choosing a material, it is necessary to pay attention not only to resistivity, but also to reverse conductivity. This value is measured in Siemens (cm).

A parameter such as electrical resistivity is measured in Ohm*mm2/m. This indicator for copper wiring laid in the apartment is 0.0175 Ohm * mm2 / m. If you try to look for an alternative to copper - a material that could be used instead, then silver is the only suitable, which one resistivity is 0.016 Ohm*mm2/m. However, when choosing a material, it is necessary to pay attention not only to resistivity, but also to reverse conductivity. This value is measured in Siemens (cm).

Siemens \u003d 1 / Ohm.

For copper of any weight, this composition parameter is 58,100,000 S/m. As for silver, its reverse conductivity is 62,500,000 S/m.

In our world high technology when every house has a large number of electrical devices and installations, the value of such a material as copper is simply invaluable. This material used to make wiring without which no room is complete. If copper did not exist, then man would have to use wires from other available materials, for example, aluminum. However, in this case, one would have to face one problem. The thing is that this material has a much lower conductivity than copper conductors.

Resistivity

The use of materials with low electrical and thermal conductivity of any weight leads to large losses of electricity. BUT it affects power loss on the equipment being used. Most specialists refer to copper as the main material for the manufacture of insulated wires. It is the main material from which individual elements of equipment powered by electric current are made.

The use of materials with low electrical and thermal conductivity of any weight leads to large losses of electricity. BUT it affects power loss on the equipment being used. Most specialists refer to copper as the main material for the manufacture of insulated wires. It is the main material from which individual elements of equipment powered by electric current are made.

- Boards installed in computers are equipped with etched copper tracks.

- Copper is also used to make a wide variety of elements used in electronic devices.

- In transformers and electric motors, it is represented by a winding made from this material.

There is no doubt that the expansion of the scope of this material will occur with further development technical progress. Although, in addition to copper, there are other materials, but still the designer uses copper to create equipment and various installations. main reason demand for this material is in good electrical and thermal conductivity of this metal, which it provides at room temperature.

Temperature coefficient of resistance

All metals with any thermal conductivity have the property of decreasing conductivity with increasing temperature. As the temperature decreases, the conductivity increases. Specialists call the property of decreasing resistance with decreasing temperature especially interesting. After all, in this case, when the temperature in the room drops to a certain value, the conductor may lose electrical resistance and it will pass into the class of superconductors.

All metals with any thermal conductivity have the property of decreasing conductivity with increasing temperature. As the temperature decreases, the conductivity increases. Specialists call the property of decreasing resistance with decreasing temperature especially interesting. After all, in this case, when the temperature in the room drops to a certain value, the conductor may lose electrical resistance and it will pass into the class of superconductors.

In order to determine the resistance index of a particular conductor of a certain weight at room temperature, there is a critical resistance coefficient. It is a value that shows the change in resistance of a circuit section with a change in temperature by one Kelvin. To perform the calculation of the electrical resistance of a copper conductor in a certain time interval, use the following formula:

ΔR = α*R*ΔT, where α - temperature coefficient electrical resistance.

Conclusion

Copper is a material that is widely used in electronics. It is used not only in windings and circuits, but also as a metal for the manufacture of cable products. In order for machinery and equipment to work effectively, it is necessary correctly calculate the resistivity of the wiring laid in the apartment. There is a certain formula for this. Knowing it, you can make a calculation that allows you to find out the optimal size of the cable cross section. In this case, the power loss of the equipment can be avoided and the efficiency of its use can be ensured.

Electrical resistance, expressed in ohms, differs from the concept of "resistivity". To understand what resistivity is, it is necessary to relate it to the physical properties of the material.

On Conductivity and Resistivity

The flow of electrons does not move freely through the material. At a constant temperature elementary particles swing around the state of rest. In addition, electrons in the conduction band interfere with each other by mutual repulsion due to a similar charge. Thus, resistance arises.

Conductivity is an intrinsic characteristic of materials and quantifies the ease with which charges can move when a substance is exposed to electric field. Resistivity is the reciprocal of the degree of difficulty that electrons have in moving through a material, giving an indication of how good or bad a conductor is.

Important! A high electrical resistivity value indicates that the material is poorly conductive, while a low value indicates a good conductive material.

