The correct choice of electrical cable to power electrical equipment is the key to long-term and stable operation of installations. Using the wrong wire has serious negative consequences.

The physics of the process of damage to an electrical line due to the use of an unsuitable wire is as follows: due to the lack of space in the cable core for the free movement of electrons, the current density increases; this leads to excess energy release and an increase in the temperature of the metal. When the temperature gets too high, the line's insulating sheath melts, which can cause a fire.

To avoid trouble, you must use a cable with cores of suitable thickness. One way to determine the cross-sectional area of a cable is to start from the diameter of its cores.

Calculator for calculating cross-section by diameter

To simplify calculations, a calculator has been developed for calculating the cable cross-section by diameter. It is based on formulas that can be used to find the cross-sectional area of single-core and stranded wires.

You need to measure the cross-section by measuring the core without insulation, otherwise nothing will work.

When it comes to calculating tens and hundreds of values, an online calculator can significantly simplify the life of electricians and electrical network designers due to convenience and increased speed of calculations. It is enough to enter the value of the core diameter, and, if necessary, indicate the number of wires if the cable is multi-core, and the service will show the required wire cross-section.

Calculation formula

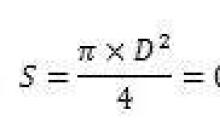

You can calculate the cross-sectional area of an electrical wire in different ways, depending on its type. For all cases, a single formula is used to calculate the cable cross-section by diameter. It looks like this:

D – core diameter.

The core diameter is usually indicated on the wire sheath or on a general label with other technical characteristics. If necessary, this value can be determined in two ways: using a caliper and manually.

The first way to measure the core diameter is very simple. To do this, it must be cleared of the insulating shell, and then use a caliper. The value that it will show is the diameter of the core.

If the wire is stranded, you need to unravel the bundle, count the wires and measure only one of them with a caliper. There is no point in determining the entire diameter of the beam - such a result will be incorrect due to the presence of voids. In this case, the formula for calculating the cross section will look like:

D – core diameter;

a is the number of wires in the core.

If a caliper is not available, the core diameter can be determined manually. To do this, a small section of it must be freed from the insulating shell and wound around a thin cylindrical object, for example, a pencil. The coils should fit snugly against each other. In this case, the formula for calculating the diameter of the wire core looks like this:

L – wire winding length;

N is the number of complete turns.

The longer the core is wound, the more accurate the result.

Selection by table

Knowing the diameter of the wire, you can determine its cross-section using a ready-made dependence table. The table for calculating the cable cross-section by core diameter looks like this:

| Conductor diameter, mm | Conductor cross-section, mm2 |

| 0.8 | 0.5 |

| 1 | 0.75 |

| 1.1 | 1 |

| 1.2 | 1.2 |

| 1.4 | 1.5 |

| 1.6 | 2 |

| 1.8 | 2.5 |

| 2 | 3 |

| 2.3 | 4 |

| 2.5 | 5 |

| 2.8 | 6 |

| 3.2 | 8 |

| 3.6 | 10 |

| 4.5 | 16 |

When the cross-section is known, it is possible to determine the permissible power and current values for copper or aluminum wire. In this way, it will be possible to find out what load parameters the current-carrying core is designed for. To do this, you will need a table of the dependence of the cross section on the maximum current and power.

| In the air (trays, boxes, voids, channels) | Section, sq. mm | In the ground | |||||||||

| Copper conductors | Aluminum conductors | Copper conductors | Aluminum conductors | ||||||||

| Current. A | power, kWt | Tone. A | power, kWt | Current, A | power, kWt | Current. A | Power, kWt | ||||

