Structural steel has markings:

St - ordinary steel;

Steel - high-quality steel;

And - high-quality steel.

For many structural tasks, ordinary steel with marking is used St3. We offer customers steel produced by Petrostal, Severstal, A. K. Serov Plant (Sverdlovsk Region). We guarantee the constant quality of rolled metal products and compliance with GOST. It is possible to prepare rolled products for finishing. You can buy a circle from us St3 and metal-roll of square section, strips of rolled products.

Steel St3 has no weldability limitations, is not prone to temper brittleness and has no flock sensitivity. This steel can be both welded without preheating and pre-heat treatment, and stamped in a cold and hot state, as well as subjected to drawing. Due to these qualities, structural steel St3 always in demand among builders and metal processors. It is indispensable for non-welded and welded structures, for parts operating at a positive temperature. Frames, frames, casings and shields are mainly made from steel of this grade. Often, casings, covers and troughs of machine tools, and other lightly loaded parts that work without friction are made from it. The thickness of rolled products for these tasks most often does not exceed 10 millimeters.

Steel modification St3Gsp is used for the manufacture of I-beams, angles and channels. steel modification St3kp used in the manufacture of car shaped profiles, lightly loaded structural elements, both welded and non-welded. Steel St3ps will find application in the creation of load-bearing elements of welded structures. They also make reinforcement of the At400C class from it. To do this, hot-rolled steel St3 is subjected to power calibration. Cold-rolled drawn steel is useful for mounting fittings, clamps, frames. The metal of this brand is also used to create grids, sheets, wire, water and gas pipes. Electric welded rectangular pipes made of this steel, which are also called profile pipes, can have a length of 6 and 12 meters. Cutting possible profile pipes pieces and size. Rectangular pipe can be easily processed by welding, thanks to the presence of four stiffening ribs, it will become a strong and durable frame for construction or advertising media.

Steel parameters are regulated by GOST 380-71 standards. Steel grade can serve as a substitute VSt3sp. It's also carbon steel. ordinary quality, from which shaped and sheet metal is made. Many foreign analogues are known. The strength of this steel increases with an increase in the amount of carbon in the composition of the material. A carbon content of more than 0.5% leads to the risk of hot cracking. Steel St3 contains from 0.14% to 0.22% carbon.

We can order rolled metal with cutting to size or pieces. Cutting uses modern tape machines or gas cutting equipment. Both legal entities and individuals work with us, you can pay for the order through Sberbank. We carry out deliveries of rolled metal in the city of St. Petersburg and the Leningrad region. Delivery to other regions is carried out as by car, and railway container. For delivery payment over the tariff transport company not required. It is possible to independently pick up your order from the territory of the Kirov Plant, where the warehouse of the METBURG company is located. To order structural steel of any grade from METBURG, you only need to make one call.

Any industrial technologist or builder knows about the grade of steel alloy St3, since this is the most common structural material. Carbon steel of ordinary quality, which can be referred to as St3 or St3sp, is the main material for the manufacture of welded and non-welded structures designed to work in conditions of positive temperatures. The symbols "sp" in the name mean the type of steel - calm. Alternatively, semi-calm steel - "ps", or boiling - "kp" can be encrypted in the name.

Characteristics and weldability of steel St3

The strength of this carbon steel is high, but even it can be increased by artificially increasing the carbon content. Here it is important to find a compromise or " golden mean", since a larger amount of carbon significantly reduces the weldability of the material (hot cracks begin to form in the seams). In practice, it is impossible to weld metal containing more than 0.5% carbon by electroslag welding. Most often, consumable mouthpieces and wire electrodes of large cross section are used in working with such materials.

If there is no alternative to electroslag welding, then AN-8 flux is used for carbon steel St3, as well as welding wires of the following grades:

- Sv-08 and Sv-08A - to obtain equal strength joints

- Sv-08GS - for working with low-carbon steels

- Sv-08 GA - universal

- Sv-08G2S - universal

- Sv-10G2 - universal

A serious problem that arises when welding carbon steels is the strength of the seam, or rather its metal. To increase strength, experts recommend increasing the manganese content, which contributes to an increase in the tendency of steel to harden, since ferrite is noticeably strengthened. Such alloying of the weld metal to the level of 1.5% Mn at the initial 0.12-0.14% C allows to achieve the same level of strength characteristics as in steel with a carbon content of 0.22-0.24% C, where the proportion of manganese is 0.5-0.7%. A similar effect - an increase in the strength of the weld metal - can also be given by small additions of chromium, nickel and other alloying substances.

