The manual jiggly was invented back in 1894 by the Italian gynecologist Leonardo Gigli. For the first time it was used, during a surgical operation, during the reception of childbirth, it served for sawing bones. In the future, due to its versatility, the wire saw began to be used not only in medicine (for amputation of limbs), but also in other areas, both in tourism and during the Second World War. There are official confirmations of its use by secret British intelligence officers.

Saw Gigli is one of the most irreplaceable things during outdoor recreation. It is ideal for home use, camping, hunting, survival in extreme conditions, but is just as good as a self-defense tool. It does not require a license, with a wire saw, you can easily protect yourself from dog attacks, and more. This saw is an excellent substitute for bulky and heavy analogues due to its compactness. Its length, in full, is about 60 cm, of which 50 cm make up the working part. One of the main positive qualities, wire saw is its meager weight of about 20 grams. It is a steel bundle, which is twisted into a whole with wires of different thicknesses, each of them is wrapped on top with a thinner wire. At its ends there are two rings with a diameter of about 3.5 cm, they have been adapted for ease of use.

Having gathered in nature, and taking a jiggly saw with you, it is possible to cut down trees, boughs, logs with a diameter of about 15–20 cm. Can also be used for cutting soft metals, plastics, rubber. Ideal for the “emergency kit” of a motorist, it will easily cut a tree that has fallen on the road. It is an indispensable assistant to gardeners and summer residents.

Basic principles of using a wire saw:

During operation, it is necessary to ensure that the saw - the string is in a tense position in the same plane as the cut, try not to put it at an angle.

The saw must be worked in such a way that it does not jam, that is, the cut must “open”.

If the saw is used by two people, it is necessary to maintain the rhythm by periodically allowing the heated string to cool.

By tying a rope to the saw rings, and throwing it, you can cut the tops from the trees.

In order for our assistant to serve for a long time and it was possible to comfortably use it alone, you need to take a freshly cut stick, bend it and make a bow saw. With such a file, it will be easy to make the passage thicker more often, or to get to the branches with fruits.

Jigli wire saw, will last more than one year, with correct use. She is not afraid of damp weather, due to the wires made of stainless steel, and their top polishing. Due to its lightness and compactness, it can be carried absolutely everywhere, from a woman's handbag, up to the body pockets of trousers. It is one of the main members of the NAZ (Wearable Emergency Supply).

Surgical saws designed for sawing bones during amputation of a limb, before bone grafting (osteosynthesis) due to reciprocating movements of many sharpened wedges mounted on the edge of the blade.

Sharply sharpened wedges are bent in pairs in different directions for a short distance. This is called "saw setting".

Requirements for surgical saws:

1. Save long time operational properties:

- the saw blade must be straight and even; teeth must have the same profile and degree of sharpening.

Sharpening saw teeth requires special skills and tools.

The teeth of the saw should be set so that the width of the cut does not exceed the thickness of the blade by more than 0.5 mm.

2. The introduction of additional elements into the design to reduce the likelihood of damage to adjacent tissues during bone sawing.

The implementation of this requirement is achieved not only by the design of the saw, but also by the use of additional devices during the operation (gauze or metal retractor, hooks).

3. Efficient dissection of the bone with the reciprocating movement of the blade without pressure on the blade.

4. Elimination of blade deviation when sawing bone For this, the saw blade is reinforced with a kind of guide profile.

With repeated sawing of a bar of hardwood or bone with a diameter of 50-60 mm, there should not be a significant change in the “wiring” of the teeth of a surgical saw, their deformation and breakage.

Design features surgical saws:

1. Working part(cloth) can be made in two versions:

- sheet (flat);

- wire (blade in the form of 3-4 turns of steel wire).

2. Handles (devices for holding the web) may look like:

- frames;

- T-shaped design.

Rice. 24. Parts of surgical saws (by: Medicon Instruments, 1986):

a - sheet saw: 1 - blade; 2 - handle; 3 - the guide part of the blade. b - wire saw: 1 - cutting element; 2 - handles; 3 - conductor Polenov to protect the tissues adjacent to the bone.

3. To stiffen the saw blade, a U-shaped guide is placed on its upper edge (Fig. 24).

Rice. 25. Surgical saws with blades of various widths (according to: Medicon instruments, 1986):

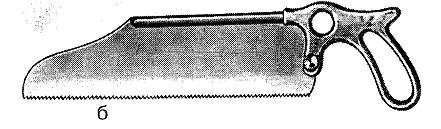

a - surgical saw (Langenbeck) with a relatively narrow blade; b - surgical saw (Waise) with a relatively wide blade.

The guide profile can be installed permanently or tilted if necessary.

The blades of sheet surgical saws differ in width:

1. Surgical saw (Langenbeck) has a relatively narrow blade.

2. Surgical saw (Wayse) is characterized by a wide blade (Fig. 25).

The base of a wide blade usually has a hinged box-shaped guide, which increases the rigidity of the structure.

The saw blade can go directly into the handle. Such a saw is called a sheet saw.

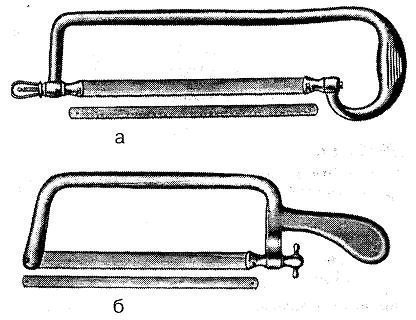

On top of the blade may be a frame connected to the handle. This saw design is called a frame saw (Fig. 26).