| 220 (V) | 380(V) | 220(V) | 380(V) | 220(V) | 380(V) | 220(V) | |||||

| 19 | 4.1 | 17.5 | 1,5 | 77 | 5.9 | 17.7 | |||||

| 35 | 5.5 | 16.4 | 19 | 4.1 | 17.5 | 7,5 | 38 | 8.3 | 75 | 79 | 6.3 |

| 35 | 7.7 | 73 | 77 | 5.9 | 17.7 | 4 | 49 | 10.7 | 33.S | 38 | 8.4 |

| *2 | 9.7 | 77.6 | 37 | 7 | 71 | 6 | 60 | 13.3 | 39.5 | 46 | 10.1 |

| 55 | 17.1 | 36.7 | 47 | 9.7 | 77.6 | 10 | 90 | 19.8 | S9.7 | 70 | 15.4 |

| 75 | 16.5 | 49.3 | 60 | 13.7 | 39.5 | 16 | 115 | 753 | 75.7 | 90 | 19,8 |

| 95 | 70,9 | 67.5 | 75 | 16.5 | 49.3 | 75 | 150 | 33 | 98.7 | 115 | 75.3 |

| 170 | 76.4 | 78.9 | 90 | 19.8 | 59.7 | 35 | 180 | 39.6 | 118.5 | 140 | 30.8 |

| 145 | 31.9 | 95.4 | 110 | 74.7 | 77.4 | 50 | 775 | 493 | 148 | 175 | 38.5 |

| ISO | 39.6 | 118.4 | 140 | 30.8 | 97.1 | 70 | 775 | 60.5 | 181 | 710 | 46.7 |

| 770 | 48.4 | 144.8 | 170 | 37.4 | 111.9 | 95 | 310 | 77.6 | 717.7 | 755 | 56.1 |

| 760 | 57,7 | 171.1 | 700 | 44 | 131,6 | 170 | 385 | 84.7 | 753.4 | 795 | 6S |

| 305 | 67.1 | 700.7 | 735 | 51.7 | 154.6 | 150 | 435 | 95.7 | 786.3 | 335 | 73.7 |

| 350 | 77 | 730.3 | 770 | 59.4 | 177.7 | 185 | 500 | 110 | 379 | 385 | 84.7 |

Converting watts to kilowatts

In order to correctly use the table of wire cross-section versus power, it is important to correctly convert watts to kilowatts.

1 kilowatt = 1000 watts. Accordingly, to obtain the value in kilowatts, the power in watts must be divided by 1000. For example, 4300 W = 4.3 kW.

Examples

Example 1. It is necessary to determine the permissible current and power values for a copper wire with a core diameter of 2.3 mm. Supply voltage – 220 V.

First of all, you should determine the cross-sectional area of the core. This can be done using a table or a formula. In the first case, the value is 4 mm 2, in the second - 4.15 mm 2.

![]()

The calculated value is always more accurate than the tabulated value.

Using a table of the dependence of cable cross-section on power and current, you can find out that for a cross-section of a copper core with an area of 4.15 mm 2, a power of 7.7 kW and a current of 35 A are permissible.

Example 2. It is necessary to calculate the current and power values for an aluminum stranded wire. Core diameter – 0.2 mm, number of wires – 36, voltage – 220 V.

In the case of a stranded wire, it is not advisable to use tabular values; it is better to use the formula for calculating the cross-sectional area:

![]()

Now you can determine the power and current values for a stranded aluminum wire with a cross section of 2.26 mm 2. Power – 4.1 kW, current – 19 A.

The ability to choose the right cable cross-section can be useful to anyone over time, and you don’t have to be a qualified electrician to do this. By incorrectly calculating the cable, you can expose yourself and your property to serious risk - too thin wires will get very hot, which can lead to a fire.

Why do you need to calculate the cable cross-section?

First of all, carrying out this slightly complicated procedure is necessary to ensure the safety of both the premises itself and the people in it. Today, humanity has not invented a more convenient method of distributing and delivering electrical energy to the consumer, like through wires. People need the services of an electrician almost every day - someone needs to connect an outlet, someone needs to install a lamp, etc. From this it turns out that even such a seemingly insignificant procedure as installing a new lamp is associated with the operation of selecting the required cross-section . What then can we say about connecting an electric stove or water heater?

Failure to comply with the standards can lead to damage to the integrity of the wiring, which often causes a short circuit or even electric shock.

If you make a mistake when choosing a cable cross-section and purchase a cable with a smaller conductor area, this will lead to constant heating of the cable, which will cause destruction of its insulation. Naturally, all this negatively affects the life of the wiring - there are often cases when, a month after successful installation, the electrical wiring stopped working and specialist intervention was required.

It should be remembered that the electrical and fire safety in the building, and therefore the lives of the residents themselves, directly depends on the correctly selected cable cross-section.

Of course, every owner wants to save as much as possible, but you should not do this at the cost of your life, putting it at risk - after all, as a result of a short circuit, a fire can occur, which may well destroy all property.

To avoid this, before starting electrical installation work, you should select a cable of the optimal cross-section. For selection, several factors must be taken into account:

- the total number of electrical devices located in the room;

- the total power of all devices and the load they consume. To the obtained value you should add 20–30% “in reserve”;

- then, through simple mathematical calculations, convert the resulting value into the cross-section of the wire, taking into account the material of the conductor.

Attention! Due to lower electrical conductivity, wires with aluminum conductors must be purchased with a larger cross-section than copper ones.