Specific conductivity is denoted by the letter σ and is calculated by the formula:

Resistivity ρ, as an inverse indicator, can be found as follows:

In this expression, E is the strength of the generated electric field (V / m), and J is the density of the electric current (A / m²). Then the unit of measurement ρ will be:

V/m x m²/A = ohm m.

For specific conductivity σ, the unit in which it is measured is Sm/m or Siemens per meter.

Material types

According to the resistivity of materials, they can be classified into several types:

- Conductors. These include all metals, alloys, solutions dissociated into ions, as well as thermally excited gases, including plasma. Of non-metals, graphite can be cited as an example;

- Semiconductors, which are in fact non-conductive materials, the crystal lattices of which are purposefully doped with the inclusion of foreign atoms with a greater or lesser number of bound electrons. As a result, quasi-free excess electrons or holes are formed in the lattice structure, which contribute to the current conductivity;

- Dielectrics or insulators, dissociated - all materials that in normal conditions do not have free electrons.

For the transport of electrical energy or in domestic and industrial electrical installations, a frequently used material is copper in the form of solid or multi-core cables. An alternative metal is aluminum, although the resistivity of copper is 60% of that of aluminum. But it is much lighter than copper, which predetermined its use in power lines of networks. high voltage. Gold as a conductor is used in electrical circuits for special purposes.

Interesting. The electrical conductivity of pure copper was adopted by the International Electrotechnical Commission in 1913 as the standard for this value. By definition, the conductivity of copper, measured at 20°, is 0.58108 S/m. This value is called 100% LACS, and the conductivity of the remaining materials is expressed as a certain percentage of LACS.

Most metals have a conductivity value less than 100% LACS. However, there are exceptions, such as silver or special copper with very high conductivity, designated C-103 and C-110, respectively.

Dielectrics do not conduct electricity and are used as insulators. Examples of insulators:

- glass,

- ceramics,

- plastic,

- rubber,

- mica,

- wax,

- paper,

- dry wood,

- porcelain,

- some fats for industrial and electrical use and Bakelite.

Between the three groups, the transitions are fluid. It is known for sure: there are no absolutely non-conductive media and materials. For example, air is an insulator at room temperature, but under conditions of a strong low frequency signal, it can become a conductor.

Determination of conductivity

If we compare electrical resistivity various substances, standardized measurement conditions are required:

- In the case of liquids, poor conductors and insulators, use cubic samples with an edge length of 10 mm;

- The resistivity values of soils and geological formations are determined on cubes with a length of each rib 1 m;

- The conductivity of a solution depends on the concentration of its ions. A concentrated solution is less dissociated and has fewer charge carriers, which reduces the conductivity. As the dilution increases, the number of ion pairs increases. The concentration of solutions is set to 10%;

- To determine the resistivity of metal conductors, wires of a meter length and a cross section of 1 mm² are used.

If a material, such as a metal, can provide free electrons, then when a potential difference is applied, an electric current will flow through the wire. As the voltage increases, more electrons move through matter into a time unit. If all additional parameters (temperature, cross-sectional area, wire length and material) are unchanged, then the ratio of current to applied voltage is also constant and is called conductivity:

Accordingly, the electrical resistance will be:

The result is in ohms.

In turn, the conductor can be of different lengths, cross-sectional sizes and be made of various materials on which the value of R depends. Mathematically, this relationship looks like this:

The material factor takes into account the coefficient ρ.

From this we can derive the formula for resistivity:

If the values of S and l correspond to the given conditions for the comparative calculation of resistivity, i.e. 1 mm² and 1 m, then ρ = R. When the dimensions of the conductor change, the number of ohms also changes.

In practice, it is often necessary to calculate the resistance of various wires. This can be done using formulas or according to the data given in Table. one.

The influence of the conductor material is taken into account using the resistivity, denoted by the Greek letter? and representing a length of 1 m and a cross-sectional area of 1 mm2. The smallest resistivity? \u003d 0.016 Ohm mm2 / m has silver. Let us give the average value of the specific resistance of some conductors:

Silver - 0.016 , Lead - 0.21, Copper - 0.017, Nickel - 0.42, Aluminum - 0.026, Manganine - 0.42, Tungsten - 0.055, Constantan - 0.5, Zinc - 0.06, Mercury - 0.96, Brass - 0.07, Nichrome - 1.05, Steel - 0.1, Fekhral - 1.2, Phosphorous bronze - 0.11, Khromal - 1.45.With different amounts of impurities and with different ratios of the components that make up the rheostatic alloys, the resistivity may change somewhat.