Rice. 26. Various forms sheet saw frames (according to: Medicon Instruments, 1986):

a - rectangular; b - trapezoid; in - arcuate.

There are the following options for continuing the sheet saw into the handle:

1. Rectilinear.

2. At an angle of 45°.

3. At an angle of 90°.

The design features of the arc saw clamps allow you to install the blades at the following angles to the plane of the arc:

1) perpendicular to the sawdust surface;

2) at an angle of 45°;

3) at an angle of 60°.

Wire saws, depending on the severity of the teeth, are of two types:

1. Wire saw Gigli (Gigli) with a small height of the teeth.

2. Wire saw Olivekron with pronounced wedge-shaped teeth.

Rules for sawing the diaphysis of the bone:

1. Before the start of the main action, it is necessary to make the so-called “washed down”, that is, to form the initial furrow by moving the saw “towards itself”. This technique eliminates the sliding of the saw teeth on the surface of the bone with possible damage to soft tissues.

2. When sawing the diaphysis of the bone of the limb, it is necessary to produce traction along its longitudinal axis in order to prevent the difficulty of the saw and to prevent the possibility of a bone fracture with the formation of sharp fragments.

3. Performing sawing movements, you need to use the entire length of the saw blade.

Small frequent movements with the saw blade, using only a limited area of its “working” zone, are not only ineffective, but will help to be accompanied by the formation of an uneven sawdust surface.

Inefficient saw movements and strong blade heating may suggest an unremoved metal rod from the lumen of the medullary canal.

4. The wire saw should be tensioned in a straight line or obtuse angle. When formed by a saw blade right angle or oncoming loop, it breaks.

5. The surgical assistant must constantly control the width of the bone gap, preventing the possibility of a bone fracture or restriction of the movement of the saw blade.

6. When deepening the cut of the bone, it is necessary to slow down the movement of the blade, eliminating the possibility of iatrogenic damage to soft tissues and neurovascular bundles.

7. Do not put pressure on the saw blade. The increase in the depth of cut is determined by the number of reciprocating movements of the blade and the sharpness of its teeth.

8. The possibility of bending the blade should be excluded when the movements of the hand deviate from the directive direction of the cut.

9. If it is necessary to make a figured cut, additional cuts should be used or a wire saw should be used.

10. The removed part of the bone must be fixed with a bone holder.

11. Due to the deviation of the plane of movement of the hands relative to the axis of the moving wire saw, it is possible to cut flat bones at different angles.

12. To hold a wire saw under the sawn area of the bone, use the Polenov guide.

This narrow metal plate also protects the underlying tissues from damage.

In case of sudden destruction of the ear of a wire saw, a Kocher hemostatic forceps can be used instead of the handle.

You can also bring a wire saw under the bone using a curved hemostat, ligature needle, grooved probe or dissector.

13. The width of the blade should correspond to the goals of manipulation:

- wide blades are most applicable for rectilinear incisions and are more often used for limb amputation;

- saws with a relatively narrow blade are designed for cutting along a curve or a broken line;

- oblique cuts of flat bones are more convenient to perform with a wire saw.

The frame saw is usually held with both hands. Wherein right hand fix the handle, and the left - the remote cross member of the frame. This position of the hands ensures a stable position of the blade.

A medical sheet saw is held with one hand like a pistol grip. It should be borne in mind that the method of fixing the saw leads to a significant deviation of the blade.

G. M. Semenov

Modern surgical instruments

A wire saw (line saw, string saw, jig saw) is a great, compact and weightless substitute for large and heavy saws for minimalist hikers! Being able to cope with trees up to 10-14 cm and logs up to 15-20 cm, it is a good replacement for its "older comrades". Unlike axes and other chopping tools, it gives an even cut, which is a definite plus.

For the first time, a saw of this type was used as far back as 1894 - during a surgical operation during childbirth for sawing a bone. It was invented by a certain Leonardo Gigli ( L. Gigli), an Italian gynecological surgeon, which later gave the saw its name: Saw Gigli (Gigli) . Later, due to its versatility, the wire saw found its application both in medicine (for example, in amputation of limbs), and in many other areas: tourism and even industrial espionage! There is even documented evidence that the Gigli saw was used by secret agents of British intelligence during World War II.

You can’t even talk about the size - when folded, the wire saw fits almost anywhere, from a pocket on a shirt or a compartment in a backpack to a pocket in a wallet. The length of the working part reaches up to 50+ cm, and the total length is slightly over 60+ cm. The saw wire weighs ~ 10-14g, which makes it even more versatile. It is convenient to take with you “just in case” when it is impractical to drag an ax or a full-size saw.

How is a wire saw made?

A wire saw is a bundle of steel wires of various thicknesses, in which the role of teeth is played by coils of thin wire wound on 2-3 pieces of thicker wire twisted together. The saw is made of stainless steel and usually has a polished surface.

The closest analogue to Gigli's saw is perhaps hand chain saws - but we will talk about them next time.

You can buy a Gigli wire saw at.

How to understand: will the kitten be fluffy?

What kind of light alcohol can be drunk for pregnant women: the consequences of drinking

Why do the legs swell in the ankles and ankles of the feet in pregnant women: causes and methods of treatment

The wedding of Prince Harry and Meghan Markle: scandalous and secret details of the marriage (photo) The future marriage of Prince Harry year NTV

How to close white plums for the winter