What affects the heating of wires

If the wiring heats up during the operation of household appliances, then you should immediately take all necessary measures to eliminate this problem. There are many factors influencing the heating of wires, but the main ones include the following:

- Insufficient cable cross-sectional area. To put it in accessible language, we can say this: the thicker the wires of the cable, the more current it can transmit without overheating. The value of this value is indicated in the marking of cable products. You can also measure the cross-section yourself using a caliper (you should make sure that the wire is not live) or by the type of wire.

- Material from which the wire is made. Copper conductors transmit voltage better to the consumer and have lower resistance compared to aluminum conductors. Naturally, they heat up less.

- Core type. The cable can be single-core (the core consists of one thick rod) or multi-core (the core consists of a large number of small wires). A multi-core cable is more flexible, but is significantly inferior to a single-core cable in terms of the permissible strength of the transmitted current.

- Cable laying method. Tightly laid wires located in the pipe heat up noticeably more than open wiring.

- Material and quality of insulation. Inexpensive wires, as a rule, have low quality insulation, which negatively affects their resistance to high temperatures.

How to calculate power consumption

You can calculate the approximate cable cross-section yourself - it is not necessary to seek the help of a qualified specialist. The data obtained as a result of the calculations can be used to purchase wires, however, the electrical installation work itself should be trusted only to an experienced person.

The sequence of actions when calculating the section is as follows:

- A detailed list of all electrical appliances in the room is compiled.

- The passport data of the power consumption of all found devices is established, after which the continuity of operation of a particular equipment is determined.

- Having identified the value of power consumption from devices that operate constantly, you should sum this value by adding to it a coefficient equal to the value of electrical appliances that turn on periodically (that is, if the device will work only 30% of the time, then you should add a third of its power).

- Next, we look for the obtained values in a special table for calculating the wire cross-section. For greater guarantee, it is recommended to add 10-15% to the obtained power consumption value.

To determine the necessary calculations for selecting the cross-section of electrical wiring cables according to their power within the network, it is important to use data on the amount of electrical energy consumed by devices and current appliances.

At this stage, it is necessary to take into account a very important point - the data of electrically consumed devices does not give an exact, but an approximate, average value. Therefore, about 5% of the parameters specified by the equipment manufacturer must be added to this mark.

The majority of not the most competent and qualified electricians are confident in one simple truth - in order to correctly install electrical wires for lighting sources (for example, for lamps), it is necessary to take wires with a cross-section equal to 0.5 mm², for chandeliers - 1, 5 mm², and for sockets – 2.5 mm².

Only incompetent electricians think about this and think so. But what if, for example, a microwave, kettle, refrigerator and lighting operate simultaneously in the same room, which require wires with different cross-sections? This can lead to a variety of situations: short circuit, rapid damage to wiring and insulating layer, as well as fire (this is a rare case, but still possible).

Exactly the same not very pleasant situation can happen if a person connects a multicooker, a coffee maker and, say, a washing machine to the same outlet.

Features of calculating the power of hidden wiring

If the design documentation implies the use of hidden wiring, then it is necessary to purchase cable products “with a reserve” - about 20–30% should be added to the obtained value of the cable cross-section. This is done to avoid heating the cable during operation. The fact is that in conditions of cramped space and lack of air access, heating of the cable occurs much more intensely than when installing open wiring. If in closed channels it is planned to lay not one cable, but several at once, then the cross-section of each wire should be increased by at least 40%. It is also not recommended to tightly lay various wires - ideally, each cable should be contained in a corrugated pipe, which provides it with additional protection.

Important! It is by the value of power consumption that professional electricians are guided when choosing a cable cross-section, and only this method is correct.

How to calculate cable cross-sections by power

If the cable cross-section is sufficient, the electric current will pass to the consumer without causing heating. Why does heating occur? We will try to explain as clearly as possible. For example, a kettle with a power consumption of 2 kilowatts is plugged into the outlet, but the wire going to the outlet can only transmit a current of 1 kilowatt for it. The cable capacity is related to the resistance of the conductor - the greater it is, the less current can be transmitted through the wire. As a result of high resistance in the wiring, the cable heats up, gradually destroying the insulation.

With the appropriate cross-section, the electric current reaches the consumer in full, and the wire does not heat up. Therefore, when designing electrical wiring, you should take into account the power consumption of each electrical device. This value can be found from the technical data sheet for the electrical device or from the label affixed to it. By summing the maximum values and using a simple formula:

and get the value of the total current.

Pn denotes the power of the electrical appliance indicated in the passport, 220 is the rated voltage.