The resistance is calculated by the formula:

where R - resistance, Ohm; resistivity, (Ohm mm2)/m; l - wire length, m; s is the cross-sectional area of the wire, mm2.

If the wire diameter d is known, then its cross-sectional area is:

![]()

It is best to measure the diameter of the wire with a micrometer, but if it is not available, then wrap tightly 10 or 20 turns of wire on a pencil and measure the length of the winding with a ruler. Dividing the length of the winding by the number of turns, we find the diameter of the wire.

To determine the length of a wire of known diameter from a given material, necessary to obtain the desired resistance, use the formula

Table 1.

Note. 1. Data for wires not listed in the table must be taken as some average values. For example, for a nickeline wire with a diameter of 0.18 mm, we can approximately assume that the cross-sectional area is 0.025 mm2, the resistance of one meter is 18 ohms, and the allowable current is 0.075 A.

2. For a different current density value, the data of the last column must be changed accordingly; for example, at a current density of 6 A/mm2, they should be doubled.

Example 1. Find the resistance of 30 m of copper wire with a diameter of 0.1 mm.

Solution. We determine according to the table. 1 resistance of 1 m of copper wire, it is equal to 2.2 ohms. Therefore, the resistance of 30 m of wire will be R = 30 2.2 = 66 ohms.

Calculation by formulas gives the following results: wire cross-sectional area: s= 0.78 0.12 = 0.0078 mm2. Since the resistivity of copper is 0.017 (Ohm mm2) / m, we get R \u003d 0.017 30 / 0.0078 \u003d 65.50m.

Example 2. How much nickel wire with a diameter of 0.5 mm is needed to make a rheostat with a resistance of 40 ohms?

Solution. According to the table 1 we determine the resistance of 1 m of this wire: R = 2.12 Ohm: Therefore, in order to make a rheostat with a resistance of 40 Ohm, you need a wire whose length is l = 40 / 2.12 = 18.9 m.

Let's do the same calculation using the formulas. We find the cross-sectional area of the wire s \u003d 0.78 0.52 \u003d 0.195 mm2. And the length of the wire will be l \u003d 0.195 40 / 0.42 \u003d 18.6 m.

- Constantan (58.8 Cu, 40 Ni, 1.2 Mn)

- Manganin (85 Cu, 12 Mn, 3 Ni)

- Nickel silver (65 Cu, 20 Zn, 15 Ni)

- Nickelin (54 Cu, 20 Zn, 26 Ni)

- Nichrome (67.5 Ni, 15 Cr, 16 Fe, 1.5 Mn)

- Rheonate (84Cu, 12Mn, 4 Zn)

- Fechral (80 Fe, 14 Cr, 6 Al)

Resistivity of nichrome

Each body through which an electric current is passed automatically provides a certain resistance to it. The property of a conductor to resist electric current is called electrical resistance.

Consider the electronic theory of this phenomenon. When moving along a conductor, free electrons constantly meet other electrons and atoms on their way. Interacting with them, a free electron loses part of its charge. Thus, the electrons encounter resistance from the conductor material. Each body has its own atomic structure, which provides different resistance to electric current. The unit of resistance is the ohm. The resistance of materials is indicated - R or r.

The lower the resistance of the conductor, the easier it is for the electric current to pass through this body. And vice versa: the higher the resistance, the worse the body conducts electric current.

The resistance of each individual conductor depends on the properties of the material from which it is made. For exact characteristics the electrical resistance of one or another material, the concept was introduced - specific resistance (nichrome, aluminum, etc.). The specific resistance is considered to be the resistance of a conductor up to 1 m long, the cross section of which is 1 sq. mm. This indicator is denoted by the letter p. Each material used in the manufacture of a conductor has its own resistivity. For example, consider the resistivity of nichrome and fechral (more than 3 mm):

- Х15Н60 — 1.13 Ohm*mm/m

- Kh23Yu5T - 1.39 Ohm * mm / m

- Х20Н80 — 1.12 Ohm*mm/m

- XN70YU - 1.30 Ohm*mm/m

- XN20YUS - 1.02 Ohm*mm/m

The specific resistance of nichrome, fechral indicates the main scope of their application: the manufacture of thermal devices, household appliances and electric heating elements of industrial furnaces.