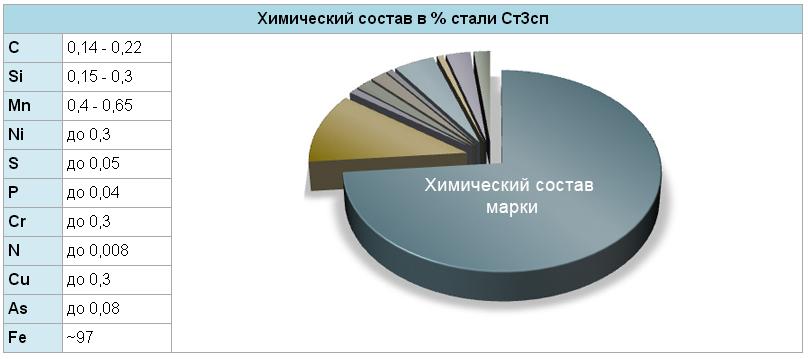

The percentage of the main chemical elements of this steel is presented in the following diagram:

Structural carbon steel application

Being, in fact, the most common structural material, where the steel composition makes it possible to obtain strong welded joints, the St3 alloy is extremely widespread. Manufacturers recommend using it for the manufacture of welded and cold-formed parts, as well as elements of industrial machines that operate without friction and with a minimum load. In particular, this alloy is used for casting troughs, casings and covers of machine tools, various gaskets, etc.

According to GOST 977-75, St3 steel enters production shops in the form of forgings or castings. It can be in the form of hot-rolled steel (GOST 380-71) or be structural sectional metal (GOST 1050-74). In this case, the difference will be in the percentage of carbon in the alloy.

At any metallurgical production that produces steels and alloys of various grades, you will definitely be offered inexpensive carbon structural steel of ordinary quality, which is used literally everywhere. Grade vst3 is used for the manufacture of standard load-bearing and non-bearing elements of welded and non-welded structures, which are operated at temperatures from -40 to +425°C. This material has no restrictions on weldability, is not prone to temper brittleness, and is characterized by relatively high corrosion resistance. Besides, that's enough durable metal, which for convenience is available in three versions: regular strength, increased strength and high strength.

Vst3 steel, produced in accordance with GOST 380-71, has the following chemical composition (in percent):

- carbon - 0.14-0.22

- manganese - 0.4-0.65

- chromium - 0.3

- nickel - 0.3

- copper - 0.3

- silicon - 0.05-0.17

- arsenic up to 0.08

- sulfur - 0.05

- phosphorus - 0.04

Metal properties vst3

The low content of nickel, chromium, manganese and silicon indicates that we are dealing with low alloy steel. The main element here, as in any structural steel of ordinary quality, is ferrite. It is ductile, but extremely brittle, so it must be saturated with carbon to make the material suitable for use in critical building structures. And yet, high-strength steels are obtained not only by increasing the carbon content, but also by alloying, as well as additional heat treatment metal.

In the production of alloy vst3, the standards prescribed in GOST 380-71 are applied. It allows replacing this metal with carbon steel of ordinary quality vst3sp in the manufacture of sheet or shaped steel. In any case, the carbon content in these alloys does not exceed 0.22%, since a noticeable excess of this parameter can lead to hot cracks.

Applied to welding work, carried out with any type of welding equipment, this steel is extremely convenient: it does not require preheating. Ease of processing can be traced in stamping work, which can be carried out with the material in both hot and cold states. In general, VST3 structural steel is indispensable for both builders and metalworkers. 1-10 mm rolled products are used for the manufacture of frames, frames, shields, casings and covers of industrial machines, i.e. parts that do not experience serious loads and work without friction.

A separate modification of st3gsp is used for the production of angles, channels and I-beams; load-bearing elements of welded structures are made from the material of the st3ps brand. Structural steel is also reinforcement, which is obtained after sizing hot-rolled bars. Cold rolling makes it possible to obtain drawn steel, from which clamps, frames, mounting fittings, wire, grids, water and gas pipes etc.

Mars space program

The history of the origin of zero What is the name of zero

Gloria planet (anti-earth) - exposing all revelations Is it true that there is a planet behind the sun

20 cases of alleged reincarnation

The secret of the "sun stones": how the Vikings got from Norway to Greenland almost blindly