For a three-phase system (380 V), the formula looks like this:

I=(P1+P2+....+Pn)/√3/380.

The resulting I value is measured in Amperes, and based on it, the appropriate cable cross-section is selected.

It is known that the throughput of a copper cable is 10 A/mm; for an aluminum cable the throughput is 8 A/mm.

For example, let’s calculate the cable cross-section for connecting a washing machine, the power consumption of which is 2400 W.

I=2400 W/220 V=10.91 A, rounding up we get 11 A.

11 A+5 A=16 A.

If you take into account that three-core cables are used in apartments and look at the table, then the value close to 16 A is 19 A, so to install a washing machine you will need a wire with a cross-section of at least 2 mm².

Table of cable cross-sections relative to current values

| Current cross-section provo- length of core(mm 2) | Current (A), for wires laid | |||||

|---|---|---|---|---|---|---|

| Open That | in one pipe | |||||

| two one- vein | three one- vein | four one- vein | one two- vein | one three- vein |

||

| 0,5 | 11 | - | - | - | - | - |

| 0,75 | 15 | - | - | - | - | - |

| 1 | 17 | 16 | 15 | 14 | 15 | 14 |

| 1,2 | 20 | 18 | 16 | 15 | 16 | 14,5 |

| 1,5 | 23 | 19 | 17 | 16 | 18 | 15 |

| 2 | 26 | 24 | 22 | 20 | 23 | 19 |

| 2,5 | 30 | 27 | 25 | 25 | 25 | 21 |

| 3 | 34 | 32 | 28 | 26 | 28 | 24 |

| 4 | 41 | 38 | 35 | 30 | 32 | 27 |

| 5 | 46 | 42 | 39 | 34 | 37 | 31 |

| 6 | 50 | 46 | 42 | 40 | 40 | 34 |

| 8 | 62 | 54 | 51 | 46 | 48 | 43 |

| 10 | 80 | 70 | 60 | 50 | 55 | 50 |

| 16 | 100 | 85 | 80 | 75 | 80 | 70 |

| 25 | 140 | 115 | 100 | 90 | 100 | 85 |

| 35 | 170 | 135 | 125 | 115 | 125 | 100 |

| 50 | 215 | 185 | 170 | 150 | 160 | 135 |

| 70 | 270 | 225 | 210 | 185 | 195 | 175 |

| 95 | 330 | 275 | 255 | 225 | 245 | 215 |

| 120 | 385 | 315 | 290 | 260 | 295 | 250 |

| 150 | 440 | 360 | 330 | - | - | - |

| 185 | 510 | - | - | - | - | - |

| 240 | 605 | - | - | - | - | - |

| 300 | 695 | - | - | - | - | - |

| 400 | 830 | - | - | - | - | - |

How to choose conductor cross-sections

There are several more criteria that the cross-section of the wires used must meet:

- Length of cable. The longer the wire, the greater the current loss observed in it. This again occurs as a result of an increase in resistance, which increases as the length of the conductor increases. This is especially noticeable when using aluminum wiring. When using copper wires to organize electrical wiring in an apartment, the length, as a rule, is not taken into account - the standard margin of 20–30% (for hidden wiring) is more than enough to compensate for possible increases in resistance associated with the length of the wire.

- Type of wires used. There are 2 types of conductors used in household electricity supply - copper or aluminum based. Copper wires are of better quality and have less resistance, but aluminum wires are cheaper. In full compliance with the standards, aluminum wiring copes with its tasks no worse than copper, so you need to carefully weigh your choice before purchasing a wire.

- Electrical panel configuration. If all the wires supplying consumers are connected to one circuit breaker, then it will be the weak point in the system. A heavy load will lead to heating of the terminal blocks, and non-compliance with the rating will lead to its constant operation. It is recommended to divide the electrical wiring into several “beams” with the installation of a separate machine.

In order to determine the exact data for choosing the cross-section of electrical wiring cables, it is necessary to take into account any, even the most insignificant parameters, such as:

- Type and type of insulation of electrical wiring;

- Length of sections;

- Laying methods and options;

- Features of temperature conditions;

- Humidity level and percentage;

- The maximum possible value of superheat;

- The difference in the powers of all current receivers belonging to the same group. All these and many other indicators can significantly increase the efficiency and benefits of energy use on any scale. In addition, correct calculations will help avoid cases of overheating or rapid abrasion of the insulating layer.