Since nichrome and fechral are mainly used in the production of heating elements, the most common products are nichrome thread, tape, Kh15N60 and Kh20N80 strip, as well as Kh23Yu5T fechral wire.

Content:

In electrical engineering, one of the main elements of electrical circuits are wires. Their task is to pass electric current with minimal losses. Experimentally, it has long been determined that in order to minimize power losses, wires are best made of silver. It is this metal that provides the properties of a conductor with a minimum resistance in ohms. But since this noble metal is expensive, its use in industry is very limited.

And the main metals for wires are aluminum and copper. Unfortunately, the resistance of iron as a conductor of electricity is too great to make a good wire out of it. Despite the lower cost, it is used only as a carrier base for power transmission line wires.

Such different resistances

Resistance is measured in ohms. But for wires, this value is very small. If you try to measure with a tester in resistance measurement mode, it will be difficult to get the correct result. Moreover, no matter what wire we take, the result on the instrument panel will differ little. But this does not mean that in fact the electrical resistance of these wires will equally affect the loss of electricity. To verify this, it is necessary to analyze the formula by which the resistance is calculated:

This formula uses quantities such as:

It turns out that resistance determines resistance. There is a resistance calculated by a formula using another resistance. This specific electrical resistance ρ (Greek letter ro) just determines the advantage of a particular metal as an electrical conductor:

Therefore, if copper, iron, silver or any other material is used to make identical wires or conductors of a special design, it is the material that will play the main role in its electrical properties.

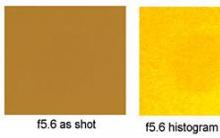

![]()

But in fact, the situation with resistance is more complicated than just calculations using the formulas above. These formulas do not take into account the temperature and the shape of the conductor diameter. And with increasing temperature, the resistivity of copper, like any other metal, becomes greater. Very good example it could be an incandescent light bulb. You can measure the resistance of its spiral with a tester. Then, by measuring the current in the circuit with this lamp, according to Ohm's law, calculate its resistance in the glow state. The result will be much greater than when measuring the resistance with a tester.

Similarly, copper will not give the expected efficiency at a high current, if we neglect the shape of the cross section of the conductor. The skin effect, which manifests itself in direct proportion to the increase in current, makes conductors with a round cross section inefficient, even if silver or copper is used. For this reason, the resistance of a round copper wire at a high current may be higher than that of a flat aluminum wire.

Moreover, even if their cross-sectional areas are the same. At alternating current the skin effect also manifests itself, increasing as the current frequency increases. The skin effect means that the current tends to flow closer to the surface of the conductor. For this reason, in some cases it is more advantageous to use silver coating of wires. Even a slight decrease in the surface resistivity of the silver-plated copper conductor significantly reduces signal loss.

Generalization of the concept of resistivity

As in any other case that is related to the display of dimensions, the resistivity is expressed in terms of different systems units. The SI (International System of Units) uses ohm m, but it is also acceptable to use ohm*kV mm/m (this is a non-systemic unit of resistivity). But in a real conductor, the value of resistivity is not constant. Since all materials are characterized by a certain purity, which can vary from point to point, it was necessary to create an appropriate representation of the resistance in a real material. Ohm's law in differential form became such a manifestation:

![]()

This law, most likely, will not be applied to household calculations. But in the course of designing various electronic components, for example, resistors, crystalline elements, it is certainly used. Since it allows you to perform calculations based on a given point, for which there is a current density and electric field strength. And the corresponding resistivity. The formula is applied to inhomogeneous isotropic as well as anisotropic substances (crystals, gas discharge, etc.).

How is pure copper obtained?

In order to minimize losses in wires and cable cores made of copper, it must be especially pure. This is achieved by special technological processes:

- on the basis of electron-beam, as well as zone melting;

- repeated electrolysis cleaning.

The influence of the middle name on the name Yuri

Name Ilya - meaning and contraindications

Baby keeps crying

What does the name Aidar mean, the mystery of the name

Name Ilya - meaning and contraindications