In order to correctly determine the optimal cable cross-section for any human household needs, it is necessary in all general cases to use the standardized following rules:

- for all sockets that will be installed in the apartment, it is necessary to use wires with an appropriate cross-section of 3.5 mm²;

- for all spotlighting elements, it is necessary to use electrical wiring cables with a cross-section of 1.5 mm²;

- As for high-power devices, cables with a cross-section of 4-6 mm² should be used.

If some doubts arise during the installation or calculation process, it is better not to act blindly. The ideal option would be to refer to the appropriate table of calculations and standards.

Copper cable cross-section table

| Cross-section of conductors (mm) | Copper conductors of wires and cables | |||

| Voltage 220 V | Voltage 380 V | |||

| Current (A) | Power, kWt) | Current (A) | Power, kWt) | |

| 1,5 | 19 | 4,1 | 16 | 10,5 |

| 2,5 | 27 | 5,9 | 25 | 16,5 |

| 4 | 38 | 8,3 | 30 | 19,8 |

| 6 | 46 | 10,1 | 40 | 26,4 |

| 10 | 70 | 15,4 | 50 | 33 |

| 16 | 80 | 18,7 | 75 | 49,5 |

| 25 | 115 | 25,3 | 90 | 59,4 |

| 35 | 135 | 29,7 | 115 | 75,9 |

| 50 | 175 | 38,5 | 145 | 95,7 |

| 70 | 215 | 47,3 | 180 | 118,8 |

| 95 | 265 | 57,2 | 220 | 145,2 |

| 120 | 300 | 66 | 260 | 171,6 |

Aluminum Cable Section Table

The main and most common method of transmitting electricity to the consumer is an electrical wire and electrical cable. An electrical wire and electrical cable is an electrical product consisting of a metal conductor or several conductors. Each core is electrically insulated. All insulated wire or electrical cable cores are placed in general insulation.

Currently, the industry produces a wide variety of electrical wires and electrical cables. Cables and wires are mainly copper and aluminum, i.e. the composition of the cable or wire cores is copper or aluminum.

Electrical cables and wires can be single-core or multi-core. The core of a cable or wire can be either single-wire (monolithic) or multi-wire. The cores are made mainly in round shape, however, often for electrical cables with a large cross-section, the shape of the stranded core can be made in the form of a triangle. Today we will tell you how to calculate the cross-section of a wire by diameter.

Marking of electrical cable (wire)

There is a standard range of wire and electrical cable cross-sections that are used. This is 1mm 2; 1.5mm 2; 2.5mm 2; 4mm 2; 6mm 2; 8mm 2; 10mm 2 etc. The type, cross-section and number of cores are indicated either on the tag that comes with the cable or wire, or on the product itself. For example, markings are often applied to the general insulation of cables and wires. Also, technical data of electrical conductors are indicated in the product passport.

Let's say there is a VVGng 3x2.5 cable available. This marking is deciphered quite simply: a copper cable with PVC insulation, in a PVC sheath, non-flammable, the number of cores is three, the cross-section of each core is 2.5 mm 2. If the letter “A” appears at the beginning of the marking, i.e. The cable type will be AVVG, which means that the cable has aluminum cores.

By marking the wire, you can also find out not only the type of wire itself, but also the number and cross-section of current-carrying wires. For example, PVS wire 3x1.5. The decoding is as follows: wire with PVC insulation and PVC sheath, connecting. The number of cores is also three, and the cross-section of each wire is 1.5 mm 2 .

Conductor cross-section

Each wire and cable core has its own cross-section. It can be either very small (1mm 2 or less) or very large (95mm 2 or more). The cross-section of the conductor affects the ability to withstand a certain amount of electric current for a long and short time. The larger the cross-section of the core, the greater the current it can withstand for an almost unlimited time.

An incorrectly selected cross-section during design may subsequently cause overheating of the conductor, damage (destruction) of its insulation during the process of high heating, which may result in a short circuit and, as a result, fire and fire.

Section mismatch

The cause of overheating of a cable or wire during operation may not always be an incorrect calculation of the cross-section. As often happens in practice, the reason is very simple. Not all manufacturers of cable and wire products are conscientious about the quality of their products. The fact is that very often the cross-section of manufactured cables and wires is actually underestimated, i.e. does not correspond to the declared value.

To avoid purchasing an electrical cable or wire with an undersized cross-section, you must first visually assess its actual cross-section. Almost any electrical specialist is able to “by eye” determine the cross-section of a conductor. But when this is not enough, a professional can independently calculate the cross-sectional area of the electrical conductor. The cross section is calculated using the usual mathematical formula:

S = π*D 2 /4– formula No. 1

S=π* R 2 – formula No. 2

where: π is a mathematical constant, which is always equal to approximately 3.14;

R – wire radius;

D – wire diameter.

The radius is equal to half the diameter:

R=D/2– formula No. 3

Calculation of the actual cross-section of the electrical conductor

Knowing the formula for calculating the cross-section of a conductor, you can calculate its actual value and find out how much the manufacturer’s declared cross-section value is underestimated or overestimated (which happens rarely).

Single-wire (monolithic core)

First, you need to remove the insulation layer from a wire core or an electrical cable core to expose the core itself. Then the diameter of the core is measured with a caliper. Because the vein is monolithic, then there will be only one measurement. After measuring the diameter of the core, you need to substitute the value of the diameter (radius) into one of the above formulas.

Example No. 1

Let’s say that a cable or wire has a declared core cross-section of 2.5 mm 2 . When measured, the core diameter turned out to be 1.7 mm. Substituting the value into formula No. 1, we get:

S = 3.14*1.7 2 /4 = 2.26865 ≈ 2.3mm 2

Calculation using formula No. 1 showed that the cross-section of the core is underestimated by 0.2 mm 2 from the standard value.

Now let’s calculate the actual value of the cross-section using formula No. 2, but first, let’s determine the radius using formula No. 3:

R = 1.7/2 = 0.85mm

We substitute the radius value into formula No. 2 and get:

S = 3.14*0.85 2 = 2.26865 ≈ 2.3mm

The calculation using the second formula turned out to be similar to the calculation using the first. Those. The cross-section of the cable core turned out to be underestimated by 0.2 mm 2.

Example No. 2

Let’s say the core diameter, when measured with a caliper, turns out to be 1.8 mm. Substituting this value into formula No. 1, we get:

S = 3.14*1.8 2 /4 = 2.5434 ≈ 2.5 mm 2

Those. the actual cross-section was 2.5 mm 2, which in principle corresponds to the standard value.

Stranded core

If you determine the cross-section of a stranded conductor, then you cannot measure the diameter using the monolithic conductor method, because the calculation will have a large error. To determine the cross-section of a stranded core, it is necessary to measure the diameter of each individual wire in the core.

If the total cross-section of the core is large enough, then measuring each wire is quite possible, because You can actually measure the diameter with a caliper. But if the stranded core has a small cross-section, then determining the diameter of each wire is very problematic due to the thinness of the conductor.

Electrical cable cross-section.

Electrical cable cross-section- This is one of the fundamental components of proper electrical wiring in the apartment. This means comfortable operation of electrical appliances and equipment, as well as the safety of consumers, i.e. all of us. The purpose of this article is to explain, for an apartment electrical network, based on the power of the electrical appliances used. And also tell us which wire is needed for this or that section of home electrical wiring.

Before starting a conversation on the main topic of the article, let me remind you of some terms.

● Vein- this, in the general sense, is a separate conductor (copper or aluminum), which can be either a solid conductor or consist of several individual wires twisted together into a bundle or wrapped in a common braid.

● Wire- this is a product that consists of one single-wire or multi-wire core, clad in a light protective sheath.

● Installation wire is a wire that is used for electrical wiring intended for lighting or power networks. It can be one, two or three wires.

- this is a wire with a core cross-section of up to 1.5 mm2. Cords are used to power light mobile (portable) electrical appliances and equipment. It is made of a multi-wire core, due to which it has increased ductility.

● Electrical cable- this is a product consisting of several insulated wires, on top of which there is from one to several protective sheaths.

To select a cable (wire) of the required cross-section for indoor wiring, you need to use the table given above, and to determine the current load on the cable, you can use the formula used earlier:

I race = P/U nom.

Where:

I race – calculated continuous current load;

P– power of connected equipment;

U nom. – network voltage;

Let's say you need to select a cable to connect an electric boiler with a power of 3 kW. Substituting the original values into the formula, we get:

Iras. = 3000 W/220 V = 13.63 A,

rounding this value up, we get 14 A.

For a more accurate calculation of the current load, there are various coefficients depending on environmental conditions and cable laying methods. There is also a coefficient of repeated-short-term mode. But they all, to a greater extent, relate to a three-phase 380 V network, so they are not required for our calculations. But to increase the safety margin of the conductor, we apply the average value of 5 A. And we get:

14 A + 5 A = 19 A

In the column of table 1. 3. 4. “Three-core wires” we look for the value of 19 A. If it is not there, you need to select the largest one closest to it. This is the value of 21 A. A cable with a core cross-section of 2.5 mm² can withstand such a long-term permissible current load. We conclude that to connect an electric boiler (or other electrical equipment) having (consuming) a power of 3 kW, you need a three-core copper cable with a conductor cross-section of 2.5 mm².

In the case when it is necessary to connect a socket (or block of sockets) from which several electrical appliances will be powered, you can use the above formula, in which the value of “P” will be equal to the sum of the powers of the devices or equipment simultaneously connected to the socket (block of sockets).

Since all electrical appliances with a power exceeding 2 kW are recommended to be connected to the power supply through a separate supply (a separate branch from the apartment electrical panel), we can conclude that the socket group of apartment electrical wiring requires a copper (preferably) cable with a core cross-section of 2.5 mm². Due to the fact that lighting devices do not have much power, the wire for the electrical wiring supplying them with electricity must have a core cross-section of at least 1.5 mm².

This is what concerns electrical wiring with copper conductors. But what about wiring that has aluminum conductors? There is a simple way to calculate the cross-section of an aluminum wire core.

Due to the fact that the electrical conductivity of aluminum is 65.9% of the electrical conductivity of copper, when connecting devices with the same power consumption to them (wires or cables), the cross-section of the aluminum core must be larger than the copper one. For example. Referring to the calculations made above in the text, it was determined that the cross-section of the copper core in the wire for connecting a 3 kW boiler should be 2.5 mm². When using a cable with an aluminum conductor, according to table. 1.3.4, the cross-section of the core must be selected by a factor higher, i.e. - 4 mm².

Turning to the PUE Ch. 1. item 3. table. 1. 3. 5 can confirm this assumption.

Table 1. 3. 5.

When choosing a cable for electrical wiring, it is necessary to use not only the principles of economy, but also take into account the mechanical strength of the wire, as well as be guided by the Electrical Installation Rules. Which state that for wiring inside residential premises it is necessary to use a cable with a core cross-section of at least 1.5 mm 2 (PUE Chapter 7; Section 7.1; Table 7.1.1). Thus, if, according to your calculations, a cable with a cross-section of less than 1.5 mm 2 is sufficient for electrical wiring, then, guided by the Safety Rules and Standards, choose the recommended wiring.

All necessary norms and rules, as well as tables can be viewed, and, if necessary, downloaded in the file "Rules for Electrical Installations" .

There is another, simplest way to select the cross-section of the wire for electrical wiring. All electricians probably use it. Its essence is that the cross-section is calculated based on a current strength of 6 - 10 A per 1 mm 2 of cross-sectional area for wires with copper conductors and 4 - 6 A per 1 mm 2 for an aluminum conductor. Thus, we can say that the operation of electrical wiring with a copper conductor at a current strength of 6 A per 1 mm 2 section is the most comfortable and safe. Whereas with a current density of 10 A per 1 mm 2, it can only be used in short-term mode. The same can be said about aluminum conductors.

Let's try using this method to select a wire for connecting equipment with a power of 3 kW, as in the example discussed above. After making calculations, a value of 14 A was obtained (3000 W / 220 V = 14 A). To select a cable with a copper conductor, we take the smallest (for a greater margin of safety) value (from the “plug” 6 - 10 A per 1 mm 2) - 6 A. From here it can be seen that for a current of 14 A you need a wire with a core cross-section

14 A / 6 A = 2.3 mm 2 ≈ 2.5 mm 2.

Which confirms our previous calculations.

As additional information, I can add: if you do not have a conductor of the required cross-section, it can be replaced with several wires with a smaller cross-section connected in parallel. So, for example, you need a cable with a cross-section of 4 mm². You have at your disposal wires of the required length, but with a cross-section of 1 mm², 1.5 mm² and 2.5 mm². It is enough to take wires whose total cross-section is not less than the required one (one wire 1.5 mm² and one wire 2.5 mm² or two wires 1.5 mm² and one wire 1 mm²) and connect them in parallel (lay them lengthwise next to each other and , “twist” the ends). An example of this would be stranded wire for extension cords. As you probably noticed, each of its conductors consists of many thin wires. And connected in parallel, into one “harness” they provide a conductor (core) of the required cross-section. This achieves its elasticity while maintaining the required throughput. But this is only suitable for wiring that connects low-power electrical appliances or is subject to short-term peak loads. For other types of wiring, a wire (cable) is recommended whose cores consist of a solid (single, single-wire or multi-wire) conductor.

Having learned how to determine the cross-section of a wire that has a core made of one (solid) wire, the question remains open: “How to calculate the cross-section of a wire whose core consists of many wires?”

Section of a stranded conductor.

Following the logic, you need to find out the cross-section of one individual wire and multiply it by the number of them in the core. This is absolutely correct, but the hairs may be too thin and therefore it is not always possible to measure them. You can, of course, measure the diameter of the entire “harness” of wiring and, using the formula indicated in the photo “Calculation of the cross-section of a wire strand relative to its diameter,” determine the cross-section of the entire strand. This, in principle, is sufficient for very rough calculations. But here you need to take into account that the wires that make up the core are round in cross section and, therefore, there is space between them when twisted. To make a more accurate calculation, you need to multiply the value obtained after calculating using the formula in the photo by 0.91. It is this coefficient that eliminates the area of the gaps between the hairs in the stranded core. For example, there is a wire with a stranded core with a diameter of 2.5 mm. Substitute the values into the formula and get:

S = 3.14 × D² / 4 = 3.14 × 2.5² / 4 = 4.90625 mm² ≈ 4.9 mm².

4.9 × 0.91 = 4.459 ≈ 4.5 mm².

Thus, the cross-section of a stranded core with a diameter of 2.5 mm is 4.5 mm². (this is just an example, so no need to link it to actual sizes).

That's probably all I wanted to say about how to calculate cable cross-section. Armed with the information received, you can independently select an electrical wire or cable that will meet safety requirements.

Remember: incorrectly selected electrical wires can cause a fire!

In order to make the site more interesting and informative, I ask you to answer a couple of simple questions. Click on the button.

For those readers who use Yandex and wish to receive messages about the publication of new articles on the site, I suggest placing a widget of my blog on the home page using the link: http://www.yandex.ru/?add=147158&from=promocode

You can subscribe to receive updates by email using the “Subscribe to new articles on the site” form, which is located on the main page.

So, the known power of each electrical appliance in the house, the known number of lighting fixtures and lighting points allow us to calculate the total power consumed. This is not an exact sum, since most values for the powers of various devices are averages. Therefore, you should immediately add 5% of its value to this figure.

Average power readings for common electrical appliances

| Consumer | Power, W |

| TV | 300 |

| Printer | 500 |

| Computer | 500 |

| Hair dryer | 1200 |

| Iron | 1700 |

| Electric kettle | 1200 |

| Toaster | 800 |

| Heater | 1500 |

| Microwave | 1400 |

| Oven | 2000 |

| Fridge | 600 |

| Washing machine | 2500 |

| Electric stove | 2000 |

| Lighting | 2000 |

| Instantaneous water heater | 5000 |

| Boiler | 1500 |

| Drill | 800 |

| Hammer | 1200 |

| Welding machine | 2300 |

| Lawnmower | 1500 |

| Water pump | 1000 |

And many believe that this is enough to select almost standard copper cable options:

- cross section 0.5 mm2 for wires for lighting spotlights;

- cross section 1.5 mm2 for lighting wires for chandeliers;

- cross-section 2.5 mm2 for all sockets.

At the level of household use of electricity, such a scheme looks quite acceptable. Until the refrigerator and electric kettle decided to turn on in the kitchen at the same time, while you were watching TV there. The same unpleasant surprise overtakes you when you plug in a coffee maker, washing machine and microwave into one outlet.

Thermal calculation using correction factors

For several lines in one cable channel, the tabulated values of the maximum current should be multiplied by the appropriate coefficient:

- 0.68 — for the number of conductors from 2 to 5 pcs.

- 0.63 — for conductors from 7 to 9 pcs.

- 0.6 — for conductors from 10 to 12 pcs.

The coefficient refers specifically to the wires (cores), and not to the number of passing lines. When calculating the number of laid wires, the neutral working wire or grounding wire is not taken into account. According to PUE and GOST 16442-80, they do not affect the heating of wires during the passage of normal currents.

Summarizing the above, it turns out that in order to correctly and accurately select the wire cross-section, you need to know:

- The sum of all maximum powers of electrical appliances.

- Network characteristics: number of phases and voltage.

- Characteristics of cable material.

- Tabular data and coefficients.

At the same time, power is not the main indicator for an individual cable line or the entire internal power supply system. When selecting a cross-section, be sure to calculate the maximum load current, and then check it with the rated current of the home circuit breaker.

Manufacturing and use of a distillation column

Do-it-yourself reinforcing column: what and how to do it correctly Drawings of a distillation column for moonshine with your own hands

The best drawings of gates and gates made of corrugated sheets Making gates with your own hands

Making a doghouse for your beloved German Shepherd Consumables for making a German Shepherd doghouse

Finishing a chimney on the roof: how to make a practical and beautiful chimney at a reasonable price Cladding a chimney